Method, product and application of brominated flame retardant and biomass to prepare mercury-removing activated carbon

A brominated flame retardant and biomass technology, which is applied in the field of activated carbon preparation, can solve the problems of difficult regeneration of activated carbon, complicated preparation method and high carbon/mercury ratio, and achieves the advantages of improving chemical adsorption capacity, simple preparation process and promoting decomposition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

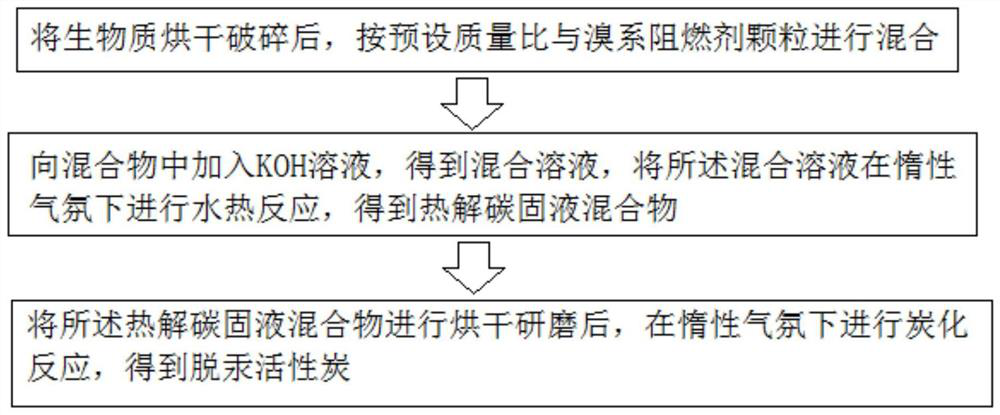

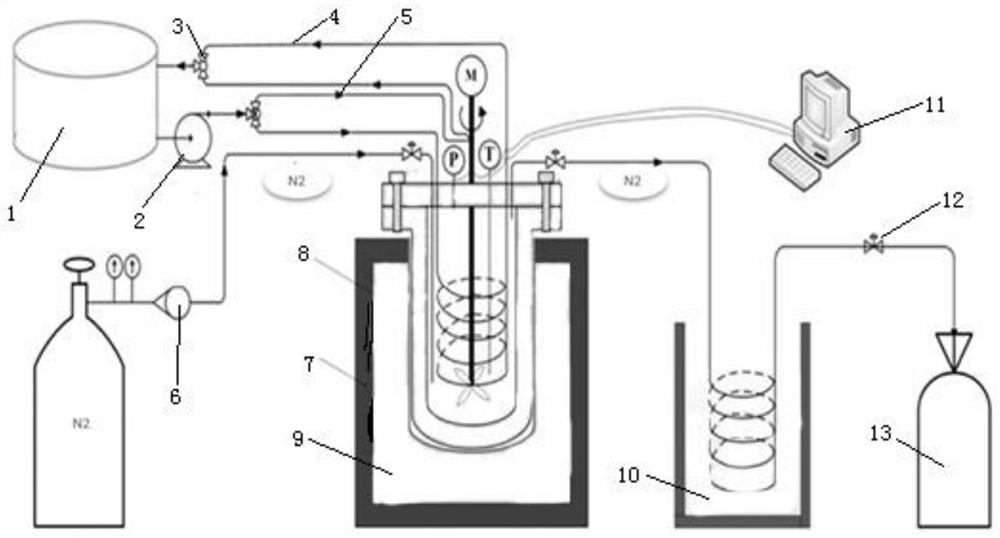

[0031] Such as figure 1 Shown, a kind of brominated flame retardant of the present invention and biomass hydrothermally prepare the method for demercury activated carbon, this method is to carry out mixed hydrothermal reaction with brominated flame retardant, biomass and KOH in the reactor, and The reaction product is subjected to high-temperature carbonization to prepare a highly active mercury-removing adsorbent, which is a cheap and highly active mercury-removing adsorbent preparation method. It specifically includes the following steps:

[0032] S1 After the biomass is dried and crushed, it is mixed with brominated flame retardant particles according to the preset mass ratio;

[0033] S2 adding KOH solution to the mixture obtained in step S1 to obtain a mixed solution, and performing a hydrothermal reaction on the mixed solution under an inert atmosphere to obtain a pyrolytic carbon solid-liquid mixture;

