Method for manufacturing seamless ring and special heat treatment system thereof

A heat treatment system and manufacturing method technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as the inability to meet the quality requirements of large seamless rings, avoid inconsistent quality performance, ensure uniform rotation, and eliminate external and internal Inconsistent effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (Embodiment 1, manufacturing method of seamless ring)

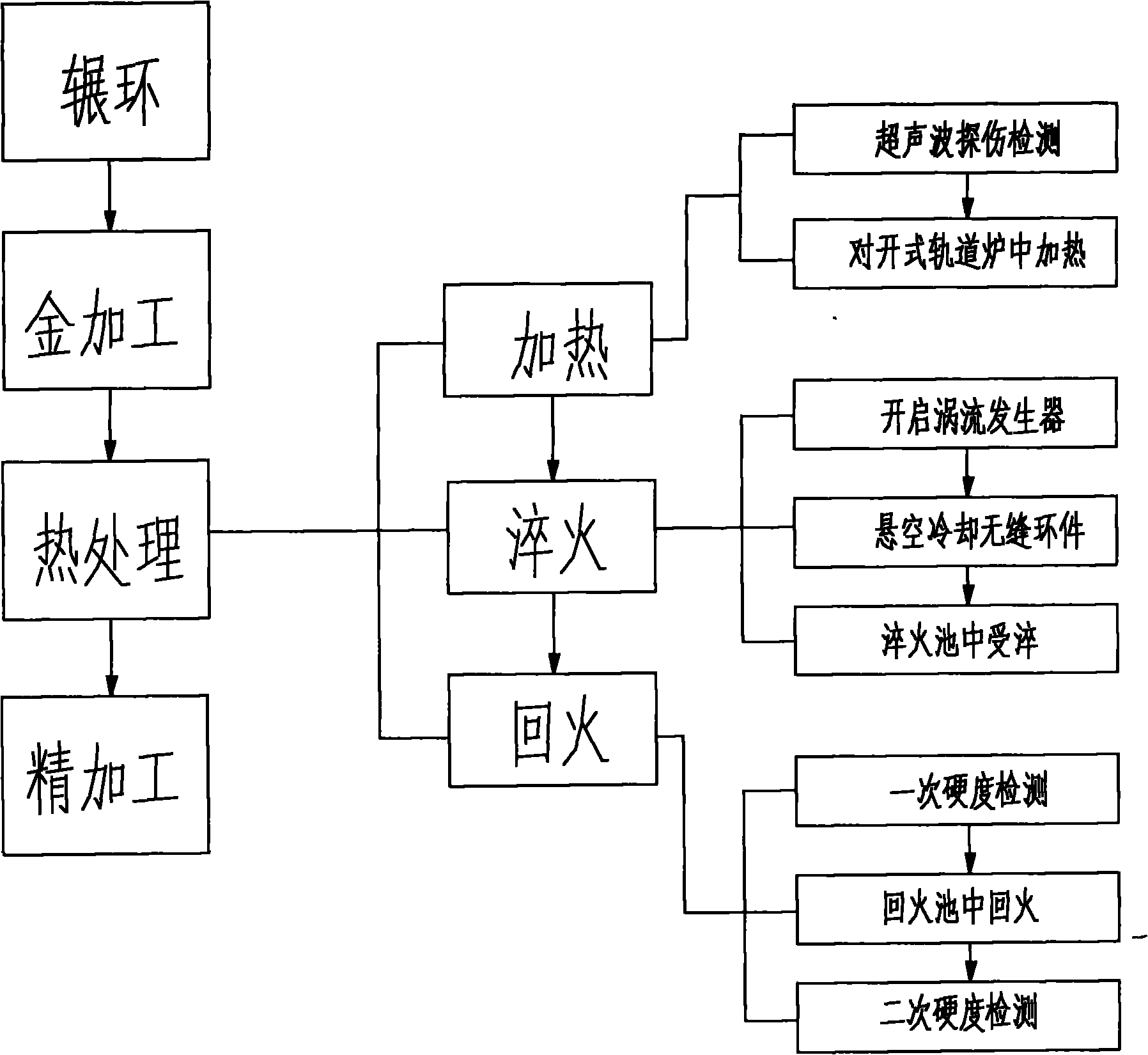

[0050] See figure 1 , the manufacturing method of the seamless ring in this embodiment includes four continuous processes of ring rolling, gold processing, heat treatment and finishing. The main materials for manufacturing seamless rings are 42CrMo and 16Mn,

[0051] The first process - ring rolling: first of all, the material inspection and testing are carried out. Calculate the volume of the material according to the size of the product to be produced. After sawing the material, put it into the furnace for heating, and then use a 2,000-ton hydraulic press and a 5-ton electro-hydraulic hammer to punch the blank. The blank is clamped on the working table of the automatic ring rolling machine by a manipulator and a rail car, and the completion is complete. The rolling process of seamless rings that meets the requirements of product drawings.

