Wear-resistant ball with favorable mechanical properties

A wear-resistant ball and mechanics technology, applied in the field of wear-resistant balls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

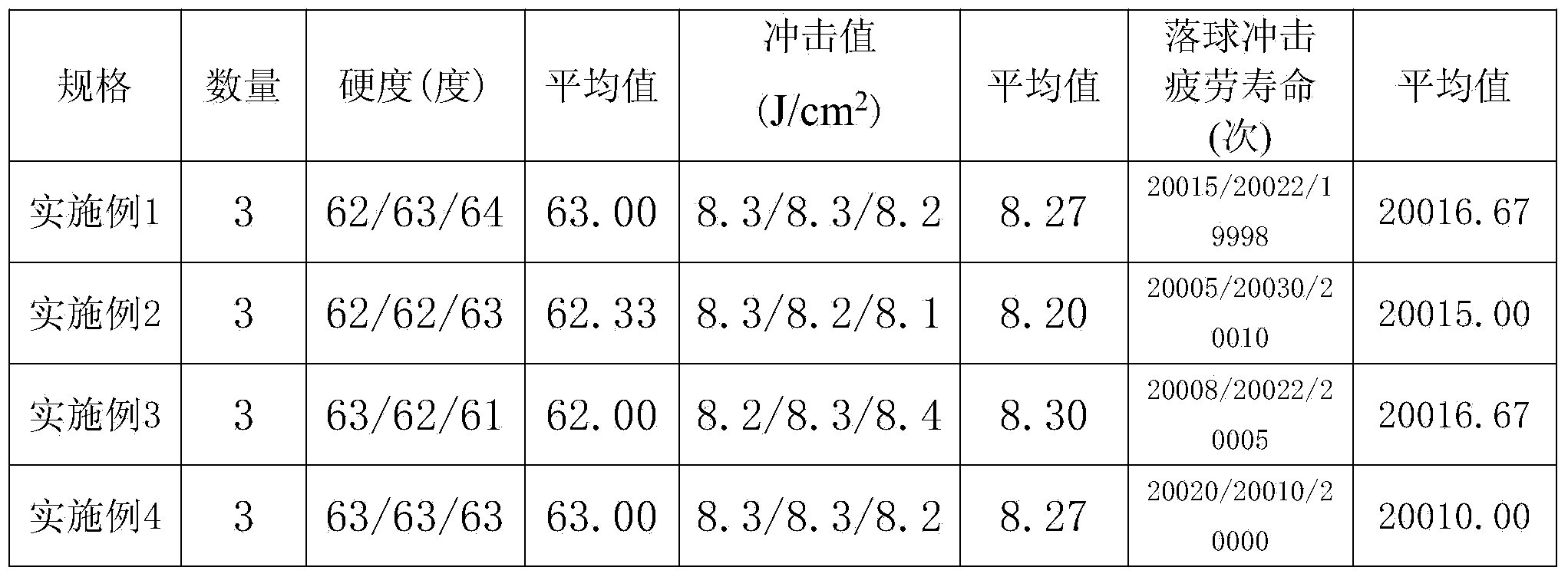

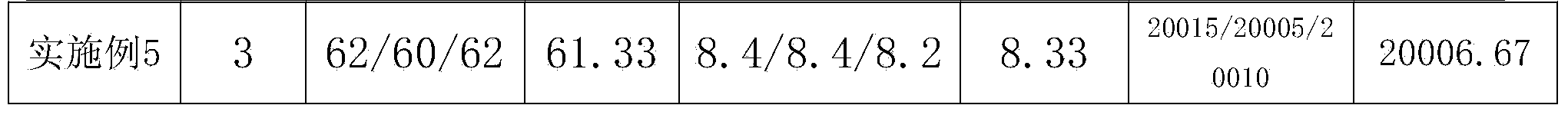

Embodiment 1

[0031] A wear-resistant ball with good mechanical properties, the components and weight percentages are: C: 2.95%, Si: 1.24%, Mn: 0.7%, Cr: 21.5%, B: 0.1%, Mo: 0.45%, Re: 0.04%, S: 0.02%, P: 0.02%; the balance is Fe.

[0032] The production method of wear-resistant ball comprises the following steps:

[0033] (1) Add steel scrap, pig iron, and ferrosilicon, and use an intermediate frequency furnace for smelting. When the temperature is 1520°C, add ferromanganese that has been preheated, and perform component analysis and adjustment; when the temperature is 1570°C, add aluminum strips for deoxidation treatment, and Carry out slag removal treatment;

[0034] (2) add Re and carry out metamorphic treatment: particle size 1.0mm, when 55% molten iron is poured into ladle, add with molten iron;

[0035] (3) Casting: Casting is carried out 6 minutes after step (2) is completed, the temperature is 1380°C, and the casting time is 6 minutes;

[0036] (4) Unpacking and grinding, the un...

Embodiment 2

[0040] A wear-resistant ball with good mechanical properties, the components and weight percentages are: C: 3.0%, Si: 1.2%, Mn: 0.8%, Cr: 21%, B: 0.2%, Mo: 0.4%, Re: 0.06%, S: 0.01%, P: 0.01%; the balance is Fe.

[0041] The production method of wear-resistant ball comprises the following steps:

[0042] (1) Add steel scrap, pig iron, and ferrosilicon, and use an intermediate frequency furnace for smelting. When the temperature is 1530°C, add ferromanganese that has been preheated, and perform component analysis and adjustment; when the temperature is 1560°C, add aluminum strips for deoxidation treatment, and Carry out slag removal treatment;

[0043] (2) add Re to carry out metamorphic treatment: particle size 1.2mm, when 50% molten iron is poured into ladle, add with molten iron;

[0044] (3) Casting: 8 minutes after step (2) is completed, the casting is carried out at a temperature of 1360° C., and the casting time is 8 minutes;

[0045] (4) Unpacking and grinding, the u...

Embodiment 3

[0049] A wear-resistant ball with good mechanical properties, the components and weight percentages are: C: 3.0%, Si: 1.2%, Mn: 0.75%, Cr: 21.3%, B: 0.15%, Mo: 0.45%, Re: 0.05%, S: 0.016%, P: 0.015%; the balance is Fe.

[0050] The production method of wear-resistant ball comprises the following steps:

[0051] (1) Add steel scrap, pig iron, and ferrosilicon, and use an intermediate frequency furnace for smelting. When the temperature is 1525°C, add ferromanganese that has been preheated, and perform component analysis and adjustment; when the temperature is 1565°C, add aluminum strips for deoxidation treatment, and Carry out slag removal treatment;

[0052] (2) add Re to carry out metamorphic treatment: particle size 1.1mm, when 52% molten iron is poured into ladle, add with molten iron;

[0053] (3) Casting: Casting is carried out 7 minutes after step (2) is completed, the temperature is: 1370°C, and the casting time is 7 minutes;

[0054] (4) Unpacking and grinding, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| crush indicators | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com