Method and device for removing sulfur, nitre and mercury in smoke

A technology of desulfurization, denitrification, mercury removal, and gas mixing device, which is applied in the field of flue gas purification, can solve the problems of insolubility and stability that are difficult to remove, and achieve the effects of convenient transformation, obvious mercury removal effect, and reduction of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

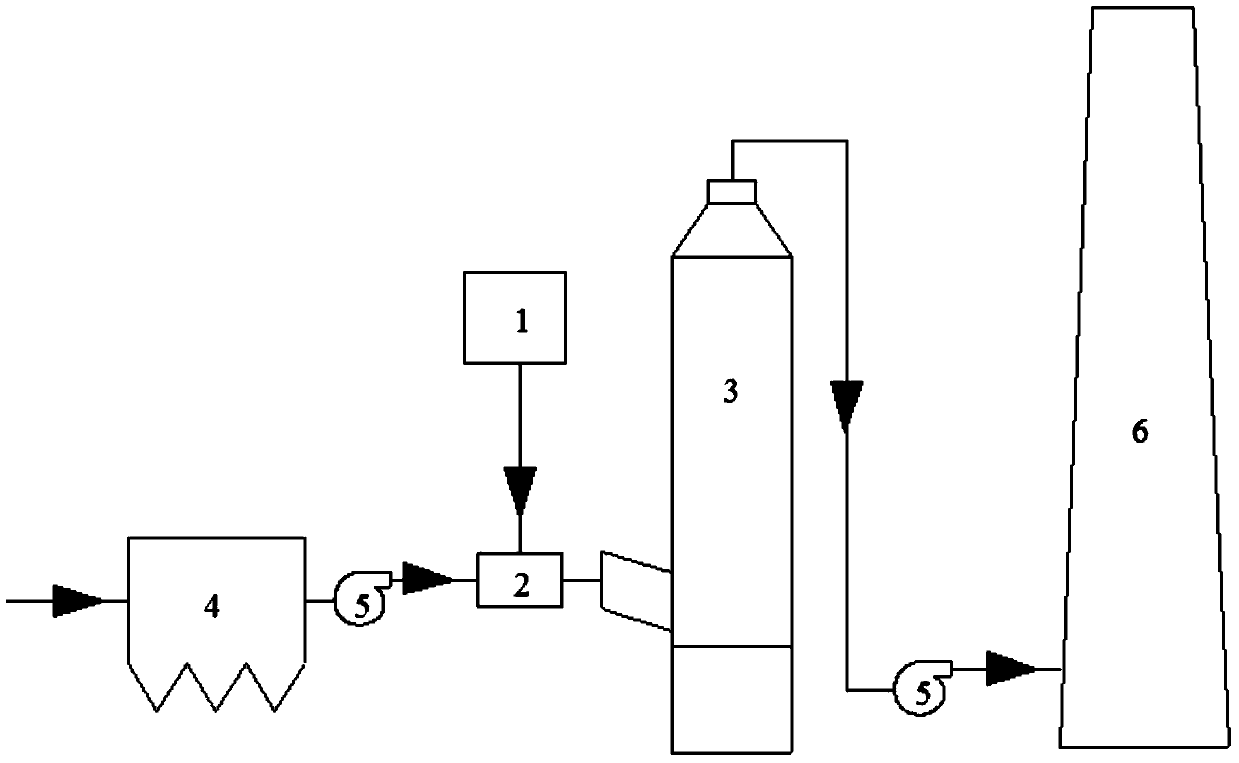

[0021] Such as figure 1 , a device for flue gas desulfurization, denitrification and mercury removal, comprising a flue gas inlet pipe, the flue gas inlet pipe communicates with a gas mixing device 2 through a dust collector 4 and a fan 5, and the gas mixing device 2 is connected with a chlorine dioxide gas preparation device 1, The gas outlet of the gas mixing device 2 is connected to the wet desulfurization device 3 , and the wet desulfurization device 3 is connected to the chimney 6 .

[0022] During the implementation of the process of this embodiment, the chlorine dioxide gas prepared by the chlorine dioxide gas preparation device 1 is sprayed into the gas mixing device 2 at the front of the wet desulfurization device 3, where the smoke after dust removal by the dust collector 4 is realized. NO and elemental mercury (Hg 0 ) pre-oxidation, the NO in the flue gas is oxidized to high-valence nitrogen oxides, and the elemental mercury (Hg 0 ) is oxidized to oxidized mercury...

