Patents

Literature

40results about How to "Uniform reinforcement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

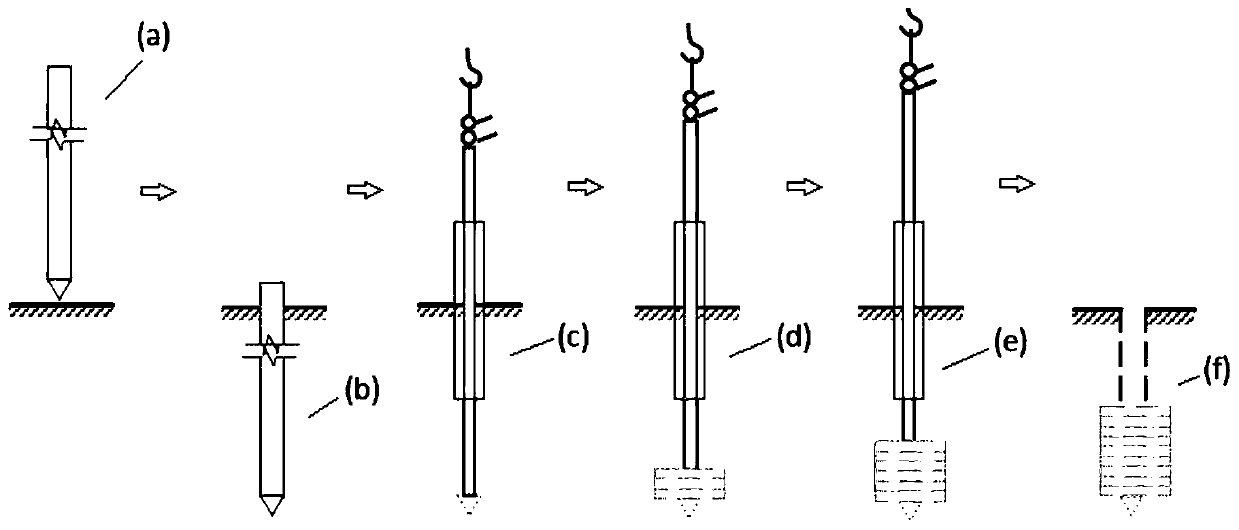

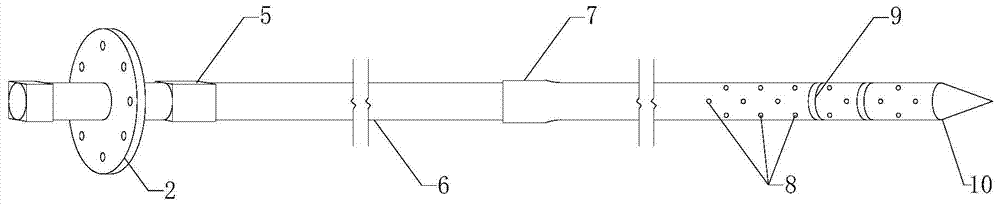

Advanced pre-grouting device suitable for shallow-buried tunnel construction in sand soil layer and construction process

InactiveCN105350519AThe structure of the grouting device is simpleThe grouting device and process are simpleTunnelsSoil preservationPistonUnderground pipeline

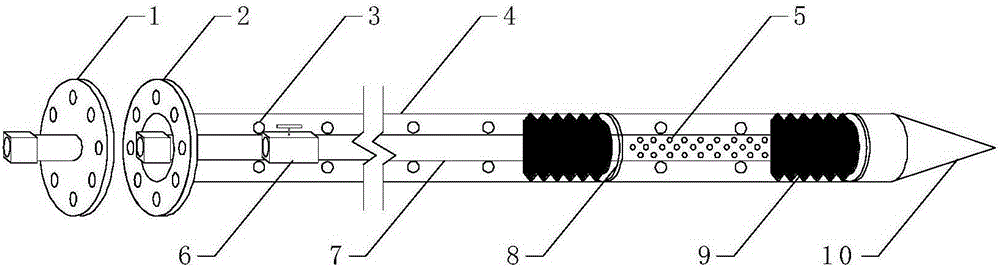

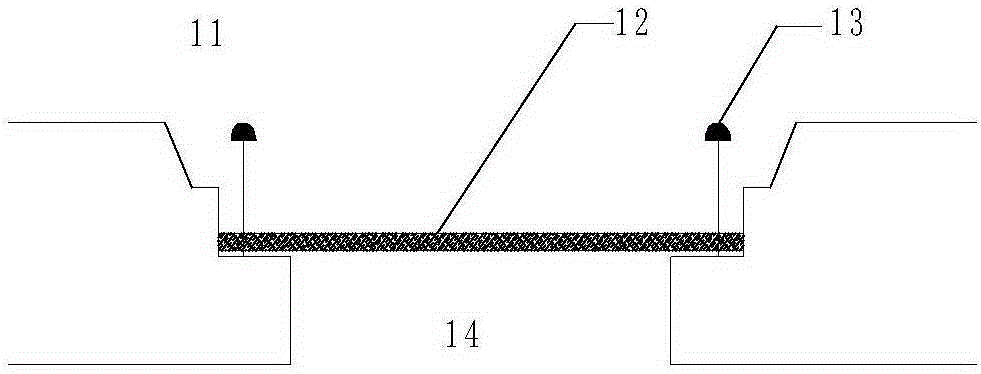

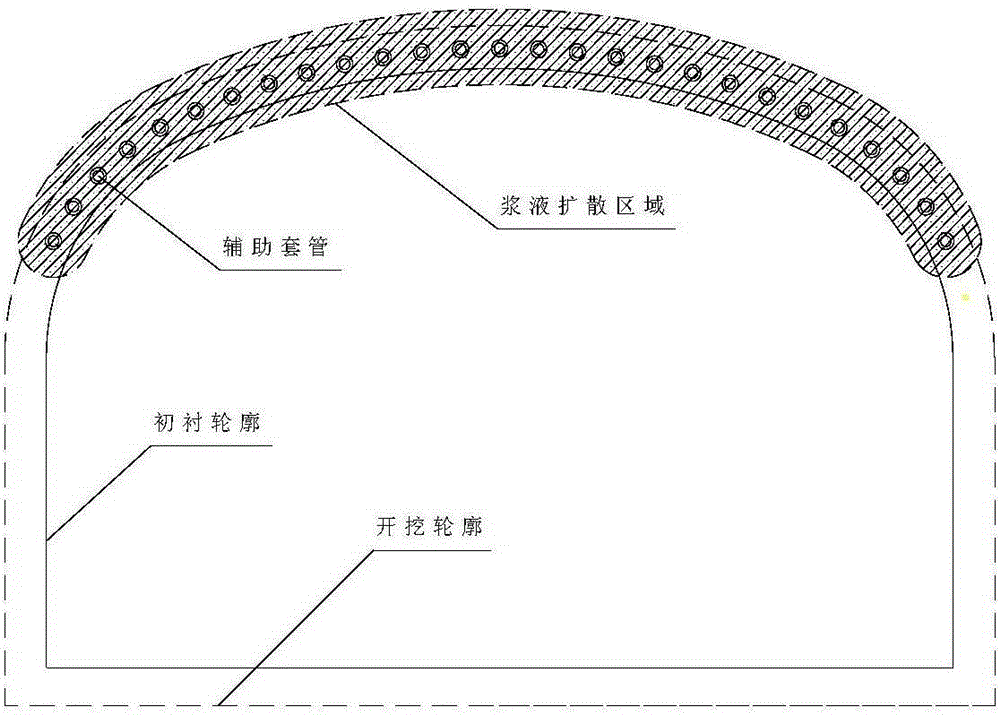

The invention discloses an advanced pre-grouting device suitable for shallow-buried tunnel construction in a sand soil layer and a construction process. The advanced pre-grouting device comprises an auxiliary casing pipe and a grouting inner pipe. The grouting inner pipe is sleeved with two rubber pistons. Two flanges are welded to the grouting inner pipe. Slurry outlet holes are distributed between the two rubber pistons. Grouting and reinforcing conducted on strata of different depths are achieved by moving the grouting inner pipe in the auxiliary casing pipe. One-way slurry outlet holes are formed in the auxiliary casing pipe and can effectively prevent slurry from flowing back. After grouting is completed, the auxiliary casing pipe forms a curtain together with slurry veins by serving as a supporting framework. According to the advanced pre-grouting device and the construction process, segmented and domain-controlled grouting is achieved through movement of the grouting inner pipe, it is ensured that the strata are evenly reinforced, no blind points are generated, and disasters are avoided; slurry is effectively utilized; meanwhile, influences on the overlying strata and the ground surface are reduced, and damage to underground pipelines, ground surface road surfaces and above-ground buildings is prevented; and the auxiliary casing pipe is left in the strata and plays a role of a high-strength beam, slurry is dispersed around the auxiliary casing pipe, and a soil body and the auxiliary casting pipe can form the whole curtain.

Owner:SHANDONG UNIV

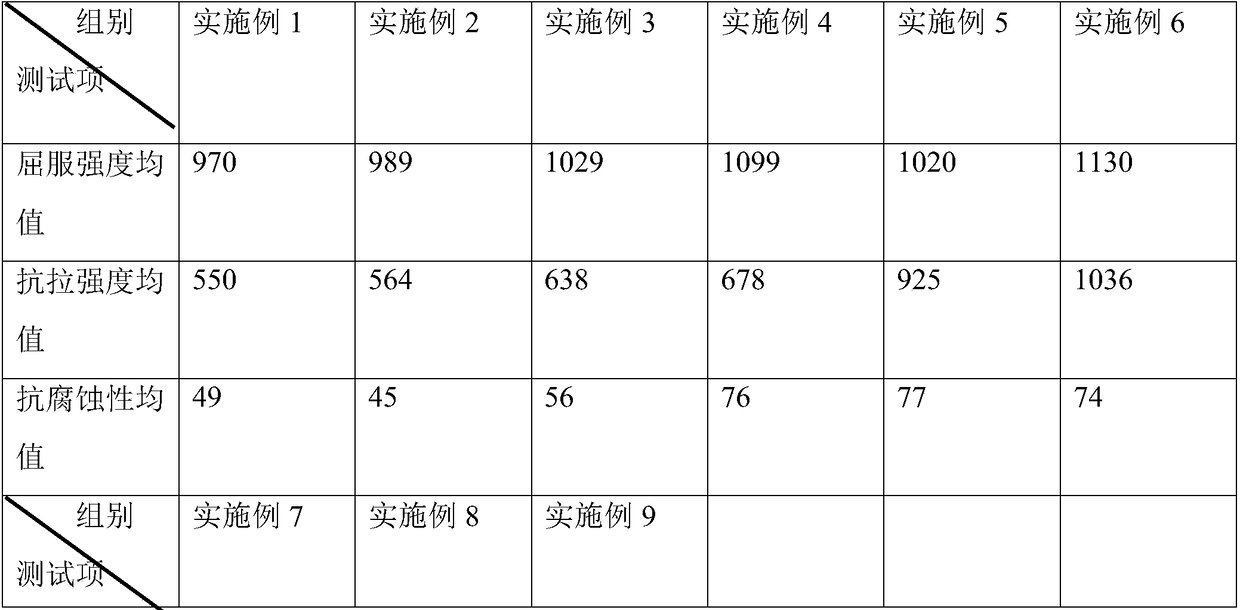

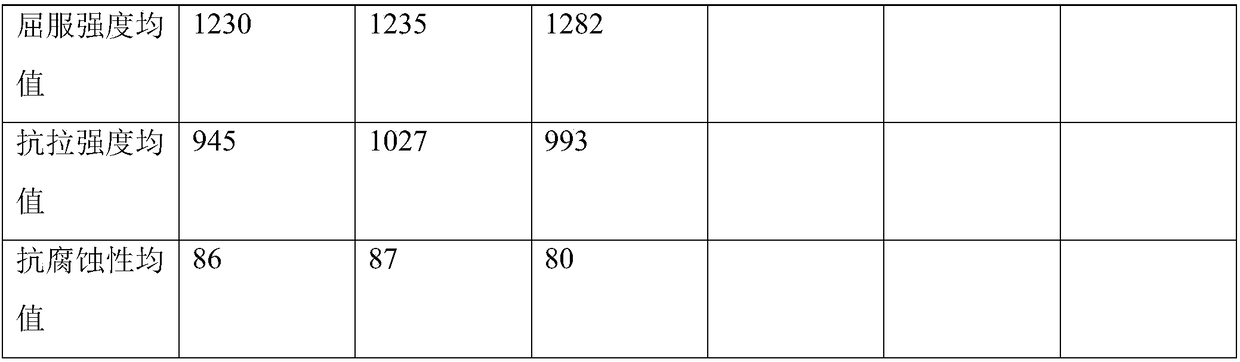

Plastic mould steel and processing technology thereof

The invention discloses plastic mould steel and a processing technology thereof. Main alloy elements in chemical components of the plastic mould steel comprise, by mass, 0.20-0.32% of C, 0.25-0.35% ofSi, 1.10-1.50% of Mn, 1.20-1.60% of Cr, 0.40-0.48% of Mo, 0.05-0.10% of V, 0.025% of P or the less, 0.005% of S or the less, 0.30-1.0% of Ni, 0.15% of Nb or the less and the balance Fe. The plastic mould steel has high polishing performance and processing performance, and in addition, the internal hardness and the surface hardness of the plastic mould steel are more uniform; heat treatment structural transformation in the processing technology is single, and the metallographic structure is more delicate and more uniform; materials are produced with the large forging ratio, and the cores of the materials are compact in structure; the deviation of the surface toughness and the core toughness of the materials is extremely small; and the processing period of a mould is shortened, and the costis reduced.

