Pit-type nitriding furnace

A technology of nitriding furnace and furnace cover, applied in coating, metal material coating process, solid-state diffusion coating, etc., can solve problems such as failure to meet customer requirements, uneven heating of inner furnace, inconsistent product hardness, etc. Achieve equipment durability, improve utilization and productivity, and achieve consistent hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

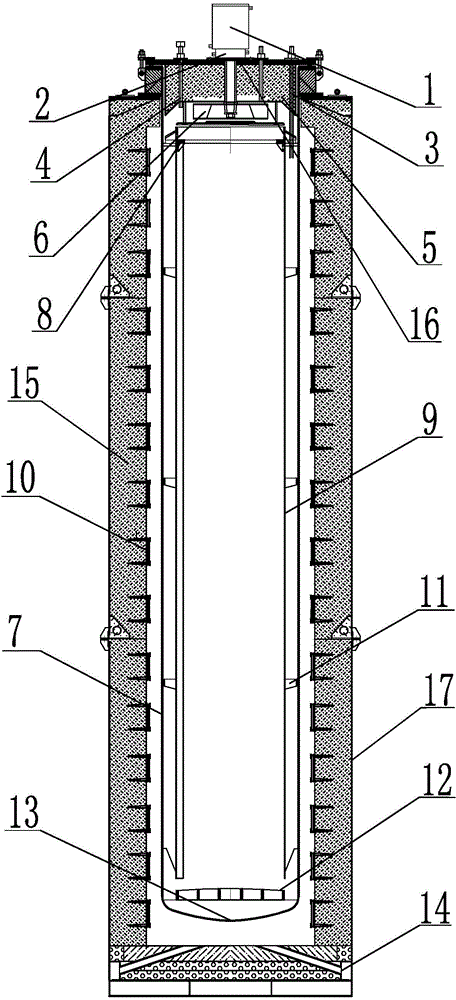

[0014] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] like figure 1 A well-type nitriding furnace shown includes a furnace shell 17, a furnace cover 16, an inner furnace 7 and an air guide barrel 9, the furnace cover 16 is installed on the top of the furnace shell 17, and the furnace shell 17 inner wall A layer of furnace lining 15 is provided, and a heating element 10 is evenly installed on the inner wall of the furnace lining 15. The heating element 10 is a resistance band, and the resistance band is fixed on the inner wall of the furnace lining 15 through a ceramic screw rod, which has a simple structure and is easy to install. It is easy to replace, improves the radiation coefficient of the electric heating element, strengthens the heat exchange in the furnace, improves the thermal efficiency of the furnace, prolongs the service life of the element, and improves the quali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com