Patents

Literature

126results about How to "Consistent hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing method of deproteinized rice

ActiveCN103211163APromote dissolutionImprove removal effectFood preparationFlavorReaction temperature

The invention provides a processing method of deproteinized rice. The processing method comprises the following steps of: (1) washing and removing impurities; (2) carrying out enzymolysis and fermentation: in a reaction tank, adding processed rice, purified water, proteolytic enzyme and lactic acid bacteria according to proportion, wherein the weight proportion of rice to purified water is 1:(5-20), the reaction temperature is 10-60 DEG C, the reaction time is 3-20 hours, the initial pH of reaction liquid is between 4.5 and 9.5, the using amount of proteolytic enzyme accounts for 0.1% to 5% of total weight of rice, and the dropping amount of lactic acid bacteria is as follows: 109-1014 bacteria is added in every ton of reaction liquid; and (3) after enzymolysis and fermentation, leaching, washing and drying to obtain the deproteinized rice. According to the method, the technology is simple, the cost is low, the appearance, the color, the flavor and the taste of the deproteinized rice processed by adopting the technology are the same as those of ordinary rice; and the protein removal ratio can be more than 95% at most.

Owner:成都东洋百信制药有限公司

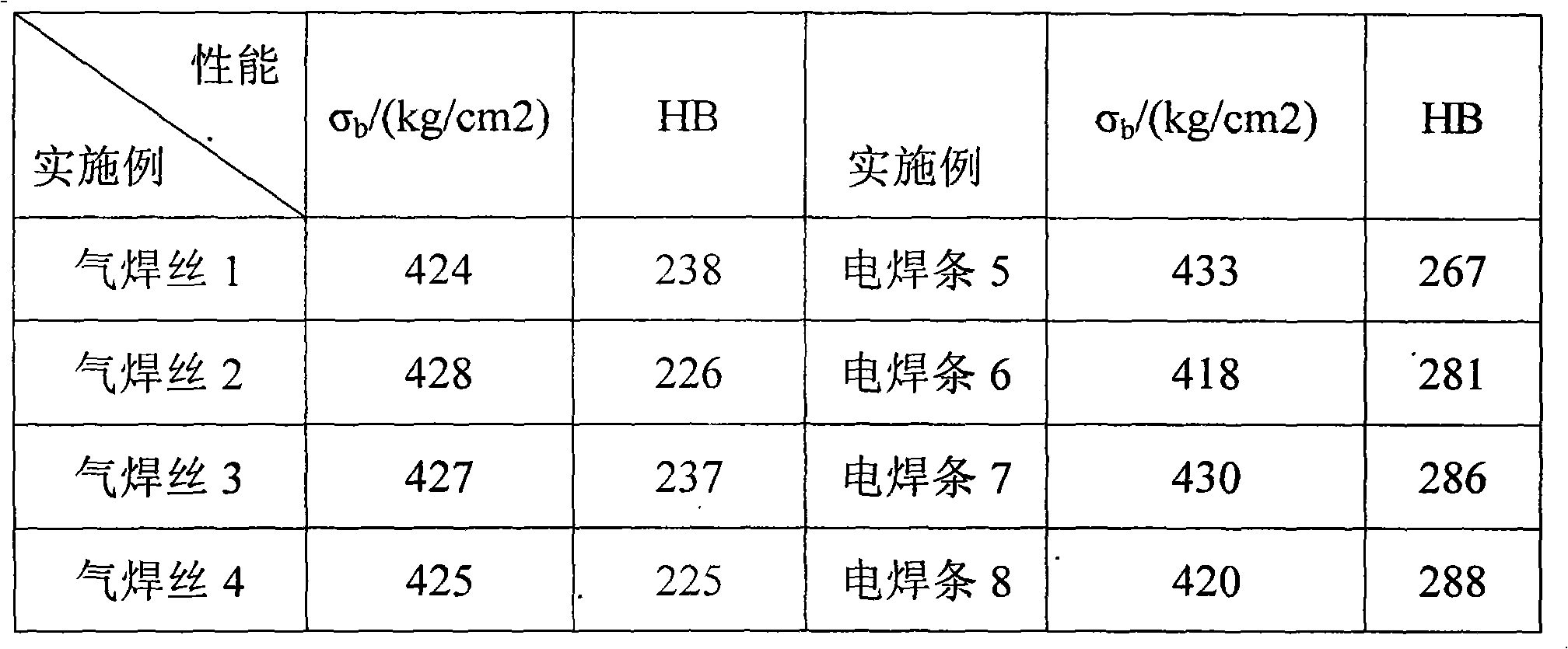

Flux-cored alloyed ductile cast iron homogeneous gas-welding wire and electric welding rod

InactiveCN101554688AConsistent weld colorConsistent weld strengthWelding/cutting media/materialsSoldering mediaSilicon alloyAluminium powder

The invention discloses a flux-cored alloyed ductile cast iron homogeneous gas-welding wire which consists of H08A steel strip and alloyed flux-cored powder cladded in the H08A steel strip, and the flux-cored powder comprises the components based on the weight percentage: 10-20% of graphite, 50-60% of 75 Si-Fe, 5-8% of Ni, 2-5% of Ti, 3.8-6% of Mg, 0.8-2.5% of Bi, 1-2.5% of Zr, 2.0-4.5% of Ba, 1.5-2.8% of Ce and 4-6% of RE, and the total weight percentage is 100%. The invention also discloses an electric welding rod, a flux-cored welding core of which consists of the H08A steel strip and the alloyed flux-cored powder cladded in the H08A steel strip, and the coating applied on the welding rod comprises the components based on the weight percentage: 5-11% of marble, 10-20% of dolomite, 5-15% of potassium feldspar, 5-15% of fluorite, 8-16% of graphite, 15-25% of 75 silicoferrite, 6-10% of 30 calcium silicon alloy, 4-6% of aluminium powder, 3-7% of ferrous powder, 5-15% of white slime, 0.5-1.5% of NaCO3, 1-3% of RE-Y, and the total weight percentage is 100%. The gas-welding wire or the electric welding rod can realize normal temperature gas welding, cold welding or low temperature preheating welding.

Owner:XIAN UNIV OF TECH

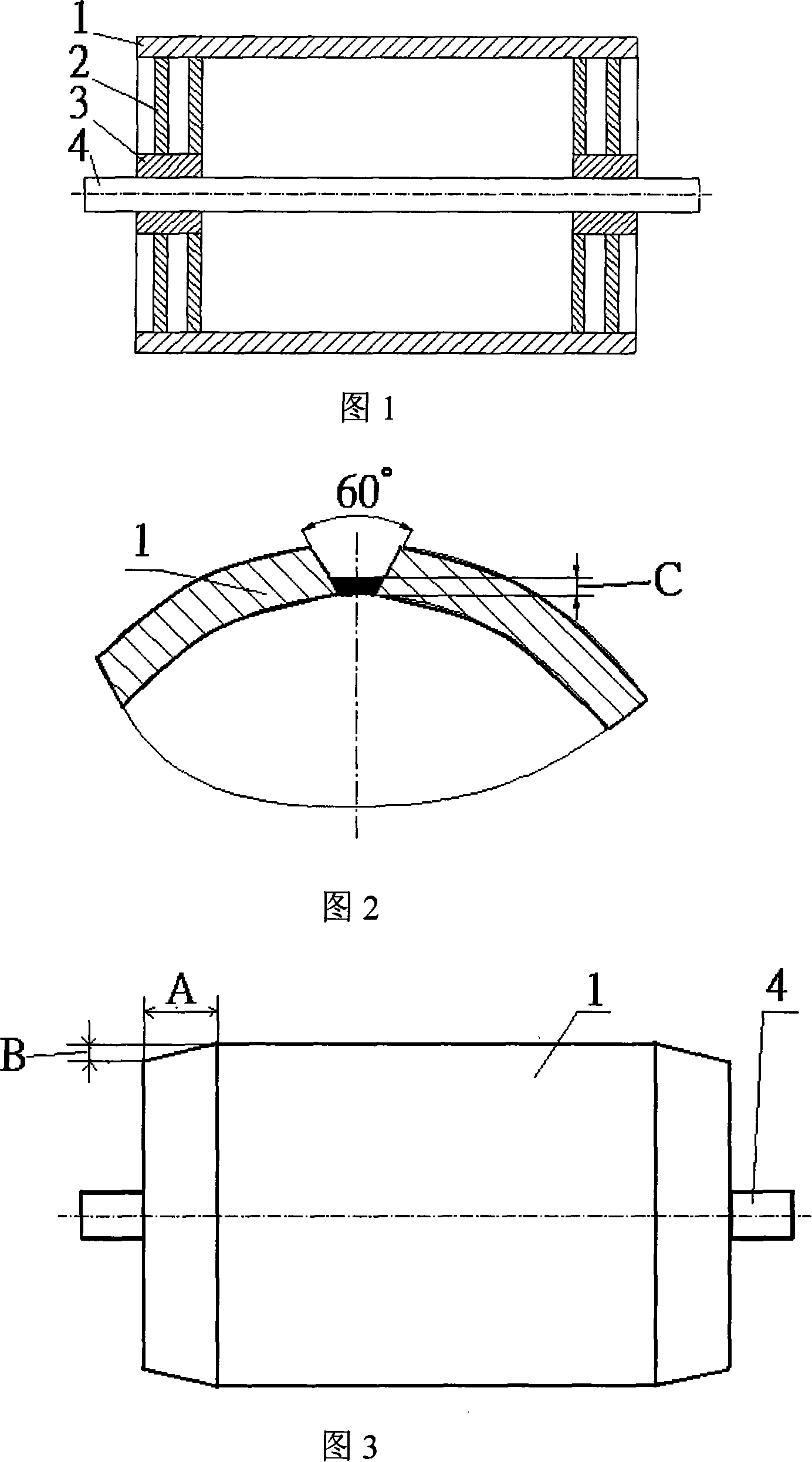

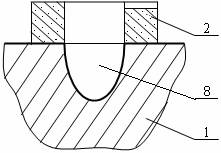

Manufacturing method of surface-quenching chromium-plating winded-welding roller

InactiveCN101134277AAvoid crackingGuaranteed depth uniformityFurnace typesHeat treatment process controlManufacturing cost reductionSand blasting

The present invention discloses surface quenched chrome plated wound and welded roller making process, which includes the steps of hot winding, bottoming welding and processing bevel, coarse turning, surface quenching, semi-finish turning, assembling welding, finish machining and post-treatment. The process of the present invention is suitable for making roller of 500-1200 mm diameter, 25 mm wall thickness and 2050-2200 mm length, and roller surface is treated through quenching, sand blasting to roughen and chrome plating. The present invention has the advantages of saving in material, low making cost and short production period.

Owner:MCC SFRE HEAVY IND EQUIP

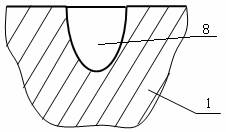

Welding material for rapidly welding and repairing defects of large-scale grey iron casting and repairing method thereof

InactiveCN101850478AQuick Weld RepairEnhanced weld crack resistanceWelding/cutting media/materialsSoldering mediaExothermic reactionMetal

The invention discloses a welding material for rapidly welding and repairing defects of a large-scale grey iron casting, comprising the following components in percentage by weight: 33%-38% of Fe2O3, 27%-30% of Al, 1.4%-1.6% of Na2CO3, 4%-6% of Na2B4O7, 4%-6% OF CaF2 and 7%-10% of CaO7, wherein when the material is used for a large-scale HT150 grey iron casting, the material further comprises 4%-5% of G, 7%-10% of pig iron and 5%-8% of SiO2; when the material is used for a large-scale HT200 grey iron casting, the material further comprises 4%-5% of G, 7%-10% of pig iron, 4%-6.5% of 75 Si-Fe, 0.5%-3.2% of Ni and 0.1%-0.5% of Bi, based on the total weight of 100%; and when the material is used for a large-scale HT250 grey iron casting, the material further comprises 3%-4% of G, 6%-10% of pig iron, 4%-6% of 75 Si-Fe, 0.5%-3.2% of Ni, 0.1%-0.5% of Bi, 0.5%-1.8% of Ti, 1.8%-2.4% of 60Si-Ca and 0.5%-3.2% of Al2O3, based on the total weight of 100%. The invention discloses a method for rapidly welding and repairing defects of the large-scale grey iron casting, comprising the following steps: filling the welding material into a space formed by a groove and a dam, leading the welding material to carry out an exothermal reaction, slowly cooling, and removing the metal which is higher than the surface of the casting in a welding area. By using the material and the method of the invention, rapidly welding and repairing the defects of the large-scale grey iron casting can be achieved at room temperature.