Owner:浙江天基重工机械有限公司

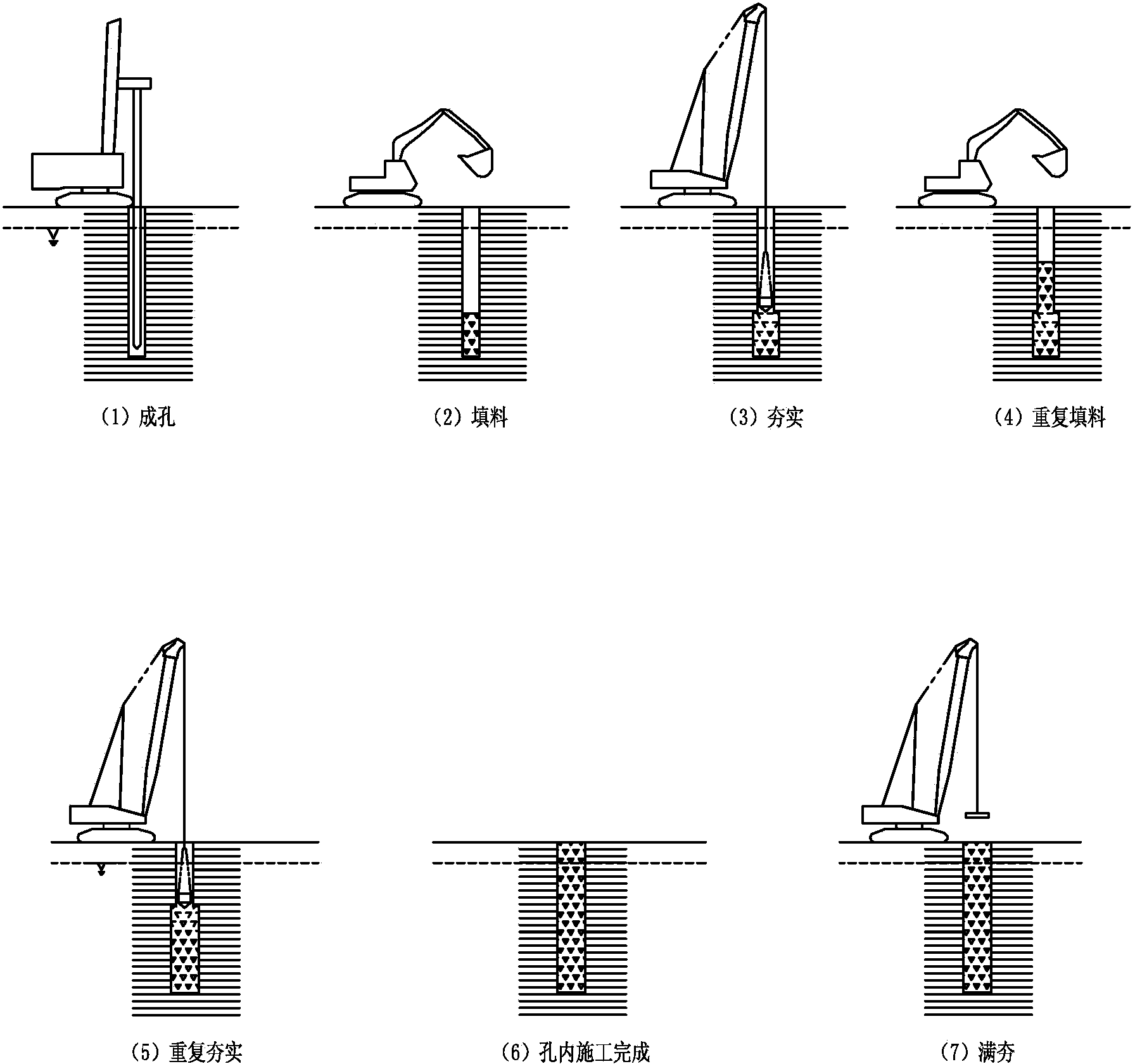

Preformed hole deep-layer underwater tamping method

InactiveCN104264655AReduce the impactRealize continuous operationSoil preservationSurface layerEngineering

A preformed hole deep-layer underwater tamping method is characterized in underwater construction: foundation soil below the underground water level is consolidated; a tamper rises from and falls in water, and the action point of the tamper and foundation soil is located below the underground water level; the tamper keeps hooked during construction to achieve underwater continuous operation. The preformed hole deep-layer underwater tamping method includes the following steps: (1) preforming a hole in foundation soil; (2) conducting padding in the hole for the first time, wherein the padding amount is controlled by the layered padding thickness; (3) conducting tamping in the hole for the first time, making the tamping energy to be matched with the layered padding thickness, keeping the tamper hooked during tamping, automatically measuring the settlement, and conducting tamping gradually until the tamping stopping standards are met; (4) repeating steps 2 and 3, conducting backfilling and tamping layer by layer from bottom to top, and conducting padding and tamping alternately until the ground elevation is reached and construction of one hole is finished; (5) repeating steps 1-4 to complete construction of all holes; (6) tamping the soil on the surface layer in a full tamping mode. The preformed hole deep-layer underwater tamping method has the advantages of underwater construction, deep-layer consolidation, low production cost, short construction period, high efficiency, energy conservation and environmental protection.

