Polythiophene derivative aqueous dispersion and preparation method thereof

A technology of polythiophene derivatives, which is applied in the field of preparation of aqueous dispersions and polythiophene derivative aqueous dispersions, can solve the problems of dispersion stability, poor electrical conductivity, poor consistency of polymerization degree, and easy occurrence of peroxidation, etc. problem, to achieve the effect of low equipment requirements, good stability and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

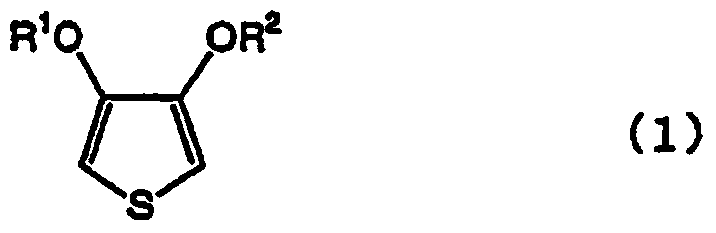

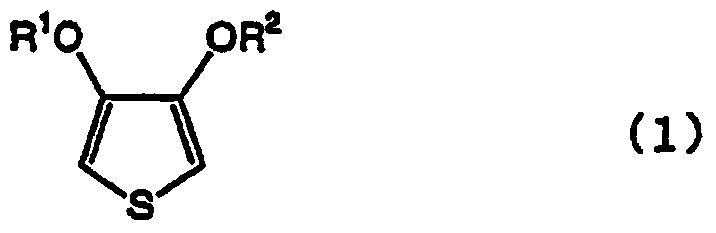

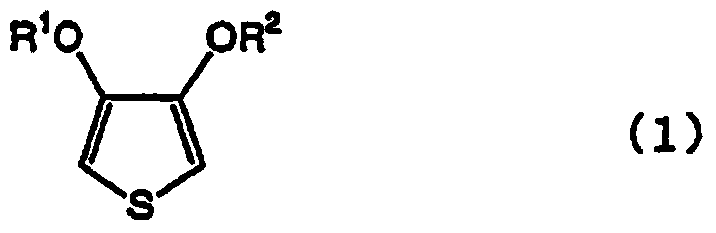

[0029] The preparation method of the aqueous dispersion of polythiophene derivatives of the present invention includes the following polymerization process: first mix the oxidant aqueous solution and 3,4-dialkoxythiophene represented by the following formula (1); drop the mixed solution Add it to the solution containing the polyanion, or another way to realize it, do not mix the oxidant aqueous solution and the thiophene monomer represented by the following formula (1), and at the same time add it dropwise to the solution containing the polyanion in proportion, and stir it under high shear for 18 -30h, polymerize 3,4-dialkoxythiophene, then add anion and cation resin and stir for 8-16h, then filter;

[0030]

[0031] (1) In the formula, R 1 , R 2 are independent of each other and are hydrogen or C 1-4 Alkyl groups, or together form C 1-4 The alkylene group, the alkylene group can be arbitrarily substituted; the molar ratio of the oxidant to 3,4-dialkoxythiophene is 1.5 t...

Embodiment 1

[0043] Add 100g of polystyrene sulfonic acid to 2000g of deionized water, add and stir for 30 minutes, then mix 50g of 35% sodium persulfate aqueous solution, 14.4g of 1% ferric sulfate aqueous solution and 9.1g of 3,4-dialkoxythiophene Add it to the above aqueous solution, drop it for about 2 hours, and stir it with a high-shear emulsifier at 3000 rpm for 24 hours at 25°C under the protection of nitrogen. After the reaction finishes, add 200g cationic resin, 200g anionic resin in reaction system. Stir mechanically at 300 rpm for 12 hours, filter off the resin, and obtain poly(3,4-dialkoxythiophene) polyanion dispersion. Test, solid content 1.34%, viscosity 1500cps, particle size d 50 110nm, conductivity (with 5% DMSO added) 380S / cm.

Embodiment 2

[0045] Add 100g of polystyrene sulfonic acid to 2000g of deionized water, add and stir for 30 minutes, then 64.4g of 30% sodium persulfate aqueous solution is evenly added dropwise to the polystyrene sulfonic acid aqueous solution at a speed of 1g / min, and at the same time 9.1g of 3,4-dialkoxythiophene was evenly added dropwise at a speed of 0.14g / min into the polystyrenesulfonic acid aqueous solution, and stirred for 30h. After the reaction, 200g of cationic resin was added to the reaction system, 200g of anionic resin was stirred for 8 hours, and the resin was filtered off to obtain poly(3,4-dialkoxythiophene) polyanion dispersion. Test, solid content 1.35%, viscosity 1450cps, particle size d 50 108nm, conductivity (with 5% DMSO added) 400S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com