Environment-friendly neutral rust remover and preparation method thereof

A rust remover, neutral technology, applied in the field of environmentally friendly neutral rust remover, can solve the problems of acid mist, corrosion, hydrogen embrittlement, waste liquid pollution, etc., to improve the rust removal effect, speed up the reaction speed, strengthen the Penetration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

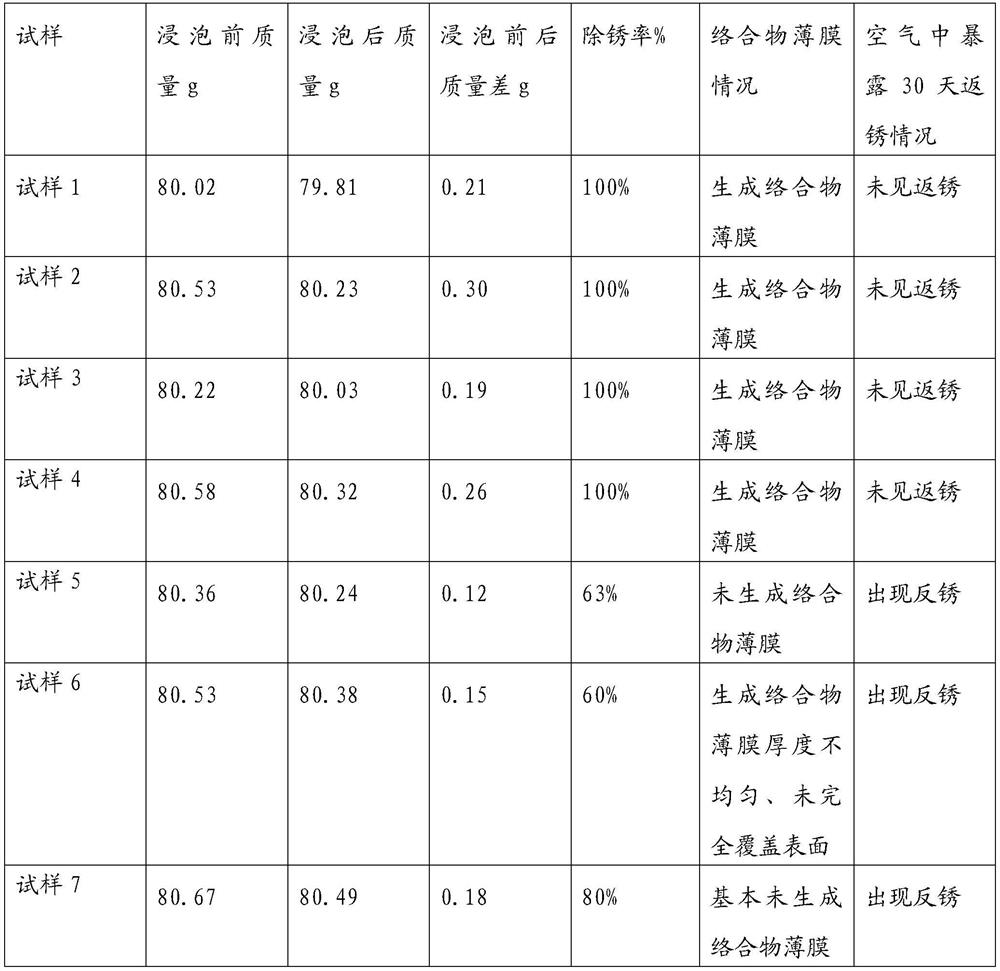

Examples

Embodiment 1

[0031] An environmentally friendly neutral rust remover, comprising the following raw material components in parts by weight: 5 parts of organic acid complexing agent citric acid, 15 parts of hydroxyethylidene diphosphonic acid (HEDP), 0.25 parts of accelerator zinc acetate, chelating agent 1.0 part of EDTA-2Na, 0.5 part of sodium gluconate, 0.5 part of surfactant PEG-400, 1 part of SDBS, 0.75 part of phosphating oxidation accelerator sodium molybdate, 2.5 part of penetrating agent ethylene glycol, neutralizing agent sodium hydroxide 10 parts, 63.5 parts deionized water.

Embodiment 2

[0033] An environmentally friendly neutral rust remover, comprising the following raw material components in parts by weight: 10 parts of organic acid complexing agent oxalic acid, 10 parts of aminotrimethylidene phosphonic acid (ATMP), 0.35 parts of accelerator zinc citrate, chelating agent glucose 0.8 part of sodium, 0.8 part of sodium tartrate, 1.8 part of surfactant SDBS, 0.7 part of phosphating oxidation accelerator sodium hypochlorite, 2.6 part of penetrating agent isopropyl alcohol, 15 parts of neutralizing agent sodium carbonate, 57.95 parts of deionized water.

Embodiment 3

[0035] An environmentally friendly neutral rust remover, comprising the following raw material components in parts by weight: 12 parts of organic acid complexing agent tartaric acid, 12 parts of hydroxyethylidene diphosphonic acid (HEDP), 0.4 parts of accelerator calcium acetate, chelating agent EDTA -2Na, 1.2 parts, 0.5 parts of sodium citrate, 1.8 parts of surfactant OP-10, 7 parts of phosphating oxidation accelerator sodium molybdate, 2.5 parts of penetrating agent ethylene glycol, 18 parts of neutralizing agent potassium hydroxide, 44.6 parts of ionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com