Flue gas dust-removal mercury-removal desulfurizing system

A desulfurization system and flue gas technology, applied in the separation of dispersed particles, chemical instruments and methods, combined devices, etc., can solve the problems of ineffective removal of gas-phase mercury, large differences in physical and chemical properties of mercury, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

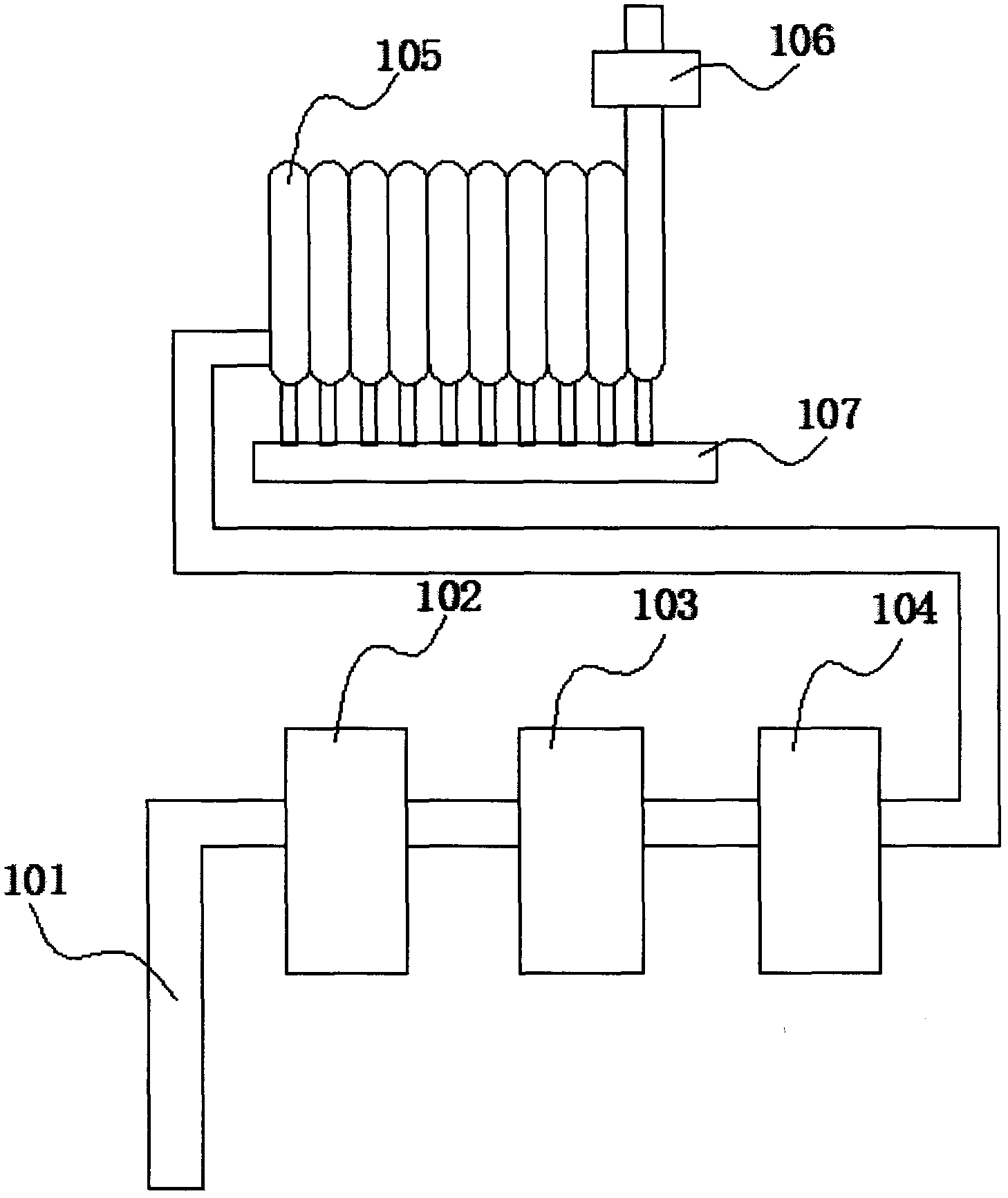

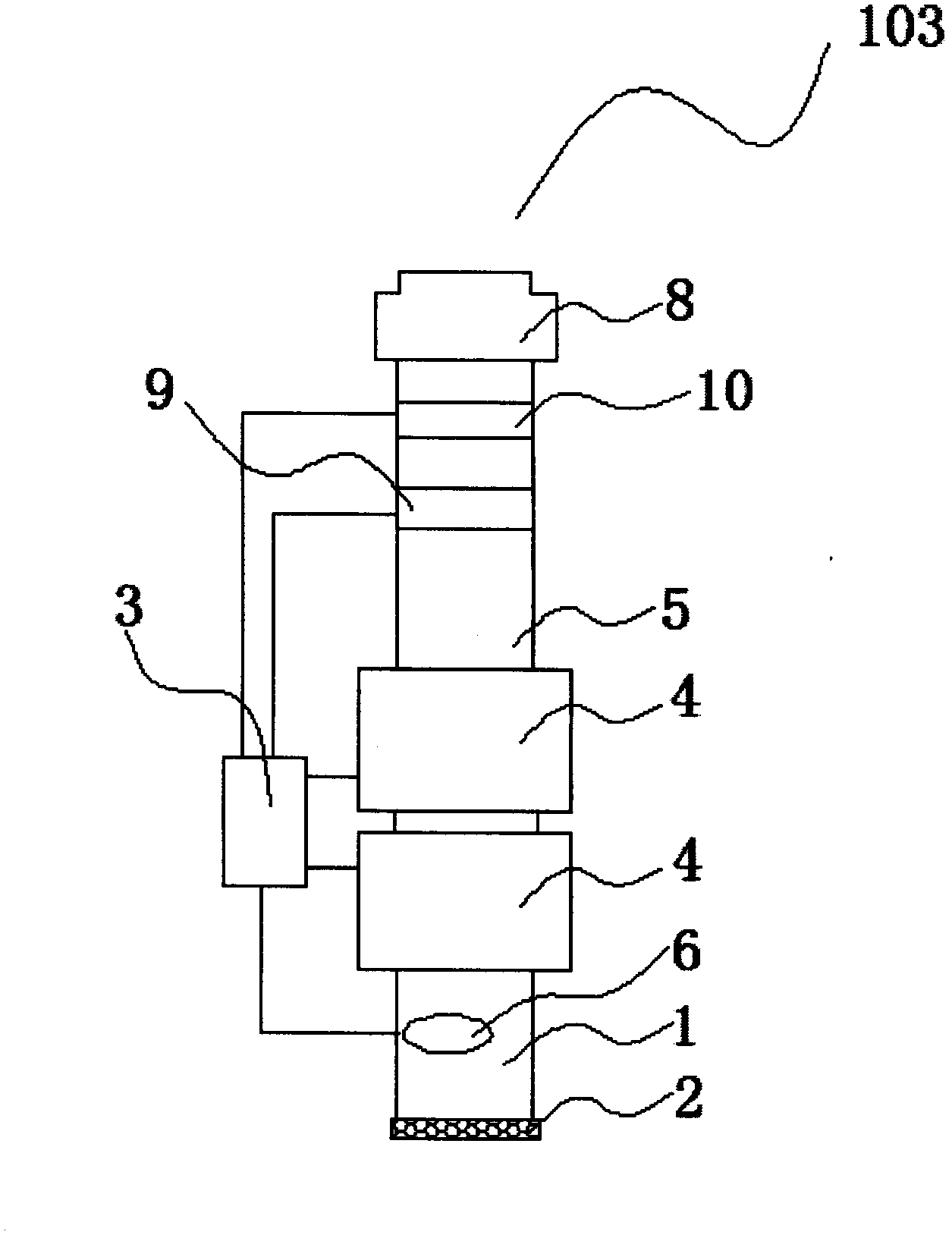

[0016] Such as figure 1 and figure 2 As shown, the flue gas dust removal, mercury and desulfurization system in the present invention is mainly composed of a flue gas temperature control pipe 101, a flue gas oxidation tower 102, a flue gas dust removal device 103, a mercury adsorption chamber 104, and an ammonia water spray pipe 105 connected in sequence. .

[0017] The flue gas temperature control pipe 101 is mainly composed of a smoke guide pipe and cooling fins arranged on the outer wall of the smoke guide pipe.

[0018] The flue gas oxidation tower 102 is mainly composed of a flue gas oxidation tower body and a chlorine gas nozzle arranged inside the flue gas oxidation tower body.

[0019] The mercury adsorption chamber 104 is provided with bromine-loaded activated carbon blocks, and the mercury adsorption chamber 104 is provided with a flue gas outlet for discharging the flue gas after mercury removal into the ammonia water spray pipe 105 .

[0020] The ammonia water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com