Precompression device for polymer compression spring

A compression spring and polymer technology, applied in the field of pre-compression devices for polymer compression springs, can solve the problems of instability, machining, and poor uniformity of finished products, and achieve the effects of uniform shape, improved production efficiency, and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

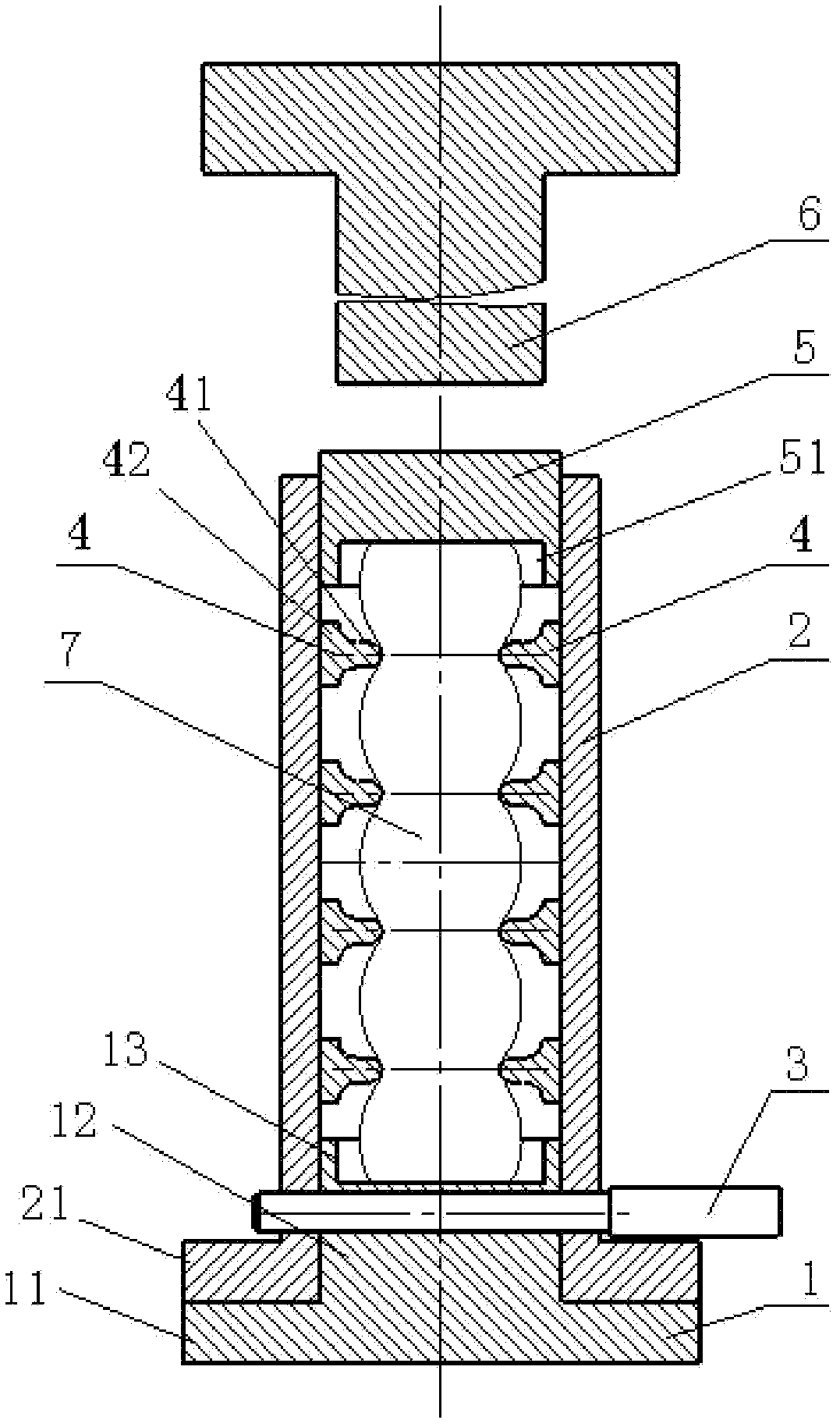

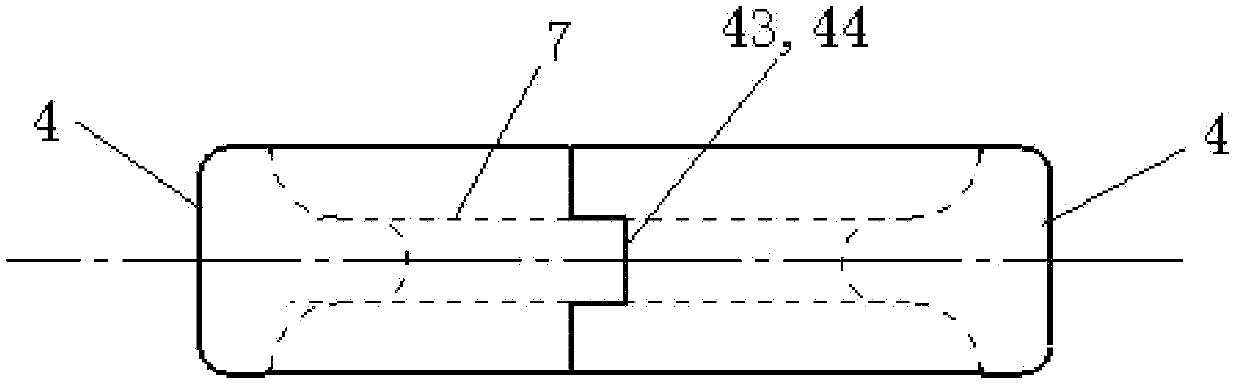

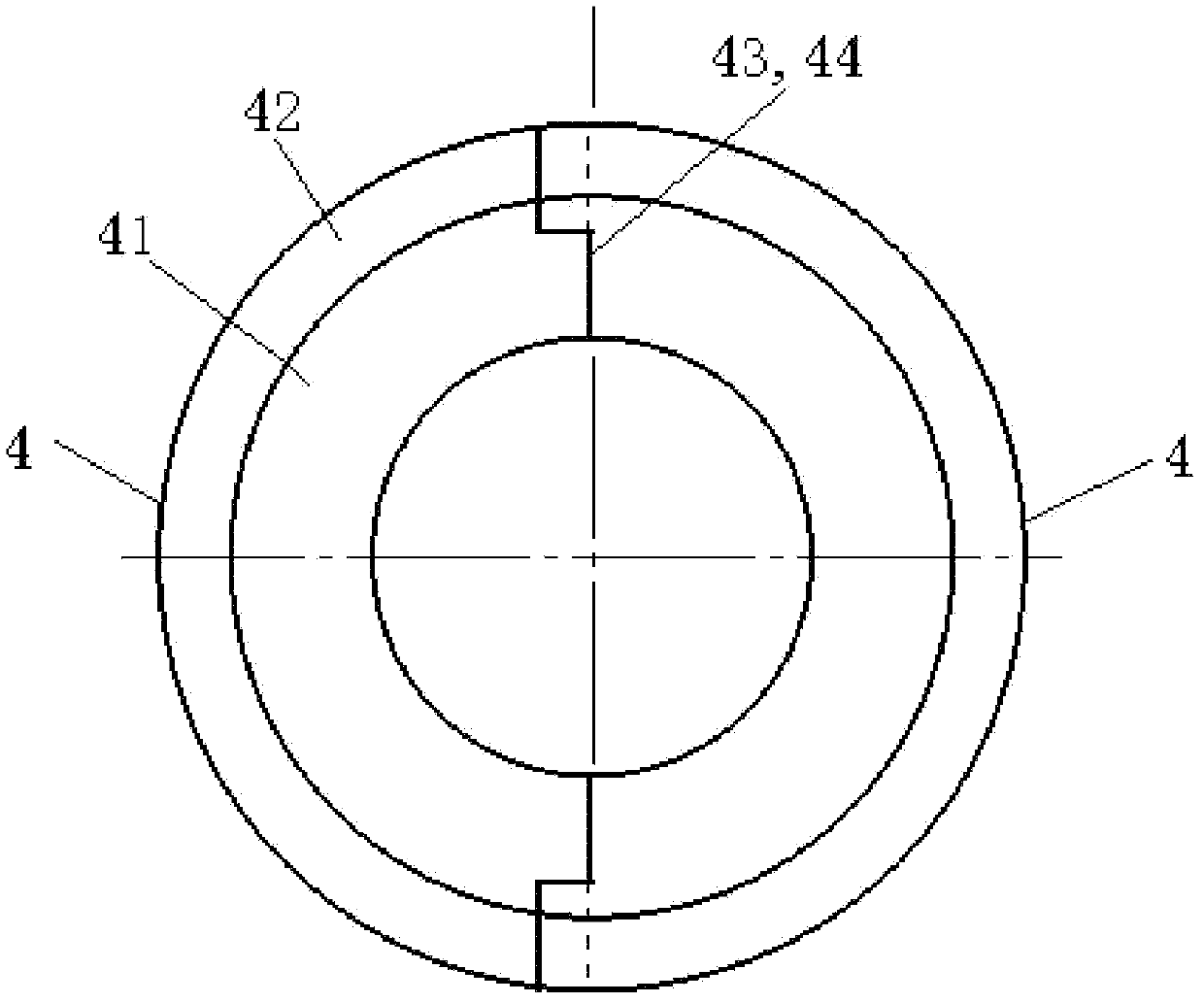

[0026] Embodiment one: if figure 2 , image 3 As shown, the positioning sleeve 4 is in a semi-circular shape as a whole, and the cross-section of the positioning sleeve 4 is in the shape of a "convex" laid down, that is, the positioning sleeve 4 includes an inner ring 41 and an outer ring 42, and the thickness of the inner ring 41 is smaller than that of the outer ring 42. thickness. In every pair of positioning sleeves 4, a protrusion 43 is respectively arranged on the two end faces of one of the positioning sleeves 4, and a groove 44 is respectively arranged on the two end faces of the other positioning sleeve 4; the end faces of each pair of