Owner:XIAN UNIV OF TECH

Novel method stabilizing bupropion hydrochloride tablets

InactiveUS20060165779A1Desired sustained release characteristicLow costOrganic active ingredientsBiocideBupropion hydrochloridePharmacology

The present invention relates to a stable bupropion hydrochloride tablet and a method of stabilizing bupropion hydrochloride tablets, which also serves as an improved tabletting process for the preparation of sustained release bupropion hydrochloride tablets.

Owner:RANBAXY LAB LTD

Polyurethane for CMP polishing pad and preparation method of polyurethane

The invention belongs to the technical field of polyurethane application, and particularly relates to polyurethane for a CMP polishing pad and a preparation method of the polyurethane. The polyurethane for the CMP polishing pad comprises a polyurethane prepolymer component A and a curing agent component B. The component A is composed of polymeric polyol A, diisocyanate and an anti-hydrolysis agent, and the component B is composed of an amine chain extender, polymeric polyol B, a hollow filler, a plasticizer and a catalyst. The structures of prepolymer molecules are arranged more regularly, andthe forming speed is high; the stability is good; the quality risk is reduced; the high-content prepolymer component does not crystallize at room temperature, has low initial viscosity, and has higher proportion when being mixed with the curing agent component, the uniform mixing is easier, consistency of hardness and uniformity after slicing of the prepared product is guaranteed, the breakage rate of electronic elements in the later polishing process is greatly reduced, and on the basis of micro-foaming, the hollow filler is added, so that the product has longer service life and storage lifeand good mechanical performance.

Owner:SHANDONG INOV POLYURETHANE

Grinding technique for forging non-corrodible steel knife

ActiveCN101254585AHardness remains the sameProduct quality is stableOther manufacturing equipments/toolsThermal treatmentHardness

The invention discloses a process for forging and grinding stainless steel, which comprises the following steps: (1) subjecting a cutter blank having a cross-section forged to taper shape; (2) primarily coarse-grinding a recessed arc surface at the middle part of a cutting tool by an edge formed by the end face and the circumference of a grinding wheel of a water mill machine; (3) secondarily coarse-grinding a blade edge by the end face of the grinding wheel of the water mill machine; (4) thirdly coarse-grinding the back of the cutting tool by the end face of the grinding wheel of the water mill machine; (5) primarily fine-grinding the recessed surface at the middle part of the cutting tool by the end face of a rubber grinding wheel of the water mill machine; (6) secondarily fine-grinding the blade edge by the end face of the rubber grinding wheel of the water mill machine; and (7) thirdly fine-grinding the back of the cutting tool by the end face of the grinding wheel. In the coarse grinding process, the temperature of the cutting tool is not larger than 200 DEG C, and the rigidity is unlikely to decrease after grinding. Compared with prior manual production, the mechanized process can ensure uniform surface lines, thickness and rigidity of the cutting tool, stable product quality, low rejection rate, simplified process, and greatly improved production efficiency.

Owner:CHONGQING DENGSHI KITCHENWARE MFR

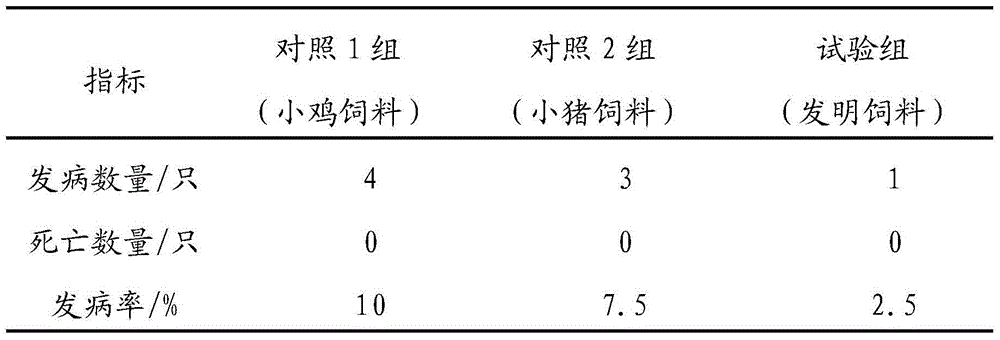

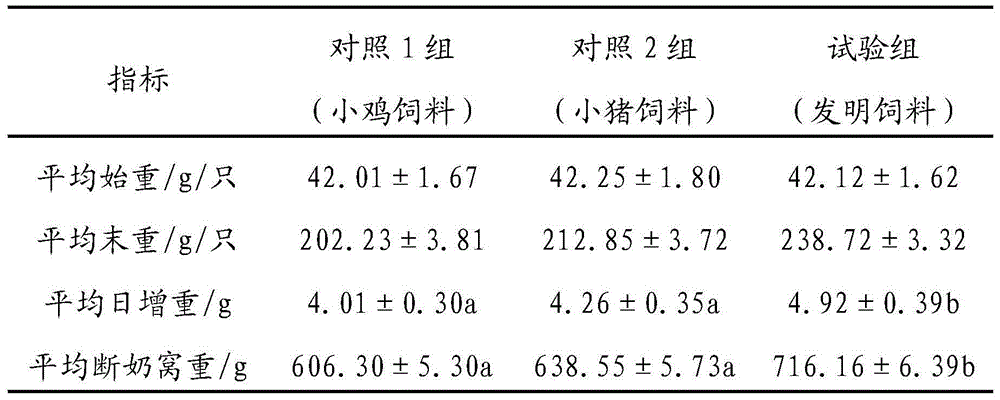

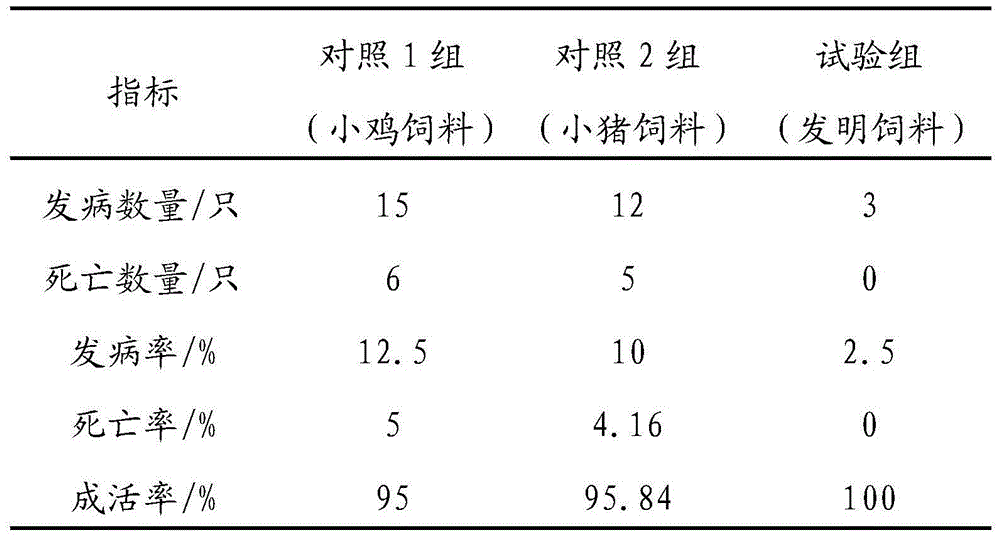

Concentrate mixed granular material for breast-feeding female bamboo rats and preparation method of concentrate mixed granular material

InactiveCN104543491AImprove disease resistanceIncrease production capacityFood processingAnimal feeding stuffDiseaseMonocalcium phosphate

The invention discloses a concentrate mixed granular material for breast-feeding female bamboo rats and a preparation method of the concentrate mixed granular material. The concentrate mixed granular material is prepared from the following components in percentage by weight: 40-55% of corn, 5-15% of wheat, 8-15% of soybean meal, 1-8% of fish meal, 5-10% of rice bran, 5-10% of brewer's grain, 1-5% of bagasse powder, 1-5% of cane molasses powder, 1-5% of bamboo leaf powder, 1-3% of monocalcium phosphate, 0.5-1% of shell powder, 0.1-0.5% of edible salt, 0.1-0.2% of compound vitamin, 0.1-0.2% of trace element premix, 0.3-0.5% of lysine, 0.1-0.2% of threonine, 0.05-0.1% of Chinese herbal additives, and 0.5-1% of loess. The concentrate mixed granular material is capable of meeting the nutritional requirements of the breast-feeding female bamboo rats to keep the disease resistance and the milk yield of the rats at the optimal level, and also capable of improving the growth performance and the survival rate of the breast-fed young bamboo rats; besides, the raw materials are convenient to get and the preparation method is simple.

