Automatic elasticity balancing device of hanger

A kind of elastic balance and automatic technology, applied in the direction of overhead lines, etc., can solve the problems of installing complex pantograph and catenary, and achieve the effect of consistent elasticity, arc resistance without falling off, and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

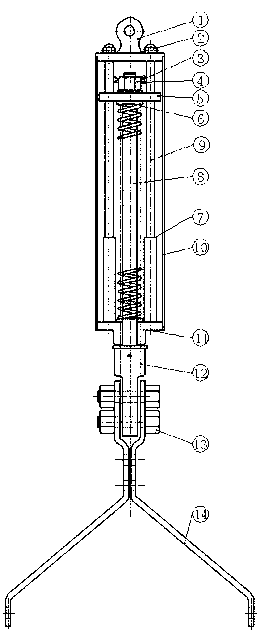

[0011] refer to figure 1 , the hanging string automatic elastic balancer is provided with a shell 10, the upper end of the shell 10 is provided with an upper end connecting ear 1, and the lower end of the shell 10 is provided with a base cover 11, and the shell 10 and the base cover 11 are fixed together. The base cover 11 in the shell 10 is provided with a guide limit shaft 9, and the upper end of the guide limit shaft 9 is fixed on the upper end connecting ear 1 with a guide limit shaft nut 2, and the guide limit shaft 9 is provided with a limit platform 7. The telescopic driving shaft 8 is put through the shell 10 by the base cover 11. The upper end of the telescopic driving shaft 8 is provided with a middle slide plate 5, and the middle sliding plate 5 is locked on the telescopic driving shaft 8 with the telescopic driving shaft fixing nut 3 and the stop pin 4. on, to limit. The middle slide plate 5 is sleeved on the guide limit shaft 9 and can slide up and down along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com