[0052] The second process - metal processing: the rolled seamless ring...

Embodiment 2

[0059] (Example 2, special heat treatment system for the seamless ring manufacturing method)

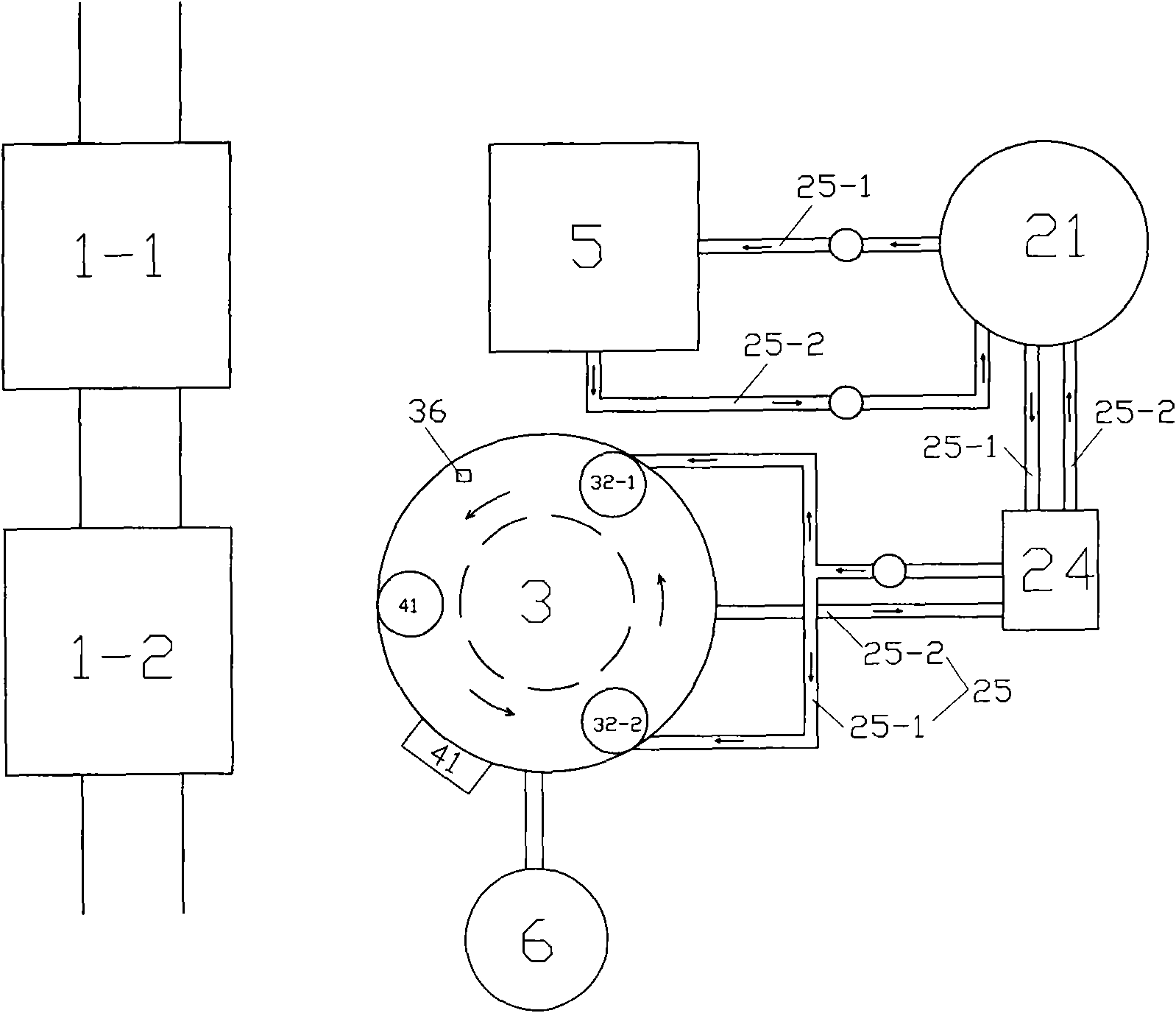

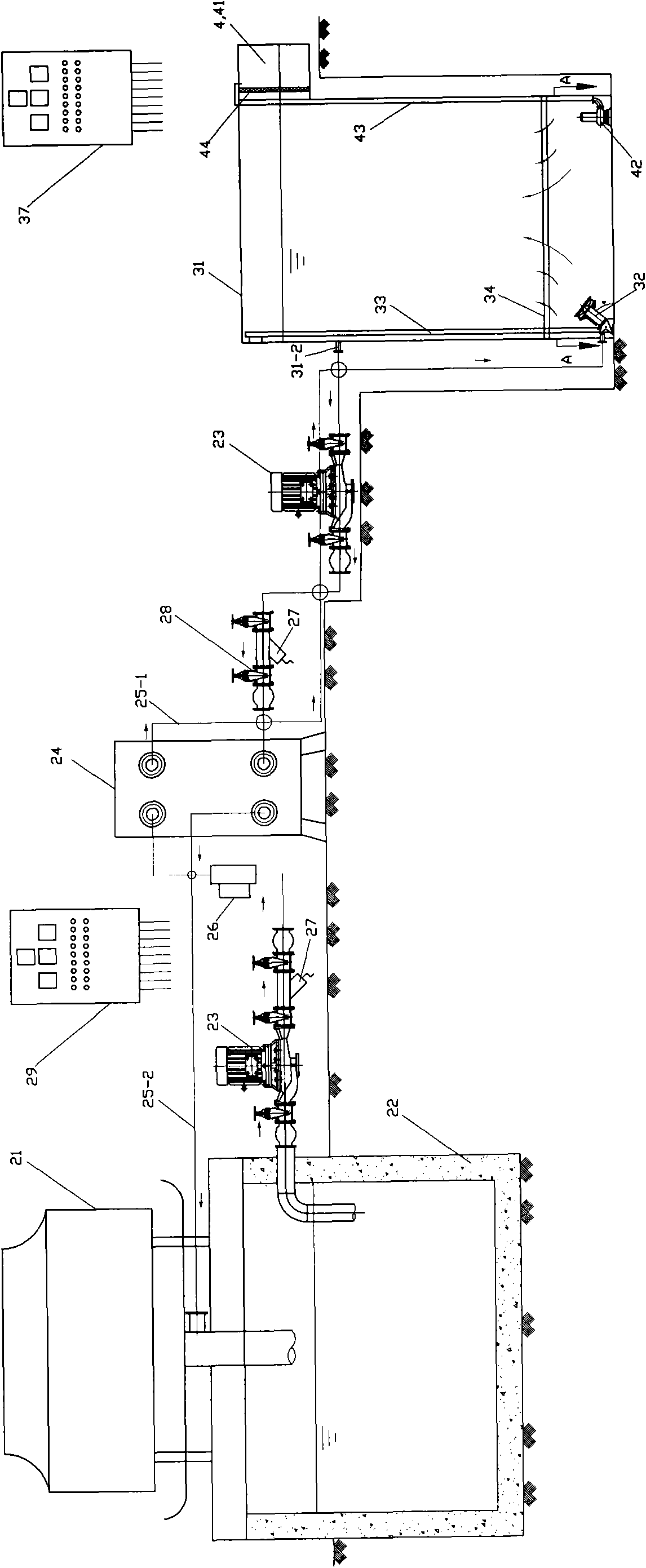

[0060] See Figure 2 to Figure 8 , the special heat treatment system in the seamless ring manufacturing method in Example 1 includes split orbital furnaces 1-1, 1-2, cooling cycle mechanism 2, quenching pool 3, filtering pool 4, tempering pool 5 and equipment Liquid pool6.

[0061] See image 3 The cooling cycle mechanism 2 includes a cooling tower 21, a cooling water pool 22 located below the cooling tower 21, two circulating pumps 23, a heat exchanger 24, a pipeline 25, an electronic descaler 26, two iron oxide chips filters 27, A plurality of pipeline control valves 28 and an electric control cabinet 29. The pipeline 25 of the cooling cycle mechanism 2 includes 2 road cold water pipelines 25-1 and 2 road hot water pipelines 25-2, and 1 road cold water pipeline 25-1 communicates with the cooling water pool 22, the heat exchanger 24 and the pool body 31. The cold water inlet 31-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com