Auxiliary equipment for overall sinking of open caisson and cofferdam structures and construction method

A technology of auxiliary equipment and cofferdam, which is applied in the direction of basic structure engineering, basic structure test, caisson, etc., can solve the problems of affecting the construction progress, increasing the construction cost, reducing the sinking coefficient of the structure, etc., so as to improve safety and avoid The effect of structural tilt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

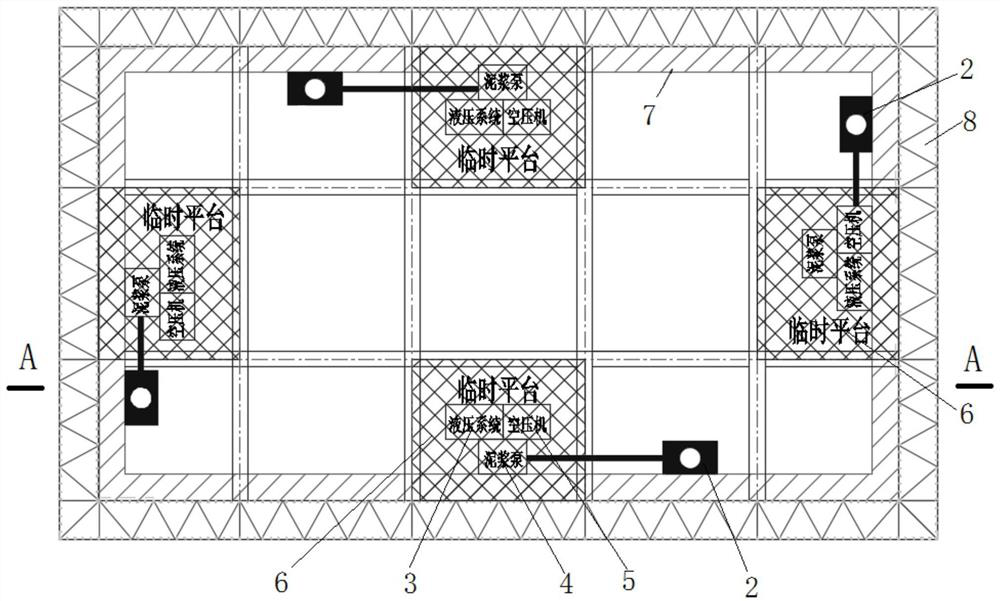

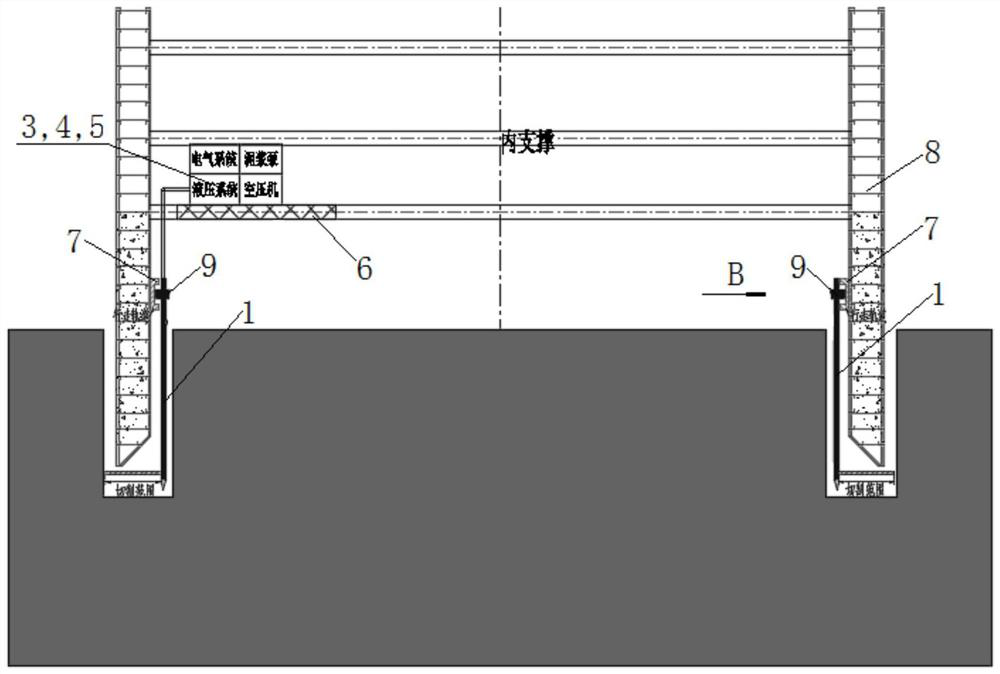

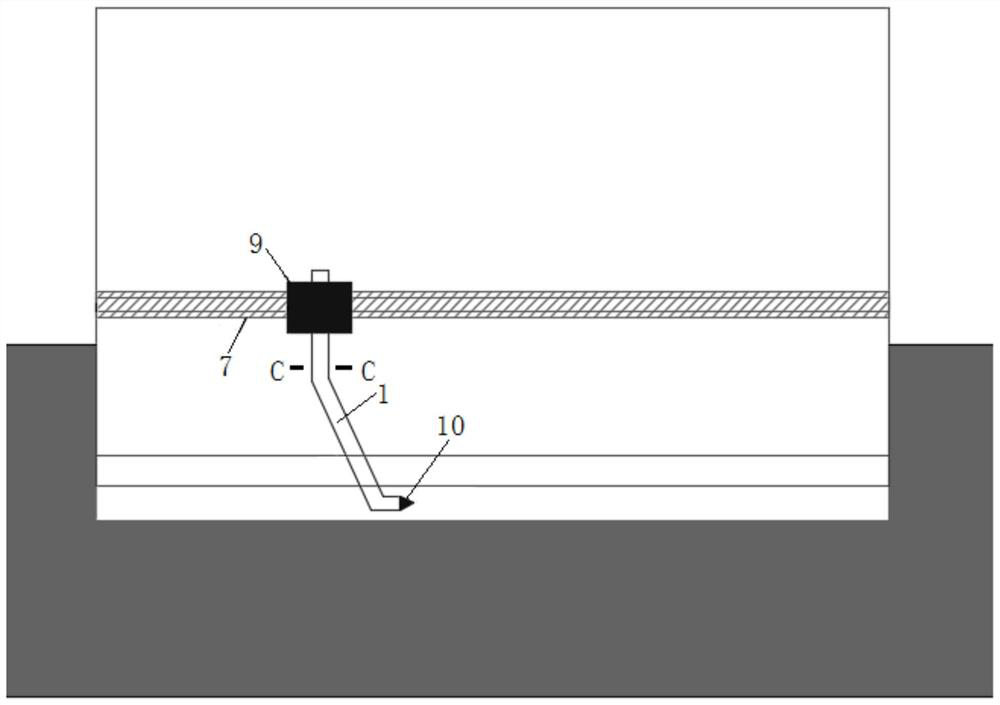

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0031] refer to Figure 1 ~ Figure 4 As shown, the overall subsidence auxiliary equipment for caissons and cofferdam structures in an embodiment provided by the present invention includes a traveling mechanism, an all-round self-propelled high-pressure jetting earth taking device 2 and a monitoring system 3, and an all-round self-propelled The high-pressure jet soil extraction equipment 2 is set on the traveling mechanism, and the lower end of the omnidirectional self-propelled high-pressure jet soil extraction equipment 2 extends below the caisson or cofferdam 8, and a pressure sensor is arranged at the lower end of the caisson or cofferdam 8 to monitor The system is connected with a pressure sensor.

[0032] Further, the all-round self-propelled high-pressure jet soil extraction equipment 2 includes a drill pipe 1, an air compressor 5, a power unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com