Mesoporous carbon carrier and preparation method thereof

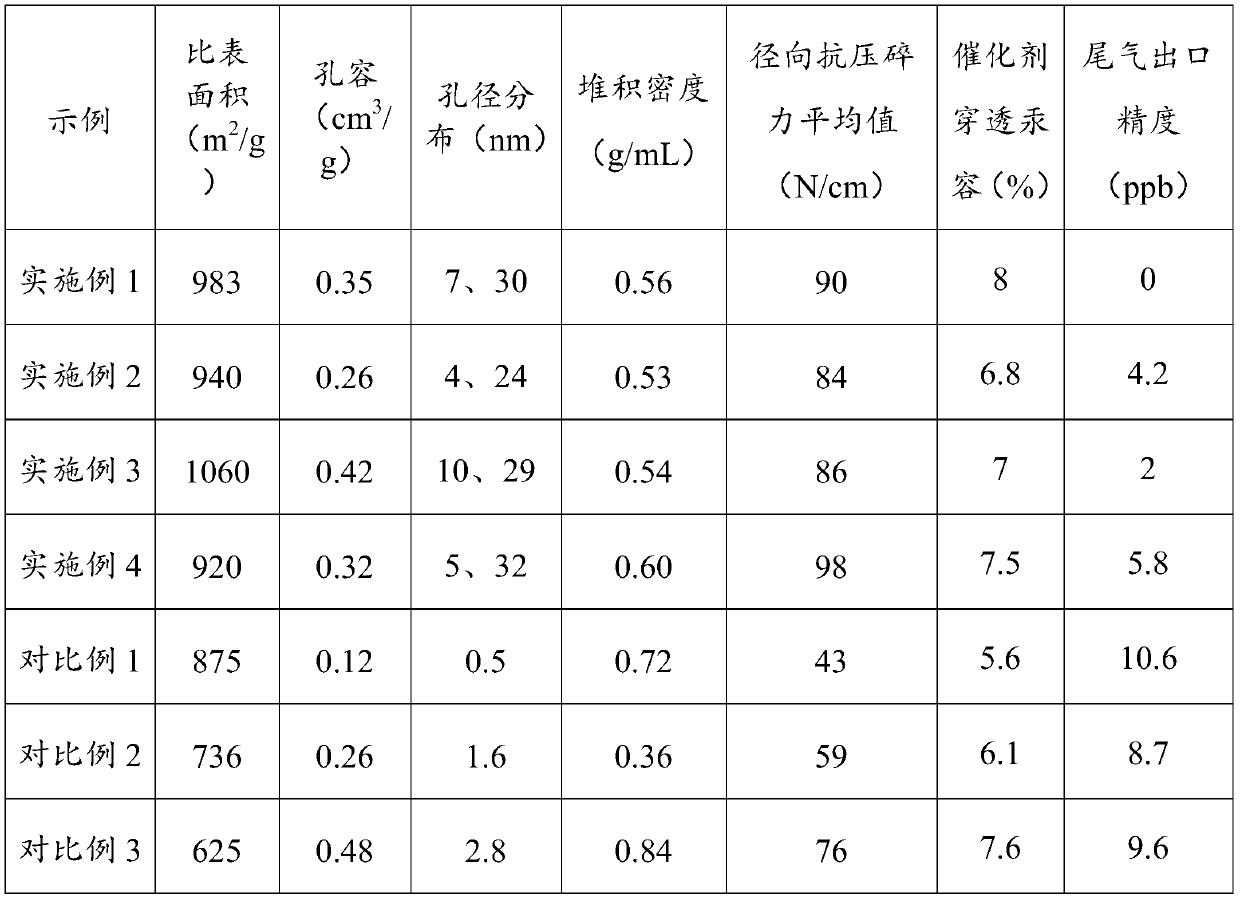

A technology of mesoporous carbon and carrier, applied in the field of mesoporous carbon carrier and its preparation, can solve the problems of poor high temperature resistance, poor mercury removal effect, poor acid and alkali resistance, etc., and achieves enhanced alkalinity and surface activity, improved mercury removal effect, the effect of increasing the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a method for preparing a mesoporous carbon carrier, comprising:

[0036] 140g of furfuryl alcohol was added into 100g of water to dissolve to make a saturated solution, and then 270g of diphenol was added to obtain the first mixed solution for subsequent use;

[0037] 350g P123 template is completely immersed in the first mixed solution for 24 hours to obtain the second mixed solution, which is set aside;

[0038] At 750°C, 55g K 2 CO 3 Add the second mixed solution for activation for 8 hours to obtain the first activated intermediate; soak the first activated intermediate in the first mixed solution for 10 hours to obtain the third mixed solution;

[0039] The third mixed solution was stirred at 80° C. for 20 h for crystallization, and then dried at 105° C. for 8 h after suction filtration; and then heat-treated at 950° C. for 35 h under the protection of nitrogen to obtain a mesoporous carbon carrier.

Embodiment 2

[0041] This embodiment provides a method for preparing a mesoporous carbon carrier, comprising:

[0042] The urea of 120g is added to dissolve in 100g water, makes saturated solution, then adds 240g phenolic resin again, obtains the first mixed solution, for subsequent use;

[0043]300g F127 template is fully immersed in the first mixed solution for 23 hours to obtain the second mixed solution, which is set aside;

[0044] At 730°C, add 45g of KOH to the second mixed solution for activation for 7 hours to obtain the first activated intermediate; soak the first activated intermediate in the first mixed solution for 9 hours to obtain the third mixed solution;

[0045] The third mixed liquid was stirred at 70° C. for 18 hours for crystallization, and then dried at 105° C. for 8 hours after suction filtration; and then heat-treated at 900° C. for 33 hours under the protection of nitrogen to obtain a mesoporous carbon carrier.

Embodiment 3

[0047] This embodiment provides a method for preparing a mesoporous carbon carrier, comprising:

[0048] Add 160g of ethylenediamine to 100g of water for dissolving to make a saturated solution, then add 300g of phenolic resin oligomer to obtain the first mixed solution for subsequent use;

[0049] The 390g tetraethylamine template is fully immersed in the first mixed solution for 25h to obtain the second mixed solution, which is set aside;

[0050] At 780°C, add 65g of NaOH to the second mixed solution for activation for 9 hours to obtain the first activated intermediate; soak the first activated intermediate in the first mixed solution for 11 hours to obtain the third mixed solution;

[0051] The third mixed liquid was stirred at 90° C. for 22 hours for crystallization, and then dried at 105° C. for 8 hours after suction filtration; and then heat-treated at 1000° C. for 37 hours under the protection of nitrogen to obtain a mesoporous carbon carrier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com