A passive piston volumetric tube with flip valve plug

A technology of passive piston and flip valve, which is applied in the contraction/expansion chamber and other directions, can solve the problems of large pressure loss change and state transition impact, and achieve the effect of stable work, small impact and small pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

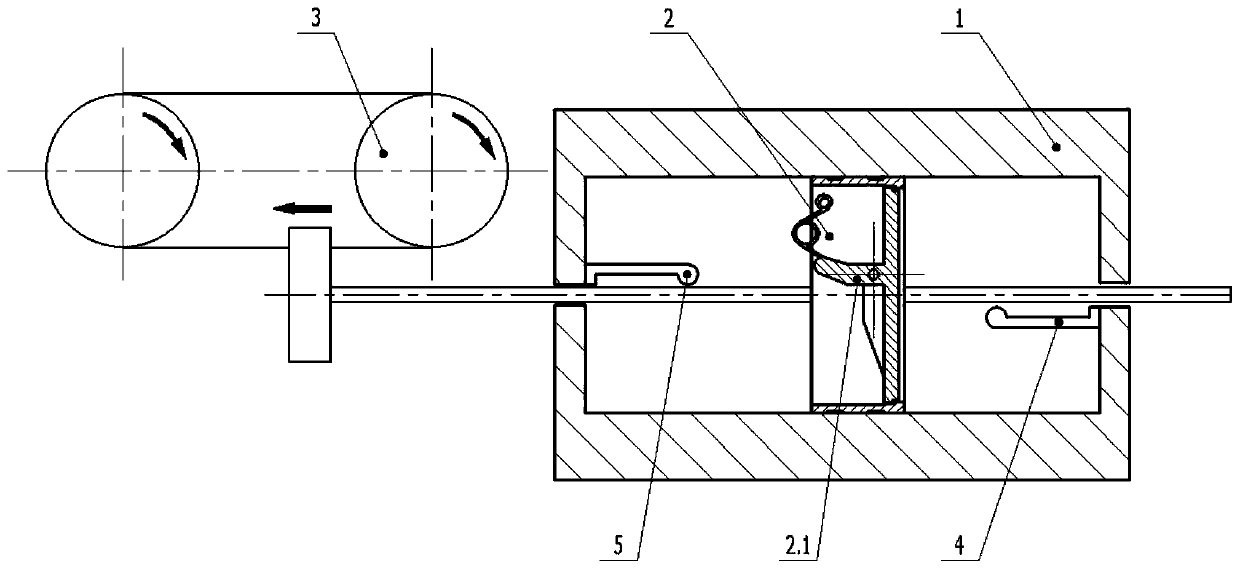

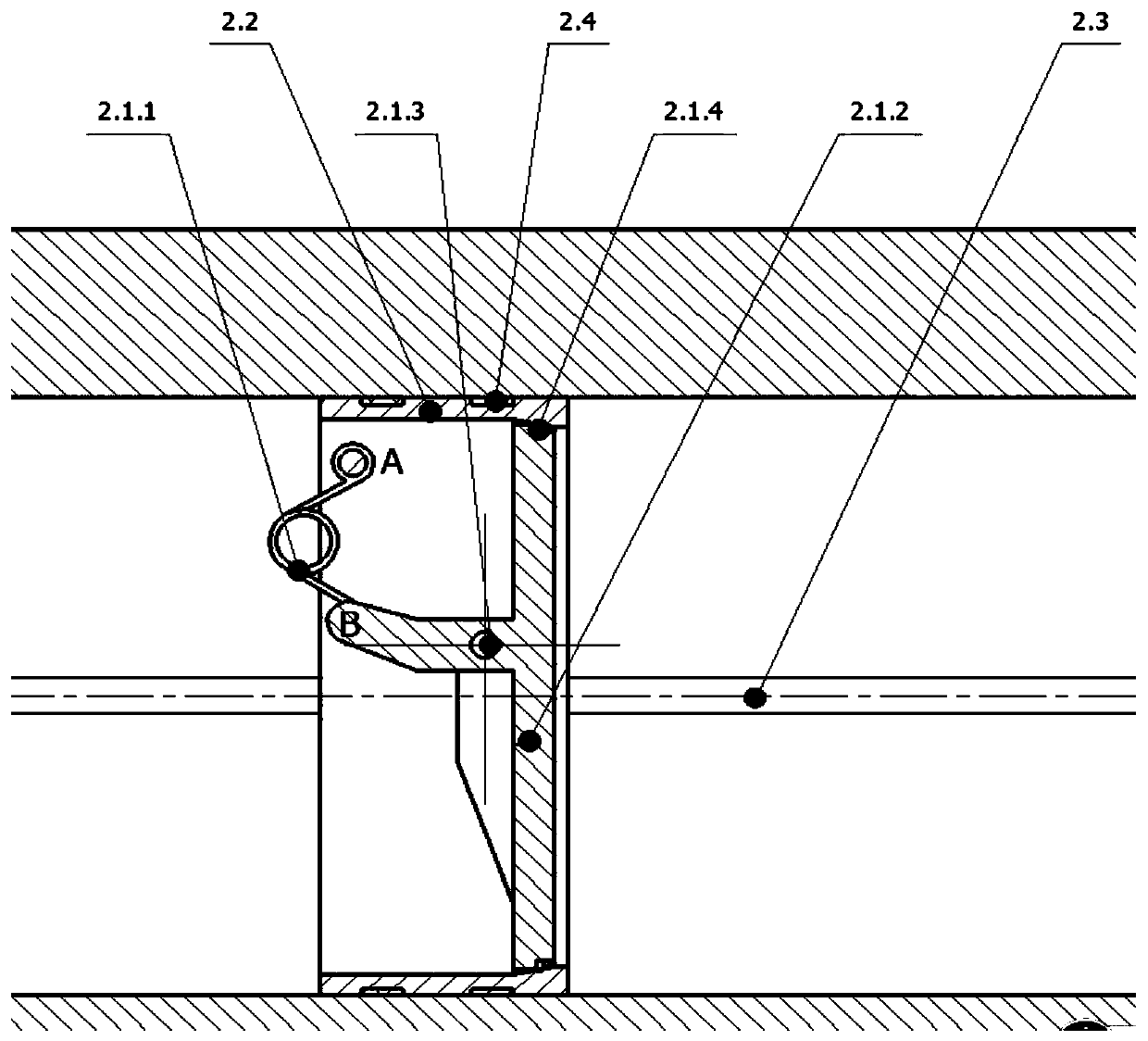

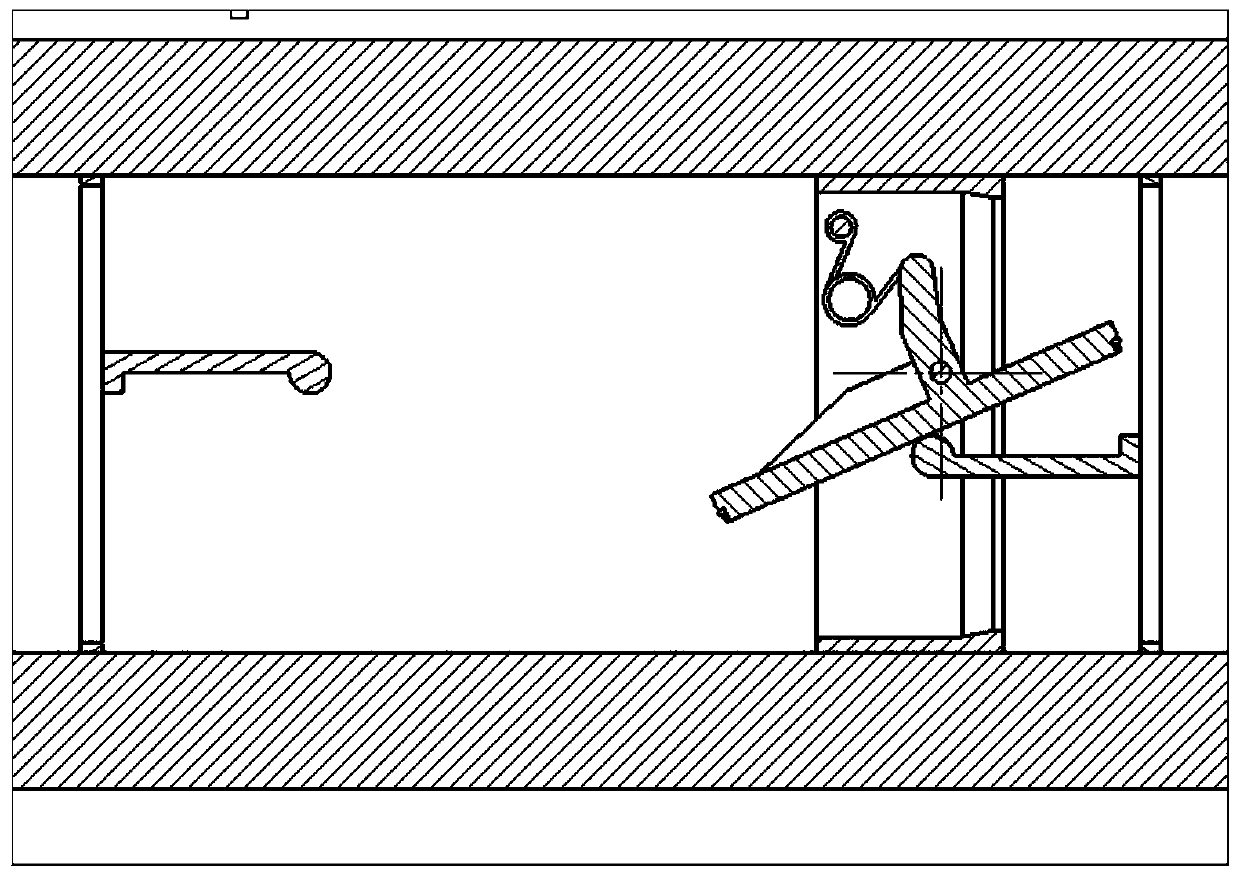

[0026] like figure 1 and figure 2 As shown, the embodiment discloses a reverse valve plug type passive piston volume tube, and its structure includes a cylinder body 1 , a piston system 2 and a return mechanism 3 . The piston system 2 includes an overturn valve plug mechanism 2.1, a piston 2.2, a piston rod 2.3 and a piston seal 2.4. The piston 2.2 is fixedly connected to the piston rod 2.3 and the piston seal 2.4 respectively, and the overturn valve plug mechanism 2.1 is located inside the piston 2.2. The overturning valve plug mechanism 2.1 includes torsion spring 2.1.1, overturning valve plug 2.1.2, rotating shaft 2.1.3 and sealing ring 2.1.4, the front part of the overturning valve plug 2.1.2 is circular and the The inner holes are compatible, and the front part of the flip valve plug 2.1.2 is sealed with the inner hole of the piston 2.2 through the sealing ring 2.1.4; the rear part of the flip valve plug 2.1.2 deviates from the axis and is equipped with a torsion spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com