Homogeneous nanocrystal modified TiO2 nanotube array and preparation method thereof

A nanotube array, nanocrystal technology, applied in nanotechnology, chemical instruments and methods, crystal growth, etc., can solve problems such as increasing the recombination probability of electrons and holes, and reducing the degradation efficiency of organic matter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

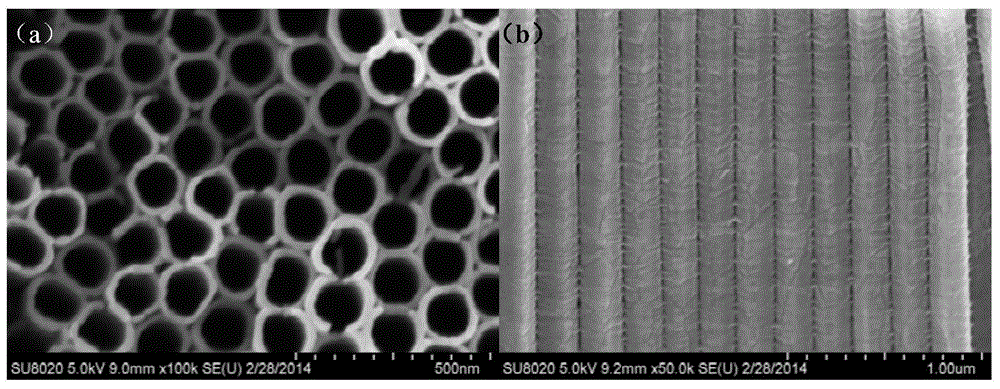

[0018] In this example, homogeneous nanocrystalline modified TiO 2 The preparation process of the nanotube array is as follows:

[0019] (1) After the surface of the titanium foil is thoroughly cleaned, it is anodized to form TiO on the surface of the titanium foil substrate. 2 Nanotube array, the electrolyte used is containing 0.3mol / LNH 4 For the ethylene glycol solution of F, the oxidation voltage is 60V, and the oxidation time is 10h.

[0020] (2) TiO obtained in step (1) 2 Anatase TiO can be obtained by calcining and crystallizing nanotube arrays at 500°C for 2 hours 2 array of nanotubes.

[0021] (3) configure TiO 2 Sol precursor solution: titanium tetrachloride (TiCl 4 ) and urea are mixed in ethanol at a molar ratio of 1:2, so that the concentration of titanium tetrachloride is 10vol%.

[0022] (4) the crystallized TiO obtained in step (2) 2 Nanotube array obtained in step (3) TiO 2 Immerse in the sol precursor solution for 10min, the temperature of the water ...

Embodiment 2

[0028] The preparation method of this embodiment is the same as that of Example 1, except that the soaking time in step (4) is changed to 30min.

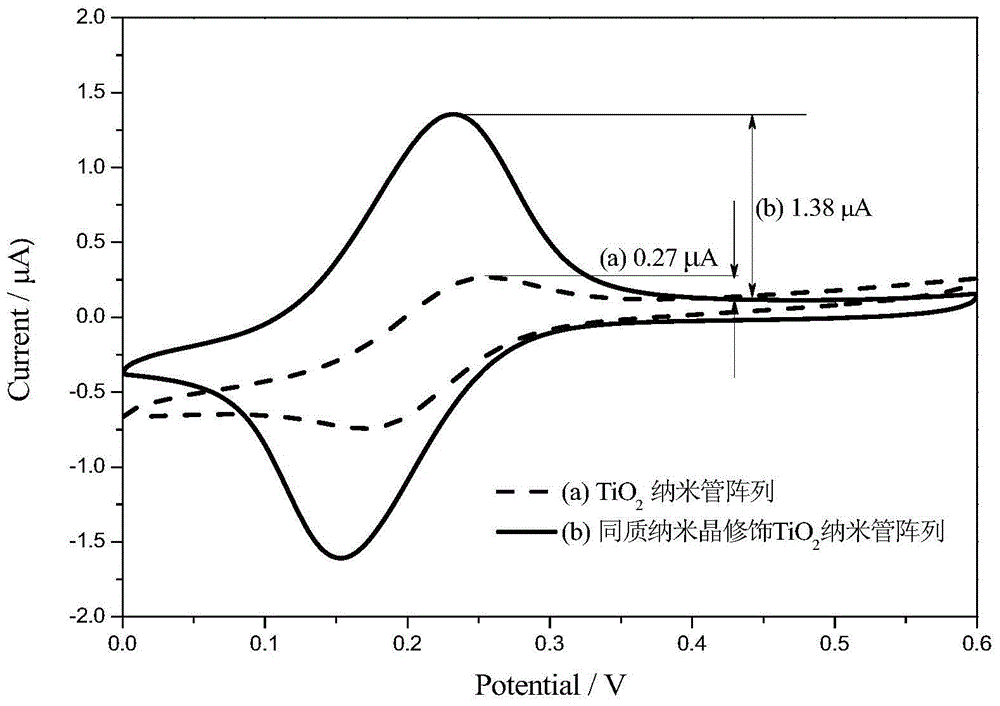

[0029] After testing, the homogeneous nanocrystalline modified TiO prepared according to the above steps 2 Nanotube array at 48mW / cm 2 Under the irradiation of ultraviolet light, the photocurrent is 254μA, which is about the same as that of ordinary TiO 2 5 times the photocurrent of NTAs.

Embodiment 3

[0031] The preparation method of this embodiment is the same as that of Example 1, except that the soaking time in step (4) is changed to 60min.

[0032] After testing, the homogeneous nanocrystalline modified TiO prepared according to the above steps 2 Nanotube array at 48mW / cm 2 Under the irradiation of ultraviolet light, the photocurrent is 173μA, which is about the same as that of the undeposited nanocrystalline TiO 2 3.5 times the photocurrent of NTAs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com