Device for treating industrial mercury-containing wastewater containing high-concentration chlorides and control method

A chloride, high-concentration technology, applied in water treatment parameter control, chemical instruments and methods, filtration treatment, etc., can solve the problems of secondary pollution, complex process, restricting industrial application, difficult operation, etc., and achieve good mercury removal effect. , The effect of reducing treatment costs and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

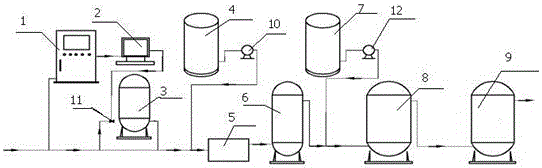

[0036] Embodiment 1: In conjunction with Figure 1, a device for treating industrial mercury-containing wastewater containing high concentrations of chlorides, including heavy metal online automatic analyzer 1, PLC process intelligent feedback control system 2, mercaptan composite inorganic ceramic filter tower 3, drug storage Tank 4, buffer pool 5, filter 6, pH automatic adjustment control system 7, adsorption tower 8, ion exchange tower 9; described heavy metal online automatic analyzer 1 is arranged at the port of the water inlet pipe, and described heavy metal online automatic analyzer 1 one end is connected with mercaptan composite inorganic ceramic filter tower 3 by pipeline; The other end of described heavy metal online automatic analyzer 1 is connected with mercaptan composite inorganic ceramic filter tower 3 by PLC process intelligent feedback control system 2; The alcohol composite inorganic ceramic filter tower 3 is connected to the buffer pool 5 through a pipeline; a...

Embodiment 2

[0050] Example 2: A certain industrial mercury-containing wastewater enters the system, and the mercury concentration in the wastewater is measured by the heavy metal online automatic analyzer to be 120 mg / L. The PLC process intelligent feedback control system is automatically opened and set in the PLC process intelligent feedback control system and mercaptan compound Electromagnetic valves are also installed between the inorganic ceramic filter towers. Mercury wastewater flows into the mercaptan composite inorganic ceramic filter towers, and the mercury concentration in the effluent is reduced to below 50mg / L. NaClO is added to the drug storage tank and flows into the buffer pool together. Mixed reaction in the medium, then go through anthracite and quartz sand double-layer filter to remove impurities, adjust the pH to 2.3 through the pH automatic adjustment control system, and then go through the adsorption tower to remove free chlorine, so that the concentration of free chlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com