Owner:GUANGXI NORMAL UNIV

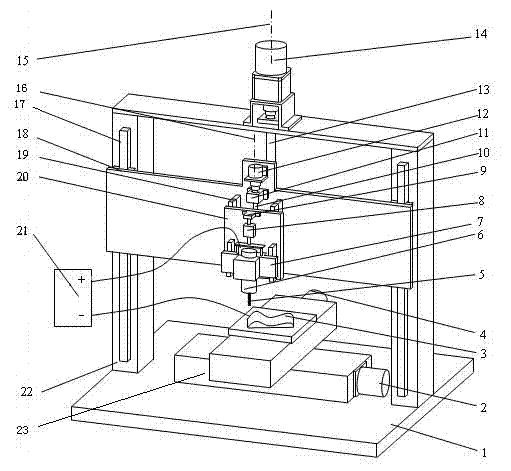

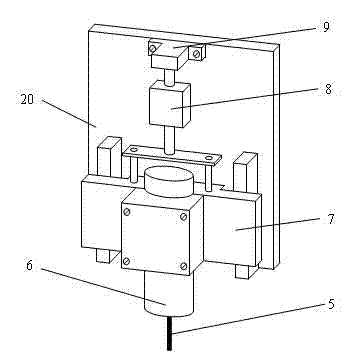

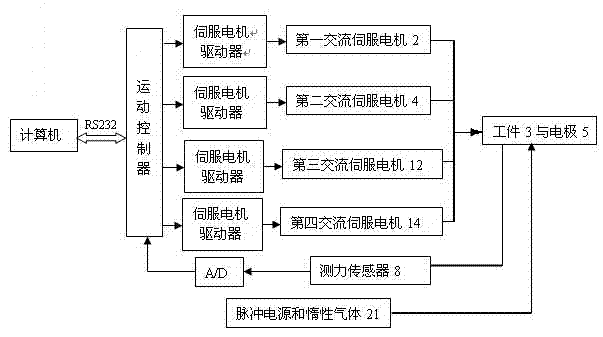

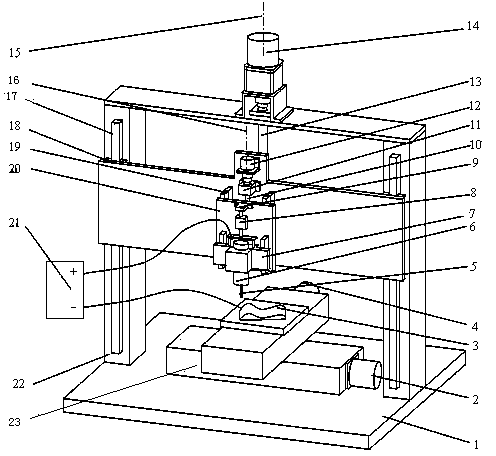

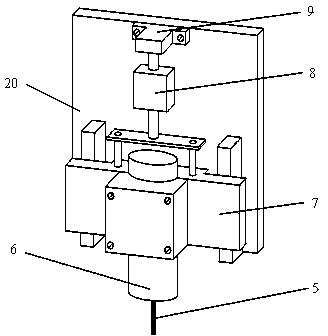

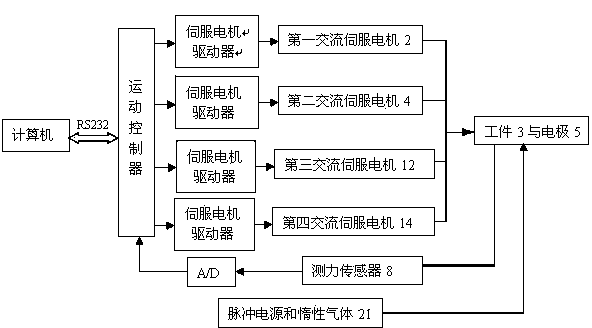

Automatic double-Z-axis electric spark deposition device and method

The invention discloses an automatic double-Z-axis electric spark deposition device and method. A first alternating-current servo motor, a second alternating-current servo motor and a fourth alternating-current servo motor in the X-axis direction, the Y-axis direction and the Z1-axis direction are controlled to move so as to drive an electrode to move to a machining starting point of a workpiece surface; when a third alternating-current servo motor runs, a Z2-axis ram descends so as to ensure that the squeezing force of a rotary deposition gun on the workpiece is equal to a preset value; the first, second and fourth alternating-current servo motors run, and a movement orbit of the workpiece surface is formed by rotating the rotary deposition gun; the height of the electrode is adjusted according to a real squeezing force value measured by a force transducer, wherein when the squeezing force is greater than the upper difference of the preset value, the third alternating-current servo motor is reversed to drive the Z2-axis ram to ascend so as to drive the rotary deposition gun and the electrode to ascend, and when the squeezing force is smaller than the lower difference of the preset value, the third alternating-current servo motor rotates forward to drive the Z2-axis ram to descend; and the elevation movement in the Z2-axis direction is only related to the squeezing force, a deposition layer is more continuous, and the thickness of the deposition layer is more uniform.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

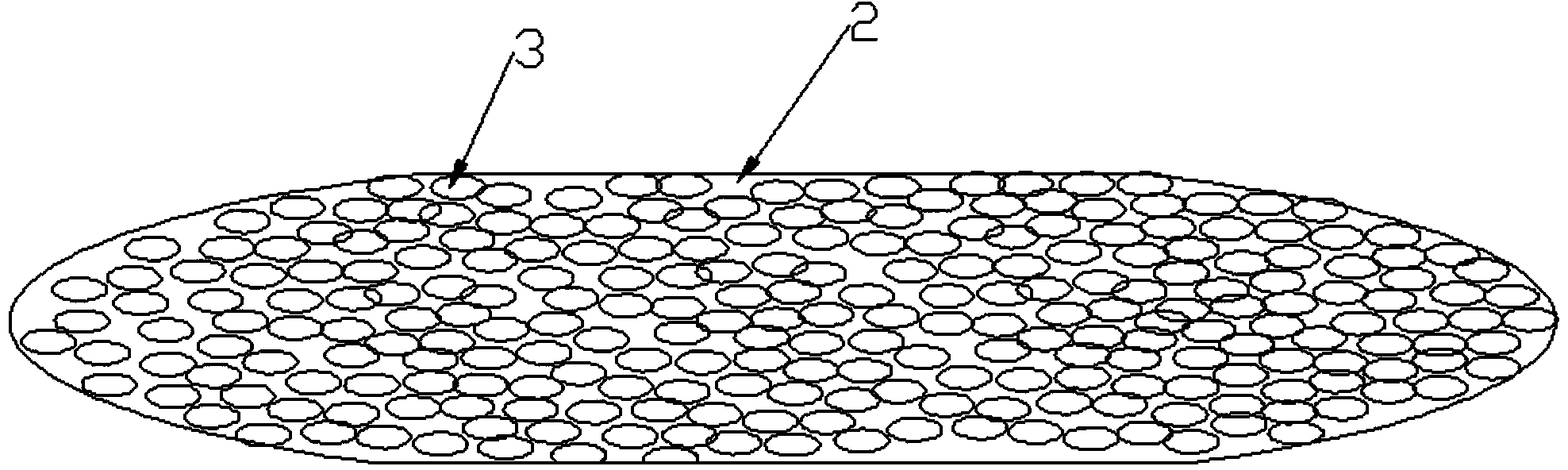

Dacron fine denier multi-hole flat fiber and method for producing same

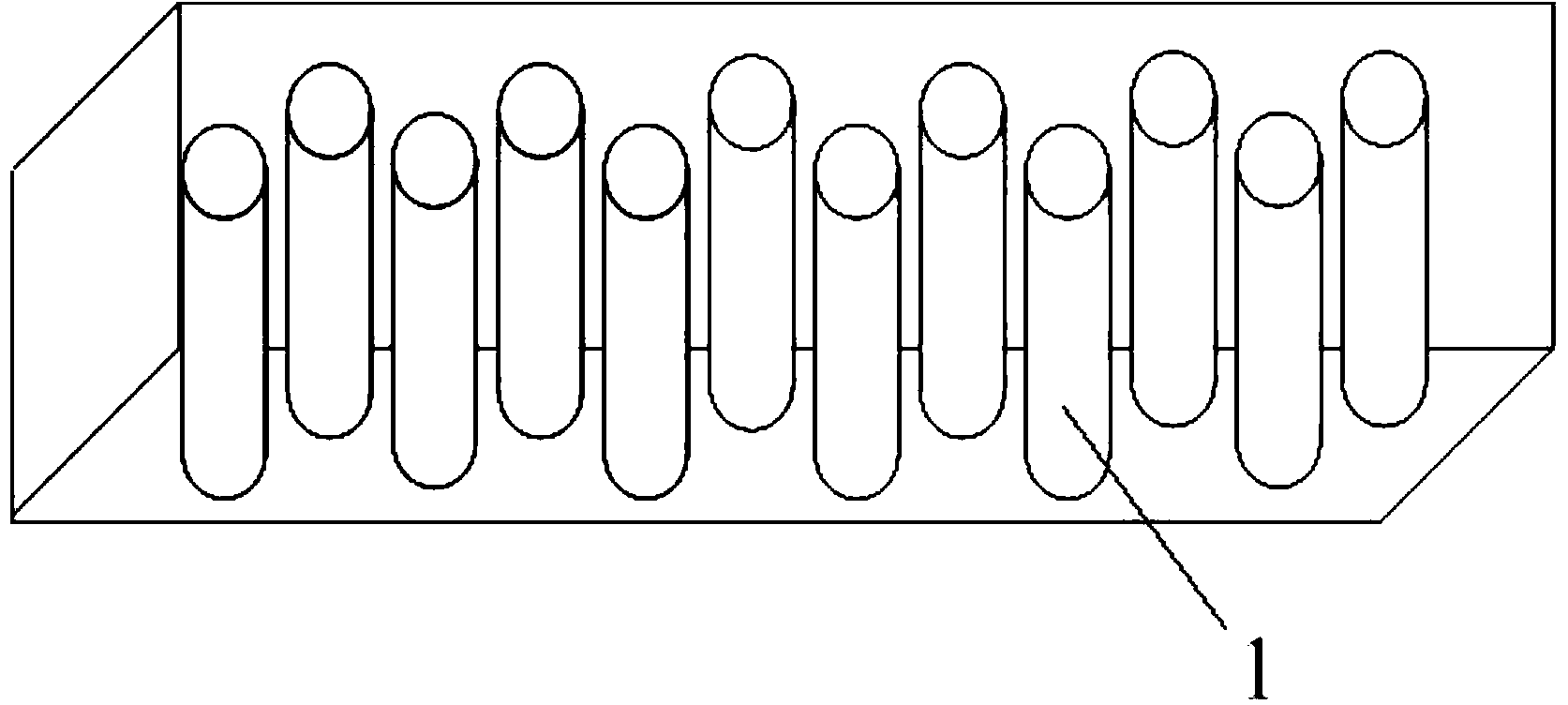

ActiveCN103510171ABeautiful appearanceImprove inner qualityNew-spun product collectionFilament/thread formingYarnFiber

The invention relates to the technical field of chemical fiber products, in particular to a dacron fine denier multi-hole flat fiber and a method for producing the dacron fine denier multi-hole flat fiber. The dacron fine denier multi-hole flat fiber comprises a fiber body. The fiber body is provided with 192 strips of monofilament, the cross section of each strip of monofilament is in the shape of a waist, the linear density of the fiber body is 207-253dtex, and the monofilament is evenly and irregularly distributed. The produced dacron fine denier multi-hole flat fiber is beautiful in appearance, good in inherent quality, small in inner-layer and outer-layer fluctuation, stable in tension, soft, long and straight in style, fine and smooth in hand feeling, even in dye absorption, bright-colored in dye, large in package density, high in capacity, consistent in whole package width, uniform in hardness, free of overlapped yarn and even in inner-layer and outer-layer quality, and is a high and new-tech product with high quality and high additional value.

Owner:ZHEJIANG HENGYOU CHEM FIBER CO LTD

Manufacture technology of steel wire cut pill

The invention discloses a technology for manufacturing a steel wire cut pill, which takes a waste steel wire rope as the manufacture raw material. The process flow comprises the following steps of: breaking the rope, breaking the strand, cutting the pill, decontaminating, derusting and screening. The technology can manufacture the steel wire cut pill with 0.2-4mm, has good performance and cleaning effect, is difficult to crush the pill, and has small consumption level and long service life. Meanwhile, the waste steel wire rope used as the raw material is the industrial waste material, so that the material source is abundant, the production cost is low, and the environment pollution can be reduced. Furthermore, the decontaminating and derusting method of the steel wire cut pill comprises the step of adding saw timber powder in a stirrer to abundantly mix and stir, thereby effectively removing the greasy dirt, the rust stain and the foreign matter on the surface with the porous absorption capability and the surface scrubbing capability of the saw timber powder, reducing the problems of high cost, water waste, uncleanness and environment pollution caused by using the conventional steel wire cut pill cleaning agent, and having prominent technical benefit, economic benefit and environmental benefit.