Owner:CHINA ZHONGHUA GEOTECHN ENG

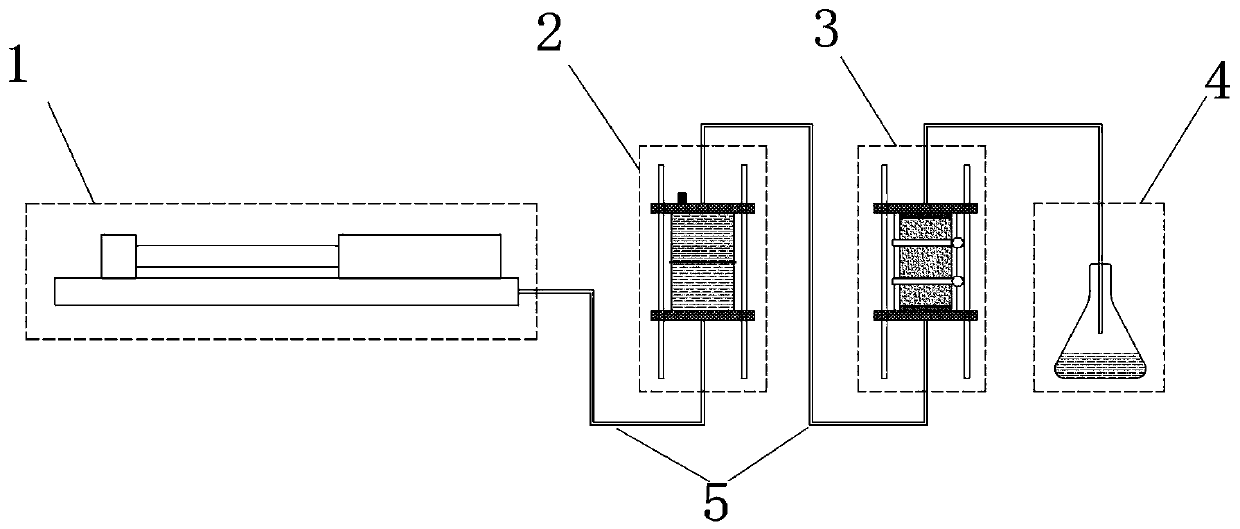

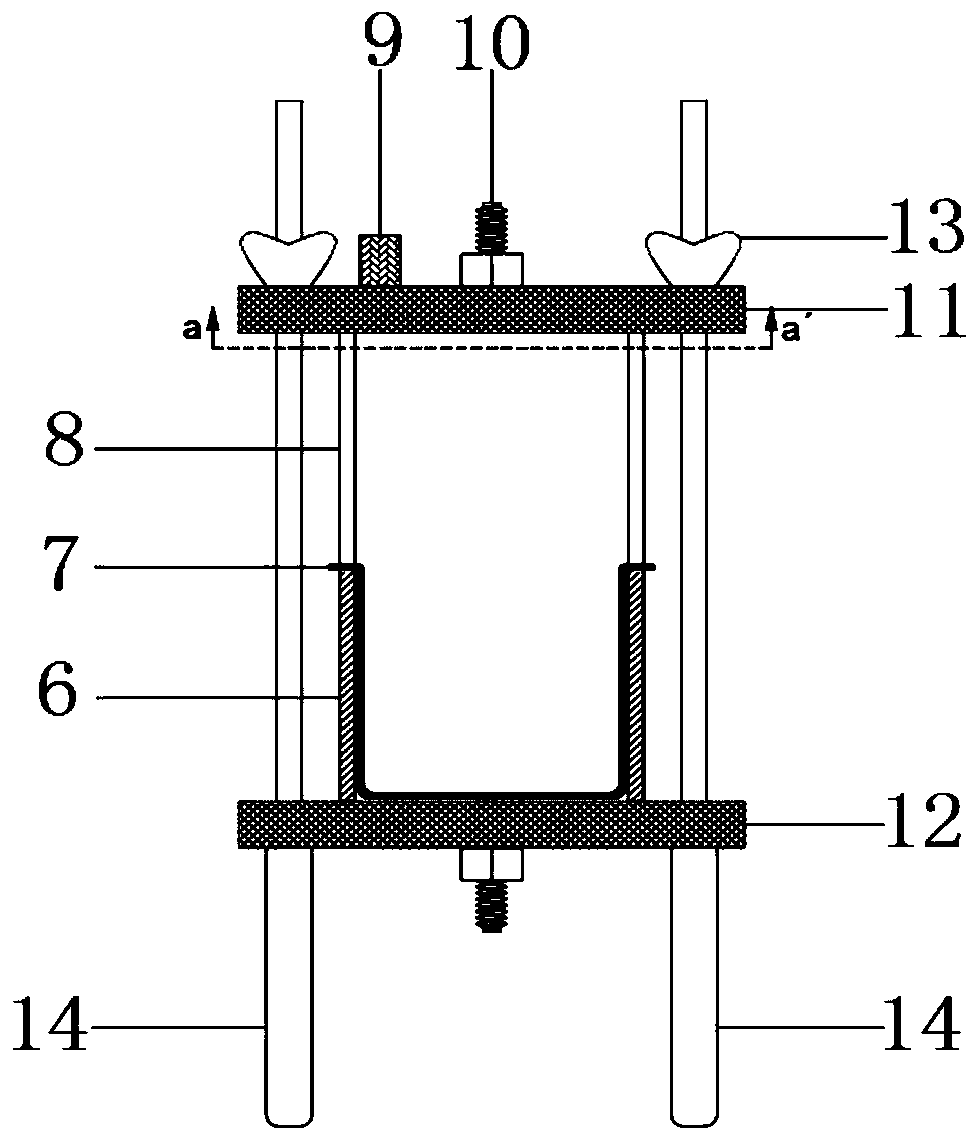

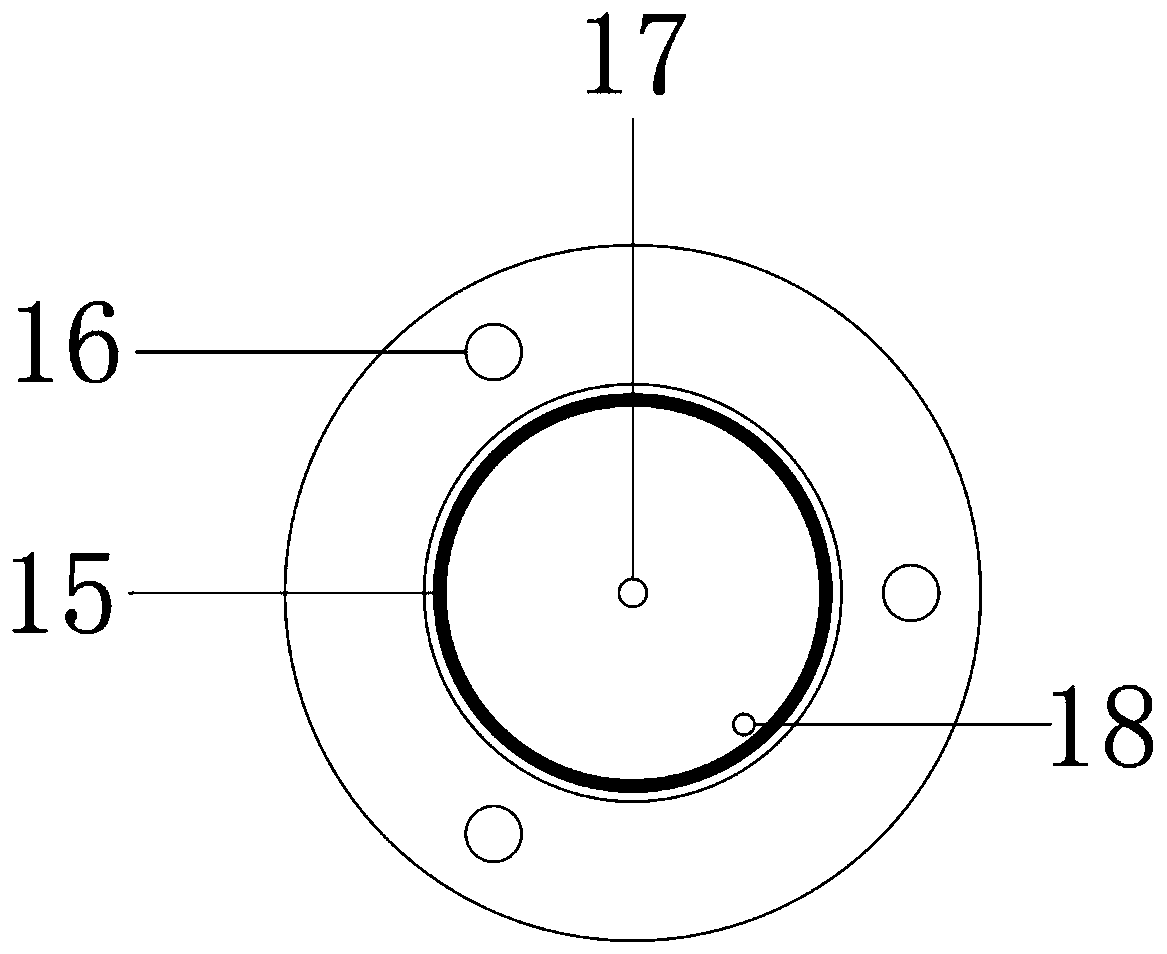

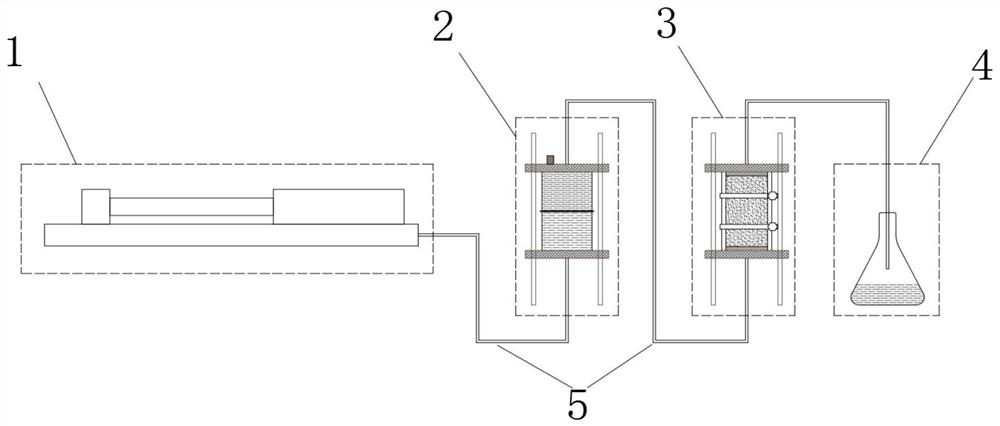

Test device for demoulding microbial-grouting reinforcing silt and method thereof

ActiveCN109959773AEvenly distributedCan control and adjust the grouting speedPreparing sample for investigationEarth material testingButt jointSlurry

The invention discloses a test device for the demoulding microbial-grouting reinforcing silt and a method thereof. The device comprises a GDS pressure controller, a slurry storage device, a reaction device and a filtrate collection bottle. The GDS pressure controller is used for providing the pressure to control the grouting speed precisely, so that serous fluid is injected into a soil sample slowly and uniformly. A sample preparation barrel in the reaction device is formed by butting joint of two organic glass tubes, thereby ensuring the airtightness of the device and realizing demoulding conveniently and completely. According to the invention, the silt is reinforced by using the microbial mineralization technology; and because of stepwise bacterial liquid injection and cement liquid, blocking of the grouting hole caused by direct mixing of the cement liquid and bacterial liquid is avoided. Meanwhile, with the bottom-to-top grouting mode, the grouting liquid can be uniformly distributed in the soil sample to ensure the high uniformity and integrity of the solidification of the soil sample.

Owner:HEFEI UNIV OF TECH

Method for efficiently absorbing water and solidifying under films through controllable vacuum negative pressure well

The invention relates to a method for efficiently absorbing water and solidifying under films through a controllable vacuum negative pressure well, or a CPC method for short. The method comprises the first step of longitudinal pipeline arranging, the second step of horizontal pipeline arranging, the third step of negative-pressure sealing well assembling, the fourth step of negative-pressure sealing well arranging, the fifth step of sealing film arranging and the sixth step of water draining and strengthening processing. Because a processing system composed of the controllable negative-pressure sealing well, longitudinal pipelines, horizontal pipelines and multiple layers of sealing films is adopted, the size of an area capable of being processed through a single suit of processing system can reach 5000-15000 square meters. The method for efficiently absorbing water and solidifying under the films through the controllable vacuum negative pressure well is high in water draining efficiency, and can greatly reduce electric quantity consumption of a unit area and improve pipeline water smoothness and sealing system stability.