positioning sleeves 4 are opposite. Setting, the protrusion 43 on the oppositely arranged end surface is engaged with the groove 44, and is clamped at the connection of the elastic balls of the polymer compression spring 7 in series, and the positioning sleeve 4 and the polymer compression spring 7 can be placed while being assembled....

Embodiment 2

[0027] Embodiment two: if Figure 4 , Figure 5 As shown, the positioning sleeve 4 is in a semi-circular shape as a whole, and the cross-section of the positioning sleeve 4 is in the shape of a "convex" laid down, that is, the positioning sleeve 4 includes an inner ring 41 and an outer ring 42, and the thickness of the inner ring 41 is smaller than that of the outer ring 42. thickness. In every pair of positioning sleeves 4, magnets 45 are respectively arranged on the two end faces of one of the positioning sleeves 4, and magnets 46 are also respectively arranged on the two end faces of the other positioning sleeve 2; The magnet 45 on the end face of the positioning sleeve 4 is connected with the magnet 46 on the end face of the other positioning sleeve 4 by relying on the principle of magnet opposite sex attraction. Object compression spring 7 is placed in the guide cylinder 2 while assembling, or is placed in the guide cylinder 2 after assembling.

Embodiment 3

[0028] Embodiment three: as Figure 6 , Figure 7As shown, the positioning sleeve 4 is in a semi-circular shape as a whole, and the cross-section of the positioning sleeve 4 is in the shape of a "convex" laid down, that is, the positioning sleeve 4 includes an inner ring 41 and an outer ring 42, and the thickness of the inner ring 41 is smaller than that of the outer ring 42. thickness. Every pair of positioning sleeves 4 is provided with a semicircular groove 47 along the outer peripheral surface, and the end faces of each pair of positioning sleeves 4 are arranged oppositely. The semicircular groove 47 provided on the outer peripheral surface forms a circular groove, and an elastic The hoop ring 8 is arranged in the circular groove formed on the outer peripheral surface of each pair of locating sleeves 4, and each pair of locating sleeves 4 is fixed as a whole, and each pair of locating sleeves 4 is clamped on the At the junction of the series structure of the elastic ball...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com