Dyeing and finishing processing technology of four-side stretch fabric based on antimony-free polyester

A processing technology, four-way elastic technology, applied in the processing of textile materials, dyeing method, fabric surface trimming, etc., can solve the problems of fabric color fastness, easy to fall off, small bond stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0061] Fabric fabric: a fabric made from a polyester coincidence yarn, wherein the amidon wire is a core yarn, and the coating is a non-chalrontal polyester wire produced by non-bismuth catalyst.

[0062] The above fabric fabric is sequentially processed, dyed processes, and post-treatment processes.

[0063] (1) Pre-processing process

[0064] The front treatment process includes a non-tension predetermined process and a predetermined process; wherein the non-tension pre-shrinking process comprises thermal water prevention treatment for the fabric gray fabric and drying the fabric gray cloth of the thermal water predecessor; The type process is a heat setting treatment for the fabric gray fabric after the non-tensioned prestrative process.

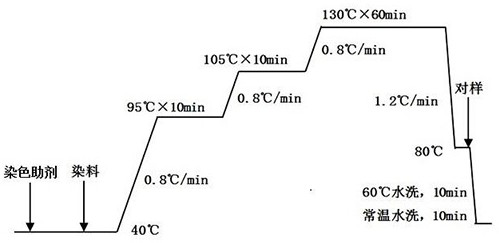

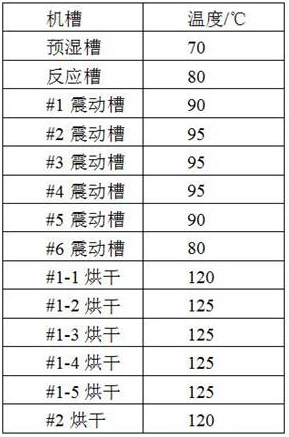

[0065] The non-tensioned prestrative process uses a non-tensioned consumptor to perform pre-shrinkage and drying treatment of the fabric blancraft; the hot water prestance process of the non-tensionable charger includes the pre-humidity stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com