Automatic double-Z-axis electric spark deposition device and method

An electric spark deposition, Z-axis technology, applied in metal material coating process, fusion spraying, coating, etc., can solve the problem of difficult control of electrode moving track and speed residence time, unclear manual pressure, discontinuous deposition layer, etc. problems, to achieve the effect of continuous deposition layer, uniform thickness of deposition layer, and expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

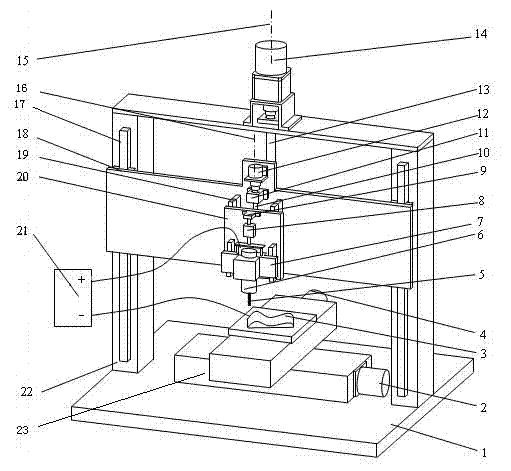

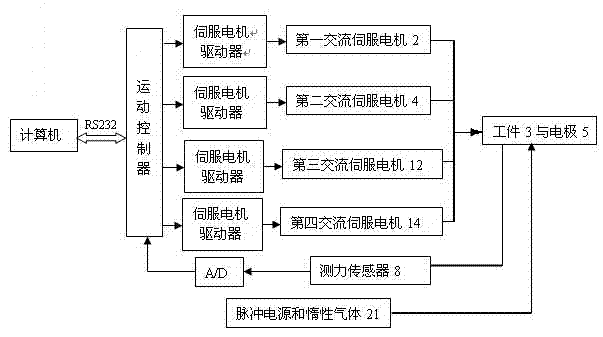

[0016] see figure 1 , the bottom of the present invention is the base 1, the XY platform 23 is placed on the base 1, the workpiece 3 is placed on the XY platform 23, and the workpiece 3 is clamped on the XY platform 23 with a clamp. The first AC servo motor 2 is installed on the X axis direction of the XY platform 23, and the XY platform 23 is driven by the first AC servo motor 2 to move along the X axis direction; the second AC servo motor 4 is installed on the Y axis direction of the XY platform 23 , the XY platform 23 is driven by the second AC servo motor 4 to move along the Y-axis direction.

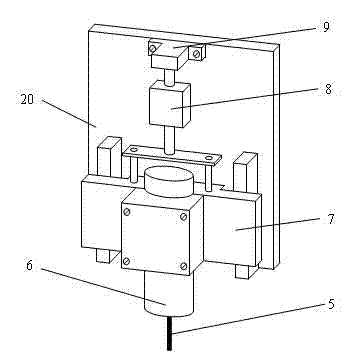

[0017] Above the workpiece 3 is an electrode 5, the electrode 5 is perpendicular to the XY platform 23, the upper end of the electrode 5 is fixedly connected to the rotary deposition gun 6, and the electrode 5 is fixed on the rotary deposition gun 6 and can rotate at high speed. The rotary deposition gun 6 is fixed on the deposition gun bracket 7, and the deposition gun bracket 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com