A staggered grid slow wave structure loaded by rectangular metal columns

A technology of slow wave structure and metal pillars, which is applied in the direction of the circuit components of the time-of-flight electron tube to achieve the effect of increasing output power, reducing requirements, improving electronic efficiency and output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

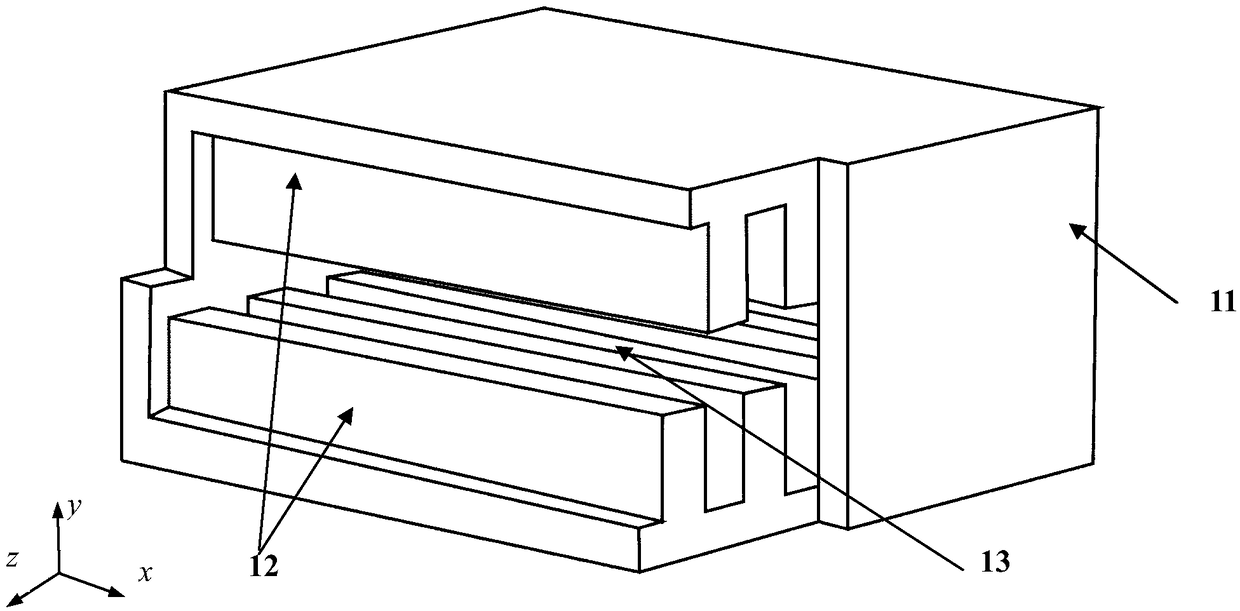

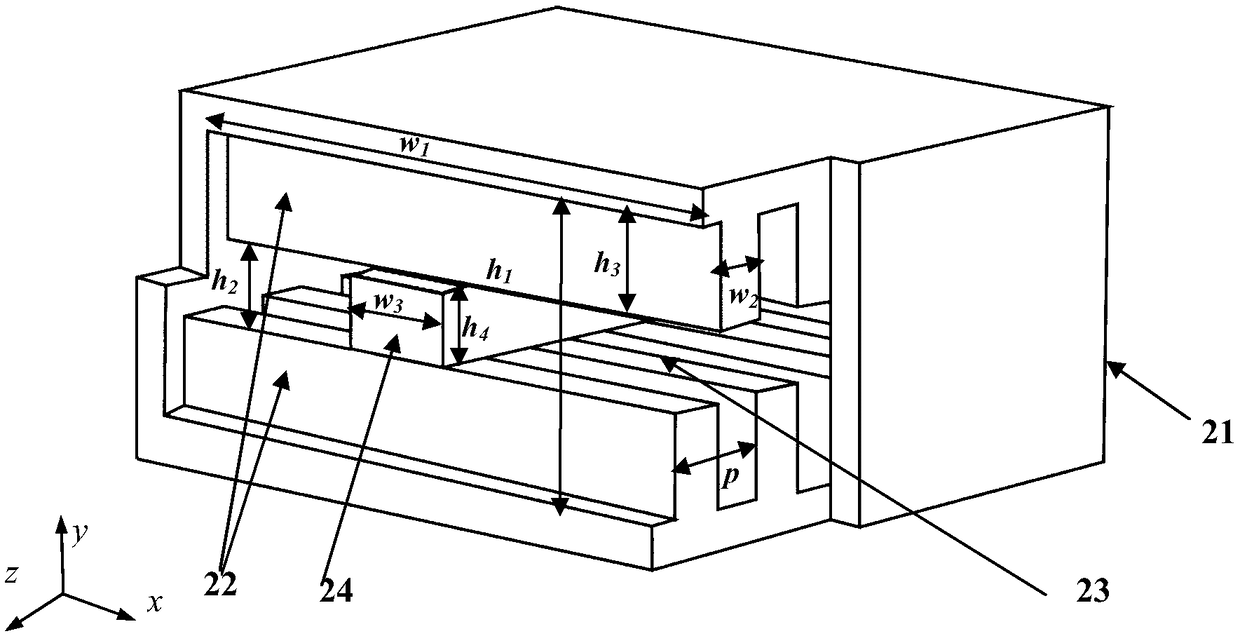

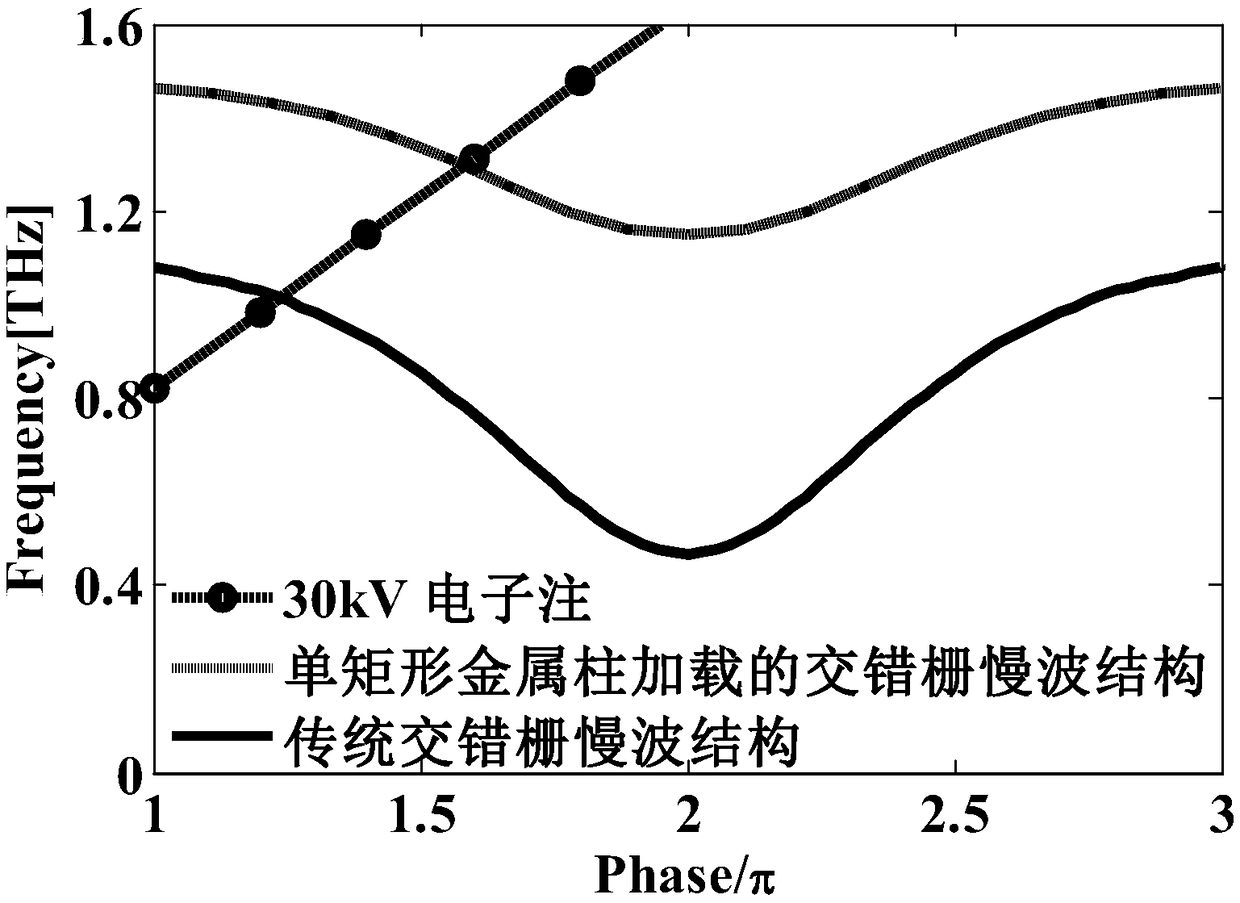

[0030] In this implementation manner, an example is taken of a staggered grating slow-wave structure loaded with a single rectangular metal pillar with a working frequency range of 0.35-1.55 THz. Such as figure 2 As shown, it includes a rectangular parallelepiped housing 21, the lower bottom surface and the upper top surface of the housing 21 have rectangular grid teeth 22 arranged periodically along the axial direction, and a belt-shaped electron injection channel formed between the upper and lower rectangular grid teeth. 23, also includes rectangular metal posts 24 loaded in the upper and lower rectangular grid teeth 22.

[0031] The number of rectangular metal pillars is 1, and the number of electron injection channels is 2. Such as figure 2 As shown, the specific dimensions are set as follows: the width and height of the cross-section of the slow wave structure are respectively w 1 = 320 μm and h 1 = 160μm, the period is p = 60μm, the height of the electron beam chan...

Embodiment 2

[0033] In this implementation manner, an example is taken of a slow-wave structure of an interlaced grid loaded with double rectangular metal pillars with a working frequency range of 0.35-1.87 THz. Such as Figure 5As shown, it includes a rectangular parallelepiped shell 51, the lower bottom surface and the upper top surface of the shell 51 have rectangular grid teeth 52 arranged periodically along the axial direction, and strip-shaped electron injection channels formed between the upper and lower rectangular grid teeth. 53 , further comprising a first rectangular metal column 54 and a second rectangular metal column 55 loaded in the upper and lower rectangular grid teeth 52 .

[0034] The number of rectangular metal pillars is 2, and the number of electron injection channels is 3. Such as Figure 5 As shown, the specific dimensions are set as follows: the width and height of the cross-section of the slow wave structure are respectively w 1 = 320 μm and h 1 = 160μm, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com