Owner:南京水科院瑞迪科技集团有限公司

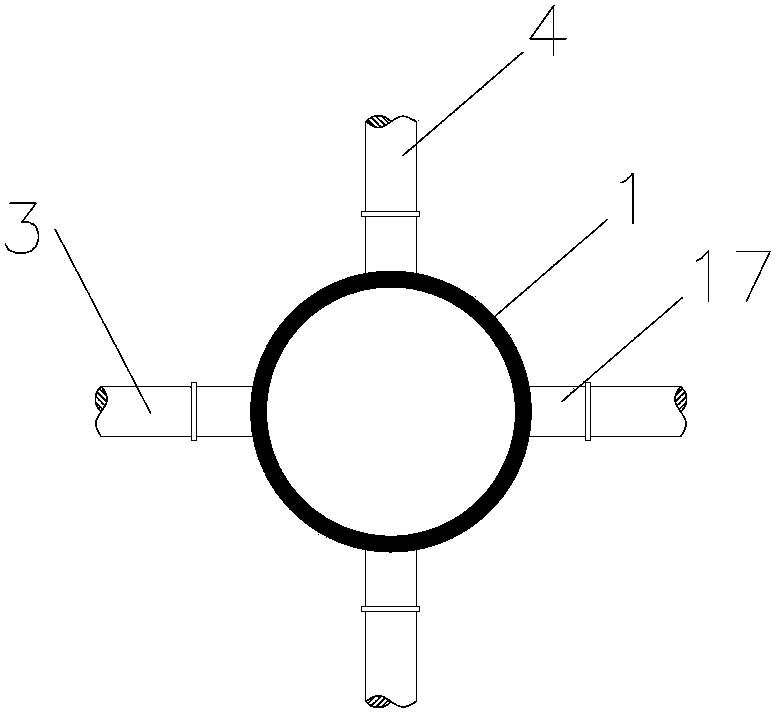

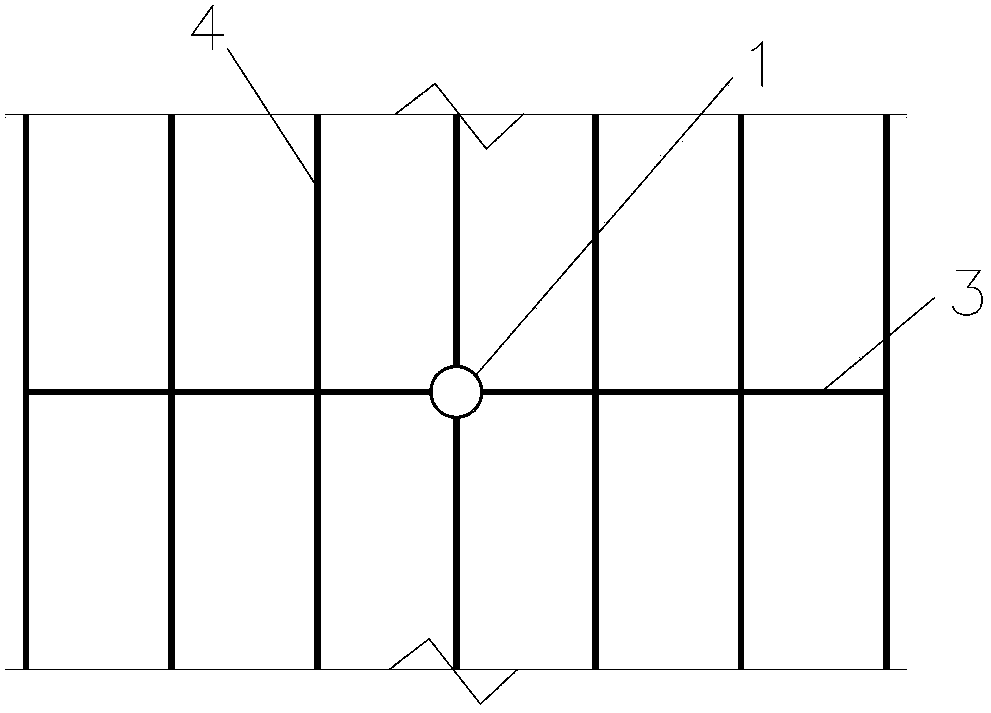

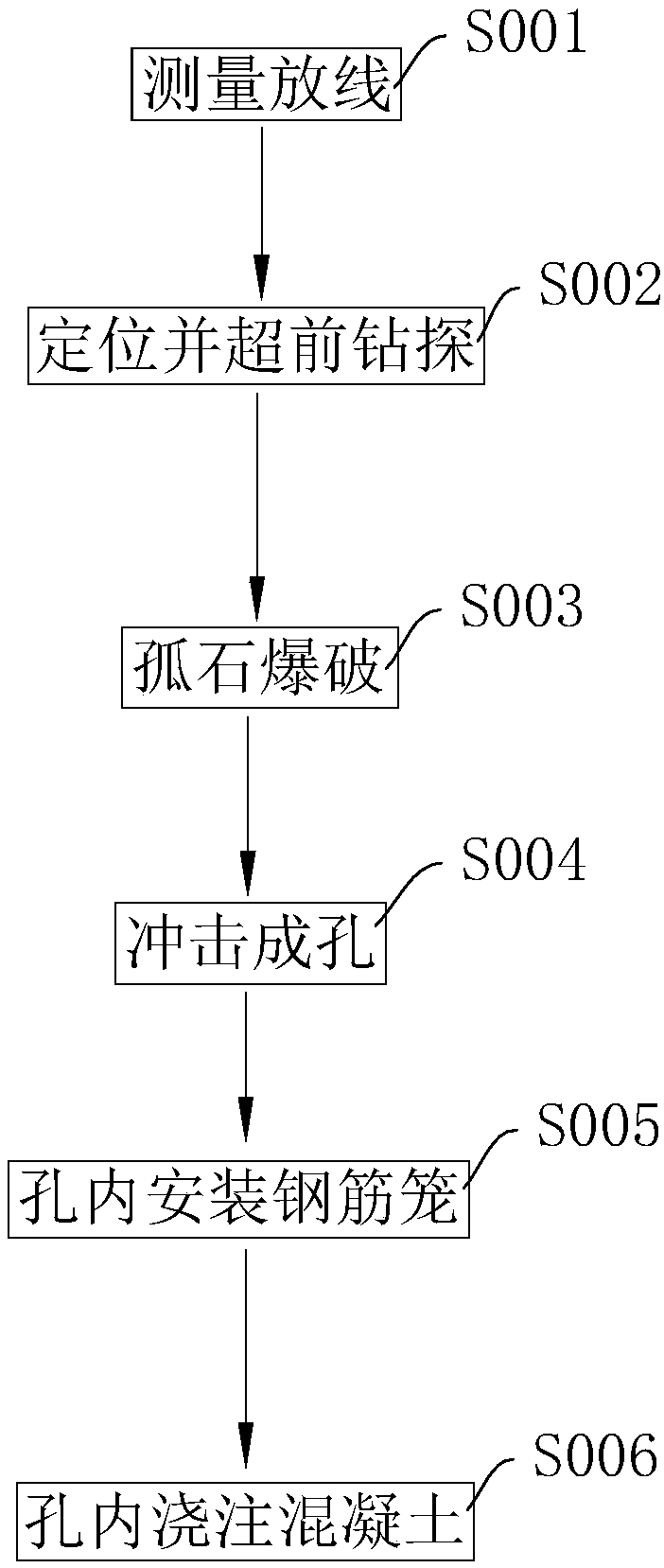

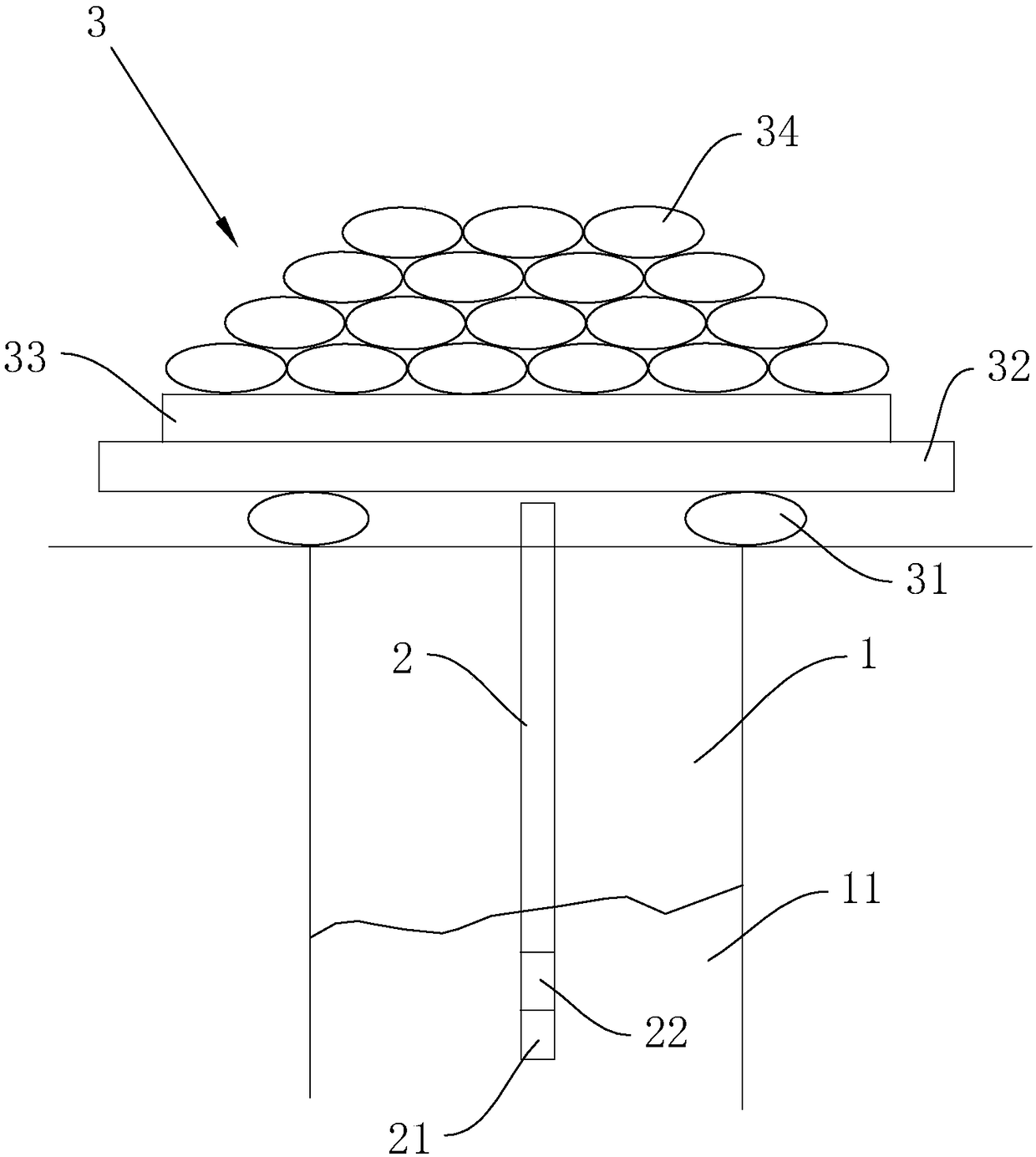

Construction method for impact-cone concrete pile

ActiveCN108589704AImprove verticalityEvenly distributed on the bearing surfaceBlastingBulkheads/pilesSoil massEngineering

The invention relates to the field of building construction. In order to solve the problem that the perpendicularity of a pile hole is low as a result of a locking hammer and an inclined hole, the invention provides a construction method for an impact-cone concrete pile. The stress face of an impact hammer is uniform, so that the perpendicularity of the pile hole is relatively high. The technicalscheme is as follows: the construction method comprises the following steps: surveying and setting out; positioning and drilling ahead; boulder blasting; impact holing, impacting again after hornstonebackfilling when a same horizontal section in the pile hole includes boulders and soil mass at the same time; mounting a steel reinforcement cage in the hole; and pouring concrete in the hole. The stress face of the impact hammer is uniformly distributed when the same horizontal section in the pile hole includes boulders and soil mass at the same time by backfilling the hornstones, the conditionthat the perpendicularity of the pile hole is reduced as the result of the locking hammer and the inclined hole is avoided, and the perpendicularity of the pile hole is ensured to further guarantee the quality of the impact-cone concrete pile.

Owner:广东梁亮建筑工程有限公司

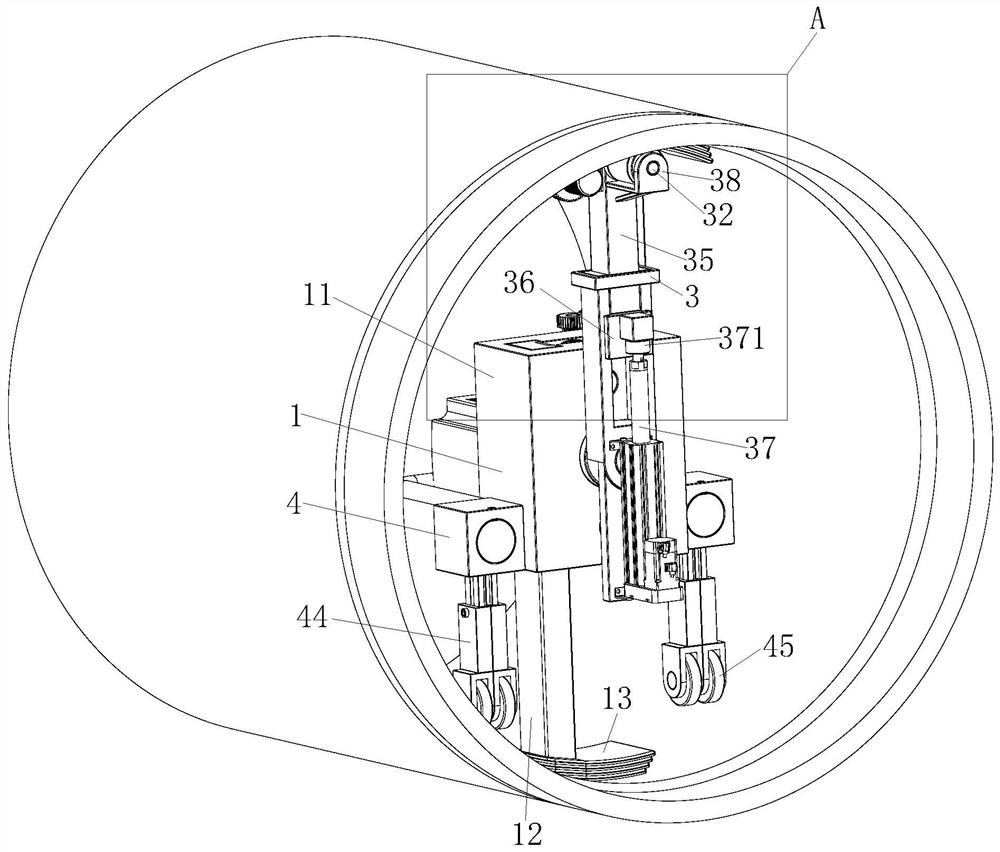

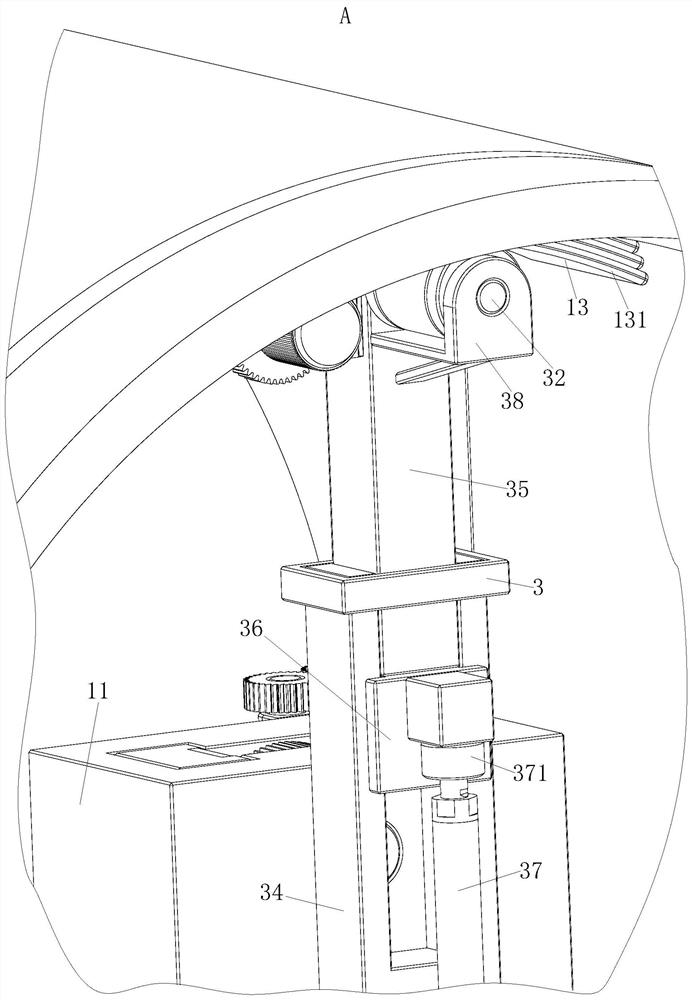

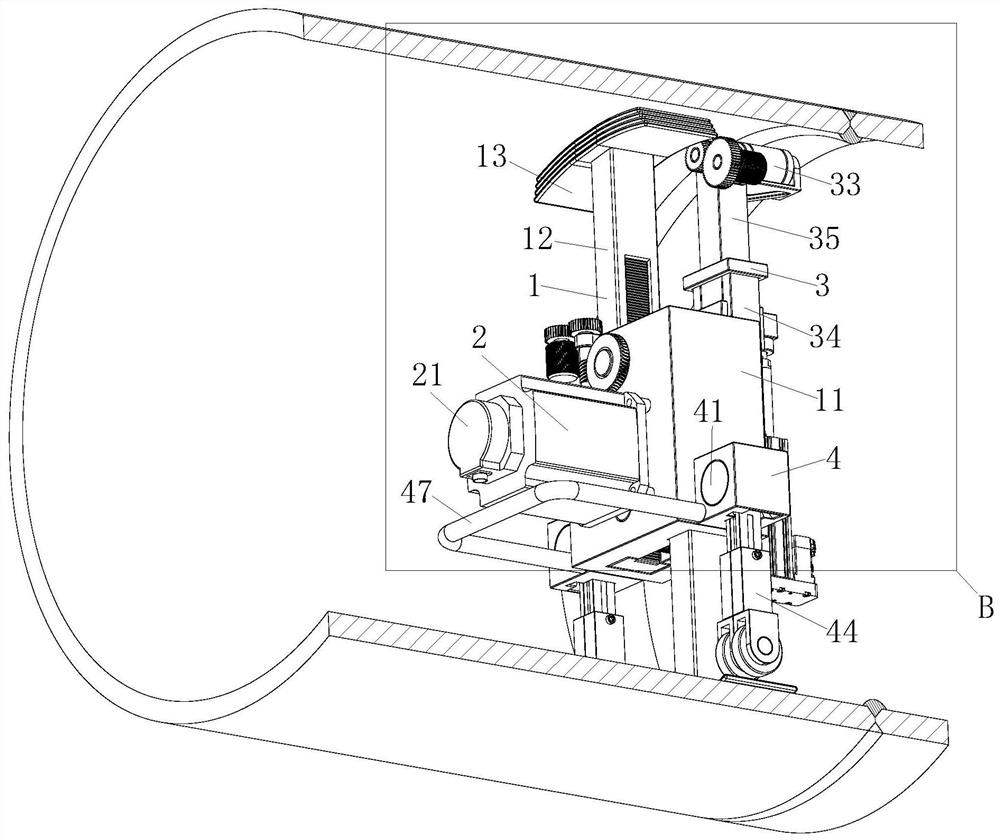

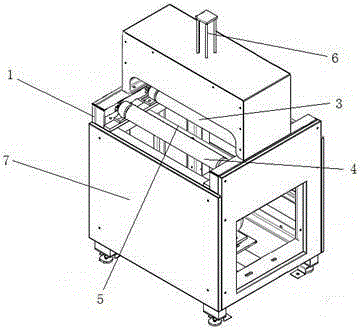

Large steel pipe inner opening welding seam polishing machine

InactiveCN113579892AQuality improvementReduce connection strengthEdge grinding machinesGrinding carriagesPolishingWeld seam

