Preparation method of copper and cerium composite silver halide/silver photocatalyst and flue gas demercuration method adopting photocatalyst

A catalyst and silver halide technology, applied in the field of pollutant prevention and control, can solve the problems of poor mercury removal effect, high price, and slight removal effect, and achieve the effects of enhancing photocatalytic activity, enhancing effective separation, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

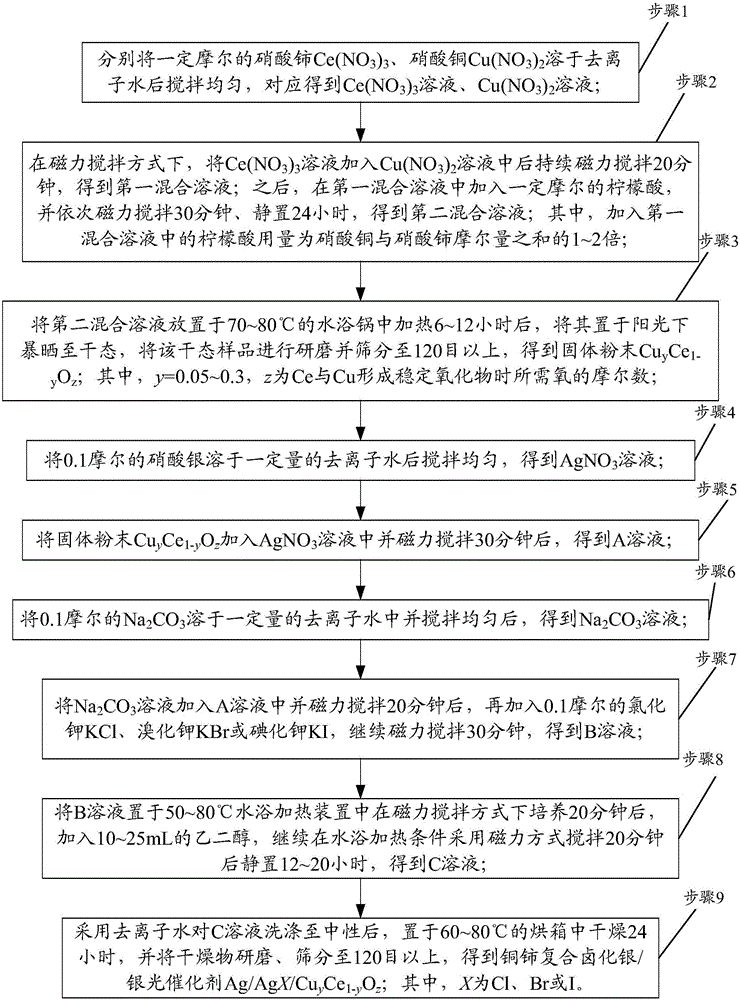

[0028] figure 1 It is a schematic flow chart of the preparation method of the copper-cerium composite silver halide / silver photocatalyst of the present invention. Such as figure 1 Shown, the copper-cerium composite silver halide / silver photocatalyst preparation method of the present invention comprises the steps:

[0029] Step 1, a certain mole of cerium nitrate Ce (NO 3 ) 3 , copper nitrate Cu(NO 3 ) 2 Dissolved in deionized water and stirred evenly, the corresponding Ce(NO 3 ) 3 solution, Cu(NO 3 ) 2 solution.

[0030] Step 2, under magnetic stirring mode, Ce(NO 3 ) 3 The solution was added Cu(NO 3 ) 2 Continue magnetic stirring for 20 minutes in the solution to obtain the first mixed solution; then, add a certain mole of citric acid to the first mixed solution, and then magnetically stir for 30 minutes and stand for 24 hours to obtain the second mixed solution; wherein, The amount of citric acid added to the first mixed solution is 1-2 times the sum of the mol...

