A kind of magnetic biochar composite adsorbent and its preparation method and application

A composite adsorption and biochar technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve environmental pollution by-products, loss of material performance, excess waste liquid, etc., to avoid secondary Less pollution, enhanced load level, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

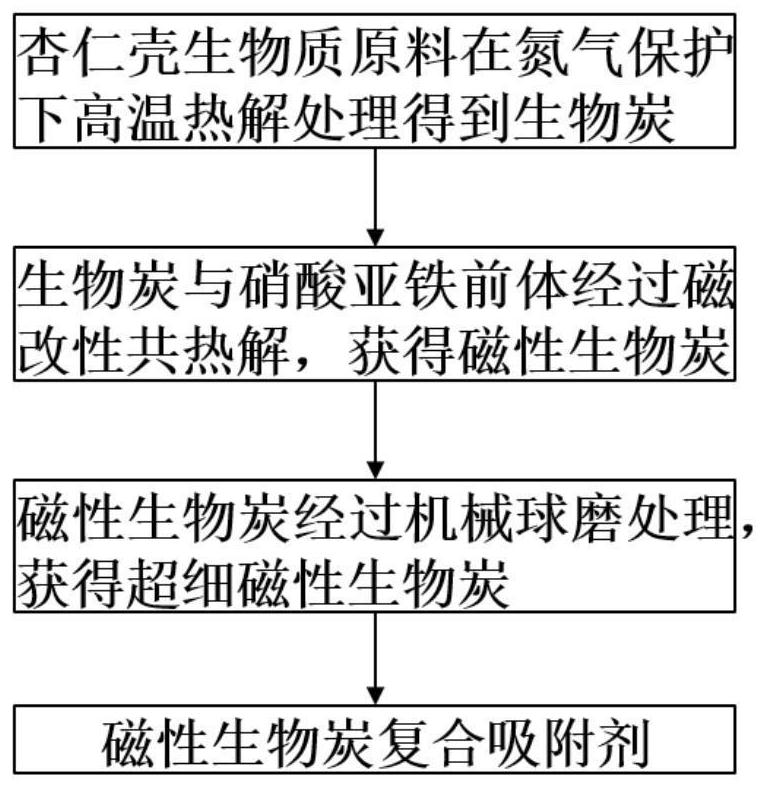

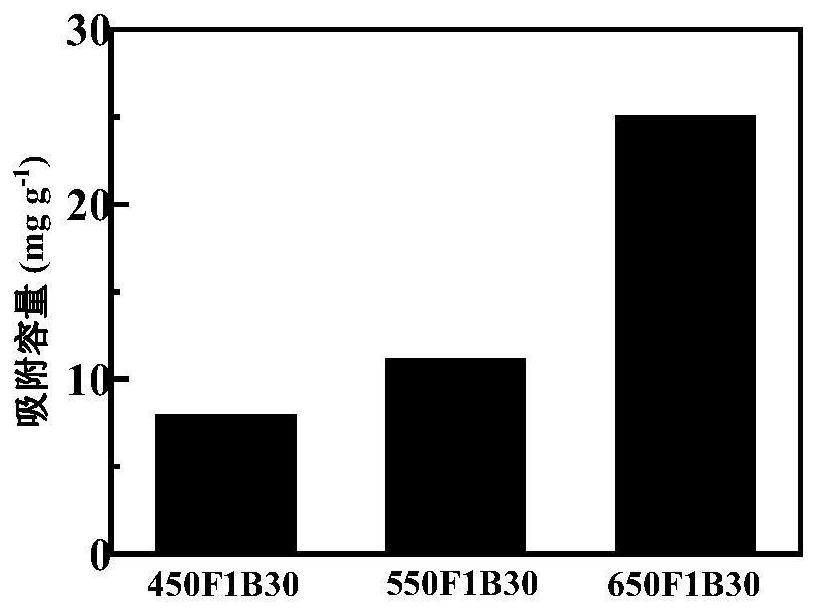

[0037] Such as figure 1 Shown, be a kind of preparation method of magnetic biochar composite adsorbent, it comprises the following steps:

[0038] 1) Wash the collected discarded almond shells, put them in an oven, and dry them at a low temperature overnight at 105°C. After obtaining completely dry almond shells, grind them into powder with a grinder, and then grind the almond shells into powder 100 mesh sieves are standby to obtain almond shell powder biomass;

[0039] 2) Take 15.0 g of the almond shell powder biomass obtained in the above steps and spread it in a 100mL crucible, then place the crucible in a tube furnace, and heat it at 10°C min under the protection of nitrogen. -1 The heating rate was heated to a constant temperature T, and the pyrolysis was maintained at this temperature for 30 minutes, and 10.0 g of almond shell biochar was obtained after overnight cooling in a tube furnace;

[0040] 3) Take 2.0 g of the almond shell biochar prepared in the above steps a...

