Dyeing method for cheese made of nylon stretch yarns

A dyeing method and technology of elastic yarn, applied in the direction of dyeing method, textile and papermaking, fiber processing, etc., can solve the problems of difficult color control, impervious dyeing, inconsistent elasticity of the package, etc., and achieve the effect of high success rate at one time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation of the present invention will be described in detail below in conjunction with preferred embodiments.

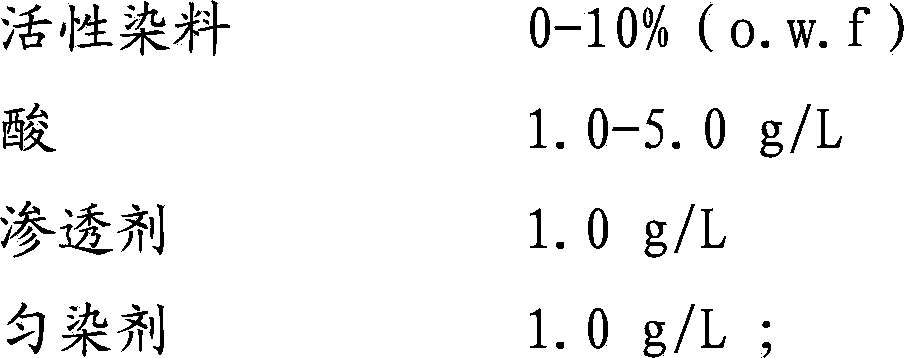

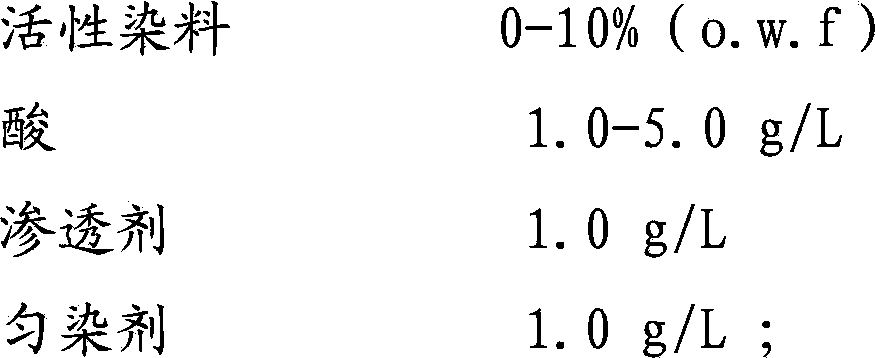

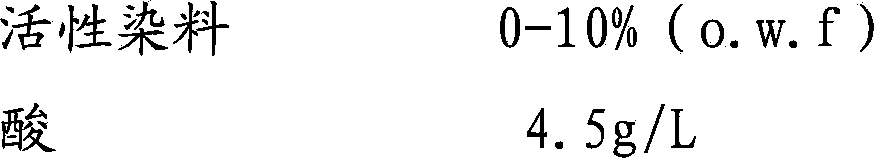

[0022] A kind of dyeing method that nylon elastic yarn is made cheese, carries out according to the following steps,

[0023] 1) Loose winding: SSM winding machine is adopted, the winding speed is 300-700r / min, the back pressure is 40-52%, the tension is 30-60%, the winding angle is 11°-18°, the loose winding bobbin is fixed Weight is 0.8-1.2kg / piece, density is 0.35-0.40g / cm 3 ;

[0024] 2) Pre-treatment: After injecting water into the dyeing vat at a bath ratio of 1:20, add 0.5-2g / L soaping agent, raise the temperature of the dyeing bath to 80°C and keep it warm for 15 minutes, and empty it after treatment; refill the dyeing vat at a bath ratio of 1:20 , after running for 5 minutes, empty after processing;

[0025] 3) Bomb reduction: After filling the dye vat with water at a process bath ratio of 1:20, the temperature of the dye bath i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com