The invention belongs to the technical field of steel pipe machining equipment, and particularly relates to a large steel pipe inner opening welding seam polishing machine. The large steel pipe inner opening welding seam polishing machine comprises a tensioning component, a rotating component and a polishing component. According to the large steel pipe inner opening welding seam polishing machine, after the polishing machine is fixed into a large steel pipe through the tensioning component, the rotating component drives the polishing component to rotate, the polishing component rotates around the axis of the large steel pipe, then the polishing component polishes away redundant metal at the weld joint while rotating, so that the surplus height of the weld joint meets the technical requirement; the polishing machine solves the problems that the conventional polishing mostly adopts manual polishing, the welding seam polishing degree cannot be controlled, and excessive local polishing and insufficient local polishing are easily caused; moreover, the polishing machine avoids the situation that the welding seam strength is reduced due to excessive local polishing, further guarantees the welding seam strength, and avoids the situation that the welding seam is too large in local surplus reinforcement due to insufficient local polishing, therefore, the frictional resistance of the medium during flowing is reduced, and the conveying energy consumption is reduced; and manual polishing is not needed, so that the physical strength expenditure of people is saved, and the labor cost is further saved.

Owner:刘良霞

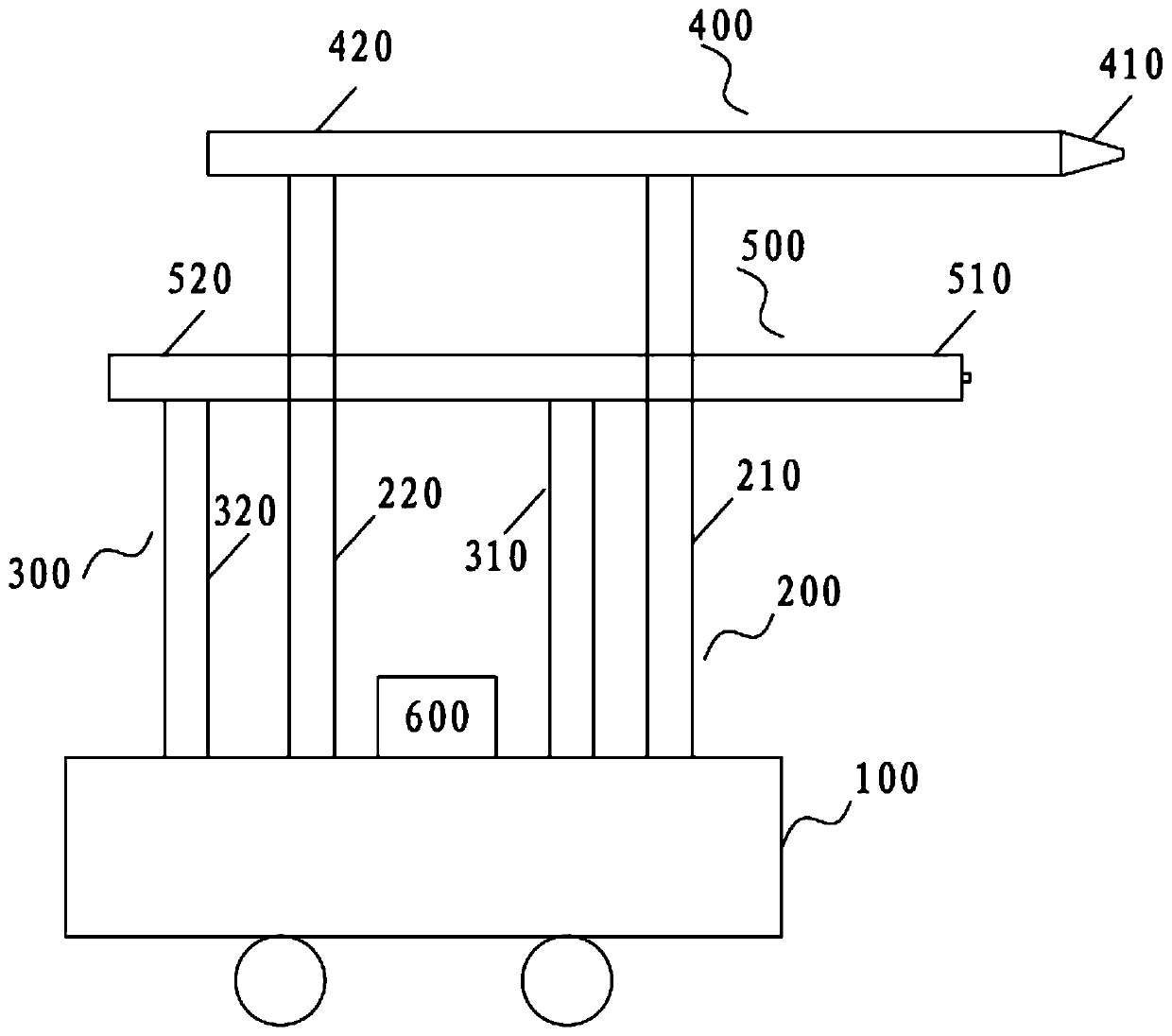

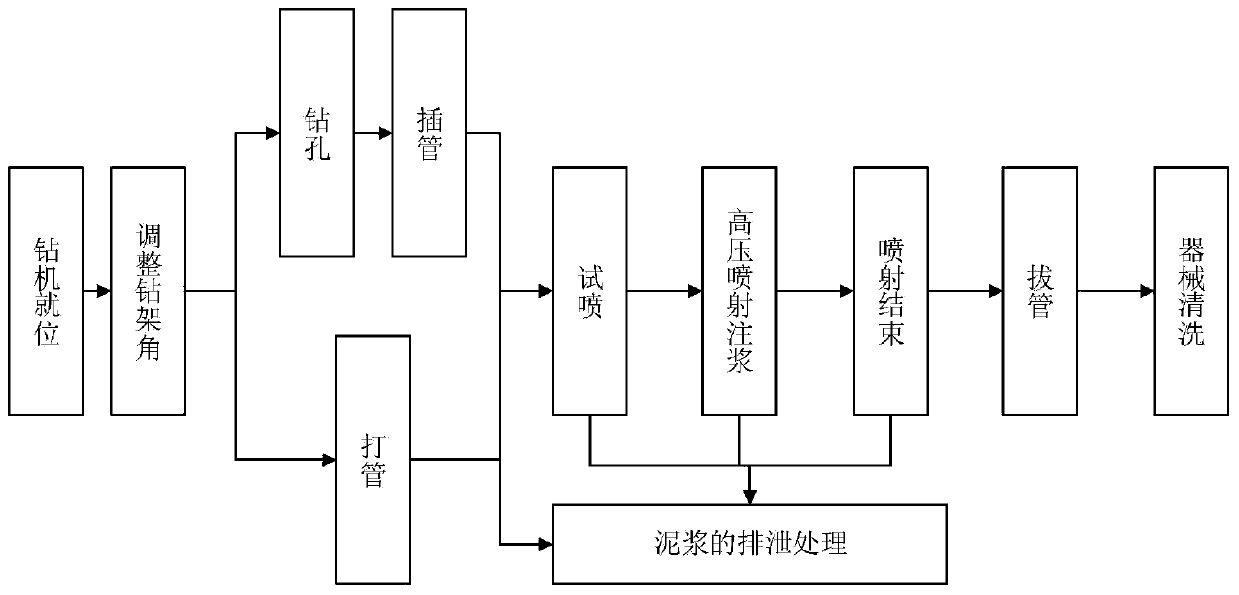

Tunnel horizontal rotary jet construction method

PendingCN109854251ALevel of achievementAchieve rotary sprayingUnderground chambersTunnel liningEngineeringCement slurry

The invention discloses a tunnel horizontal rotary jet construction method. The tunnel horizontal rotary jet construction method comprises the steps that a borehole is drilled by using a horizontal rotary jet drilling machine, wherein the horizontal rotary jet drilling machine comprises a movable machine body, a borehole supporting frame group, a rotary jet supporting frame group, a drilling device and a rotary jet device; the drilling device is withdrawn from the borehole after drilling is completed; the rotary jet device is sent to the tail end of the borehole after a drill rod is withdrawncompletely from the borehole; and pre-prepared cement slurry is supplied to a spray head assembly of the rotary jet device by using grouting equipment; the spray head assembly is started to enable thehigh-speed sprayed cement slurry to drive soft rock around the borehole to rotate, stir and melt into a whole; as the spray head assembly withdraws from the borehole while rotary jet grouting, a reinforced pile body is formed along a first type borehole from inside to outside; horizontal rotary jet grouting is stopped after the spray head assembly completely is withdrawn from the borehole; and after all the reinforced piles are solidified and the strength of an array-shaped stability system formed by the reinforced piles is tested to meet the requirements, large-section mechanical excavationis carried out to form a tunnel.