Embodiment 2

[0051] A preparation method of a magnetic biochar composite adsorbent, comprising the following steps:

[0052] 1) Wash the collected discarded almond shells, put them in an oven, and dry them at a low temperature overnight at 105°C. After obtaining completely dry almond shells, grind them into powder with a grinder, and then grind the almond shells into powder 100 mesh sieves are standby to obtain almond shell powder biomass;

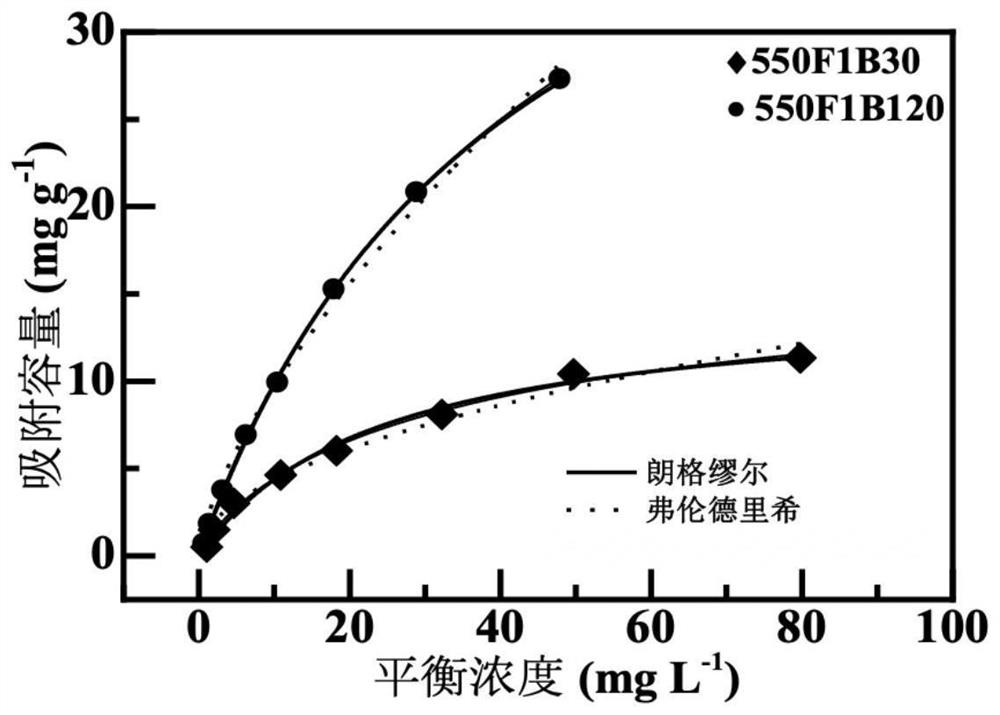

[0053] 2) Take 15.0 g of the almond shell powder biomass obtained in the above steps and spread it in a 100mL crucible, then place the crucible in a tube furnace, and heat it at 10°C min under the protection of nitrogen. -1 The heating rate was heated to 550°C, and the pyrolysis was maintained at this temperature for 30 minutes, and 10.0 g of almond shell biochar was obtained after overnight cooling in a tube furnace;

[0054] 3) Take 2.0 g of the almond shell biochar prepared in the above steps and spread it in a crucible, and use 5.6 mL of 1M Fe(NO ...

Embodiment 3

[0071] A preparation method of a magnetic biochar composite adsorbent, comprising the following steps:

[0072] 1) Wash the collected discarded almond shells, put them in an oven, and dry them at a low temperature overnight at 105°C. After obtaining completely dry almond shells, grind them into powder with a grinder, and then grind the almond shells into powder 100 mesh sieves are standby to obtain almond shell powder biomass;

[0073] 2) Take 15.0 g of the almond shell powder biomass obtained in the above steps and spread it in a 100mL crucible, then place the crucible in a tube furnace, and heat it at 10°C min under the protection of nitrogen. -1 The heating rate was heated to 650°C, and pyrolysis was maintained at this temperature for 30 minutes, and 10.0 g of almond shell biochar was obtained after overnight cooling in a tube furnace;

[0074] 3) Take 2.0 g of the almond shell biochar prepared in the above steps and spread it in a crucible, and use 5.6 mL of Fe(NO 3 ) 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com