Sulfur-loaded molecular sieve for mercury removal and preparation method thereof

A molecular sieve and mercury removal technology, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of increased carbon content in fly ash, affecting the secondary utilization of fly ash, and easy volatilization, etc., to achieve uniformity Specific surface area, improved mercury removal performance, good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

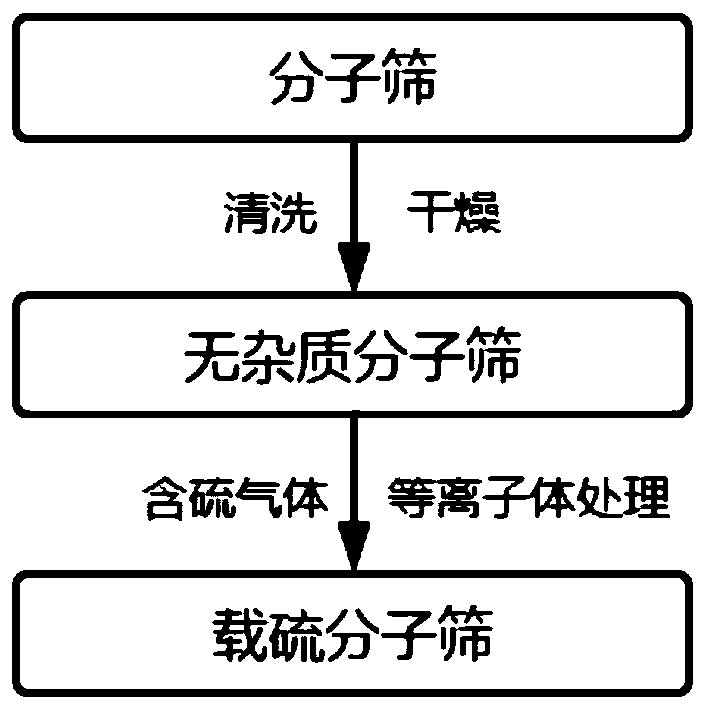

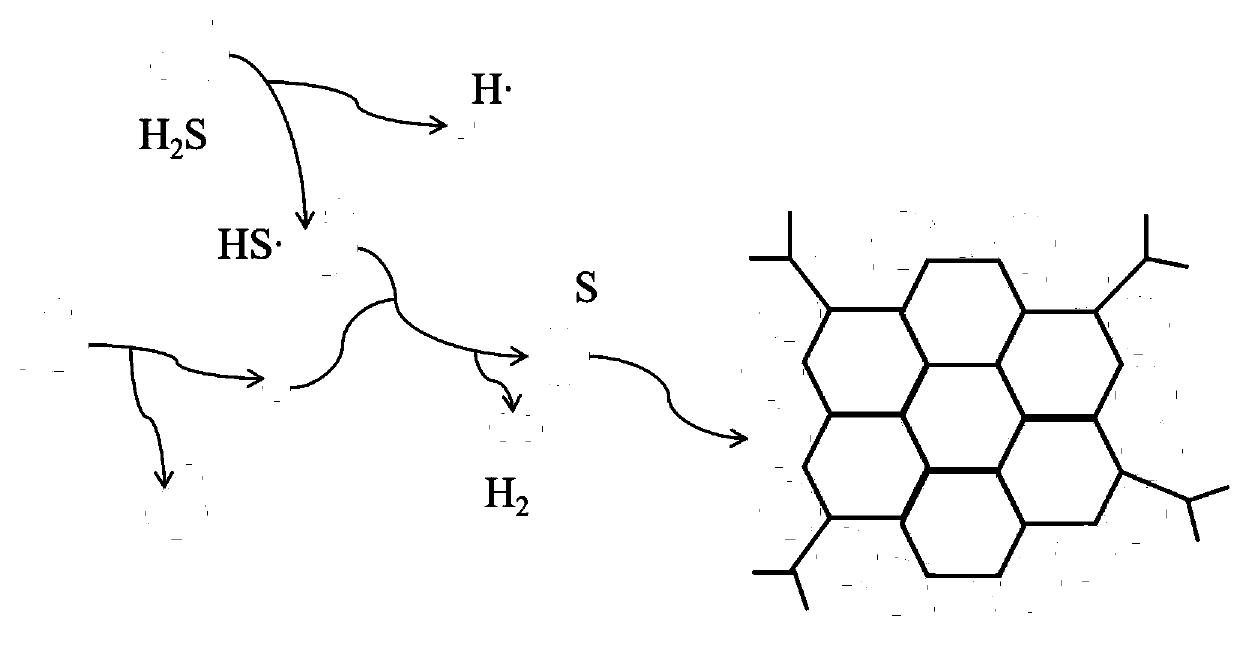

[0029] A method for preparing sulfur-loaded molecular sieves for mercury removal provided by the embodiments of the present invention, such as figure 1 As shown, it includes the following steps: use deionized water to clean the molecular sieve, remove impurities and dry, then place the cleaned and dried molecular sieve in a sulfur-containing gas, and perform plasma treatment together, and the sulfur-containing gas becomes high under the action of the plasma Active sulfur atoms or free radicals are loaded on the molecular sieve to form elemental sulfur on the surface of the molecular sieve, that is, sulfur active sites, thereby completing the preparation of the sulfur-loaded molecular sieve.

[0030] Specifically, studies have shown that when the active substances loaded on the surface of the adsorbent exist in the form of atoms, ions or free radicals, they will have better mercury removal performance, but most of the chemically loaded active substances exist in the form of mole...

Embodiment 1

[0047] Choose natural zeolite as the source of molecular sieves, in 1% H 2 The natural zeolite was treated with plasma under S atmosphere, the plasma treatment voltage was 2kV, the frequency was 10kHz, and the treatment time was 5min, and the sulfur-loaded natural zeolite was prepared. The sulfur-loaded natural zeolite was subjected to a mercury adsorption performance test experiment, the gas flow rate in the experiment was 1L / min, and the initial mercury concentration was 50 μg / m 3 , the amount of adsorbent is 30mg, the adsorption temperature is 140°C, and the adsorption time is 30min. Experimental results show that the mercury removal efficiency of the original natural zeolite is 9%, while the mercury removal efficiency of the plasma-treated natural zeolite is 62%.

Embodiment 2

[0049] Choose natural zeolite as the source of molecular sieves, in 1% H 2 The natural zeolite was treated with plasma under S atmosphere, the plasma treatment voltage was 3kV, the frequency was 15kHz, and the treatment time was 10min, and the sulfur-loaded natural zeolite was prepared. The sulfur-loaded natural zeolite was subjected to a mercury adsorption performance test experiment, the gas flow rate in the experiment was 1L / min, and the initial mercury concentration was 70μg / m 3 , the amount of adsorbent is 30mg, the adsorption temperature is 140°C, and the adsorption time is 30min. Experimental results show that the mercury removal efficiency of the original natural zeolite is 7%, while the mercury removal efficiency of the plasma-treated natural zeolite is 73%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com