Drill string tubular component

A tubular, component technology, applied in drill pipe, drill pipe, casing, etc., that can solve problems such as stopping the drilling process, slowing down, and hindering the movement of the drill string.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

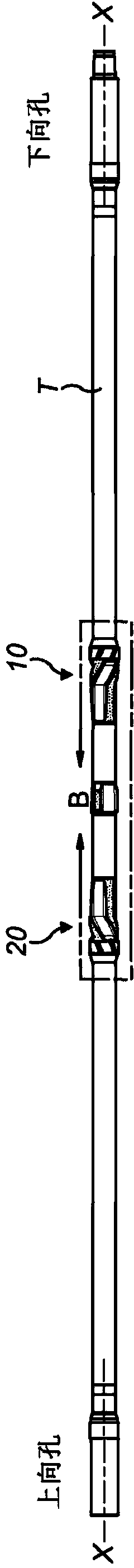

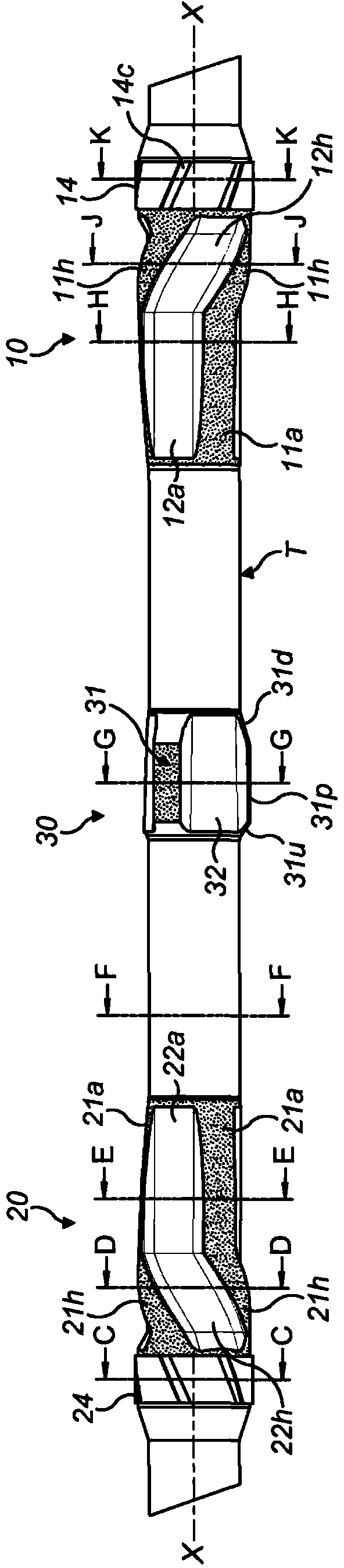

[0064] Referring now to the drawings, a drill string tubular member includes a base tube T having a downhole end and an uphole end (see figure 1 ), and at those ends, there are usually corresponding interface (box) and pin (pin) connectors for connecting to the drill string. Typically, the tubing is provided within the bottom hole assembly (BHA) adjacent the drill bit, and the tubing T may optionally be a heavyweight drill collar or heavyweight drill pipe known for these purposes. The interface and pin connectors at the ends of the tube T typically have an outer diameter that is larger than the nominal outer diameter of the tube T between the two ends. In the example shown, the nominal outer diameter of the central section of the tube T is typically 5-7 / 8". The tube T typically comprises 5-7 / 8" heavyweight drill pipe.

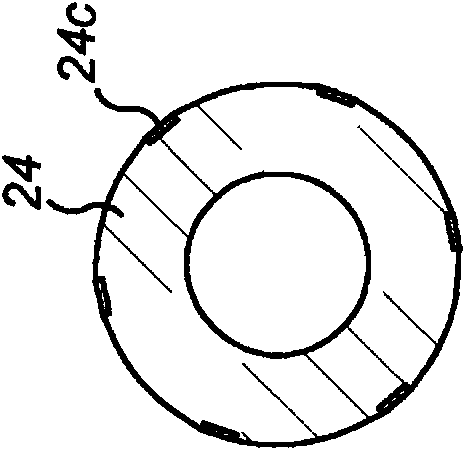

[0065] On the outer surface of the tube T there are usually three collars comprising radial protrusions. Said at least one first axial impeller is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com