Aluminothermy welding method of aluminium alloy

A technology of aluminothermic welding and aluminum alloy, which is applied in the direction of aluminothermic welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of no power supply, thermal expansion and contraction properties are not completely the same, weld structure and density are not very high, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] 1. Example of aluminothermic welding of aluminum alloy:

[0018] Taking the rapid welding of the broken shaft test piece under field conditions as an example, the process steps are as follows:

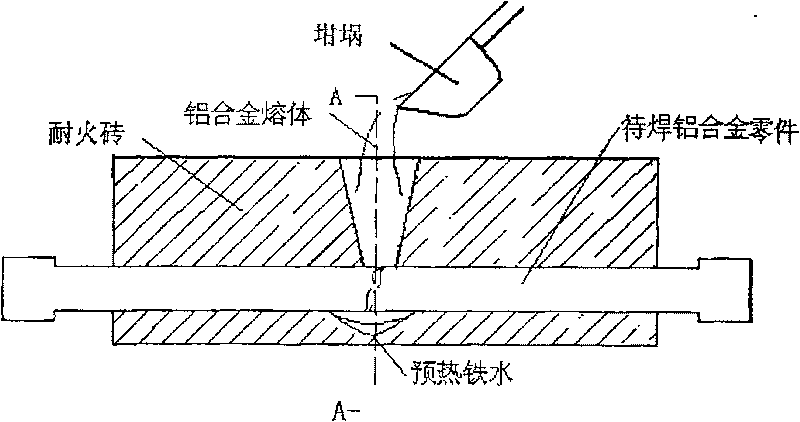

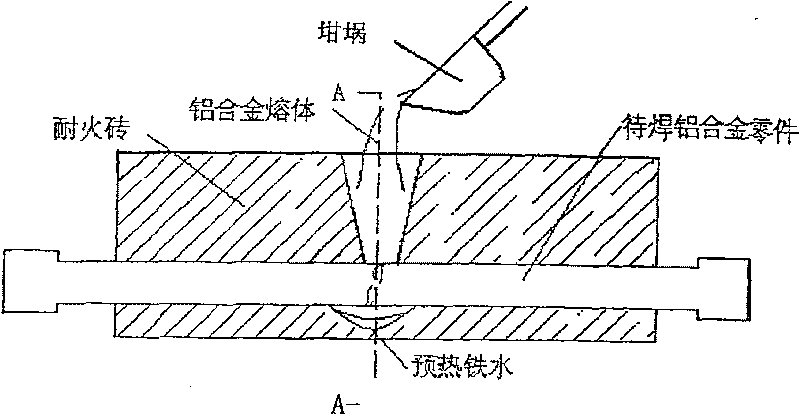

[0019] (1) According to the size and shape of the broken shaft, light refractory materials are used to quickly make on-site such as figure 1 For the welding mold shown, remove the soil and other dirt at the fracture, put the parts to be welded into the mold, and leave a gap of 5mm between the fractures;

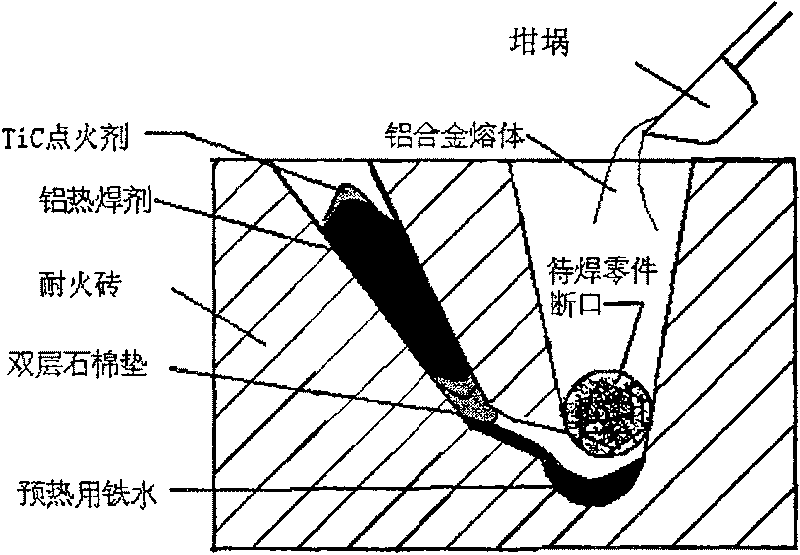

[0020] (2) Put the thermite flux in such as figure 1 In the crucible shown in the figure; the TiC igniter is buried in the thermite flux, part of which is exposed, and the exposed part is ignited to ignite the thermite flux in the crucible; when the thermite reaction of the thermite flux is completed, the solid aluminum alloy Put it on the surface of the reactant and let it melt to obtain liquid aluminum alloy melt;

[0021] (3) While performing step (2), press as figure 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com