Ultra-low V mercury-removing catalyst containing Ce and preparation method thereof

A catalyst and mercury removal technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems such as environmental damage, high toxicity, unfavorable flue gas denitrification and mercury removal, and reduce emissions and costs Inexpensive, excellent oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

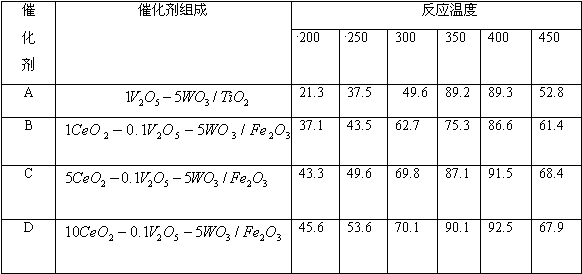

Examples

Embodiment 1

[0038] Example 1: A novel Ce-containing ultra-low V catalyst for denitrification and demercuration, the catalyst label is B.

[0039] The characteristic expression is: . The preparation process of the Ce-containing ultra-low V catalyst comprises the following steps:

[0040] 1) Weigh 0.041175g of ammonium metavanadate and 1.80195g of ammonium tungstate, add them to 5ml of ammonium oxalate, mix with 400ml of deionized water, and stir in a water bath at 60~70°C until fully dissolved and evenly distributed.

[0041] 2) Using a one-step impregnation method, 20 g of nano Powder and 0.3201g of CeO2 powder were impregnated in the solution prepared in step 1), and the obtained mixed slurry was ultrasonically impregnated for 2 hours, and then magnetically stirred for 12 hours.

[0042] 3) Dry the solution after magnetic stirring at a constant temperature of 110° C. for 10 hours.

[0043] 4) The samples obtained after drying were calcined at 260°C for 2h and 550°C for 4h in ...

Embodiment 2

[0047] Example 2: A new type of Ce-containing ultra-low V catalyst for denitrification and demercuration, the catalyst label is C.

[0048] Its characteristic expression is:

[0049] The preparation process of the Ce-containing ultra-low V catalyst comprises the following steps:

[0050]1) Weigh 0.042915g of ammonium metavanadate and 1.87815g of ammonium tungstate, add them to 5ml of ammonium oxalate, mix with 400ml of deionized water, and stir in a water bath at 60~70°C until fully dissolved and evenly distributed.

[0051] 2) 20 g of nano powder and 1.66845g of CeO 2 The powder was immersed in the above prepared solution, and the obtained mixed slurry was ultrasonically immersed for 2 hours, and then magnetically stirred for 12 hours.

[0052] 3) Dry the solution after magnetic stirring at a constant temperature of 110° C. for 10 hours.

[0053] 4) The samples obtained after drying were calcined at 260°C for 2h and at 550°C for 4h in an air atmosphere. After ...

Embodiment 3

[0057] Example 3: A new Ce-containing ultra-low V catalyst for denitrification and mercury removal, the catalyst designation is D.

[0058] Its characteristic expression is:

[0059] The preparation process of the Ce-containing ultra-low V catalyst comprises the following steps:

[0060] 1) Weigh 0.04545g of ammonium metavanadate and 1.9887g of ammonium tungstate, add them to 5ml of ammonium oxalate, mix with 400ml of deionized water, and stir in a water bath at 60~70°C until fully dissolved and uniform.

[0061] 2) Adopt one-step dipping method, take 20g powder and 3.52935g CeO 2 The powder was immersed in the above prepared solution, and the obtained mixed slurry was ultrasonically immersed for 2 hours, and then magnetically stirred for 12 hours.

[0062] 3) Dry the solution after magnetic stirring at a constant temperature of 110° C. for 10 hours.

[0063] 4) The samples obtained after drying were calcined at 260°C for 2h and at 550°C for 4h in an air atmospher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com