Coating cloth processing method

A processing method and technology of coating cloth, which can be applied in the direction of coating, device for coating liquid on the surface, textile and paper making, etc., can solve the problem of insufficient contact between water-based PU coating and coagulant, and achieve shortening and shortening of time and time. Process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1, the processing method of coated cloth of the present invention comprises:

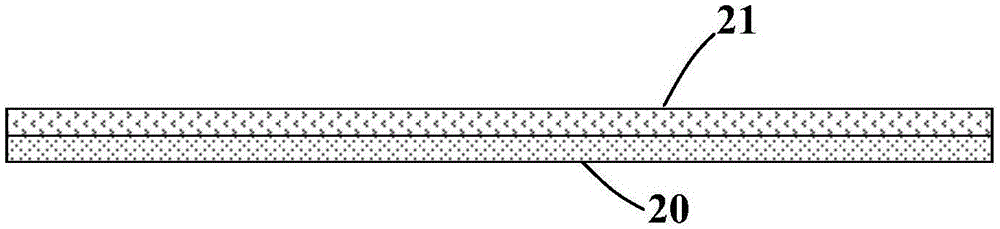

[0031] Step 1, forming a water-based PU slurry layer on the surface of a non-woven fabric, the means of forming the water-based PU slurry layer includes but not limited to coating or dipping; the water-based PU slurry is made of 97% to 99.9% of the mass proportion A mixed slurry made of water-based polyurethane resin (water-based PU) and 0.1% to 3% water-based thickener.

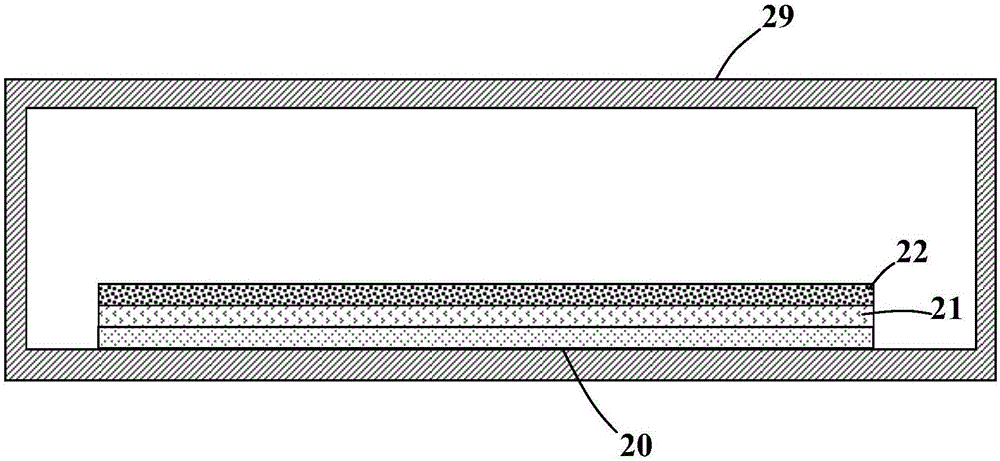

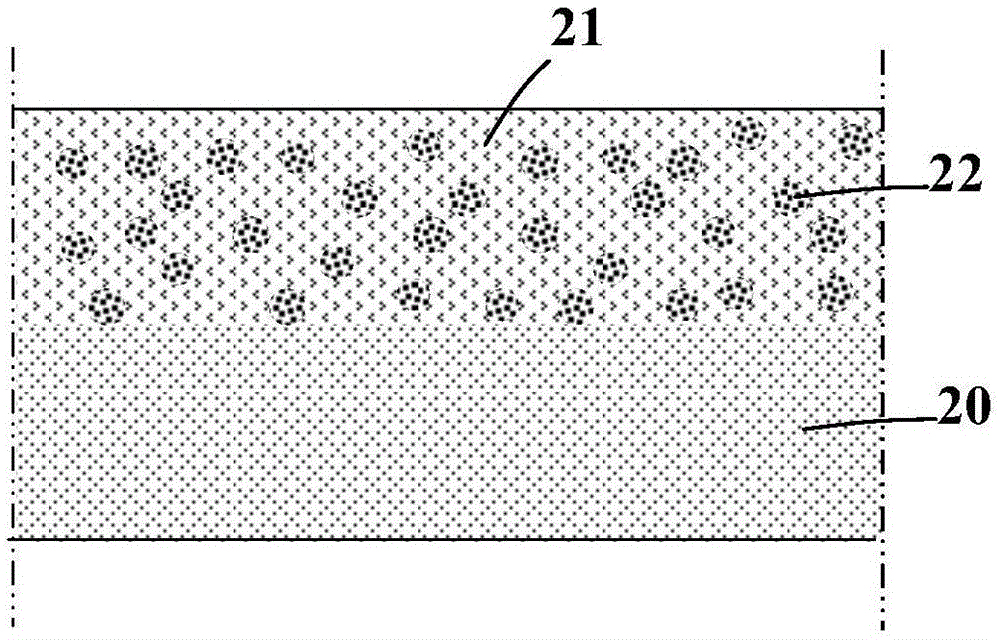

[0032] In step 2, the material in step 1 is placed in a closed room to contact the surface of the water-based PU slurry layer with a coagulant, and the means of contact include but not limited to spraying and coating. The coagulant is pressed into the water-based PU slurry layer by means of high temperature and high pressure, so that the entire water-based PU slurry layer is fully in contact with the coagulant for cross-linking or complexation. The coagulant is a substance that cross-links or complexes the water...

Embodiment 2

[0035] Embodiment 2, the processing method of coated cloth of the present invention, comprises:

[0036] Step 1, forming a water-based PU slurry layer on the surface of a release cloth, the means of forming the water-based PU slurry layer includes but not limited to coating or dipping. The water-based PU slurry is a mixed slurry prepared by configuring a water-based polyurethane resin (water-based PU) with a mass proportion of 97% to 99.9% and a water-based thickener of 0.1% to 3%.

[0037] Step 2, covering a nonwoven fabric on the surface of the water-based PU slurry layer;

[0038] In step 3, the material of step 2 is placed in a closed room to contact the surface of the release cloth with the coagulant, and the means of contact include but not limited to spraying and coating. The coagulant is pressed into the water-based PU slurry layer through the release cloth by means of high temperature and high pressure, so that the entire water-based PU slurry layer is fully in conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com