Owner:北京瑞威世纪铁道工程有限公司

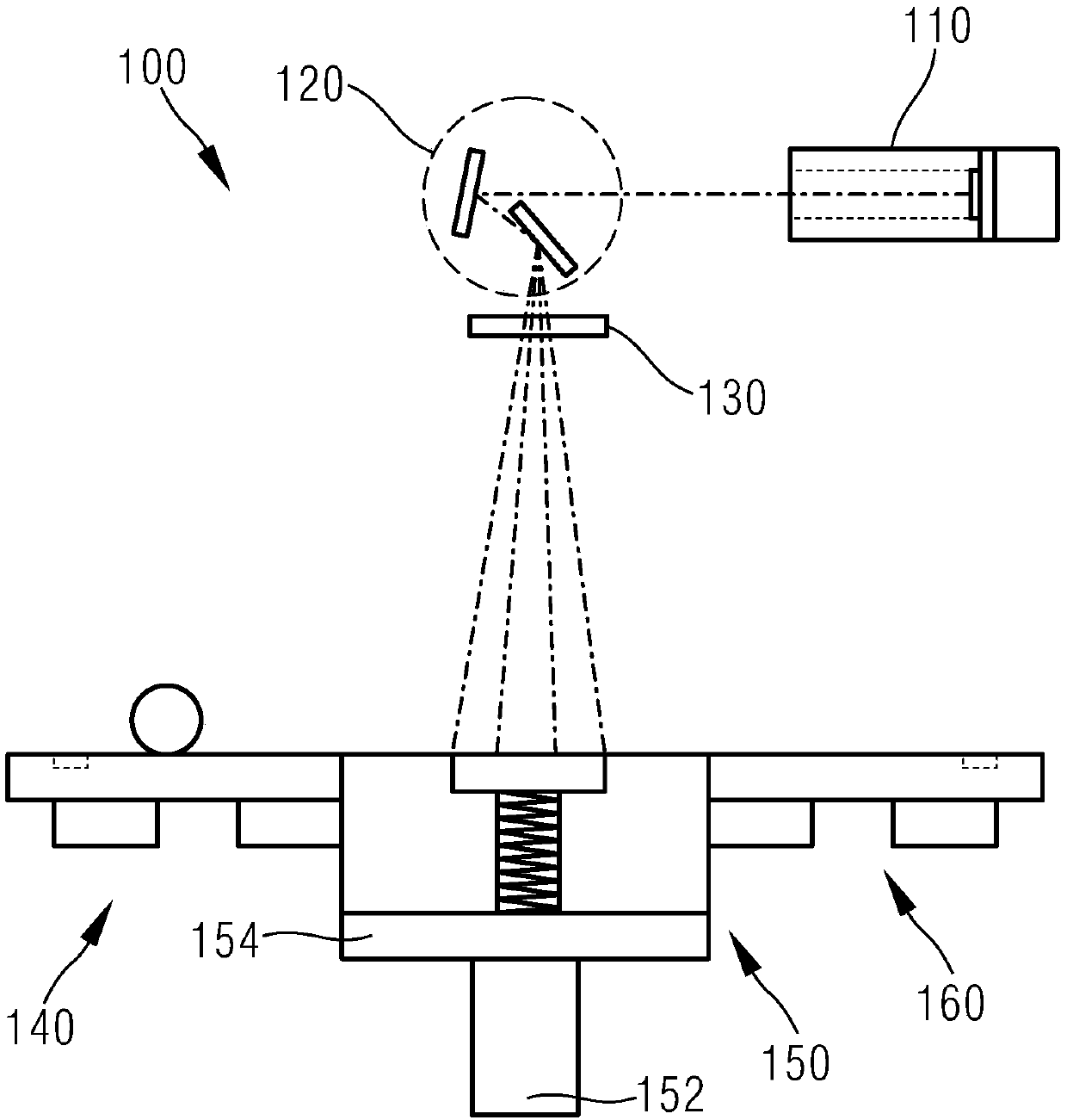

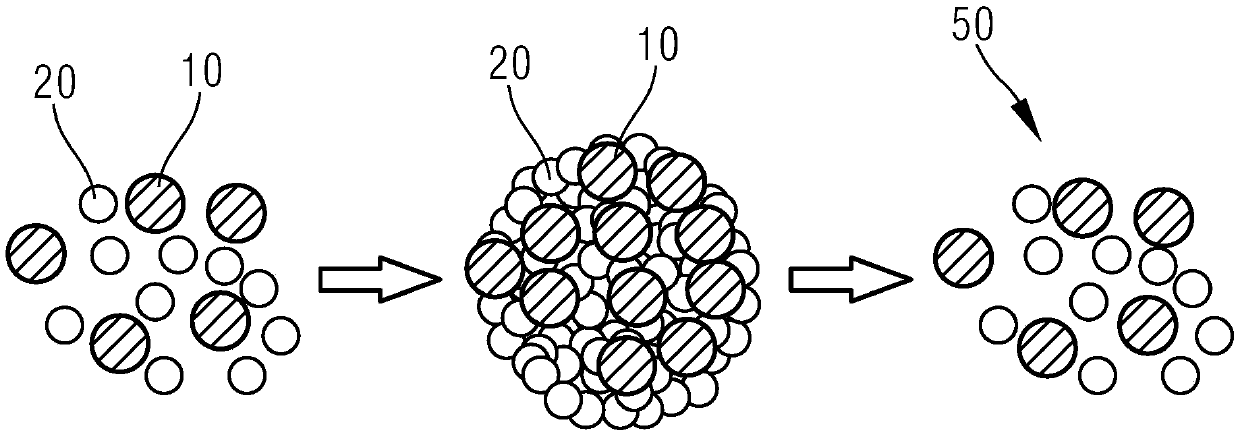

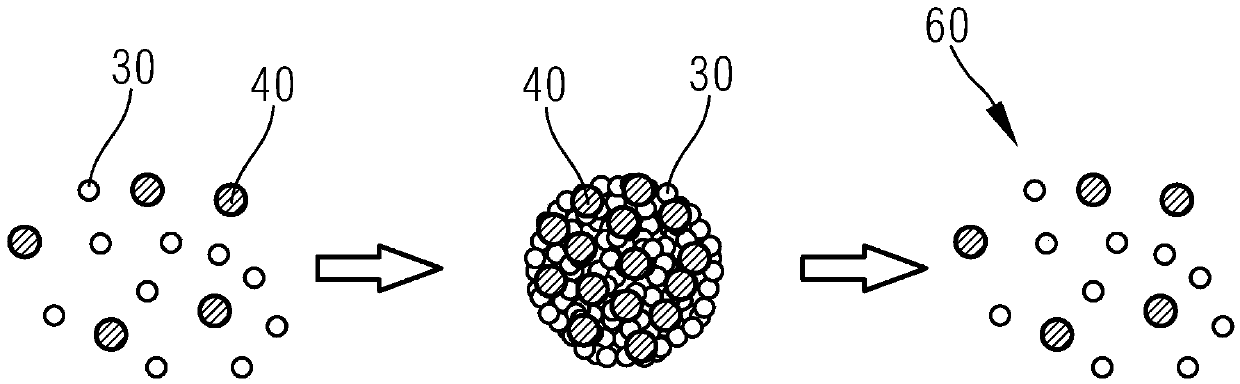

3D printing metal powder, 3D printing method and method for preparing 3D printing metal powder

InactiveCN110893465AImprove mechanical propertiesFunction increaseAdditive manufacturing apparatusIncreasing energy efficiency3d printNanoparticle

The invention provides 3D printing metal powder, a 3D printing method and a method for preparing 3D printing metal powder. The method for preparing the 3D printing metal powder comprises the followingsteps: decomposing metal basic powder into a metal powder matrix by a mechanical grinding process; adding reinforced particles in the metal basic powder matrix and mixing the metal powder matrix andthe reinforced particles; adding a binder and bonding the metal powder matrix and the reinforced particles by the binder and through a spray drying process so as to obtain disperse particles, whereinthe size of the disperse particles is more than those of the metal powder matrix and the reinforced particles; and removing the binder from the disperse particles by a sintering process so as to obtain 3D printing metal composite powder. Uniform reinforcement can be guaranteed and the mechanical property and the function of the nanoparticles can be improved; and furthermore, the internal microcracks of the metal powder added with the nanoparticles can be reduced.

