Layered composite brazing coating material and preparation method thereof

A technology of layered composite and brazing material, which is applied in the direction of metal layered products, chemical instruments and methods, welding/cutting media/materials, etc., can solve the problems of low work efficiency, high cost, waste of brazing flux, etc., and achieve formability Good, easy to store, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of layered composite braze-coated material of the present invention is divided into strip and tubular two kinds:

[0024] 1. Preparation of strip brazing material:

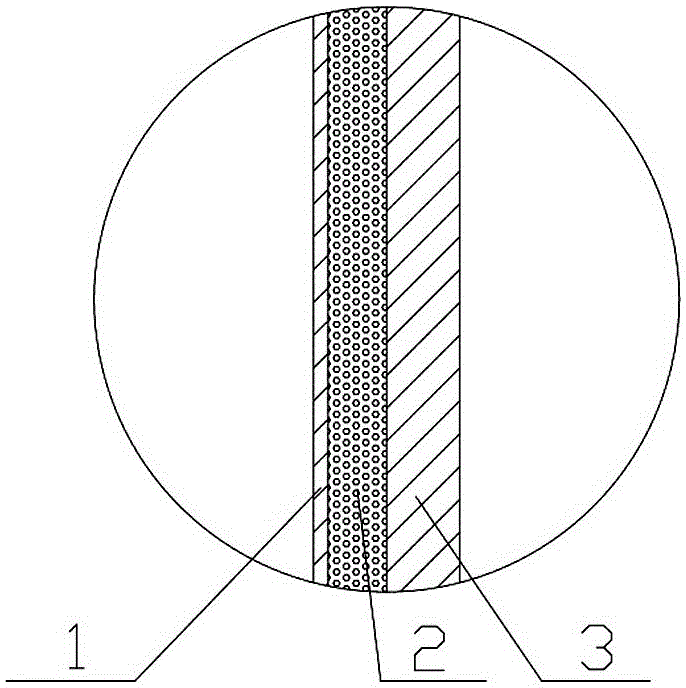

[0025] First, the mixture of cemented carbide particles, brazing flux and organic binder is uniformly coated on the surface of the brazing alloy, and then a certain thickness of brazing alloy is placed on the surface of the mixture, and the precision rolling mill is used to roll it into the required A finished product of three-layer composite brazing coating material with a band structure composed of a brazing alloy inner layer 1, a mixture middle layer 2 and a brazing alloy outer layer 3;

[0026] 2. Preparation of tubular brazing material:

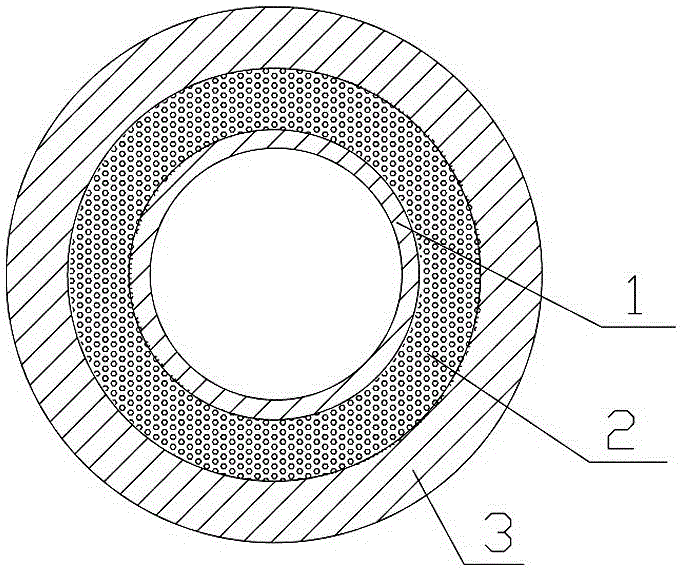

[0027] First, the mixture of cemented carbide particles, flux and organic binder is uniformly coated on the surface of the tubular solder alloy, and then the strip-shaped solder alloy is rolled through multiple passes, and the tubular solder al...

Embodiment 1

[0030] The outer layer 3 of the solder alloy is BAg40CuZnCdNi (national standard brand HL312, calculated by mass fraction percentage, Ag-Cu16-Zn18-Cd26-Ni0.2) with a thickness of 0.1 mm, and the inner layer 1 of the solder alloy is 0.3 mm thick. mm BAg40CuZnCdNi solder alloy strip, the cemented carbide particles in layer 2 of the mixture should be cast tungsten carbide powder of 20-30 meshes, the brazing flux should be FB102, the ratio of cemented carbide particles to brazing flux is 10:1 by weight, and the finished product The layered composite brazing material has a thickness of 0.6 mm and a width of 3 mm. The base material is Q235 carbon steel, and the size after brazing is 57mm×25.5mm×6mm. Carry out abrasive wear test to the brazed coating product of embodiment 1, abrasive wear test is carried out on MLG-130A type dry type rubber wheel abrasive wear tester, test load is 20N, abrasive material is No. 120 brown corundum sand, rubber wheel speed is 100r / min, the sand flow ra...

Embodiment 2

[0032] The outer layer 3 of the brazing alloy is a BCu58ZnMn (national standard brand HL105, calculated by mass fraction percentage, Cu-Zn38-Mn) brazing alloy strip with a thickness of 0.2mm, and the inner layer 1 of the brazing alloy is a BCu58ZnMn brazing alloy with a thickness of 0.3mm Belt, cemented carbide particles in layer 2 of the mixture choose 20-30 mesh cast tungsten carbide powder, brazing flux chooses QJ308, the ratio of cemented carbide particles to brazing flux is 10:1 by weight, and the finished layered composite brazing coating material The thickness is 0.5mm and the width is 3mm. The base material is Q235 carbon steel, and the size after brazing is 57mm×25.5mm×6mm. Carry out abrasive wear test to the brazed coating product of embodiment 2, abrasive wear test is carried out on MLG-130A type dry type rubber wheel abrasive wear tester, test load is 20N, abrasive material is No. 120 brown corundum sand, rubber wheel speed is 100r / min, the sand flow is 100g / min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com