Efficient coal-fired flue gas sulfur removal and mercury removal method and device

A coal-fired flue gas and mercury removal technology, which is applied in the field of environmental pollution control, can solve the problems of poor removal effect of zero-valent mercury vapor, unrealized industrial application, complicated regeneration process, etc., and achieve rich porosity, good absorption effect, and improved The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

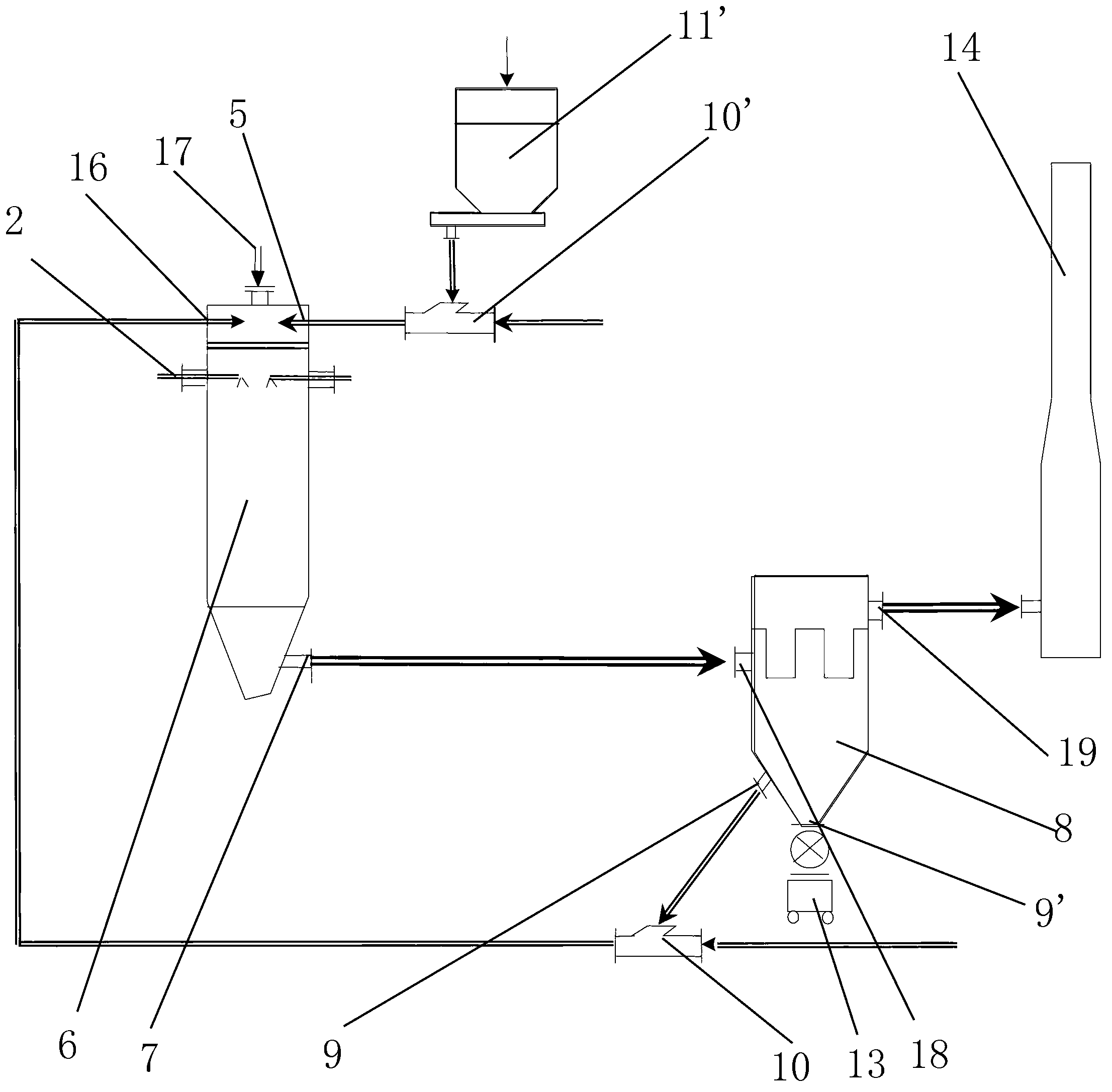

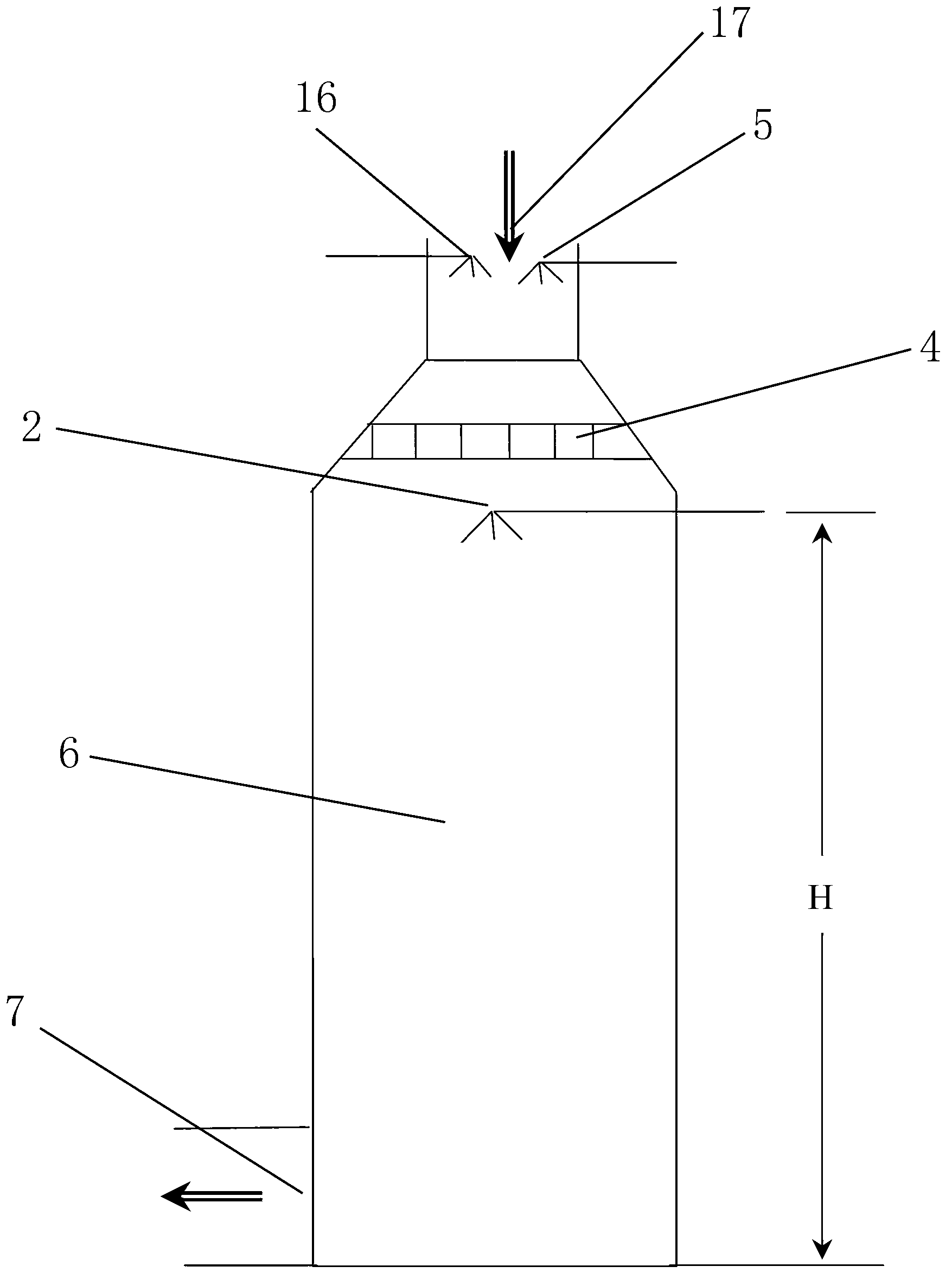

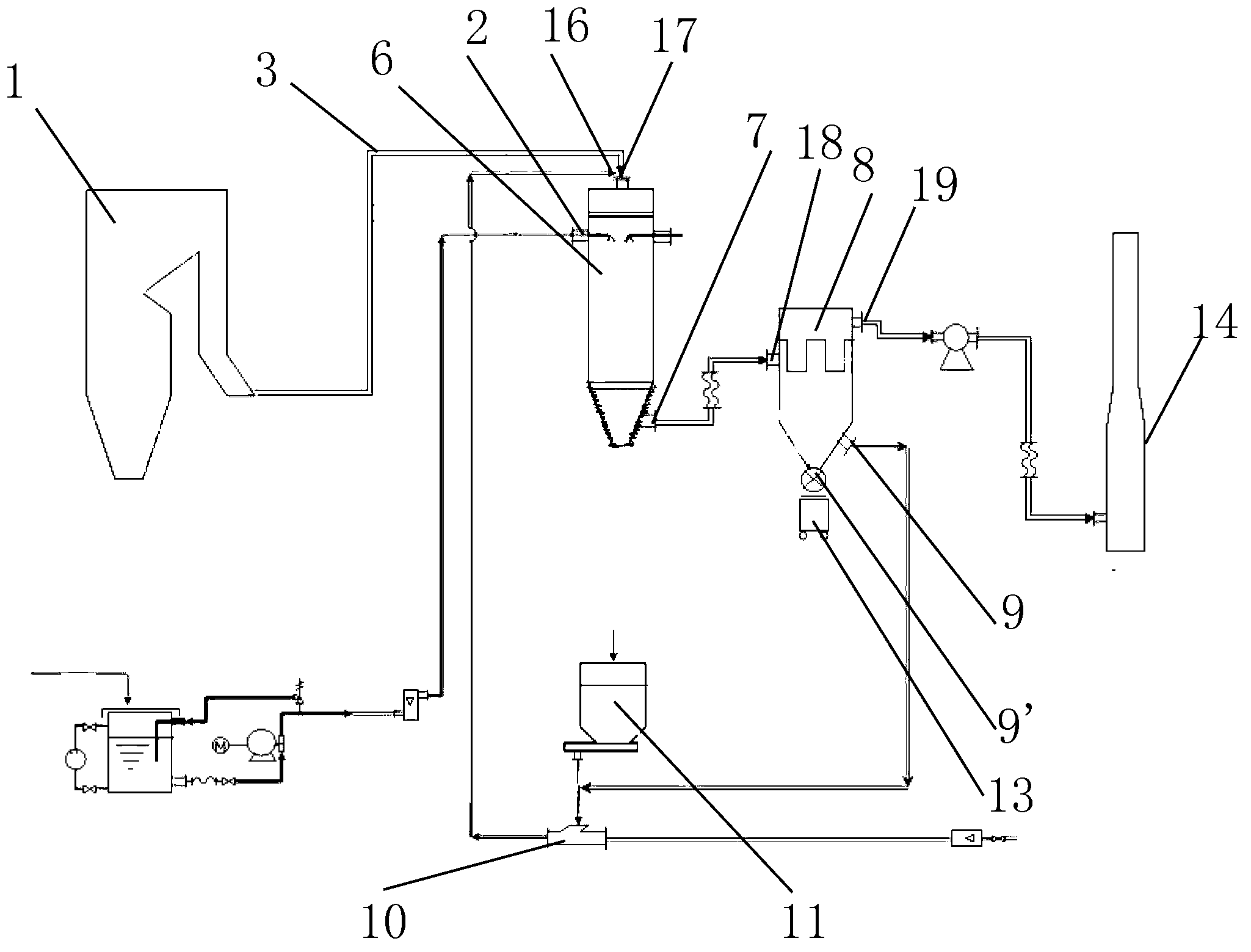

[0044] The desulfurization and mercury removal device experiment was carried out in a 2t / h coal-fired experimental boiler. The experimental system is as follows image 3 As shown, the size of the flue gas desulfurization and mercury removal reaction tower is Ф1200mm×7800mm, the flue