Owner:GUIZHOU UNIV

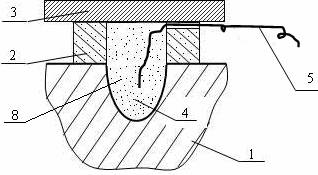

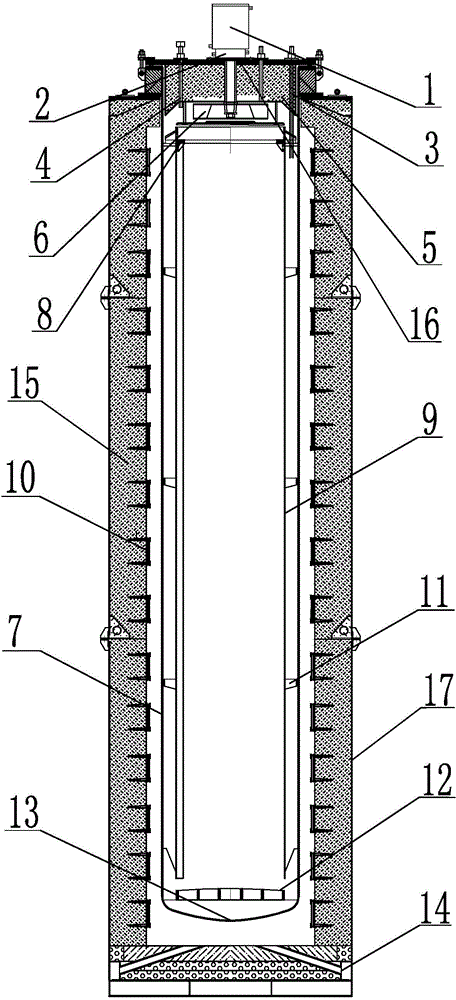

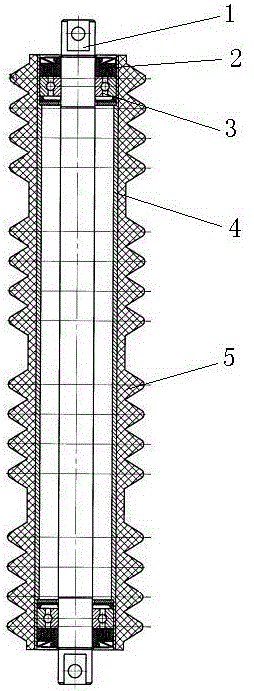

Pit-type nitriding furnace

InactiveCN104928619AHigh strengthAvoid deformationSolid state diffusion coatingEngineeringWater tanks

The invention relates to a pit-type nitriding furnace. The pit-type nitriding furnace comprises a furnace shell, a furnace cover, an inner furnace container and a wind guide barrel. The inner furnace container is arranged inside the furnace shell. The wind guide barrel with the two ends open is hung in the inner furnace container. A tripod is arranged between the wind guide barrel and the inner furnace container for supporting. The bottom of the inner furnace container is an arc surface. A furnace container bottom board is arranged at the position where the bottom of the inner furnace container and an inner furnace container body are connected and is provided with holes. A draught fan is fixed in the middle of the upper end of the furnace cover. A cooling water tank is arranged between the draught fan and the furnace cover. A heat collection box is fixed to the lower end of the furnace cover. The draught fan is connected with a blade through a shaft penetrating through the heat collection box. The draught fan is arranged on the furnace cover, the wind guide barrel is arranged inside the inner furnace container, and the draught fan and the inner furnace container are matched, so that gas is emitted and circulates from bottom to top and heat inside the furnace is distributed more uniformly. The tripod is arranged between the wind guide barrel and the inner furnace container and further improves the intensity of the inner furnace container, and the inner furnace container can be effectively prevented from deforming.

Owner:浙江长兴天盛工业炉有限公司

Fireproof fiber board

The invention discloses a fireproof fiber board and relates to the technical field of fireproof material manufacture. The fireproof fiber board is prepared from the following raw materials in parts by weight: 100-120 parts of aluminum silicate fibers, 9-12 parts of silicon-aluminum sol, 12-15 parts of tetraethyl orthosilicate and 8-10 parts of additives. Compared with the prior art, the fireproof board is small in volume weight and consistent in surface and interior hardness, and can be processed into various products by use of mechanical equipment; the products processed from the fireproof fiber boards are high in dimensional accuracy.

Owner:LIUZHOU YITING TRADE

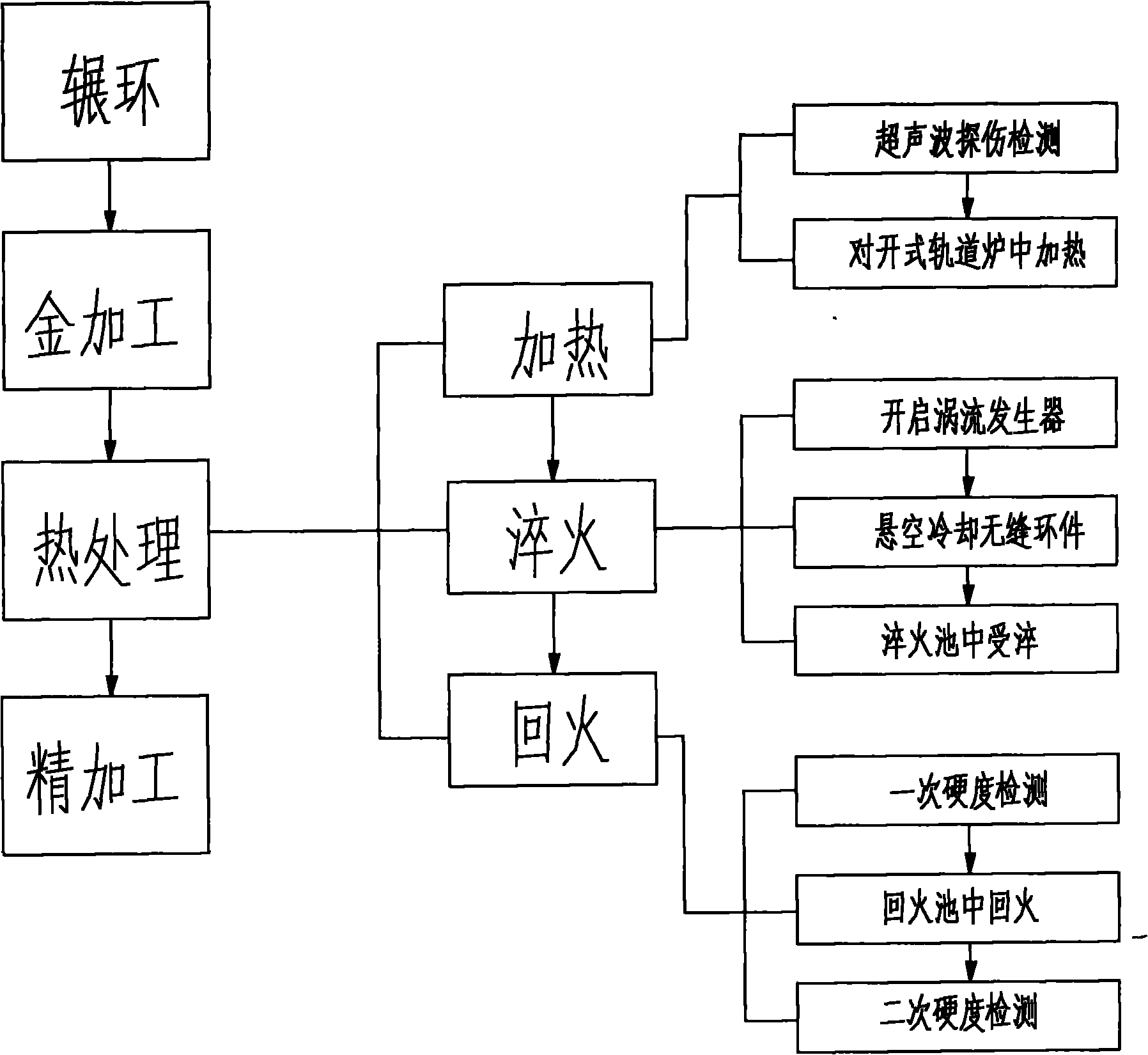

Method for manufacturing seamless ring and special heat treatment system thereof

ActiveCN101831537AInconsistent quality performanceConsistent quality performanceFurnace typesHeat treatment furnacesHardnessContinuous flow

The invention discloses a method for manufacturing a seamless ring and a special heat treatment system thereof. The manufacturing method comprises four continuous flows of ring rolling, metal working, heat treatment and finish machining, wherein the heat treatment flow comprises three processes of heating, quenching and tempering. The quenching process of the heat treatment flow comprises the steps of: (1) opening a vortex generator which is positioned at the bottom of a quenching tank, wherein the quenching liquid in the quenching tank forms stable vortex; and (2) lifting the seamless ring out of a split track furnace and putting the seamless ring into the quenching tank for quenching. In the method for manufacturing the seamless ring and the special heat treatment system, the vortex generator is opened first before the seamless ring is quenched, and when stable vortex which moves at a constant speed is formed in the quenching tank, a heated workpiece is put into the quenching tank, so that inconsistent quality performance of the seamless ring due to the inconsistency of the concentration and temperature of the quenching liquid is avoided. Therefore, the consistency of the surface hardness and core hardness of the seamless ring and the consistency of the overall hardness can be guaranteed.

Owner:CHANGZHOU SHUANGQIANG MASCH MFG CO LTD

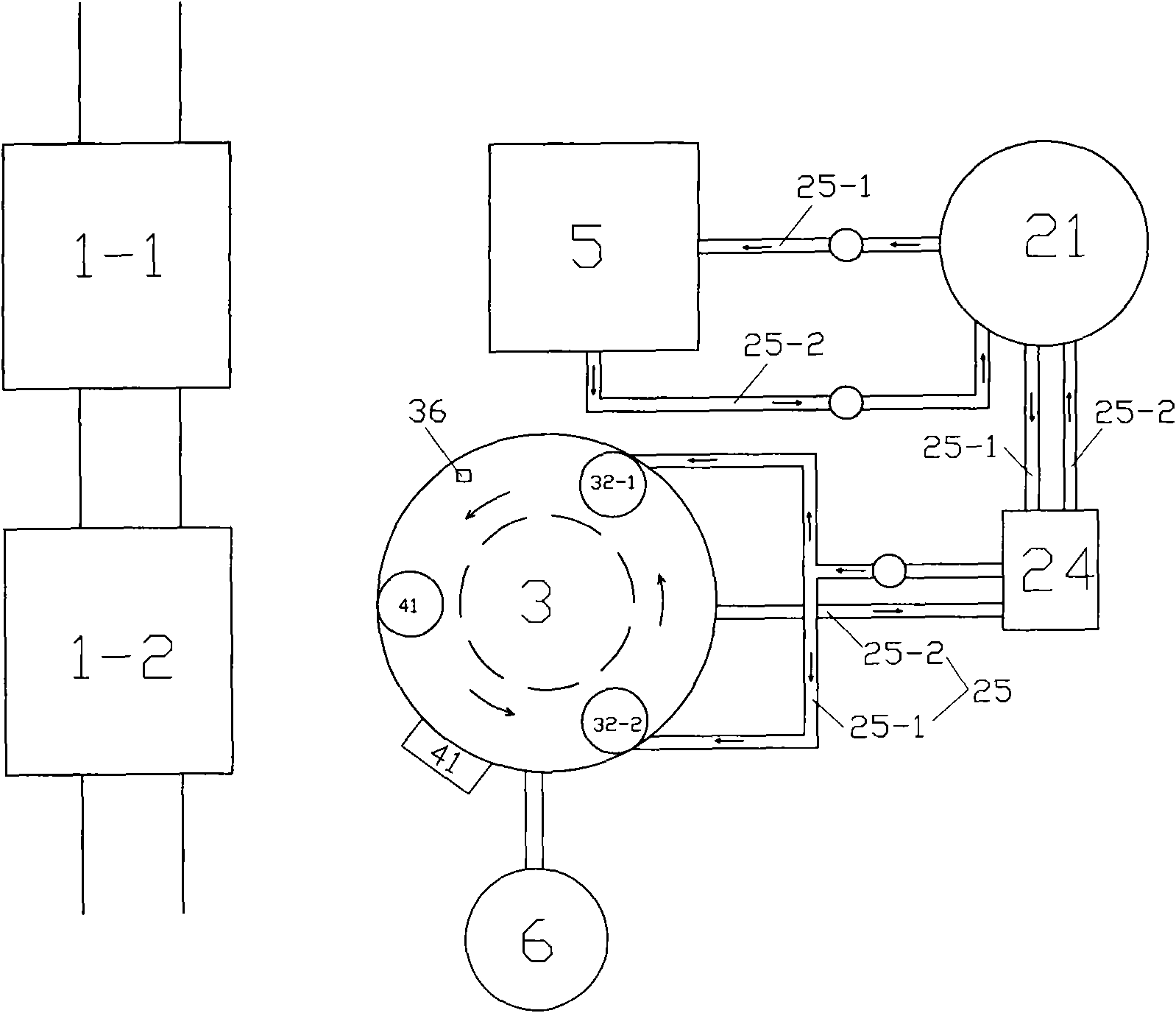

Wind power gear ring bearing seamless ring part process

InactiveCN107414425AImprove mechanical propertiesConsistent hardnessBearing componentsElectricityManufacturing technology

The invention relates to the technical field of bearing manufacturing, in particular to a process for a seamless ring of a wind power ring gear, including material preparation, heating, billet making, forging, residual heat quenching, tempering, and machining. The wind power ring gear seamless ring process of the present invention changes the hardness of the surface and the core of the large ring that cannot be achieved by the conventional heat treatment process, and the hardness of the entire circumference is consistent, which solves the problem of uneven hardness and does not meet the standard, and improves the wind power gear ring. The mechanical performance of the seamless ring is changed from the original casting and hole reaming process to rolling, which saves labor, materials and energy.

