Composite braze coating material and preparation method thereof

A technology of brazing coating and brazing material, which is applied in the direction of welding/cutting media/materials, manufacturing tools, welding equipment, etc., can solve the problems of high oxygen content of powdered solder, low work efficiency, waste of brazing flux, etc., and achieve cleanliness High, good formability, strong bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of composite brazing coating material of the present invention is as follows:

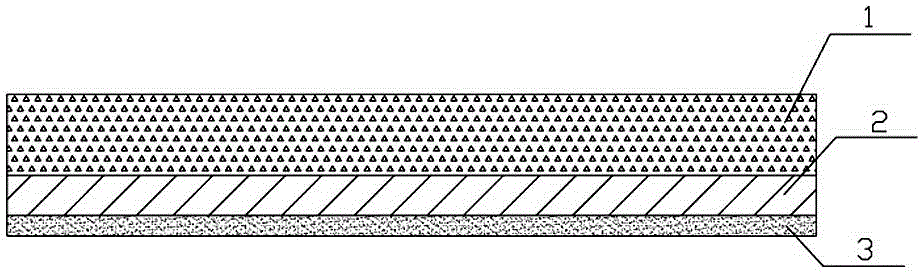

[0026] The solder alloy is prepared into a strip or plate of the required size through smelting, extrusion, rolling and other processes, and the cemented carbide particles are sprayed on the upper surface of the solder alloy strip or plate by cold spraying equipment, and then the The corresponding general-purpose flux is sprayed onto the lower surface of the brazing alloy strip or plate by thermal spraying equipment to form a composite brazing coating of a certain size consisting of cemented carbide coating 1, brazing alloy layer 2 and flux coating 3 Material.

Embodiment 1

[0029] The solder alloy is prepared into a BCu solder strip with a thickness of 0.2mm through smelting, extrusion, rolling and other processes. The cemented carbide is made of cast tungsten carbide powder and Co powder with 20-30 mesh as raw materials. The powder block WC12Co is obtained by vacuum sintering, and then the particle size of the spray powder is controlled to be 15-45 μm by crushing, screening and grading. The CS-2000 cold spraying system independently developed by Xi'an Jiaotong University is used to deposit 0.5mm of hard alloy coating on the upper surface of BCu solder strip, and the PPS-3000 plasma spraying system is used to deposit 0.3mm of YJ2 flux layer on the lower surface of BCu solder strip , the substrate is Q235 carbon steel, and 24 mesh brown jade sand is used for sandblasting, and then the brazing material and substrate are brazed by induction heating. The product of embodiment 1 is carried out abrasive wear test, and abrasive wear test is carried out ...

Embodiment 2

[0031] The solder alloy is prepared into a BCu58ZnMn solder strip with a thickness of 1mm through smelting, extrusion, rolling and other processes. The cemented carbide is made of 20-30 mesh cast tungsten carbide powder and Co powder, and is subjected to stirring ball milling, spray granulation and vacuum The powder block WC12Co is obtained by sintering, and then the particle size of the spray powder is controlled to be 15-45 μm by crushing, screening and grading. The CS-2000 cold spraying system independently developed by Xi'an Jiaotong University was used to deposit a 2mm hard alloy coating on the surface of the BCu58ZnMn solder strip, and the PPS-3000 plasma spraying system was used to deposit a 0.5mm YJ2 flux layer on the lower surface of the BCu58ZnMn solder strip. The substrate is Q235 carbon steel, which is sandblasted with 24 mesh brown jade sand, and then the brazing material and substrate are brazed by induction heating. The product of embodiment 2 is carried out abr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com