Novel mercury removal method for renewable natural gas

A technology of natural gas and a new method, applied in the field of mercury removal from renewable natural gas, can solve problems such as narrow application range, expensive mercury removal agent, heavy economic burden of natural gas production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

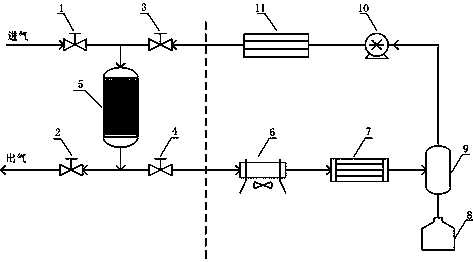

[0021] Example 1: Single-tower renewable mercury removal method

[0022] The single-tower renewable mercury removal method means that the number of natural gas mercury removal towers is one. as attached figure 1 As shown, the left side of the dotted line is the mercury removal tower, which is filled with a renewable mercury removal agent, and the right side is the mercury removal agent regeneration device. The regeneration device is mainly composed of an air cooler, a refrigerator, a gas-liquid separator, a liquid mercury storage tank, and a circulation Composed of air pump and heater. During mercury removal in the mercury removal tower, valve 1 and valve 2 are opened, valve 3 and valve 4 are closed, and the regeneration device does not work. During the regeneration of mercury removal agent, valve 1 and valve 2 are closed, valve 3 and valve 4 are opened, and the regeneration device works. After the regenerated mercury removal agent is cooled to room temperature, the mercury...

Embodiment 2

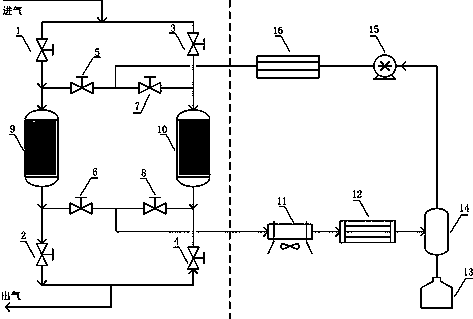

[0024] Example 2: Two-tower renewable mercury removal method

[0025] The double-tower renewable mercury removal method means that the natural gas mercury removal tower and the mercury removal agent regeneration device are fixed in the production process of the natural gas natural gas treatment plant, and the number of mercury removal towers is two. as attached figure 2 As shown, the left side of the dotted line is the mercury removal tower, which is filled with a renewable mercury removal agent, and the right side is the mercury removal agent regeneration device. The regeneration device is mainly composed of an air cooler, a refrigerator, a gas-liquid separator, a liquid mercury storage tank, and a circulation Composed of air pump and heater. The difference from embodiment 1 is that since this embodiment has two mercury removal towers, they can be used simultaneously or separately, and the regeneration of the mercury removal agent can be regenerated simultaneously or separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com