Embodiment 2

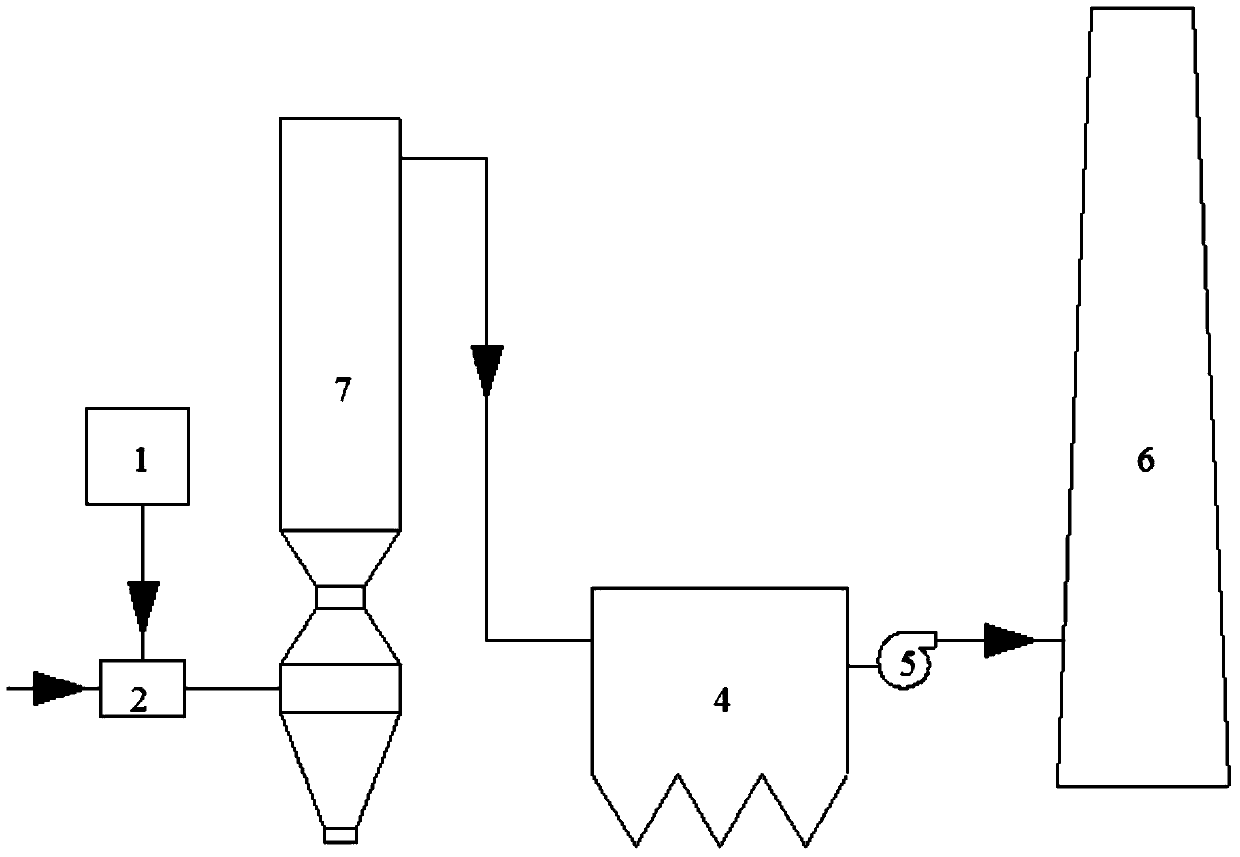

[0024] Such as figure 2 , a device for flue gas desulfurization, denitrification and demercuration, comprising a flue gas inlet pipe, a flue gas inlet pipe and a chlorine dioxide gas preparation device 1 are all connected to a gas mixing device 2, and the gas outlet of the gas mixing device 2 is connected to a semi-dry desulfurization device 7. The semi-dry desulfurization device 7 is connected to the chimney 6 through the dust collector 4 and the fan 5 .

[0025] In the process of implementing the present embodiment, the chlorine dioxide gas prepared by the chlorine dioxide gas preparation device 1 is sprayed into the gas mixing device 2 at the front of the semi-dry desulfurization device 7, where the pre-oxidation of the flue gas is realized. Oxidize NO in the flue gas to high-valence nitrogen oxides, and convert elemental mercury (Hg 0 ) is oxidized to oxidized mercury (Hg 2+ ), with HgCl 2 The form exists in the flue gas, the pre-oxidized flue gas then enters the semi-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com