A method for preparing sludge activated carbon by activating municipal sludge with urine

A technology for preparing activated carbon and municipal sludge, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of low specific surface area of activated carbon and large consumption of activating reagents, and achieve stable product quality, significant technological progress, and benefits. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

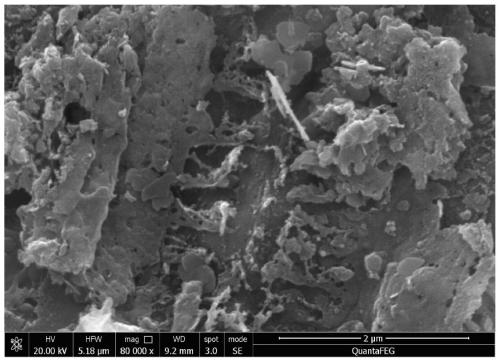

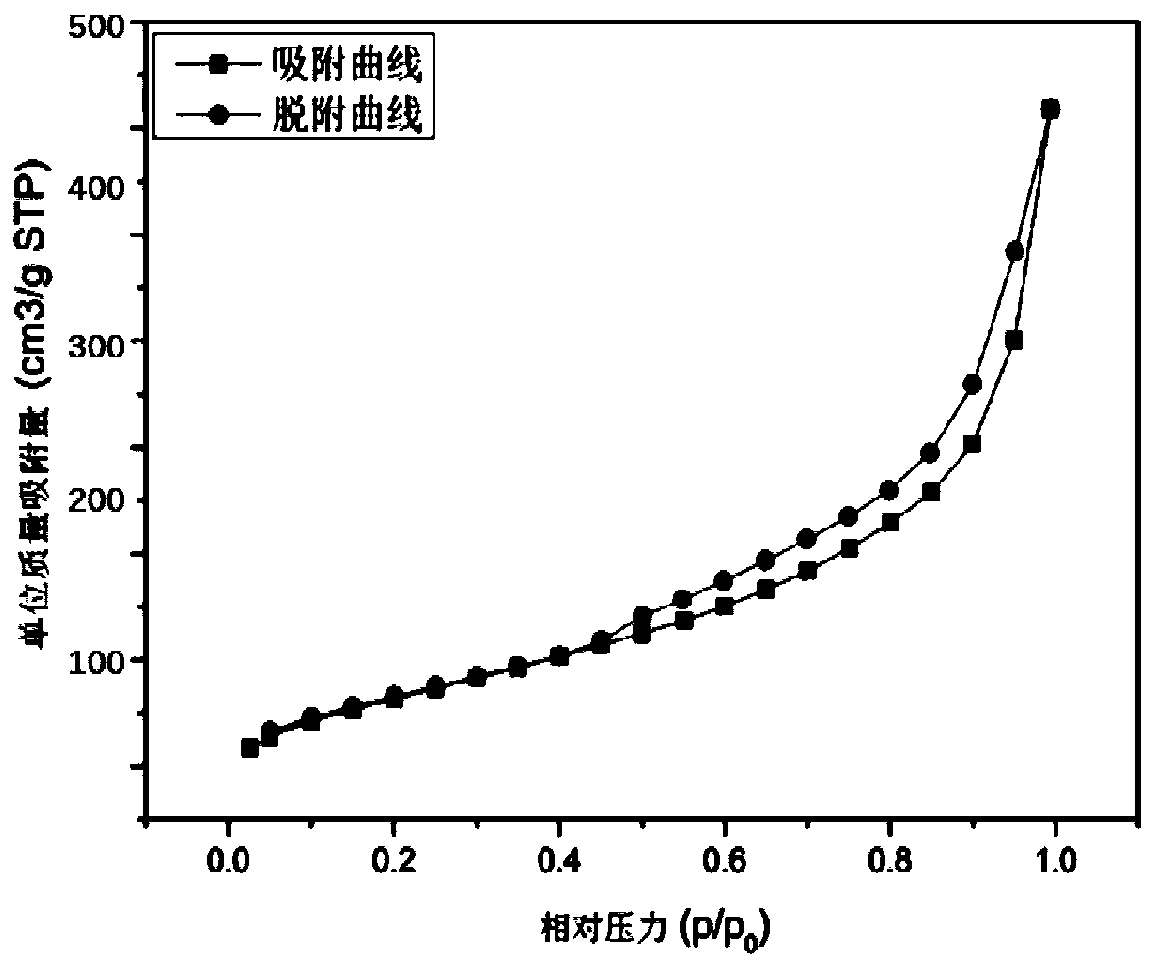

Image

Examples

Embodiment 1

[0025] A method for preparing sludge activated carbon by activating municipal sludge with urine, specifically comprising the following steps:

[0026] (1) Add 15g of dried sludge from urban sewage plant to 100g of urine containing 15% urea and mix for 60 minutes;

[0027] The moisture content of the dry sludge of the urban sewage plant is 2.7%;

[0028] Described mixing is to stir with electric mixer control rotating speed 120rpm;

[0029] (2) Centrifuge the mixed municipal sludge at a controlled speed of 4000rpm, control the ambient temperature of the resulting filter cake at 105°C, and dry it for 24 hours to obtain the precursor of municipal sludge;

[0030] (3) Under the protection environment of high-purity nitrogen, the obtained municipal sludge precursor was carbonized in a tube furnace at a controlled heating rate of 10°C / min to 600°C for 2 hours, and then naturally cooled to room temperature to be carbonized sludge;

[0031] (4) Put the carbonized sludge obtained in...

Embodiment 2

[0040] A method for preparing sludge activated carbon by activating municipal sludge with urine, specifically comprising the following steps:

[0041] (1) Add 20g of dried sludge from urban sewage plant to 100g of urine containing 15% urea and mix for 60 minutes;

[0042] The moisture content of the dry sludge of the urban sewage plant is 1.8%;

[0043] Described mixing is to stir with electric mixer control rotating speed 150rpm;

[0044] (2) Centrifuge the mixed municipal sludge at a controlled speed of 4000rpm, control the ambient temperature of the resulting filter cake at 105°C, and dry it for 24 hours to obtain the precursor of municipal sludge;

[0045] (3) Under the protection environment of high-purity nitrogen, the obtained municipal sludge precursor was carbonized in a tube furnace at a controlled heating rate of 20°C / min to 400°C for 2 hours, and then naturally cooled to room temperature to be carbonized sludge;

[0046] (4) Put the obtained carbonized sludge in...

Embodiment 3

[0052] A method for preparing sludge activated carbon by activating urban sludge with urine, specifically comprising the following steps:

[0053] (1) Add 20g of dried sludge from urban sewage plant to 100g of urine containing 10% urea and mix for 60 minutes;

[0054] The moisture content of the dry sludge of the urban sewage plant is 3.6%;

[0055] Described mixing is to stir with electric mixer control rotating speed 130rpm;

[0056] (2) Centrifuge the mixed municipal sludge at a controlled speed of 4000rpm, control the ambient temperature of the resulting filter cake at 105°C, and dry it for 24 hours to obtain the precursor of municipal sludge;

[0057] (3) Under the protection environment of high-purity nitrogen, the obtained municipal sludge precursor was carbonized in a tube furnace at a controlled heating rate of 20°C / min to 600°C for 2 hours, and then naturally cooled to room temperature to be carbonized after carbonization sludge;

[0058] (4) Put the obtained carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com