Owner:SIEMENS AG

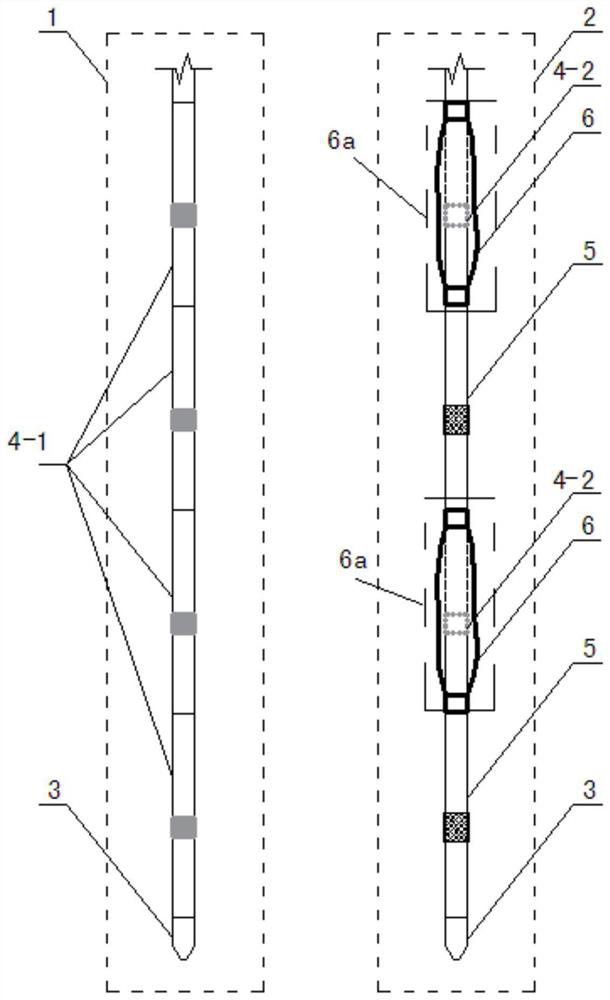

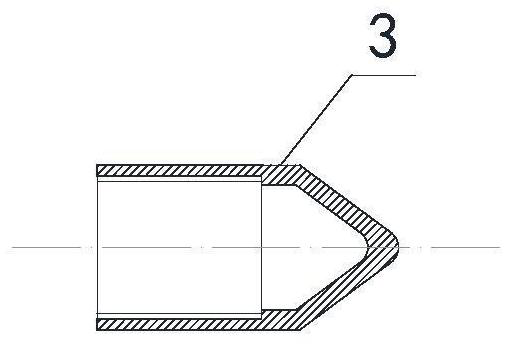

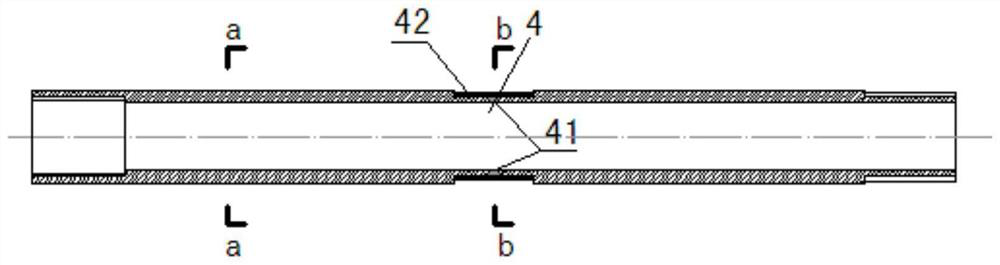

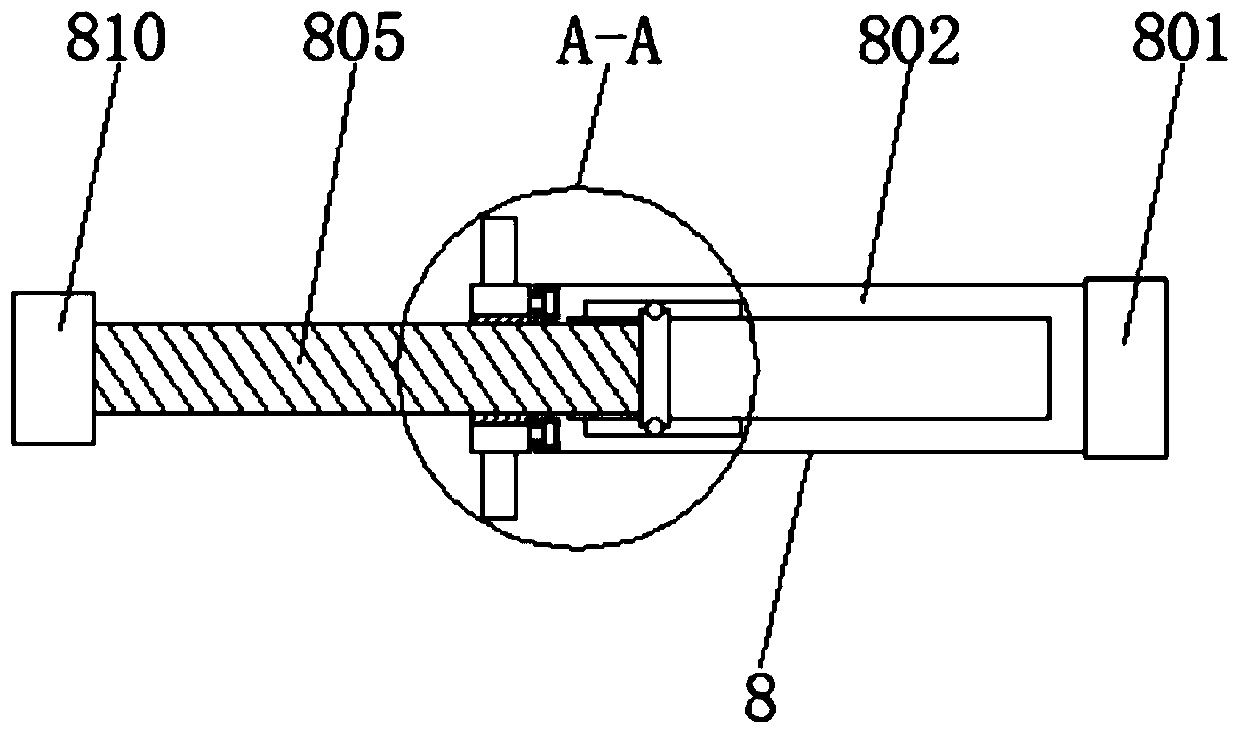

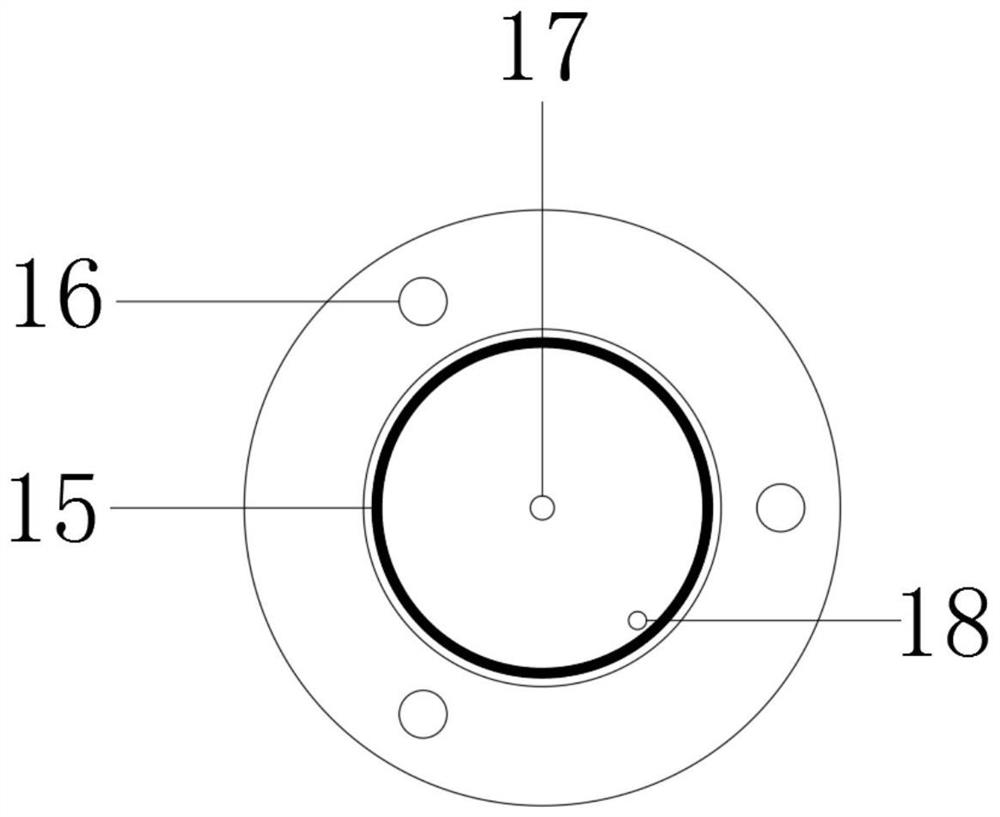

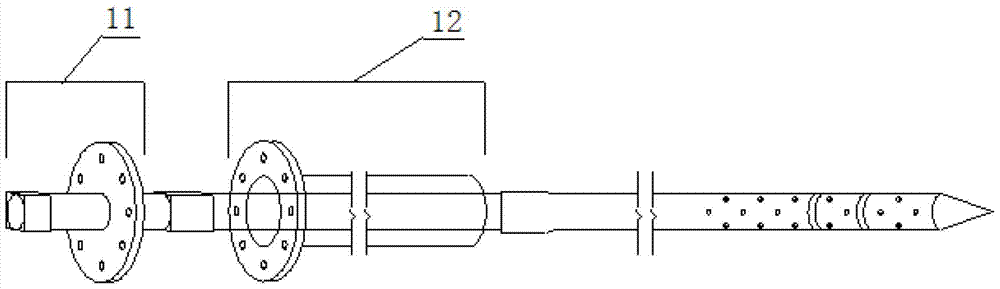

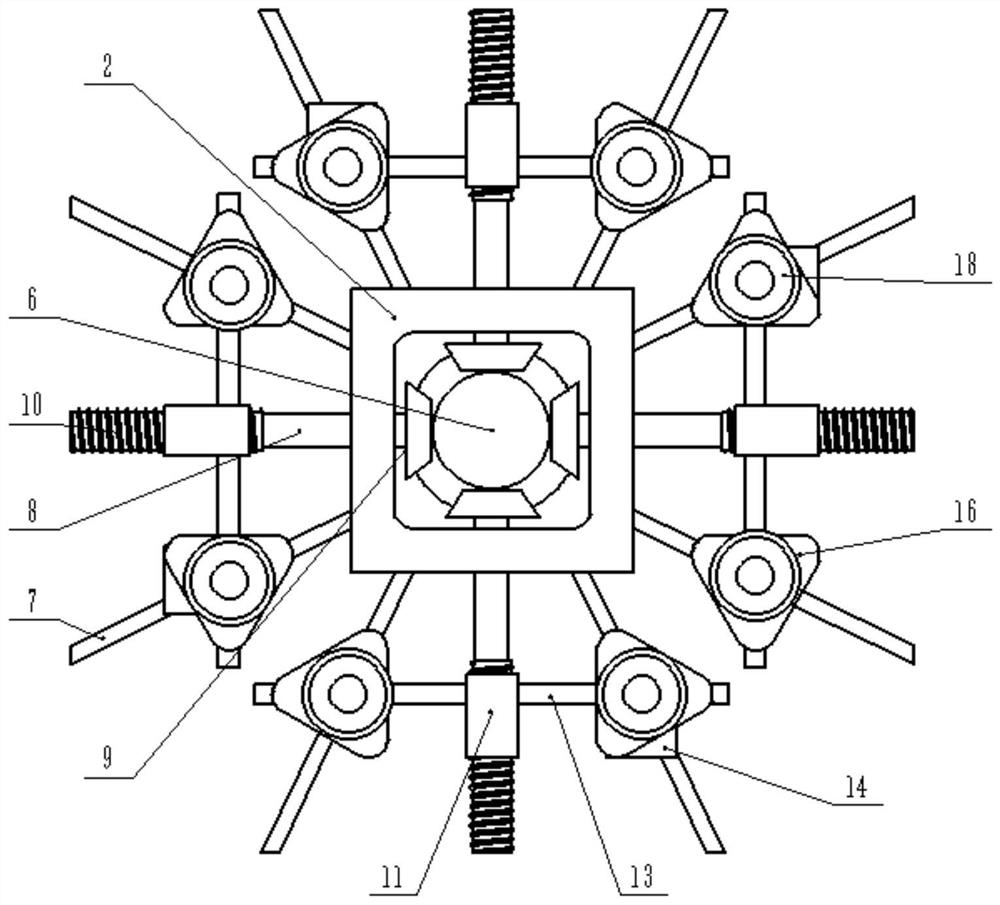

Step-by-step sectional type tunnel curtain grouting construction pipe set, device and construction method

PendingCN114135321AIncrease injection volumeReduce disturbanceUnderground chambersTunnel liningCement groutSlurry

The invention discloses a step-by-step sectional type tunnel curtain grouting construction pipe set, device and construction method, the step-by-step sectional type tunnel curtain grouting construction pipe set comprises a plurality of sets of construction suites, each construction suite comprises two grouting pipes and a vacuum pipe, and the grouting pipes and the vacuum pipes are used for being inserted into grouting holes with different depths; each grouting pipe is formed by connecting a plurality of first grouting pipe sections in sequence; the vacuum pipe is formed by connecting a plurality of vacuum pipe sections and a plurality of isolation pipe sections which are communicated at intervals, each isolation pipe section is of a double-layer sleeve structure and comprises a second grouting pipe section and an isolation bag sleeve which are sleeved together, and the two ends of each isolation bag sleeve are attached to the outer walls of the two ends of the corresponding second grouting pipe section in a sealed mode to form an expansion bag cavity shape with the two ends closed. By means of the device and method, it is guaranteed that cement grout is fully injected into the surrounding rock stratum, the grout injection amount is increased, even network-shaped grout veins are formed in the surrounding rock, the reinforcing effect is good, the grout diffusion range is effectively controlled, and waste caused by disordered diffusion of materials is avoided.