gas superficial flow velocity is 3.8m / s, and the rear of the desulfurization and mercury removal reaction tower is equipped with a bag filter to collect the by-products after the reaction. The raw coal of Datong, Shanxi Province was used for experimental research, the sulfur content of the coal was 0.32%, and the mercury content in the coal was 0.35mg / kg.

[0045] The temperature of the flue gas entering the reaction tower device is 128°C, SO 2 The concentration is 578mg / Nm 3 , the concentration of mercury vapor is 21.6μg / Nm 3 . By spraying water into the reaction tower and keeping the tower temperature at 75°C, the concentration of particulate matter in the reaction tower after desulfurization ...

Embodiment 2

[0047] An 85t / h coal-fired boiler, the sulfur content of coal combustion is 0.5%, and the mercury content of coal combustion is 0.11mg / kg. The flue gas temperature at the outlet is 139.9°C, and the flue gas volume is 234000-236000Nm 3 / h, flue gas SO 2 The concentration is 920mg / Nm 3 . Adopt the dry flue gas desulfurization and mercury removal device of the application of the present invention, such as image 3 As shown, the physical and chemical properties of fly ash changed significantly after water vapor transport, and a part of CaO was transformed into porous Ca(OH) 2 , improve the adsorption capacity of fly ash to mercury. The temperature of the flue gas after desulfurization and dust removal is 76-79°C, and the CaO / SO 2 When the molar ratio is lower than 1.2, SO in the treated flue gas 2 The concentration is 89mg / Nm 3 , The desulfurization efficiency reaches 89.3%. Using this device combined with the bag filter can remove about 98.6% of the mercury vapor in the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com