Integral abrasion resistant anti-ageing comb-shaped carrier roller for belt conveyer

An integral, anti-aging technology, applied in the direction of rollers, conveyor objects, transportation and packaging, etc., can solve the problems of easily scratched tape, large dust on peeling tape, easy wear of rubber ring, etc., to prolong service life and work. The effect of excellent performance, contact motion performance, replacement and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and example further illustrate the present invention.

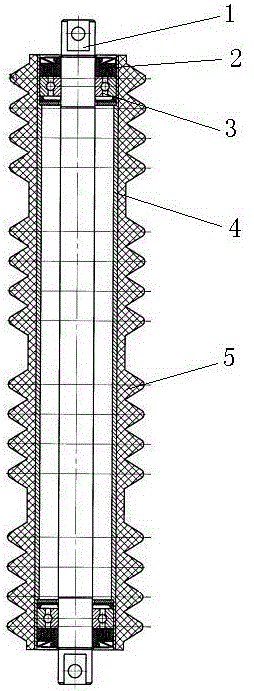

[0026] Such as figure 1 As shown, the idler shaft 1, the idler cylinder 4 and the bearing 3, and the structural relationship among the three are the same as the existing ones. The seal 2 is arranged on the outside of the bearing, and a seal is provided at each end of the idler cylinder, so as to seal the two bearings in the idler cylinder from external factors such as dust and rain. The sealing member can be a commercially available product, and can be purchased according to specifications and models.

[0027] The integral rubber comb ring 5 is made according to the size of the idler cylinder. It can be divided into upper and lower parts according to the symmetrical plane of the longitudinal section, and formed with corresponding molds. Set on the idler cylinder and rotate together with the idler cylinder. It can also be divided into left and right parts along the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com