Mixed scented tea processing and packaging machine

A packaging machine and scented tea technology, which is applied in the field of machinery and equipment, can solve the problems of unsatisfactory processing and packaging of mixed scented tea, uneven scented tea finished products, and low packaging efficiency, and achieve the effects of simple structure, automation, and consistent proportions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

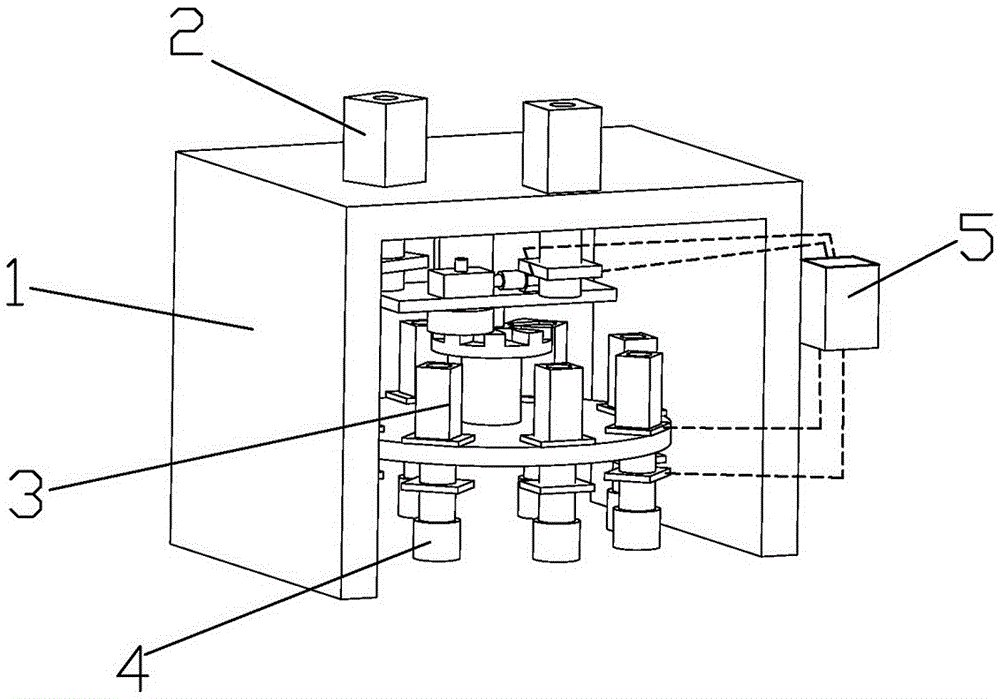

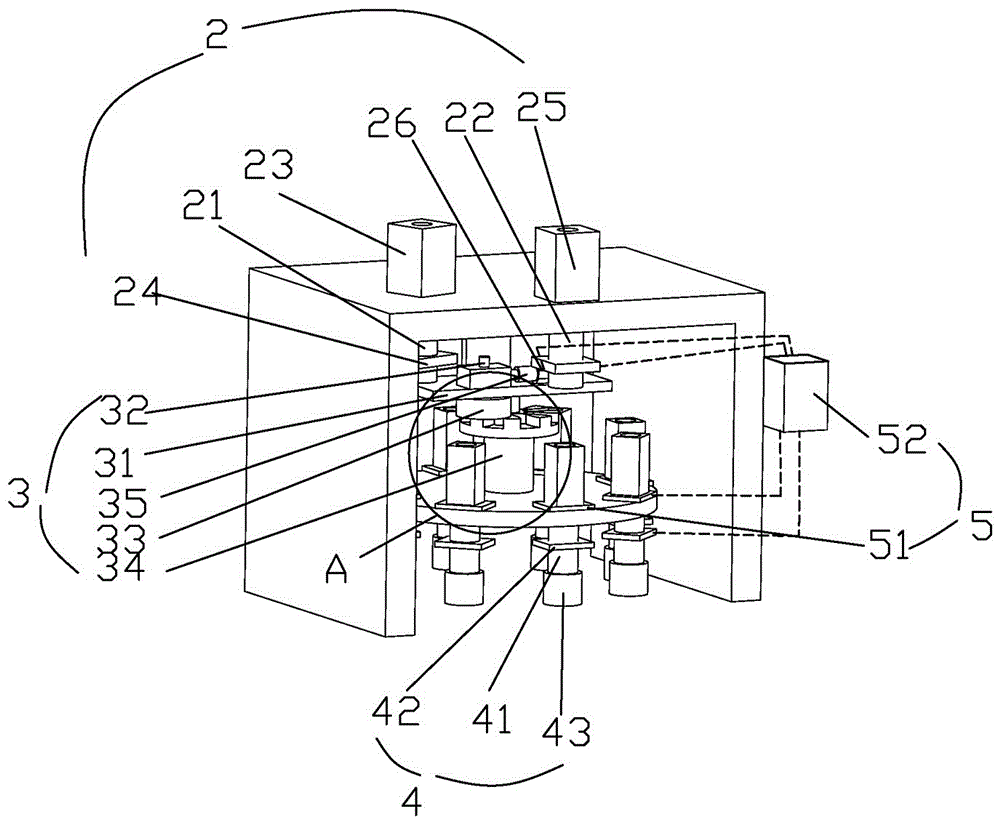

[0021] Embodiment 1: reference figure 1 , a mixed scented tea processing and packaging machine, including a frame 1, and also includes a feeding part 2 arranged on the top of the frame 1, a mixing part 3 arranged below the feeding part 2, and a discharge part arranged