Owner:CHANGZHOU SHUANGQIANG MASCH MFG CO LTD

Free-cutting bismuth-nickel copper alloy material and preparation method thereof

The invention relates to a free-cutting bismuth-nickel copper alloy material which contains the following chemical components in percentage by mass: 2.2-2.4% of manganese, 0.3-0.4% of silicon, 8.5-10.2% of nickel, 0.08-0.12% of Hf, 0.35-0.40% of Bi and the balance of copper. The bismuth, silicon, Hf, manganese and other elements are added to enhance the wear resistance and toughness, obviously improve the cutting characteristic, save the cutting tool and cutting time, enhance the corrosion resistance and avoid lead pollution; and by reasonably controlling the after-casting treatment temperature and using waste copper as the raw material, the core hardness is basically consistent with the surface hardness, and the alloy quality is uniform. When the refining agent is used for casting production, the porosity in the casting is lowered by 1-2 degrees, the oxide inclusion content is at level 2 or so, and the yield is obviously enhanced.

Owner:CHUZHOU UNIV

Castlion electrode with low-carbon steel core wire

InactiveCN1483548AStrong crack resistanceReduce manufacturing costWelding/cutting media/materialsSoldering mediaPotassium ferrocyanideSodium nitrite

The present invention relates to a cast iron electrode with low-carbon steel core wire, and is characterized by that the extrior of the low-carbon steel core wire is covered with a layer of coating which is composed of 30-34% of reduced iron powder, 13-21% of marble flour, 13-17% of ilmenite, 4-8% of ocher powder, 2-8% of clay, 1-4% of potassium ferrocyanide and other 12 kinds of raw materials. Said electrode can meet requirements for welding several cast iron mother materials.

