Multi-layer hot-pressing composite membrane and preparation method thereof

A technology of composite diaphragm and lamella, applied in the field of orthodontic treatment, can solve the problems of good economic benefit and difficult to control the thickness of lamella, and achieve the effect of good economic benefit, reduction of production cost and guarantee of orthodontic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

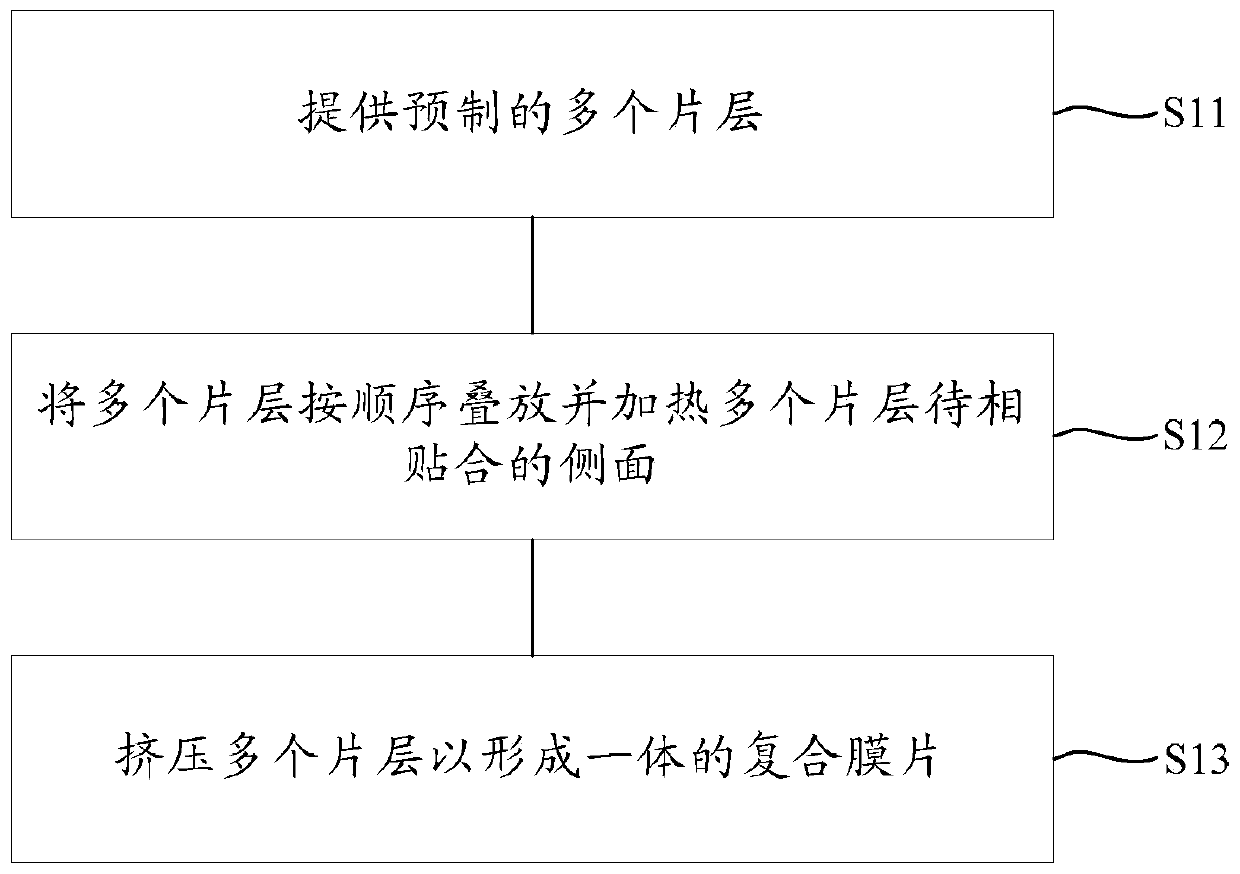

[0024] refer to figure 1 , the present invention provides a multi-layer hot-pressed composite membrane and a preparation method thereof, by determining the thickness of the composite membrane to be formed according to the actual orthodontic plan, and then using a forming equipment to pre-fabricate the sheet, by adding or Reduce the number of layers to adjust the thickness of the composite membrane to be formed, and combine multiple layers into a composite membrane by hot pressing, so the actual preparation does not require multiple extruders to run at the same time, reducing production costs , in addition, because the sheet is prefabricated, the overall temperature of the sheet is not high during the hot pressing process, and the phenomenon of overall thermal melting will not occur, so the deviation between the actual thickness of each sheet an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com