at the bottom of the mixing part 3 Part 4, the raw materials of the mixed scented tea enter the mixing part 3 from the feeding part 2 and mix respectively, and the mixed scented tea is discharged from the discharging part 4 for packaging.

[0022] refer to figure 2 , the feeding part 2 includes a first feed pipe 21 and a second feed pipe 22 that are nested on the frame 1 in a circumferential arrangement; the upper end of the first feed pipe 21 is connected with a first feed hopper 23, and its lower end is provided with a The first feed valve 24 for controlling the opening or closing of the first feed pipeline 21; Closed second feed valve 26.

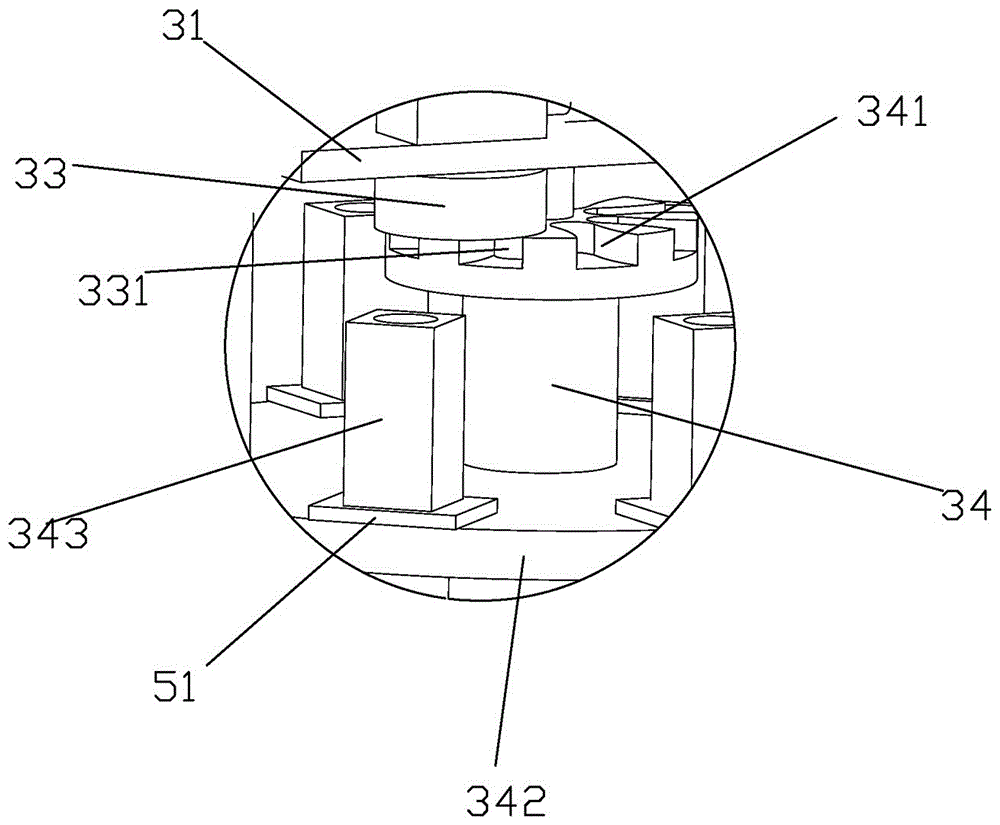

[0023] refer to figure 2 and image 3 The mixing unit 3 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com