Owner:卢宏新

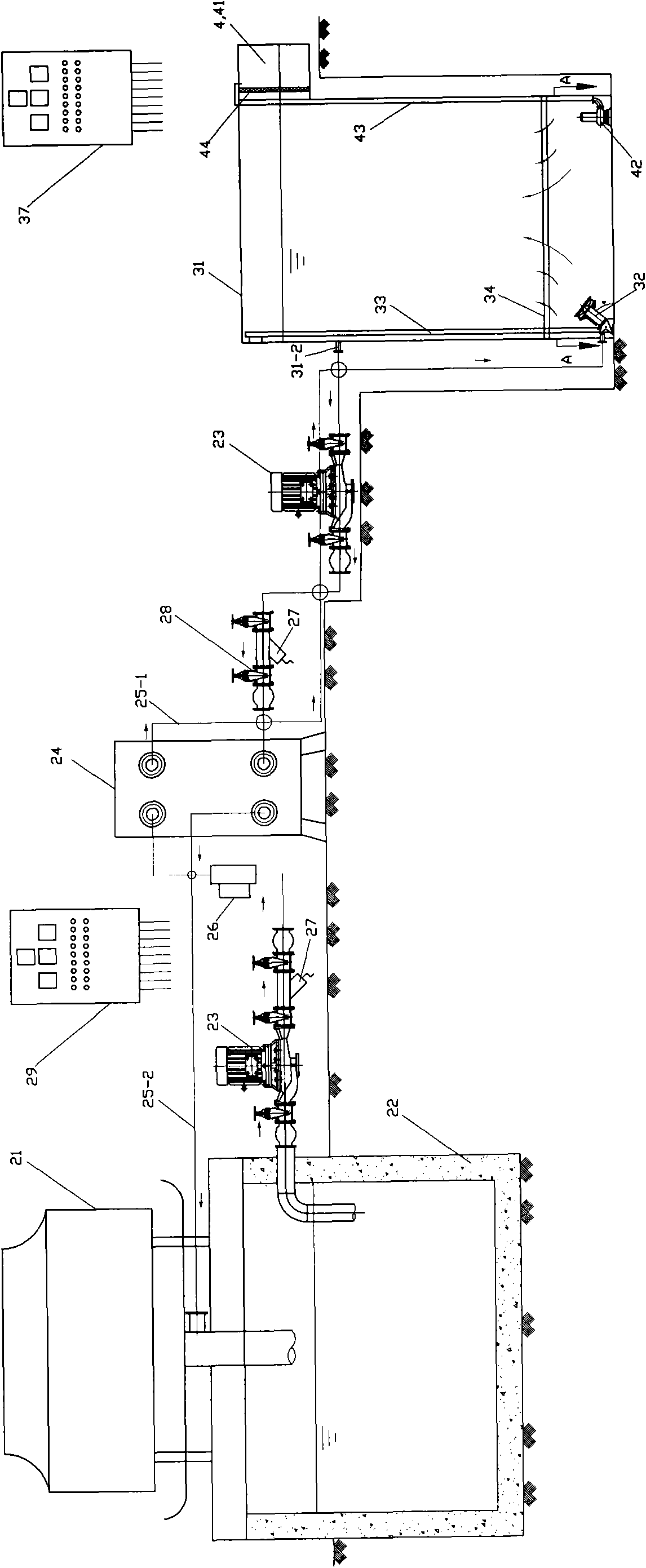

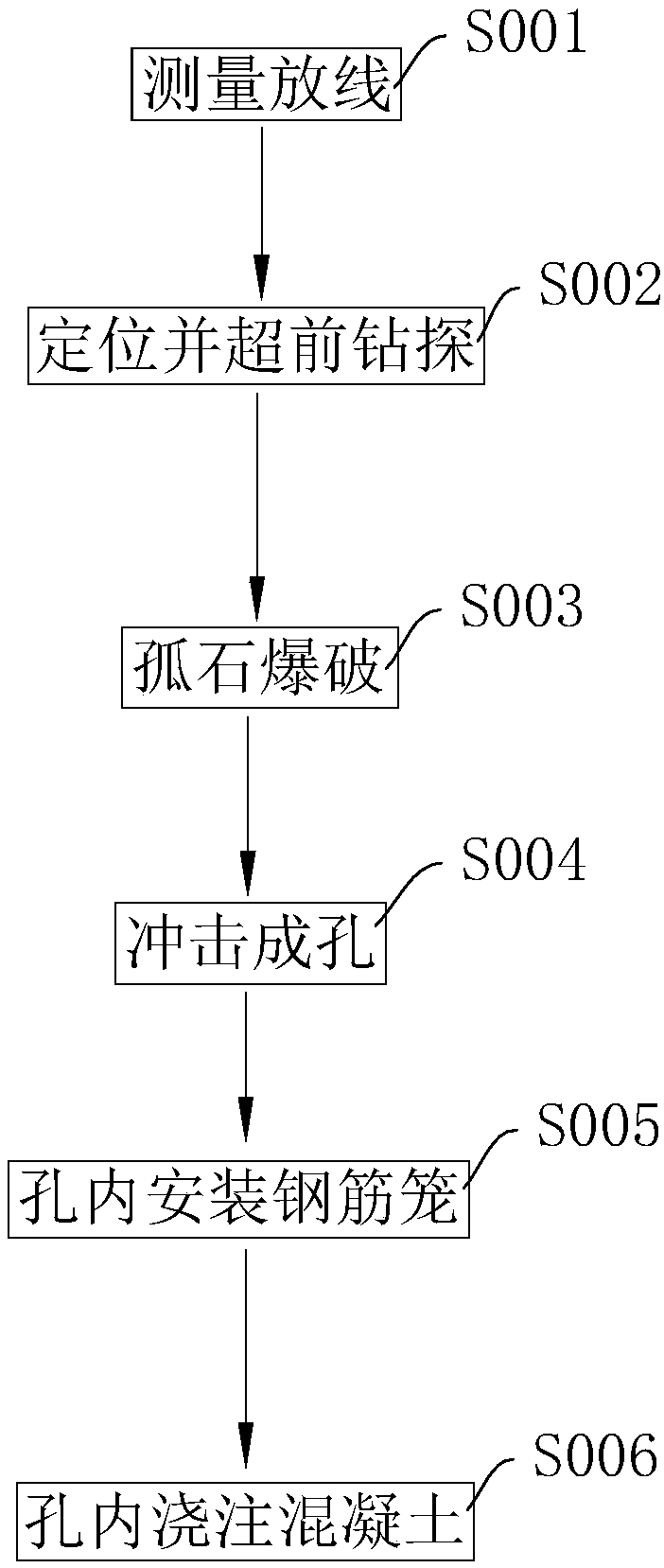

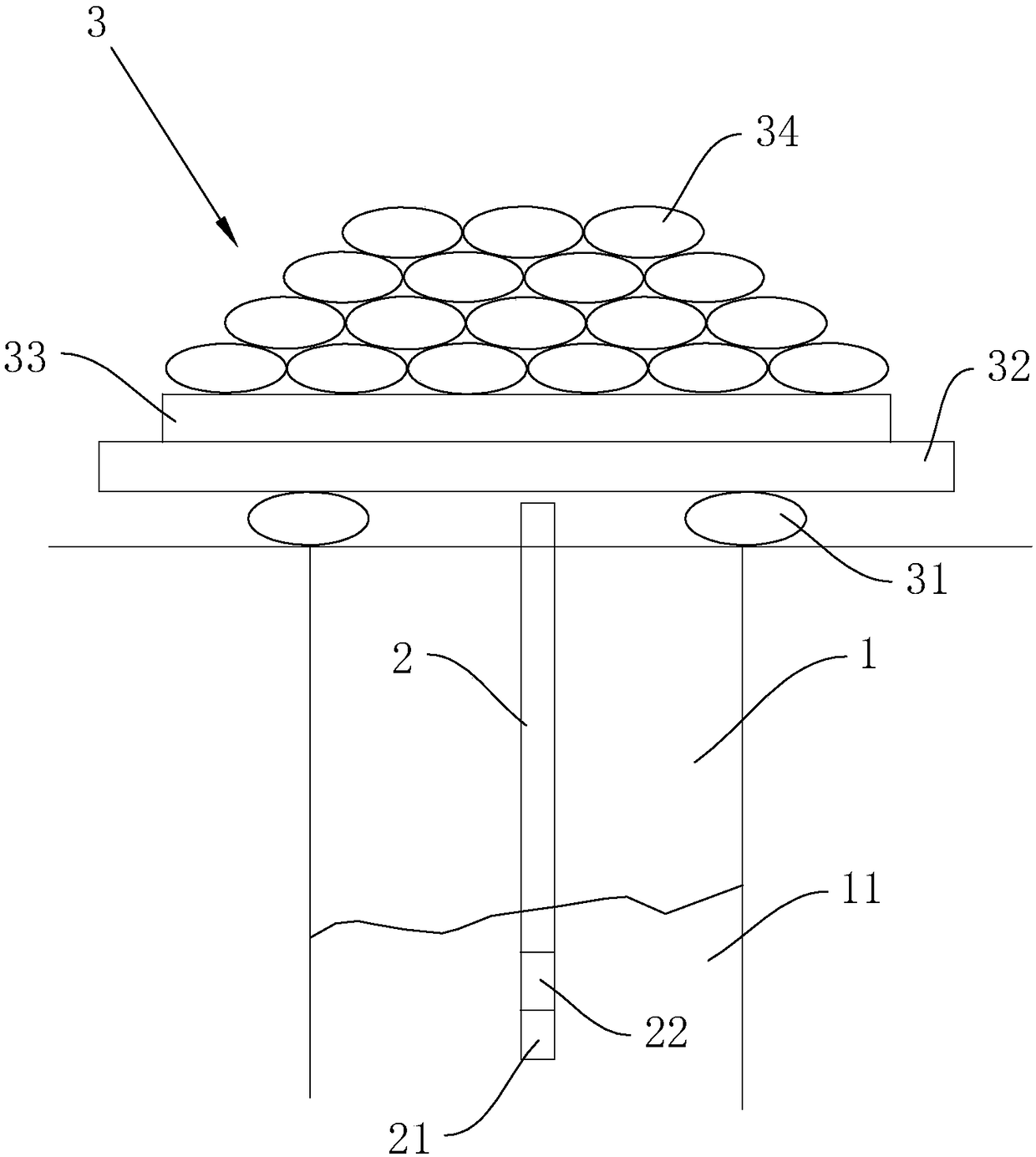

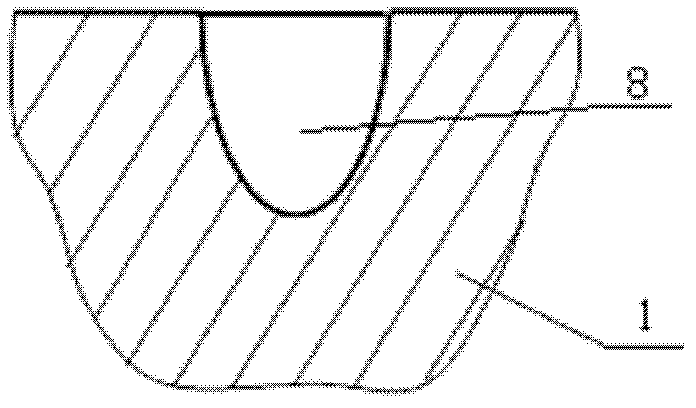

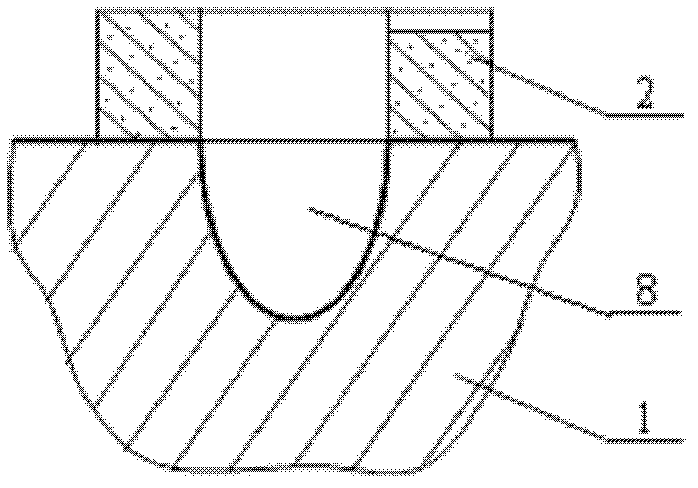

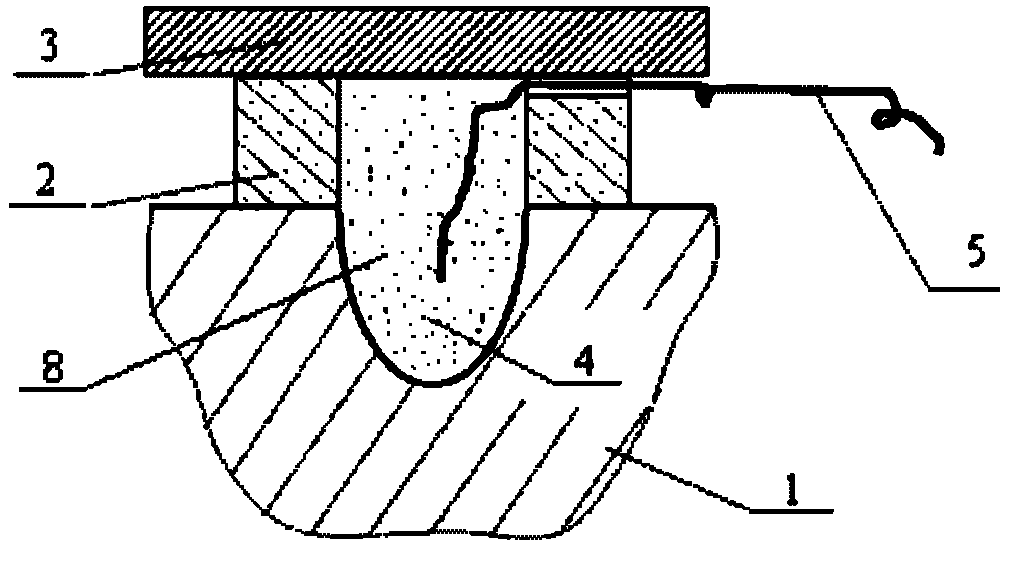

Construction method for impact-cone concrete pile

ActiveCN108589704AImprove verticalityEvenly distributed on the bearing surfaceBlastingBulkheads/pilesSoil massEngineering

The invention relates to the field of building construction. In order to solve the problem that the perpendicularity of a pile hole is low as a result of a locking hammer and an inclined hole, the invention provides a construction method for an impact-cone concrete pile. The stress face of an impact hammer is uniform, so that the perpendicularity of the pile hole is relatively high. The technicalscheme is as follows: the construction method comprises the following steps: surveying and setting out; positioning and drilling ahead; boulder blasting; impact holing, impacting again after hornstonebackfilling when a same horizontal section in the pile hole includes boulders and soil mass at the same time; mounting a steel reinforcement cage in the hole; and pouring concrete in the hole. The stress face of the impact hammer is uniformly distributed when the same horizontal section in the pile hole includes boulders and soil mass at the same time by backfilling the hornstones, the conditionthat the perpendicularity of the pile hole is reduced as the result of the locking hammer and the inclined hole is avoided, and the perpendicularity of the pile hole is ensured to further guarantee the quality of the impact-cone concrete pile.

Owner:广东梁亮建筑工程有限公司

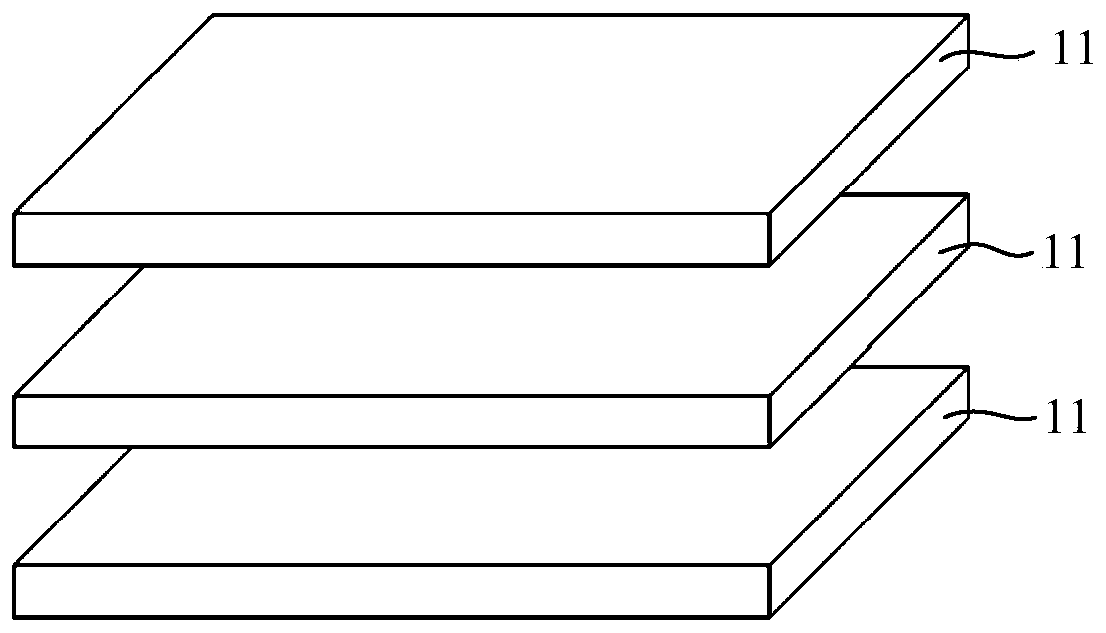

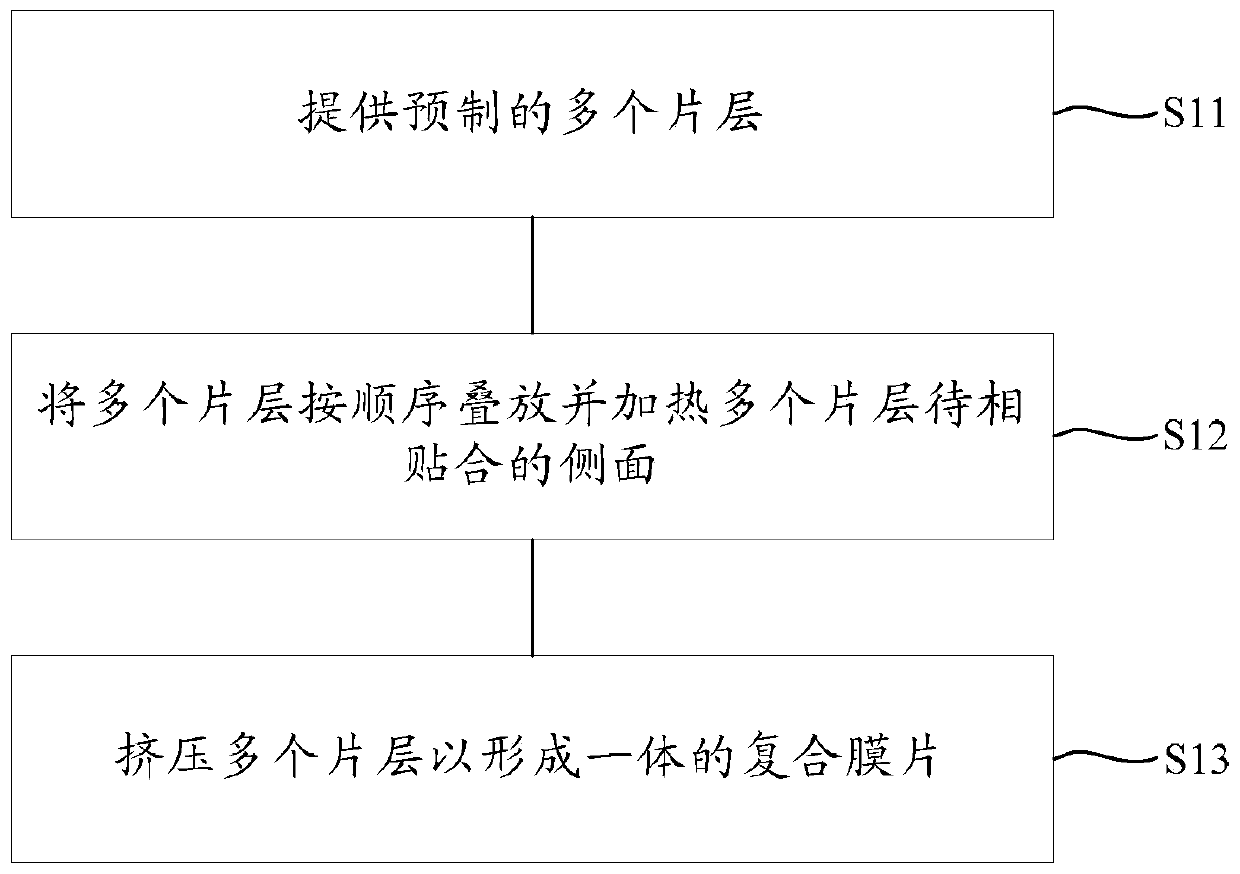

Multi-layer hot-pressing composite membrane and preparation method thereof

InactiveCN110920186AConsistent hardnessSolve the problem that the thickness is difficult to controlOthrodonticsSynthetic resin layered productsEconomic benefitsMechanical engineering

