Construction method for impact-cone concrete pile

A construction method and punching pile technology, applied in sheet pile wall, foundation structure engineering, blasting and other directions, can solve the problems affecting the quality of punching cast-in-place pile, uneven stress contact surface, incomplete development of boulders, etc. The total amount of explosives, the reinforcing effect is uniform, and the effect of ensuring the blasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

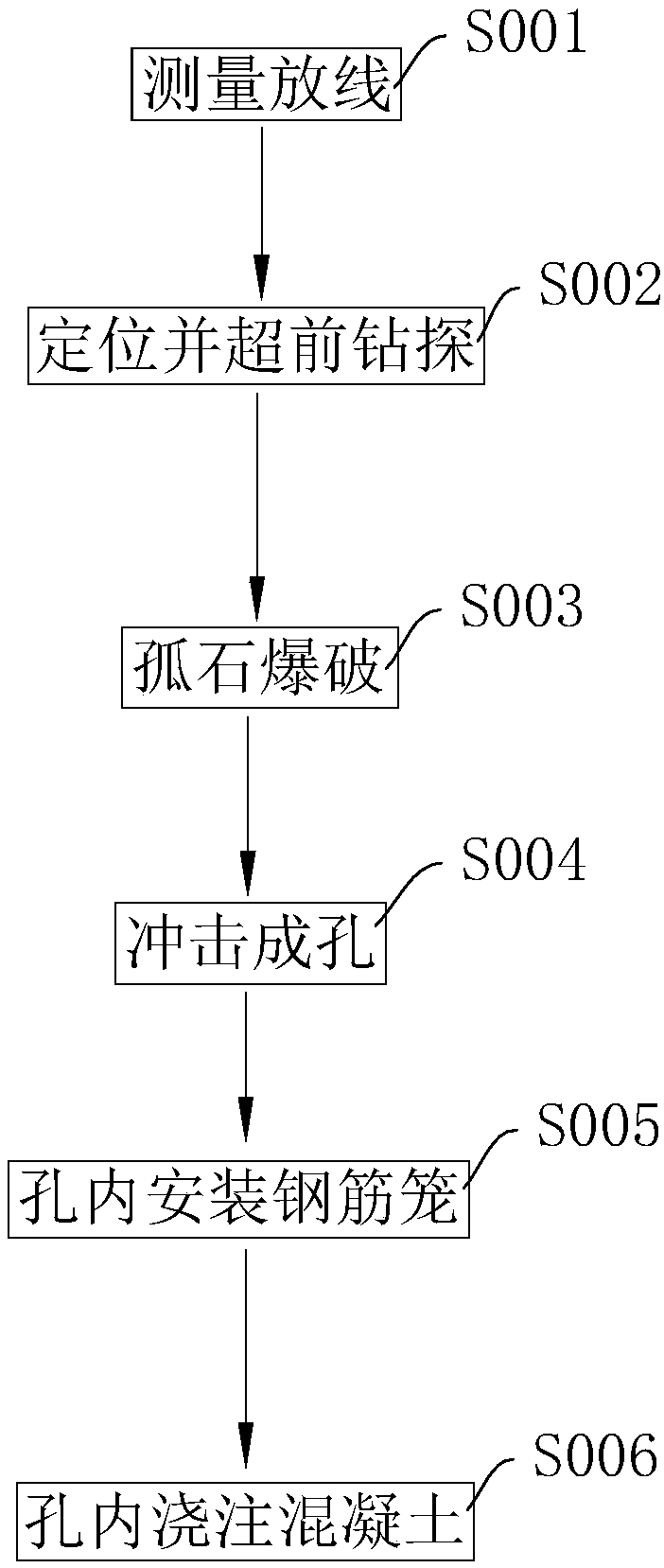

[0045] A kind of perforated cast-in-place pile construction method, with reference to figure 1 , including the following steps:

[0046] S001 measuring and setting out, the details are as follows:

[0047] Use theodolite and total station to measure the pile position, insert a steel bar in the center of the pile position, drive a control pile on each side to control the center of the pile position, and fix the control pile with mortar.

[0048] S002 positioning and advanced drilling, details are as follows:

[0049] For high-precision pile positioning, the first hole is drilled at the center of the borehole coordinates. According to the engineering geological survey report, the development of boulders is complex and uncertain, and the second hole is drilled to take cores from the entire hole and take color digital photos. Site exploration holes are designed and arranged, and each hole is drilled into continuous micro-weathered rock for not less than 5.5m.

[0050] S003 Boul...

Embodiment 2

[0068] The difference from Example 1 is that in S004, when the boulders are underdeveloped, causing the impact hammer to hit the pile hole water surface section with both boulders and soil, backfill the cornerstones with a particle size within the range of 40cm-60cm, and then continue to impact Bottom of the pile hole until the design depth is reached.

