Welding material for rapidly welding and repairing defects of large-scale grey iron casting and repairing method thereof

A welding material and rapid welding technology, applied in welding/cutting media/materials, welding media, welding equipment, etc., can solve the problems of energy consumption, secondary environmental pollution, high energy consumption, etc., and achieve enhanced crack resistance of welds , Good workability and crack resistance, the effect of rapid welding repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] First, the welding consumables for welding and repairing of large HT150 gray iron castings are prepared, which are uniformly mixed by weight percentage of powders of the following components: Fe 2 o 3 35%, Al28%; Na 2 CO 3 1.5%, Na 2 B 4 o 7 5%, CaF 2 5%, CaO7%; and G5%, pig iron 7.5%, SiO 2 6%, the total weight is 100%.

[0053] Then, using the above-mentioned prepared welding materials, implement according to the following steps:

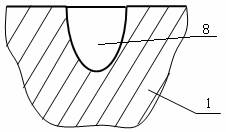

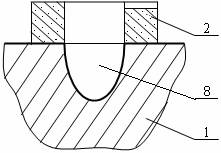

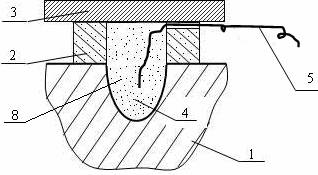

[0054] Step 1. Grinding the defective part of the defective casting 1 to process the bevel 8;

[0055] Step 2. Shape around the upper edge of the groove 8. Use molding sand or cement to build the embankment 2 along the upper periphery of the defect groove 8, and leave the introduction groove of the ignition fuze 5 on the upper edge of the embankment 2;

[0056] Step 3, filling the welding material: filling the corresponding welding material 4 into the groove 8 and the embankment 2, embedding the ignition fuze 5, compacting and fil...

Embodiment 2

[0062] First, the welding consumables for the welding and repairing of large HT150 gray iron castings are prepared, which are composed of powders of the following components by weight percentage: Fe 2 o 3 33%, Al30%; Na 2 CO 3 1.4%, Na 2 B 4 o 7 6%, CaF 2 4%, CaO8%; and G4%, pig iron 8.6%, SiO 2 5%, the total weight is 100%.

[0063] Then, adopt the step of embodiment 1, implement welding repair.

Embodiment 3

[0065] First, the welding consumables for the welding and repairing of large HT150 gray iron castings are prepared, which are composed of powders of the following components by weight percentage: Fe 2 o 3 36%, Al27%; Na 2 CO 3 1.6%, Na 2 B 4 o 7 4%, CaF 2 4%, CaO9%; and G4%, pig iron 7.4%, SiO 2 7%, the total weight is 100%.

[0066] Then, adopt the step of embodiment 1, implement welding repair.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com