Tubular braze coating material

A brazing coating and tubular technology, applied in the direction of welding/cutting media/materials, welding media, metal processing equipment, etc., can solve the problems of brazing flux waste, low work efficiency, high cost, etc., and achieve consistent proportions, good formability, and convenience storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

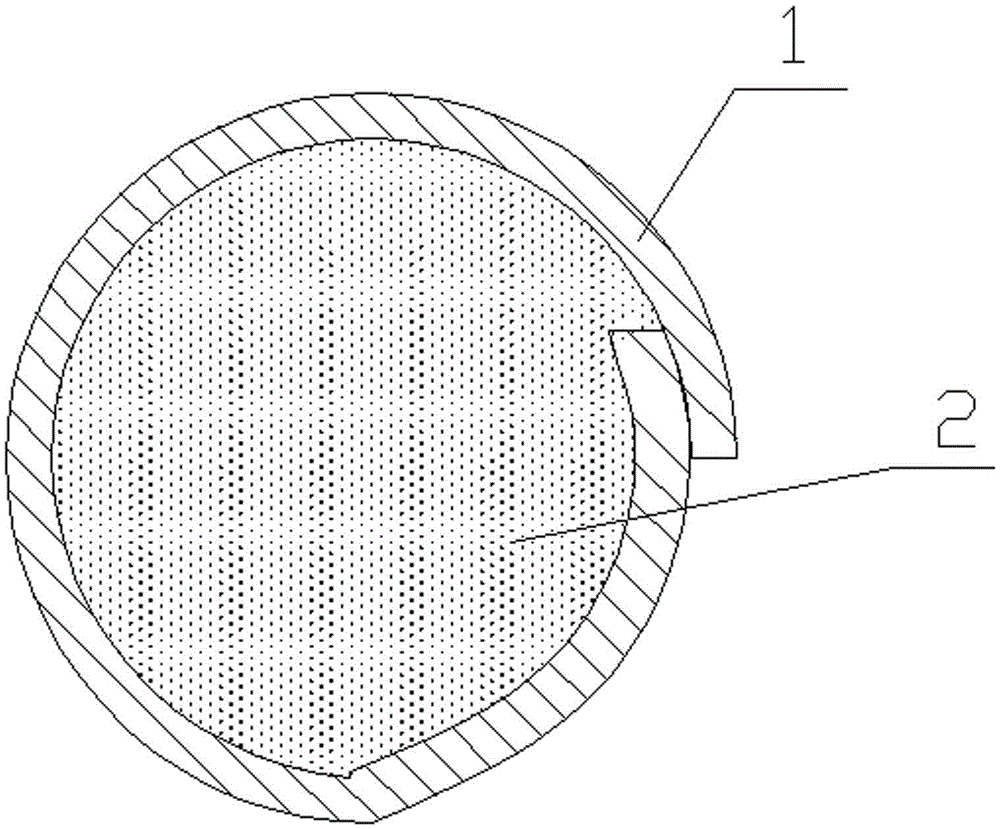

[0020] BAg40CuZnCdNi (national standard brand HL312, calculated by mass fraction percentage, Ag-Cu16-Zn18-Cd26-Ni0.2) with a thickness of 0.2mm is selected as the solder alloy, and the carbide particles are selected from 20-30 mesh casting carbonization For tungsten powder, FB102 is selected as the flux. The ratio of flux to cemented carbide particles is 1:10 by weight. After powder feeding (a mixture of cemented carbide particles and flux), drawing, straightening and other processes, the A tubular brazing material with a diameter of 3 mm and a length of 400 mm, wherein the brazing filler metal coating layer 1 accounts for 11% of the total weight of the tubular brazing material, and the mixture of cast tungsten carbide powder and flux 2 accounts for 10% of the total weight of the tubular brazing material. 89%. The base material is Q235 carbon steel, and the abrasive wear test is carried out on the product of this embodiment. The abrasive wear test is carried out on a MLG-130A ...

Embodiment 2

[0022] BCu58ZnMn (national standard grade HL105, calculated by mass fraction percentage, Cu58-Zn38-Mn4) with a thickness of 0.2mm is selected as the brazing filler metal alloy strip, the hard alloy particles are selected from 20-30 mesh cast tungsten carbide powder, and the brazing flux is selected QJ308, the ratio of flux to cemented carbide particles by weight is 1:10, after powder feeding (a mixture of cemented carbide particles and flux), drawing, straightening and other processes, it is made into a diameter of 5mm and a length of It is a 400mm tubular brazing material, wherein the brazing filler metal coating layer 1 accounts for 7% of the total weight of the tubular brazing material, and the mixture 2 of cast tungsten carbide powder and flux accounts for 93% of the total weight of the tubular brazing material. The base material is Q235 carbon steel, and the abrasive wear test is carried out on the product of this embodiment. The abrasive wear test is carried out on a MLG-...

Embodiment 3

[0024] BAg50CuZnCdNi (national standard brand HL315, calculated by mass fraction percentage, Ag-Cu15-Zn17-Cd15-Ni3) with a thickness of 0.2mm is selected as the solder alloy, and the cast tungsten carbide powder of 20-30 meshes is selected as the cemented carbide particles. , the flux is FB102, the ratio of flux to cemented carbide particles is 1:10 by weight, after powder feeding (a mixture of cemented carbide particles and flux), drawing, straightening and other processes, the diameter is made Tubular brazing material with a diameter of 4 mm and a length of 400 mm, wherein the brazing alloy cladding layer 1 accounts for 9% of the total weight of the tubular brazing material, and the mixture 2 of cast tungsten carbide powder and flux accounts for 91% of the total weight of the tubular brazing material . The base material is Q235 carbon steel, and the abrasive wear test is carried out on the product of this embodiment. The abrasive wear test is carried out on a MLG-130A dry ru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com