The invention relates to a multi-layer hot-pressing composite membrane and a preparation method thereof, wherein the multi-layer hot-pressing composite membrane comprises a plurality of prefabricatedsheet layers, and the sheet layers are sequentially arranged from top to bottom and are spliced into an integrated structure through hot pressing. The problem that the thickness of the sheet layers isdifficult to control is effectively solved, and the thickness of each sheet layer is accurately controlled, so that the hardness of the prepared membrane is consistent with the set hardness, the correction effect is ensured, a plurality of extrusion devices are not needed, and the economic benefit is good.

Owner:上海马可菲斯医疗技术有限公司

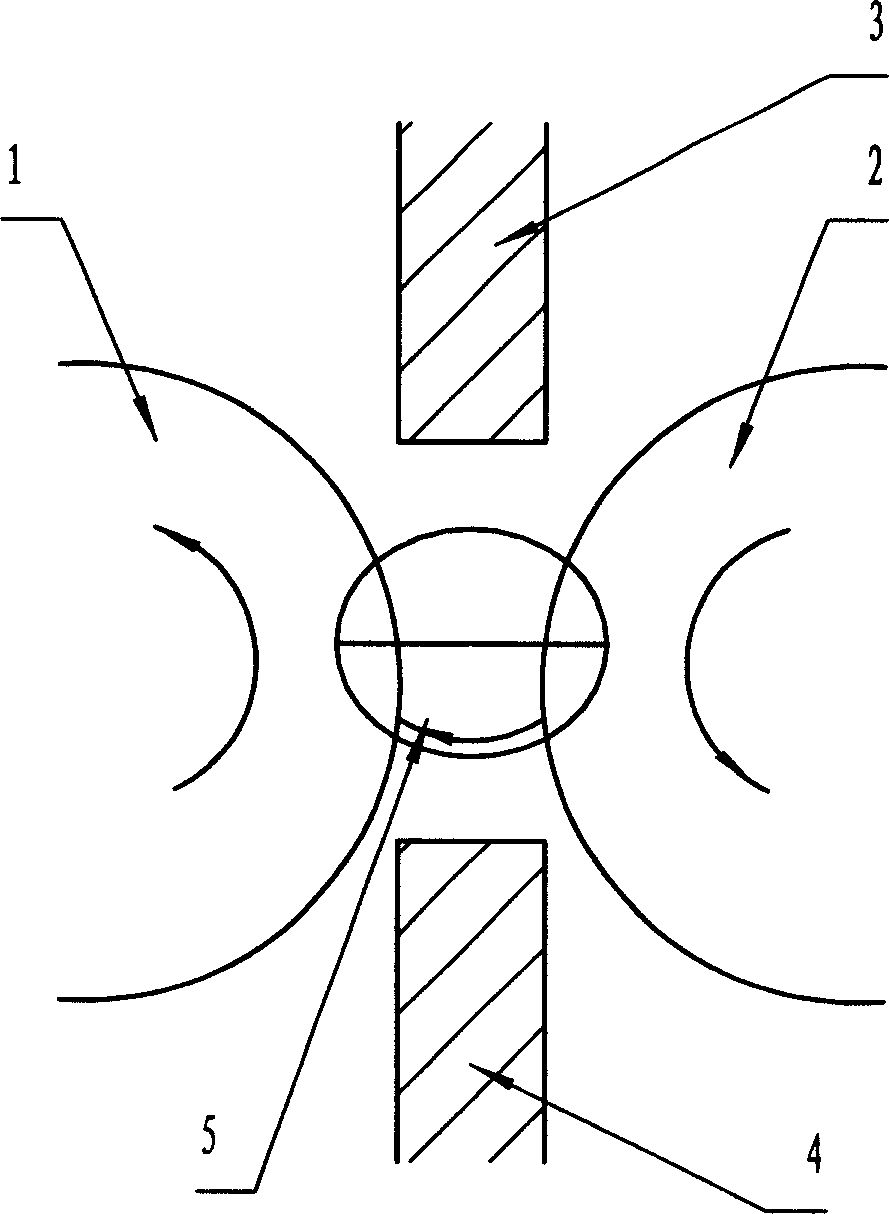

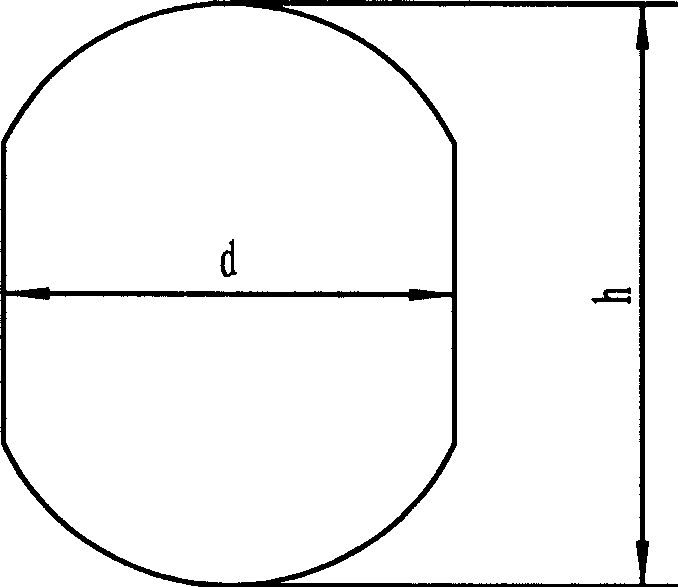

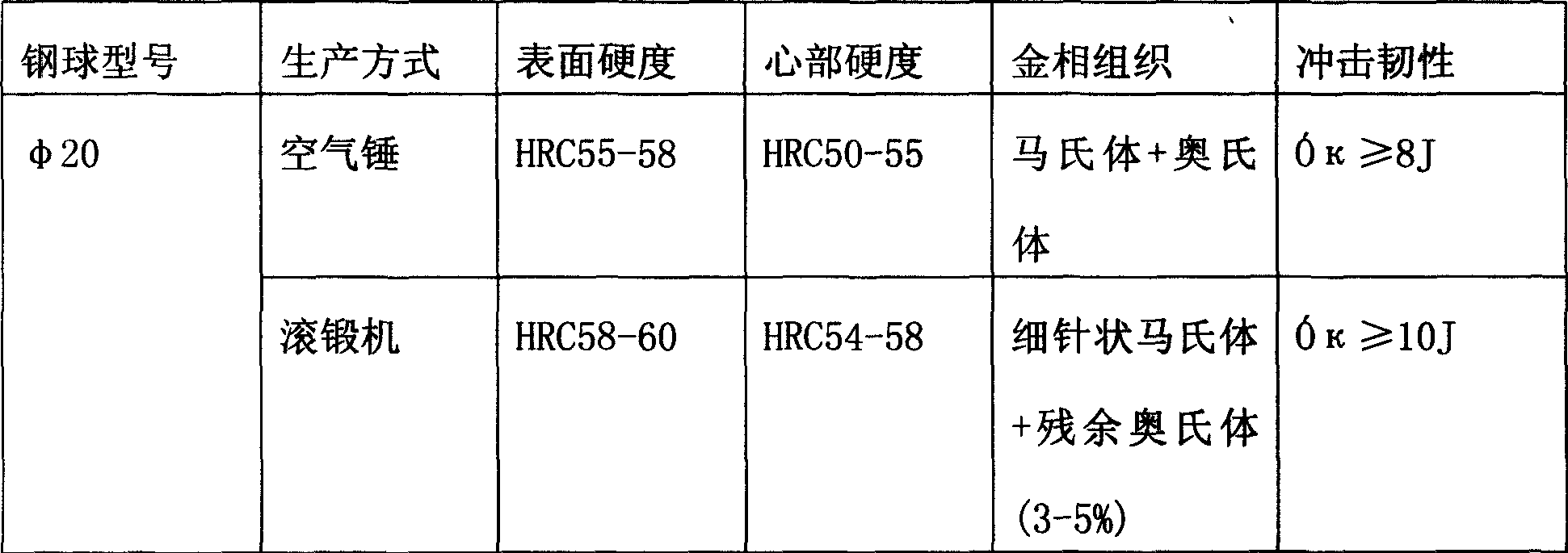

Grinding ball production method

ActiveCN1850435AImprove efficiencyReduce energy consumptionBearing componentsFurnace typesHardnessHeating furnace

A process of the grinding ball is disclosed in the invention. The square steel or the round steel is heated uniformly in the heating-furnace and forged into ellipse shape in the spacing mould by pneumatic hammer. Then the elliptical material is rolled to shape by the spiral roller and is treated in the hot water. The process is proper to producing grinding balls of all kinds of diameters.

Owner:SHANDONG HUAMIN STEEL BALL

High-performance rubber guide wheel for centerless grinding machine

The invention discloses a high-performance rubber guide wheel for a centerless grinding machine. The high-performance rubber guide wheel for the centerless grinding machine is prepared from, by weight, 56-70 parts of natural rubber, 20-45 parts of ethylene propylene diene monomer, 16-20 parts of styrene-butadiene rubber, 1.2-1.8 parts of zinc oxide, 0.7-1.5 parts of sulfur, 1-2 parts of dicumyl peroxide, 0.2-0.8 part of accelerant CBS, 0.8-1.5 parts of accelerant NOBS, 1-1.8 parts of accelerant PZ, 20-35 parts of modified epoxy resin, 15-35 parts of modified ferroferric oxide, 50-60 parts of white carbon black, 5-15 parts of nanometer glass beads, 0.5-2.5 parts of phenyltriethoxysilane, 0.8-1.6 parts of isopropyl dioleic(dioctylphosphate) titanate, 2-6 parts of caprolactam, 10-20 parts of nano ceramic microspheres, 4-10 parts of graphene, 5-15 parts of kaolin, 0.5-1.5 parts of stearic acid, 1-2 parts of pine tar, 1-2 parts of castor oil, 1-2 parts of coumarone and the like.

