Ag and two-dimensional MXene modified high-temperature flue gas dust removal, denitration and mercury removal catalytic film and preparation method thereof

A high-temperature flue gas and catalytic membrane technology, applied in the field of air purification, can solve the problems of few applications in the field of catalysis, and achieve the effects of simplifying the flue gas purification process, good promotion value, and adjustable load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

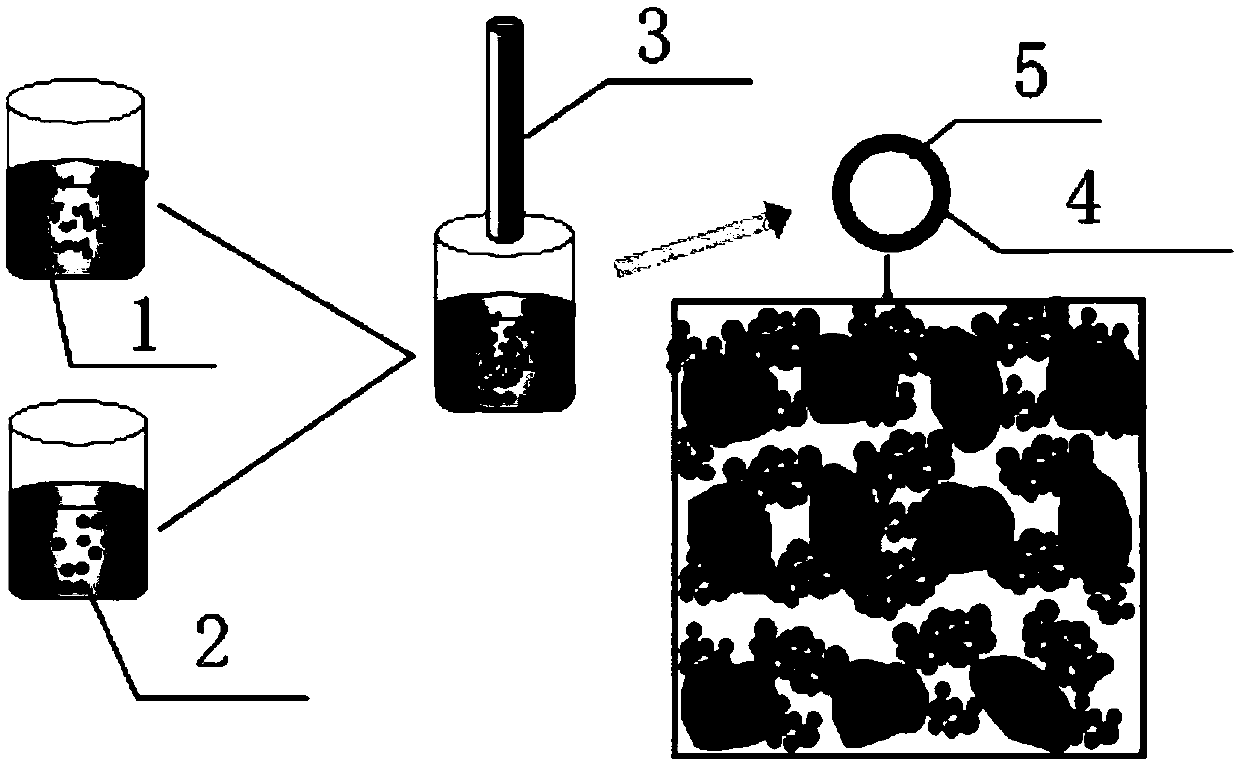

[0034] Such as figure 1 As shown, the typical embodiment of the present invention Ag and two-dimensional MXene modified high temperature flue gas dedusting denitrification demercuration catalytic membrane preparation method comprises the following steps:

[0035] (1) Dilute MXene solution 1 with deionized water, add AgNO 3 , after 1~2h of ultrasound;

[0036] (2) Disperse the active metal, dispersant, and carrier 2 in sub-water, and sonicate for 1~2h;

[0037] (3) Slowly add solution B to solution A, stir to add binder, stir for 1~4h to obtain an active solution;

[0038] (4) Apply the prepared catalytic layer sol to the 3 channels of the support body by suction, then dry it in a drying oven and then calcinate to obtain a catalytic membrane. The catalytic membrane is composed of a ceramic support body, distributed on a porous ceramic The active catalyst layer 4 and the separation layer 5 in the pores of the membrane support carrier are composed.

Embodiment 1

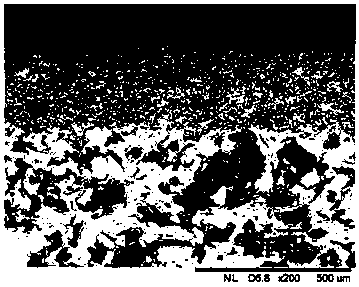

[0040] 10g Ti 3 AlC 2 The particles were placed in 40% HF acid for 2 h, centrifuged, washed with water and alcohol, and dried at low temperature to obtain Ti 3 C 2 Tx powder, Ti 3 C 2 Tx powder was dispersed in deionized water at a concentration of 2 mg / mL, ultrasonicated for 2 h, and centrifuged to obtain the supernatant to obtain a MXene nanosheet dispersion (such as figure 2 shown). Take 5mL MXene nanosheet dispersion and dilute to 50 mL, add 0.09gAgNO 3 , sonication for 2 h. Take vanadium nitrate and tungsten nitrate in 250mL deionized water, add 1.6g oxalic acid, add 5g 5nm TiO 2 , 30mL ethylene glycol, after ultrasonication for 2 h, the two solutions were mixed, and 2 g of 10%-PVA was added to obtain an active solution (such as image 3shown), the loading of V in the active solution was 1.8 wt%, and the loading of W was 8 wt%. The tubular membrane (the average pore size of the support body is about 40um, such as Figure 4 (shown) was impregnated in the active...

Embodiment 2

[0043] Prepare the MXene nanosheet dispersion according to the method shown in Example 1, take 7mL of the MXene nanosheet dispersion and dilute it to 50mL, add 0.94g AgNO 3 , sonication for 2 h. Take vanadium nitrate, molybdenum nitrate, and yttrium nitrate in 250mL deionized water, add 4g20nmTiO 2 , 2g 40nm ZrO 2 , 56mL of glycerol, after ultrasonication for 2 h, the two solutions were mixed, and 3.1 g of 10%-methylcellulose was added to obtain an active solution. The loading of V in the active solution was 1.2 wt%, and the loading of Mo was 6 wt%. The loading of Y was 8 wt%. The plate membrane (average pore size 10 um) was dipped in the active solution for 2 minutes, then dried for 48 h at 70°C and 40% RH, and placed in a muffle furnace with a heating rate of 0.5°C / min, 450°C Sintering under temperature conditions for 3h to obtain a catalytic membrane (the surface morphology of the catalytic membrane is as follows figure 2 shown).

[0044] After testing, the dust remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com