A kind of preparation method of copper sulfide mercury removal agent

A copper sulfide and mercury removal technology, which is applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of mercury removal accuracy, high bulk density, toxicity and odor of residual sulfides, and improve mercury removal activity, The large pore structure increases the contact probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

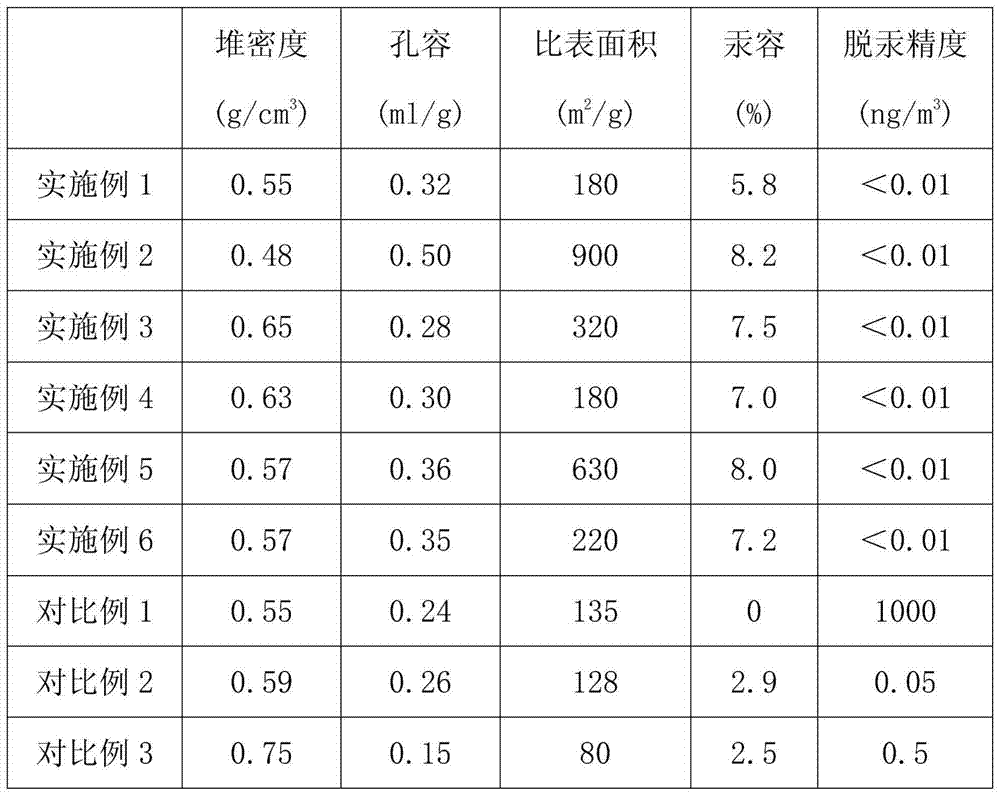

Examples

Embodiment 1

[0028] The preparation method of the copper sulfide mercury removal agent described in the present embodiment comprises the following steps:

[0029] (1) Copper sulfide powder with a mass ratio of 1:8:1, Y-Al 2 o 3 Mix with cement evenly to form a mixture, in which the copper sulfide powder has a grain size of 11-30nm and a particle size of 150 mesh, Y-Al 2 o 3 The particle size of the carrier is 300 mesh and the specific surface area is 160m 2 / g, the pore volume is 0.35ml / g, and the particle size of cement is 120 mesh;

[0030] (2) The mixture is placed in a sugar coating machine to roll, and sprayed into a CMC aqueous solution with a mass concentration of 1%, the addition of the CMC aqueous solution is determined according to the size of the ball and the degree of surface dryness, and the consumption of the CMC aqueous solution is the mixture in the present embodiment. 20% of the mass, the spherical object is obtained by rolling ball molding;

[0031] (3) Drying the sp...

Embodiment 2

[0035] The preparation method of the copper sulfide mercury removal agent described in the present embodiment comprises the following steps:

[0036] (1) Mix copper sulfide powder, activated carbon and Portland cement with a mass ratio of 5:90:5 to form a mixture, wherein the copper sulfide powder has a grain size of 30-50 nm and a particle size of 120 mesh, and the activated carbon The particle size of the carrier is 250 mesh and the specific surface area is 980m 2 / g, the pore volume is 0.52ml / g, and the particle size of Portland cement is 150 mesh;

[0037](2) the mixture is placed in a sugar coating machine to roll, and sprayed into a CMC aqueous solution with a mass concentration of 5%, the addition of the CMC aqueous solution is determined according to the size of the ball and the degree of surface dryness, and the consumption of the CMC aqueous solution is the mixture in the present embodiment. 30% of the mass, the spherical object is obtained by rolling ball molding; ...

Embodiment 3

[0040] The preparation method of the copper sulfide mercury removal agent described in the present embodiment comprises the following steps:

[0041] (1) Mix copper sulfide powder, molecular sieve and Portland cement with a mass ratio of 2:7:3 to form a mixture, wherein the copper sulfide powder has a grain size of 80-90nm and a particle size of 200 mesh, molecular sieve The particle size of the carrier is 350 mesh and the specific surface area is 380m 2 / g, the pore volume is 0.33ml / g, and the particle size of Portland cement is 200 mesh;

[0042] (2) The mixture is placed in a sugar coating machine and rolled, and sprayed into a CMC aqueous solution with a mass concentration of 3%. The amount of the CMC aqueous solution is determined according to the size of the ball and the degree of surface dryness. In this embodiment, the consumption of the CMC aqueous solution is the mixture 40% of the mass, the spherical object is obtained by rolling ball molding;

[0043] (3) Drying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com