Owner:崇夕山

Production method of flame-retardant fiber board

The invention discloses a production method of a flame-retardant fiber board and relates to the technical field of preparation of refractory materials. The flame-retardant fiber board is prepared from the following raw materials in parts by weight: 100-120 parts of aluminium silicate fiber, 9-12 parts of silicon-aluminium sol, 12-15 parts of ethyl orthosilicate and 8-10 parts of additive. The production method of the flame-retardant fiber board comprises the following operation steps: weighing the raw materials according to the parts by weight, putting the raw materials into a thick liquid making machine, adding water and stirring for obtaining cotton pulp, preparing the cotton pulp into a board blank by adopting a vacuum moulding machine, putting the board blank into a drying chamber, and drying at the temperature of 100-140 DEG C until moisture content is lower than 8%, so that the flame-retardant fiber board is obtained. Compared with the prior art, the flame-retardant fiber board obtained by adopting the production method disclosed by the invention has low volume-weight, the hardness of the surface is consistent with that of the interior, the flame-retardant fiber board is applicable to processing of various finished products by virtue of mechanical equipment, and the finished products processed by adopting the flame-retardant fiber board is high in dimension accuracy.

Owner:LIUZHOU YITING TRADE

Cerium-containing leadless free-cutting zinc-copper-nickel alloy material and preparation method thereof

ActiveCN104032169AImprove corrosion resistanceGood cold and hot processing formabilityPorosityCupronickel

A cerium-containing leadless free-cutting zinc-copper-nickel alloy material comprises the chemical elements in percent by mass: 40-42% of Zn, 9-11% of Ni, 0.5-0.8% of Co, 0.15-0.18% of B, 0.05-0.08% of Mn, 0.03-0.05% of Ce, 0.05-0.08% of As, 0.08-0.1% of Hf, and the balance Cu. The zinc-copper-nickel alloy possesses the characteristics of excellent corrosion resistance and cold / hot processing formability originally owned by zinc-copper-nickel alloy; by adding B, Ce, Hf and other elements, the copper alloy is improved in cutting performance and electric conductivity, and the lead pollution problem is solved; and by reasonably controlling the processing temperature after casting and taking waste copper as a raw material, the hardness of the core part and the hardness of the surface are basically consistent, and the alloy quality is uniform. An employed refining agent is used for casting production, is capable of reducing the porosity degree of a casting by 1-2 degree and enabling the oxide inclusions to be around second grade, and helps to obviously improve the yield.

Owner:GUANGXI SHENGLONG METALLURGICAL CO LTD

Welding material for quickly welding and repairing defects of large-sized QT500-7 nodular cast iron parts and method

InactiveCN102528325AReduced whitening and cracking tendencyEnhanced weld crack resistanceWelding/cutting media/materialsSoldering mediaMetallurgy

Owner:XIAN UNIV OF TECH

Automatic double-Z-axis electric spark deposition device and method

The invention discloses an automatic double-Z-axis electric spark deposition device and method. A first alternating-current servo motor, a second alternating-current servo motor and a fourth alternating-current servo motor in the X-axis direction, the Y-axis direction and the Z1-axis direction are controlled to move so as to drive an electrode to move to a machining starting point of a workpiece surface; when a third alternating-current servo motor runs, a Z2-axis ram descends so as to ensure that the squeezing force of a rotary deposition gun on the workpiece is equal to a preset value; the first, second and fourth alternating-current servo motors run, and a movement orbit of the workpiece surface is formed by rotating the rotary deposition gun; the height of the electrode is adjusted according to a real squeezing force value measured by a force transducer, wherein when the squeezing force is greater than the upper difference of the preset value, the third alternating-current servo motor is reversed to drive the Z2-axis ram to ascend so as to drive the rotary deposition gun and the electrode to ascend, and when the squeezing force is smaller than the lower difference of the preset value, the third alternating-current servo motor rotates forward to drive the Z2-axis ram to descend; and the elevation movement in the Z2-axis direction is only related to the squeezing force, a deposition layer is more continuous, and the thickness of the deposition layer is more uniform.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

Environment-friendly zinc-copper-nickel alloy material and preparation method for same

The invention discloses an environment-friendly zinc-copper-nickel alloy material, which comprises the following chemical components in percentage by mass: 11.5 to 12.9 percent of nickel, 0.6 to 0.9 percent of cobalt, 2.3 to 2.5 percent of manganese, 0.15 to 0.18 percent of iron, 0.05 to 0.09 percent of bismuth, 21.5 to 21.9 percent of zinc, 0.5 to 0.6 percent of Si, 0.03 to 0.05 percent of Sb and the balance of copper. The alloy material contains bismuth, Si and Sb, is easy to cut, low in cost and anticorrosive, and has high comprehensive mechanical performance; after-casting treatment temperature is reasonably controlled, waste copper is used as a raw material, so that the hardness of a core part is substantially consistent with that of the surface, and the alloy material is uniform in quality; the alloy material is applied to the production of rods and wires, and can be used for precision parts, glasses accessories, zippers, keys, optical and clock industries and the like; a refining agent is used for casting production, so that the porosity of a casting can be reduced by 1 to 2 degrees, the content of oxide inclusions is at about level 2, and the yield is remarkably increased.

Owner:CHUZHOU UNIV

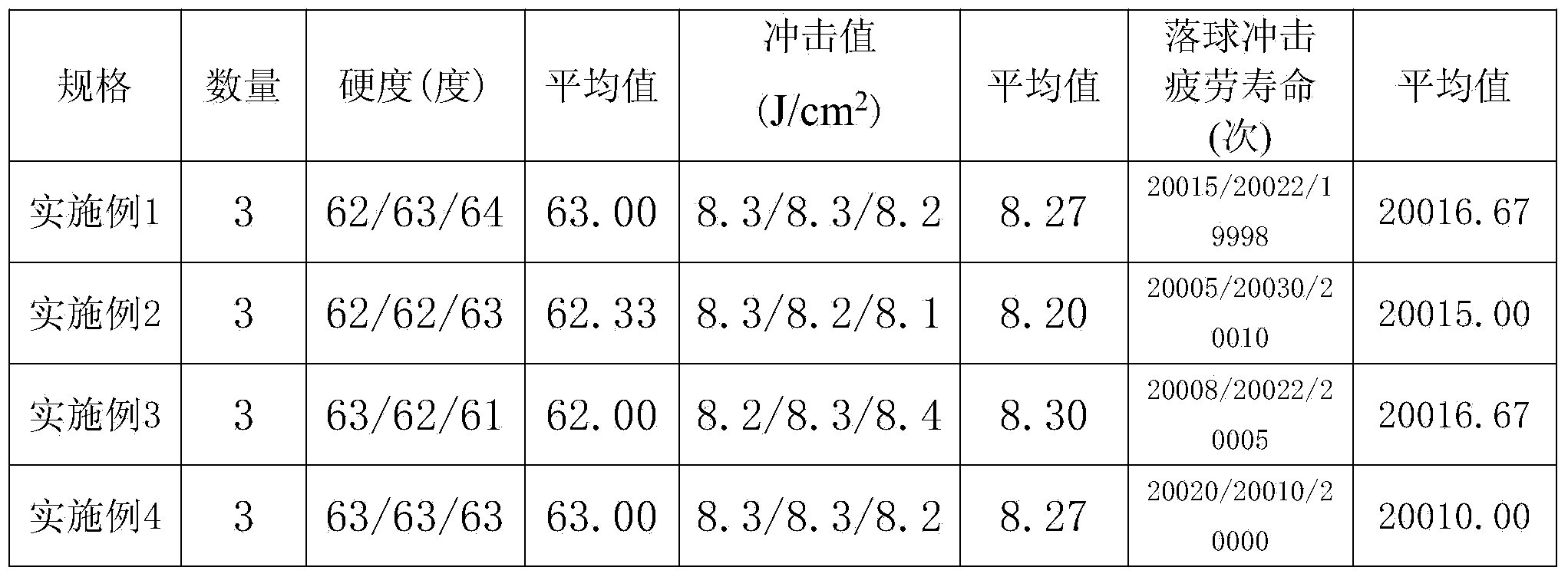

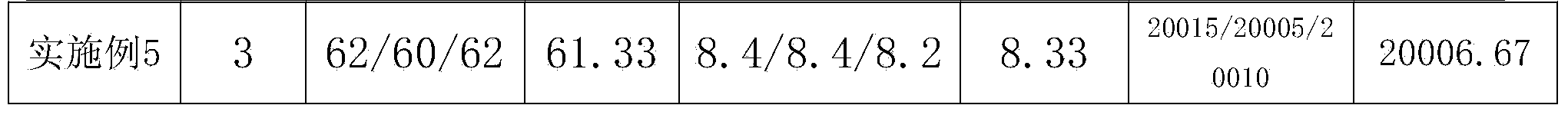

Wear-resistant ball with favorable mechanical properties

InactiveCN104164614AImprove mechanical propertiesImprove toughnessGrain treatmentsBall impactHardness

The invention discloses a wear-resistant ball with favorable mechanical properties, which comprises the following components in percentage by weight: 2.95-3.0% of C, 1.2-1.24% of Si, 0.7-0.8% of Mn, 21-21.5% of Cr, 0.1-0.2% of B, 0.4-0.45% of Mo, 0.04-0.06% of Re, at most 0.02% of S, at most 0.02% of P and the balance of Fe. By using the reasonable formula design and the reasonable smelting, casting and heat treatment techniques, the overall mechanical properties of the wear-resistant cast ball are enhanced. The casting time and casting duration are controlled to prevent the shrinkage porosity and shrinkage voids from generation and enhance the toughness and wear resistance of the wear-resistant cast ball. The Shore A-type hardness is greater than or equal to 62, the impact value is greater than or equal to 8.2 J / cm<2>, the falling ball impact fatigue life is greater than or equal to 20000 times, the core hardness and surface hardness are basically the same, and the breaking ratio is lower than 7%.

Owner:吴永

Integral abrasion resistant anti-ageing comb-shaped carrier roller for belt conveyer

InactiveCN105858113AExcellent contact sports performanceImprove sealingRollersAdhesive beltEngineering

Owner:云南小龙潭矿务局有限责任公司机修分公司

Low-chromium alloy cast ball

The invention discloses a low-chromium alloy cast ball, and belongs to the technical field of wear resistant materials. The low-chromium alloy cast ball comprises, by mass, 2.4-3.0% of C, 0.6-1.6% of Mn, 0.8-1.6% of Cr, 0.5-0.8% of Si, 0.05-0.1% of Cu, 0.02% or below of S, 0.02% or below of P, 0.1-1.0% of Mo, and the balance Fe. The cost of the ball is low, the HRC of the ball is not lower than 50, the impact value of the ball is not lower than 1.6J / cm<2>, the life span of fatigue of falling balls is not lower than 11000, the core portion hardness of the ball is basically consistent with the surface hardness of the ball, and the toughness of the ball is good.

Owner:安徽新马铸造科技有限公司

Wear-resistant zinc alloy material and preparation method thereof

The invention relates to a wear-resistant zinc alloy material which contains the following chemical components in percentage by mass: 12.6-13.8% of aluminum, 3.6-3.8% of magnesium, 2.1-2.3% of silicon, 4.2-4.4% of nickel, 0.2-0.4% of cerium, 0.15-0.25% of Y, 2.0-2.3% of Mo, 0.02-0.04% of Ga, 0.12-0.18% of In and the balance of zinc. The crystal structure of the alloy is denatured, so that the alloy coating can not easily shed, the friction factor is lowered, and the wear resistance is enhanced. By adding the magnesium, aluminum, nickel, Mo and other elements, the strength of the zinc alloy is increased, and the wear resistance is enhanced. The alloy has favorable processability, and can be processed into bearing bushes, shaft sleeves, worm gears, sliders, screw nuts and other series antiwear products. When the refining agent is used for casting production, the porosity in the casting is lowered by 1-2 degrees, the oxide inclusion content is lowered by 2 levels or so, and the yield is obviously enhanced.

Owner:ANHUI KING AUTO ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com