Embodiment

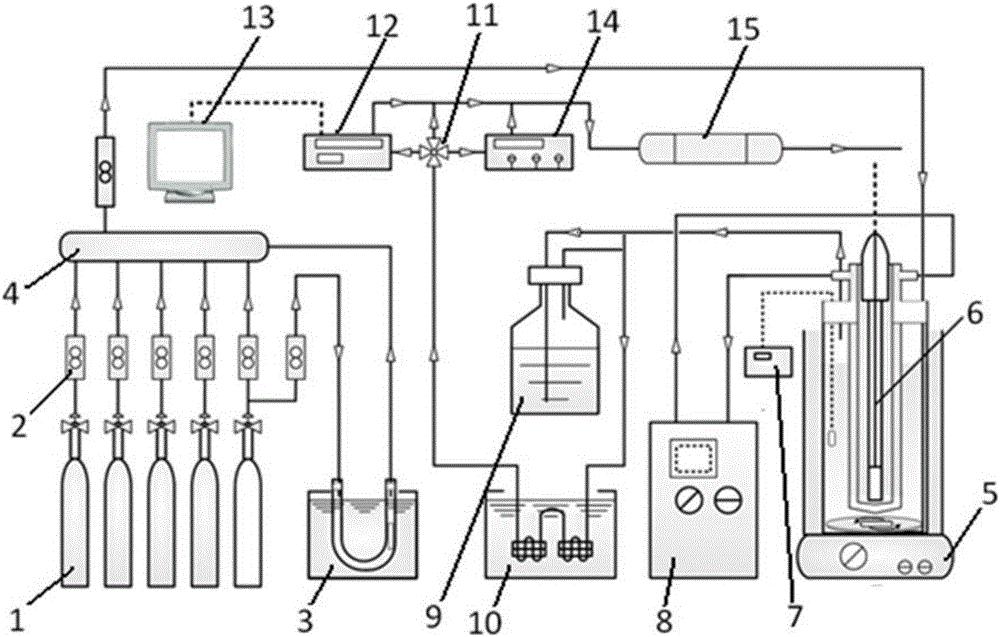

[0052] image 3 It is the flue gas mercury removal equipment used when the copper-cerium composite silver halide / silver photocatalyst is used for flue gas mercury removal in the present invention. Such as image 3 As shown, the flue gas demercuration equipment used when the present invention adopts copper-cerium composite silver halide / silver photocatalyst to carry out flue gas demercuration includes: a steel cylinder 1 used as the original flue gas source, equipped with elemental mercury permeation pipe to A constant-temperature water bath 3 for adding mercury to the original flue gas source part from the steel cylinder 1, a mixer 4 for mixing the original flue gas and mercury-containing flue gas, and controlling the correspondence between the steel cylinder 1 and the constant-temperature water bath 3 and mixer 4 The flow meter 2 that outputs the gas flow rate of the original flue gas, the untreated flue gas output by the mixer 4 enters the reaction solution containing coppe...

example 1

[0057] Ce(NO 3 ) 3 The solution is 0.02 mole of cerium nitrate dissolved in 100 ml of deionized water, Cu(NO 3 ) 2 The solution is 0.0023 moles of copper nitrate dissolved in 50 milliliters of deionized water, the amount of citric acid is twice the sum of the molar weights of copper nitrate and cerium nitrate, and the resulting solid powder is Cu 0.1 Ce 0.9 o z , the photocatalyst is Ag / AgCl / Cu 0.1 Ce 0.9 o z or Ag / AgBr / Cu 0.1 Ce 0.9 o z . The photocatalyst is Ag / AgCl / Cu 0.1 Ce 0.9 o z The experimental parameters for flue gas demercuration are shown in Table 1:

[0058] Table 1 The parameters of the first flue gas mercury removal experiment

[0059] Reaction temperature / pressure

[0060] According to the flue gas mercury removal experimental parameters shown in Table 1, the photocatalyst Ag / AgCl / Cu 0.1 Ce 0.9 o z elemental Hg 0 The removal efficiency of the removal is about 93%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com