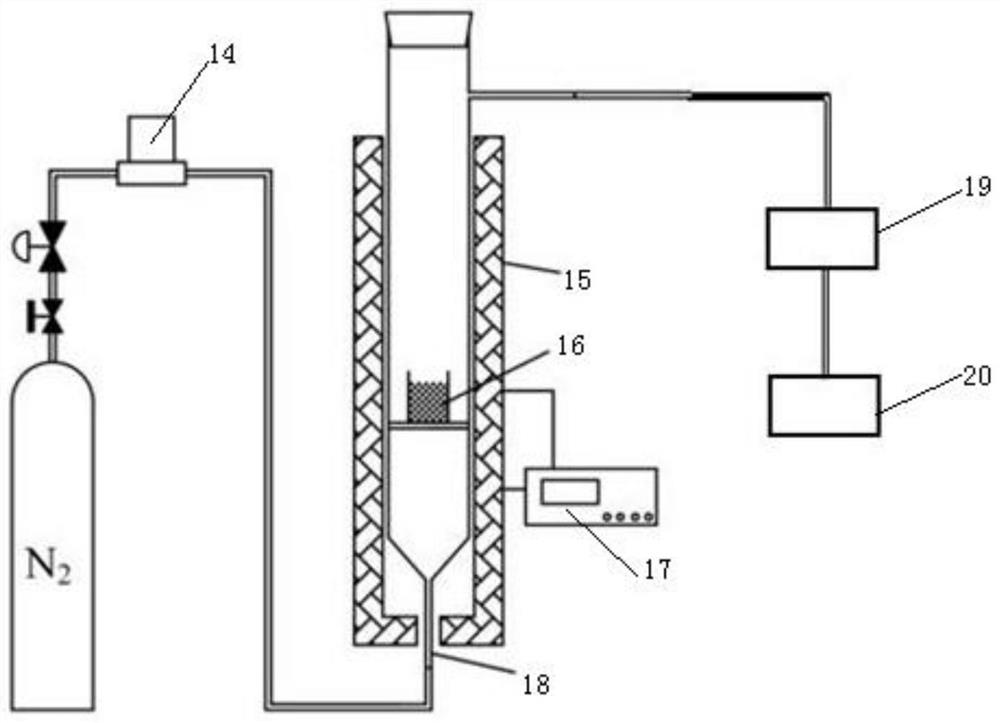

[0034]S3 drying and grinding the pyrolytic carbon solid-liquid mi...

Embodiment 1

[0047] In this embodiment, tetrabromobisphenol A (TBBPA) and Phyllostachys pubescens powder are used as reaction raw materials, and the method for mixing hydrothermal preparation of mercury-removing activated carbon comprises the following steps:

[0048] In step (1), the biomass is washed with deionized water and dried in an oven at 105° C. for 12 hours.

[0049] In step (2), the biomass obtained in step (1) is crushed and sieved with a 60-mesh sieve.

[0050] Step (3), according to weight ratio 1:1, weigh each 10g of the biomass obtained in step (2) and tetrabromobisphenol A (TBBPA), after mixing, add the solution that contains 4.13gKOH in the mixture, after fully mixing , placed in a hydrothermal reactor.

[0051] In step (4), feed high-purity nitrogen gas into the reactor at a flow rate of 500ml / min for 30 minutes to remove oxygen and other impurity gases that affect the hydrothermal reaction in the system.

[0052] In step (5), the temperature of the hydrothermal reacti...

Embodiment 2

[0059] In this embodiment, tetrabromobisphenol A (TBBPA) and Phyllostachys pubescens powder are used as reaction raw materials, and the method for mixing hydrothermal preparation of mercury-removing activated carbon comprises the following steps:

[0060] In step (1), the biomass is washed with deionized water and dried in an oven at 105° C. for 12 hours.

[0061] In step (2), the biomass obtained in step (1) is crushed and sieved with a 60-mesh sieve.

[0062] Step (3), take by weighing 5g of biomass obtained in step (2) and 15g of tetrabromobisphenol A (TBBPA), after mixing, add a solution containing 4.06gKOH to the mixture, after fully mixing, place in hydrothermal in the reactor.

[0063] In step (4), feed high-purity nitrogen gas into the reactor at a flow rate of 500ml / min for 30 minutes to remove oxygen and other impurity gases that affect the hydrothermal reaction in the system.

[0064] In step (5), the temperature of the hydrothermal reaction is set as: raising the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com