[0069] Since the particle size of the backfilling cornerstones ranges from 40cm to 60cm, the cornerstones have sufficient volume and are easy to distribute in the pile holes, and there are fewer gaps between adjacent cornerstones.

Embodiment 3

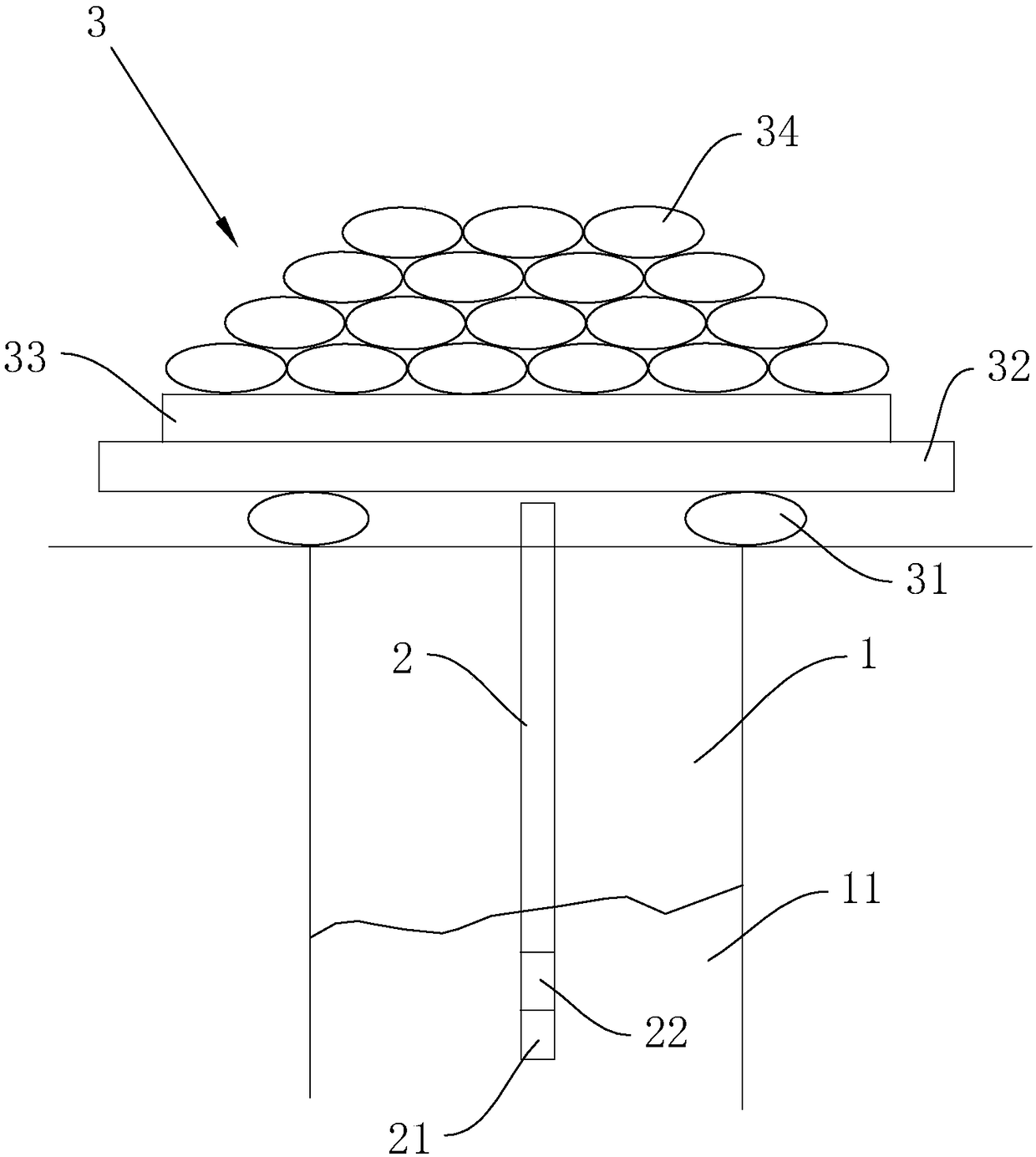

[0071] The difference with embodiment 2 lies in S003, refer to figure 2 , use the PVC pipe buried in the advanced drilling hole 1 as the conduit, and pour water into the PVC pipe 2 during the placement of the PVC pipe. For every 10 meters in length of the PVC pipe, the irrigation water pressure increases by 0.3 MPa. When the length of the PVC pipe is less than 10 meters, the water pressure is increased by 10 Meter calculation to ensure that the PVC pipe position is accurate and there is no sand or soil in the pipe.

[0072] According to the distribution of the boulders 11, high-pressure water is poured into the PVC pipe holes and the explosives 21 are hoisted downward in sections using a scale. According to the distribution height of the boulders 11 shown by advanced drilling, the explosives 21 are placed. 60mm. If a stuck hole is found during the charging process, the charging will be stopped and processed in time. Before the detonator is loaded into the detonating package,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com