Owner:中铁隧道勘察设计研究院有限公司

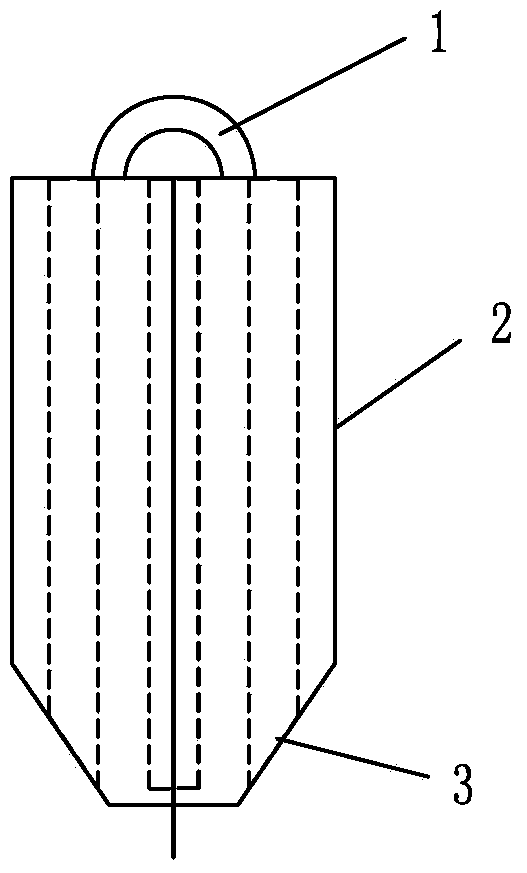

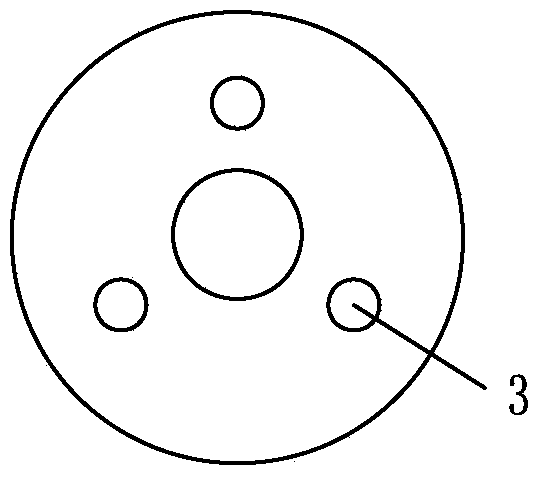

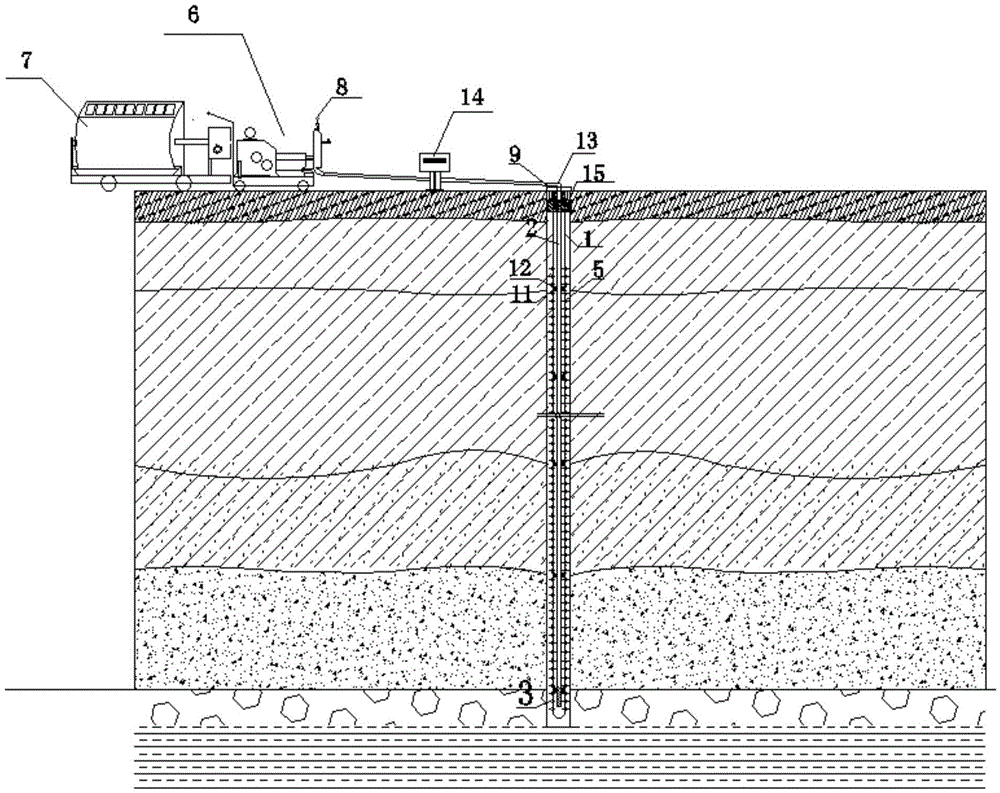

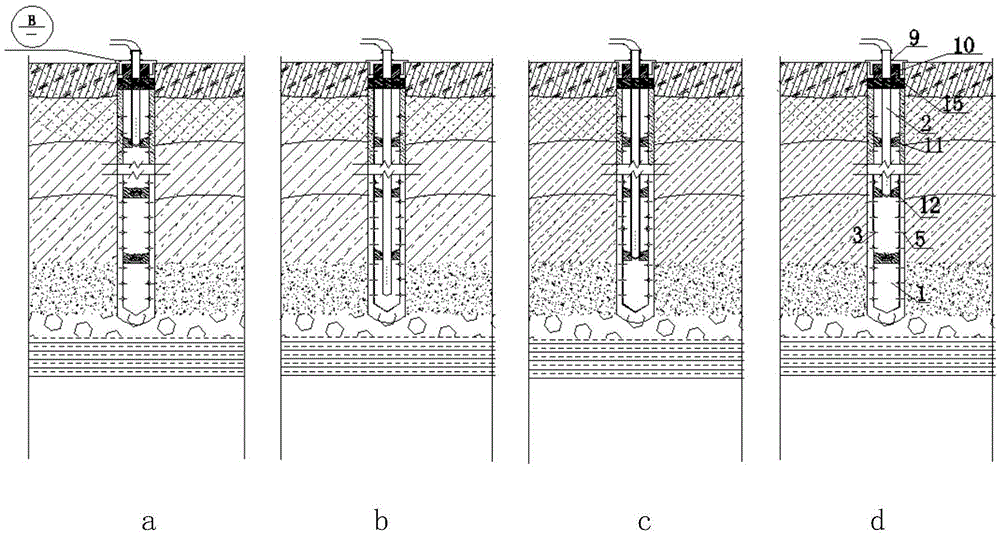

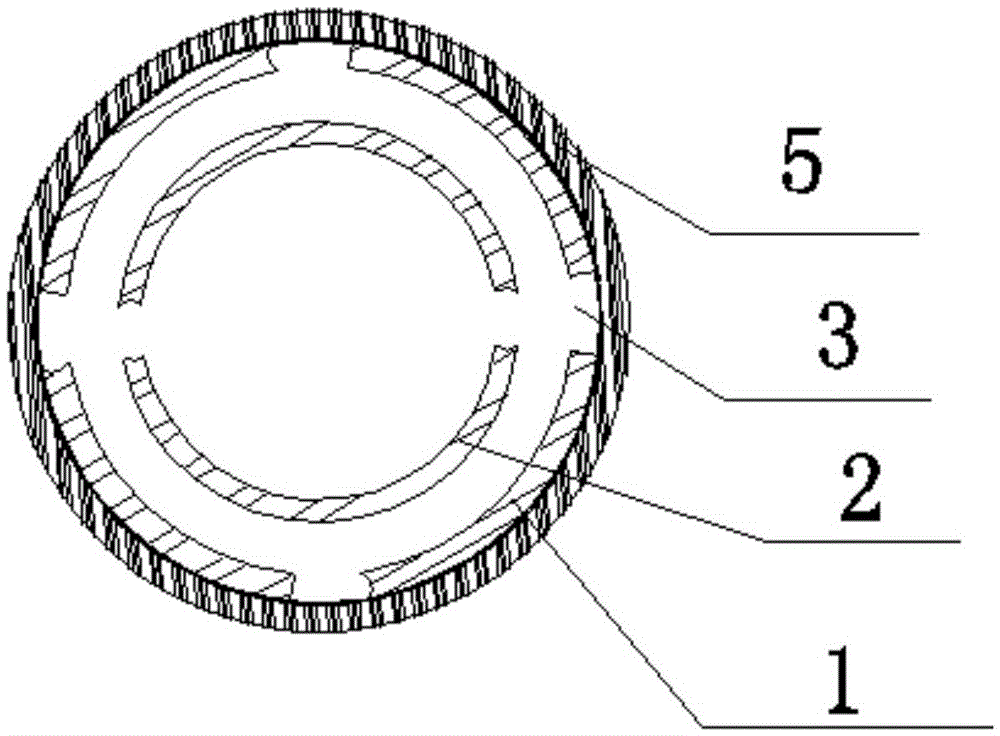

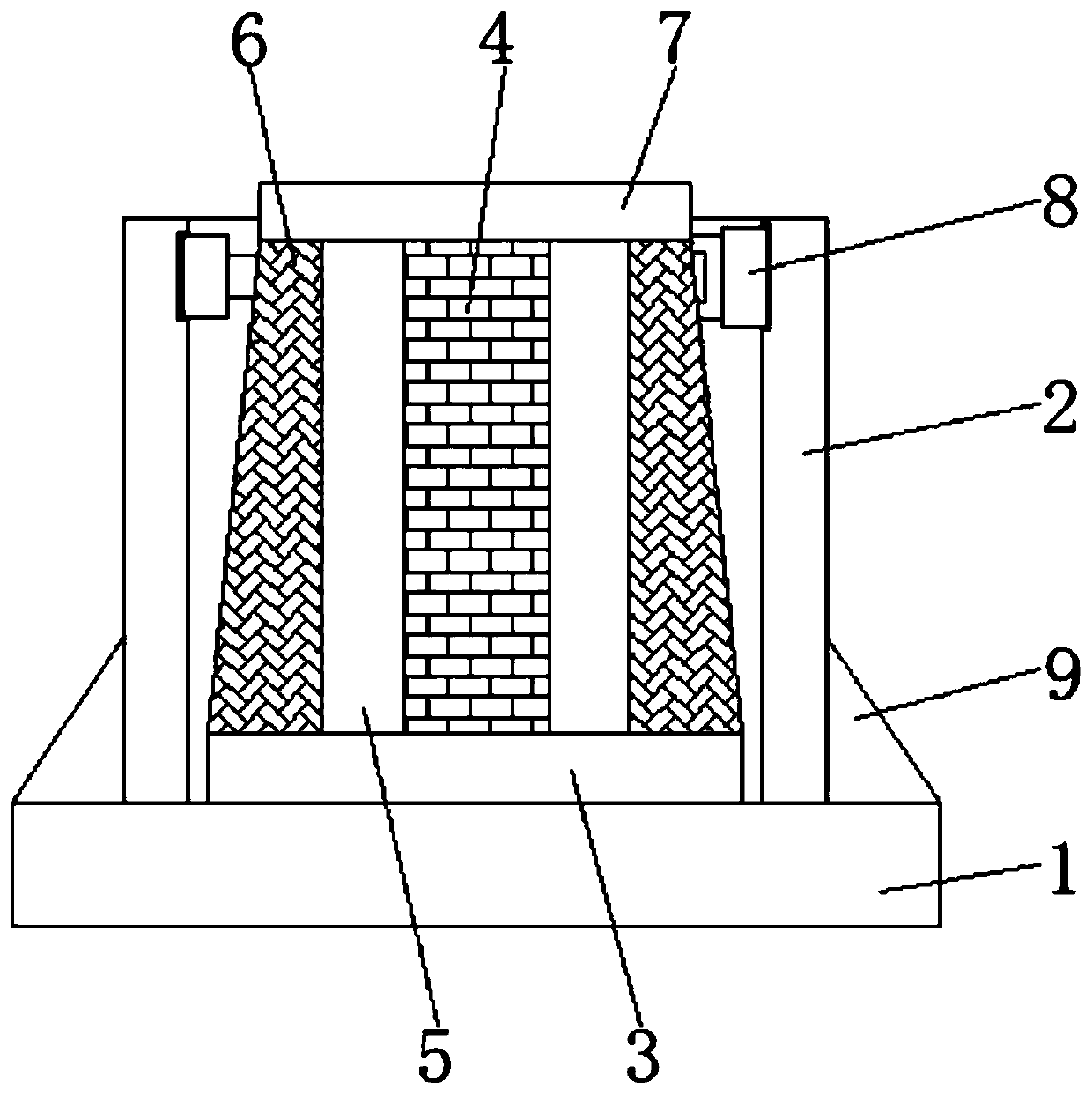

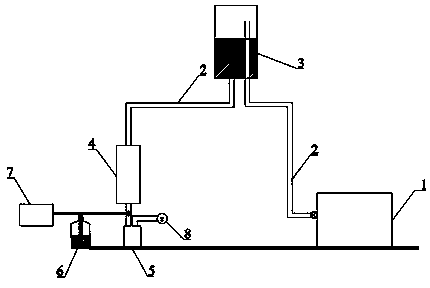

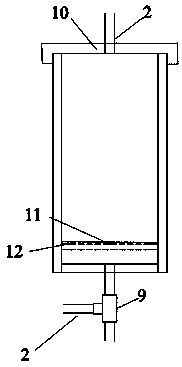

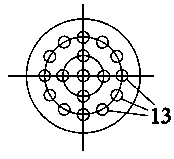

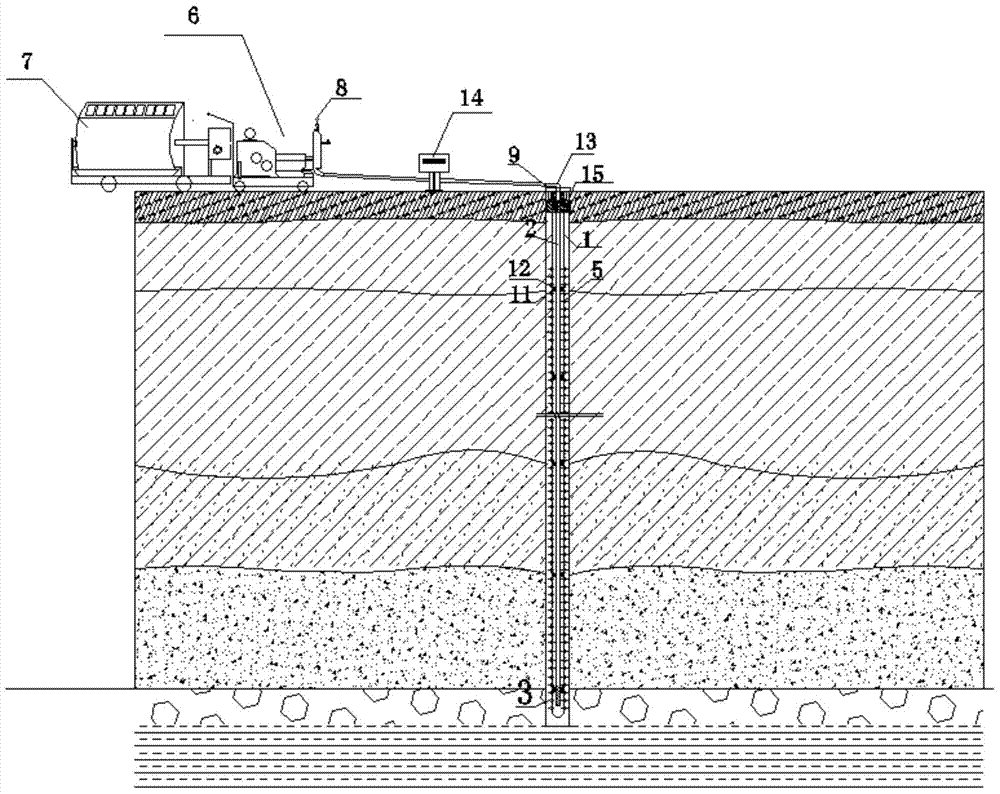

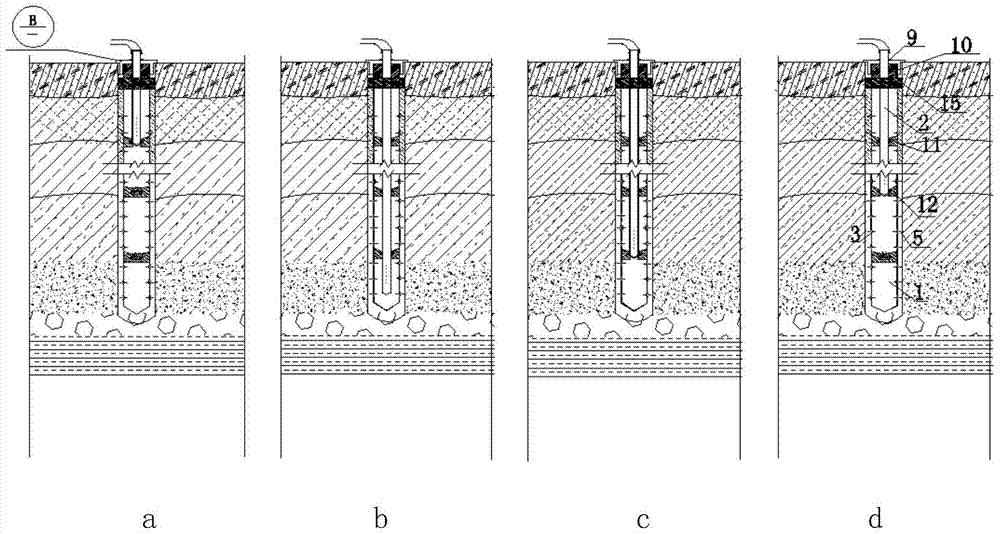

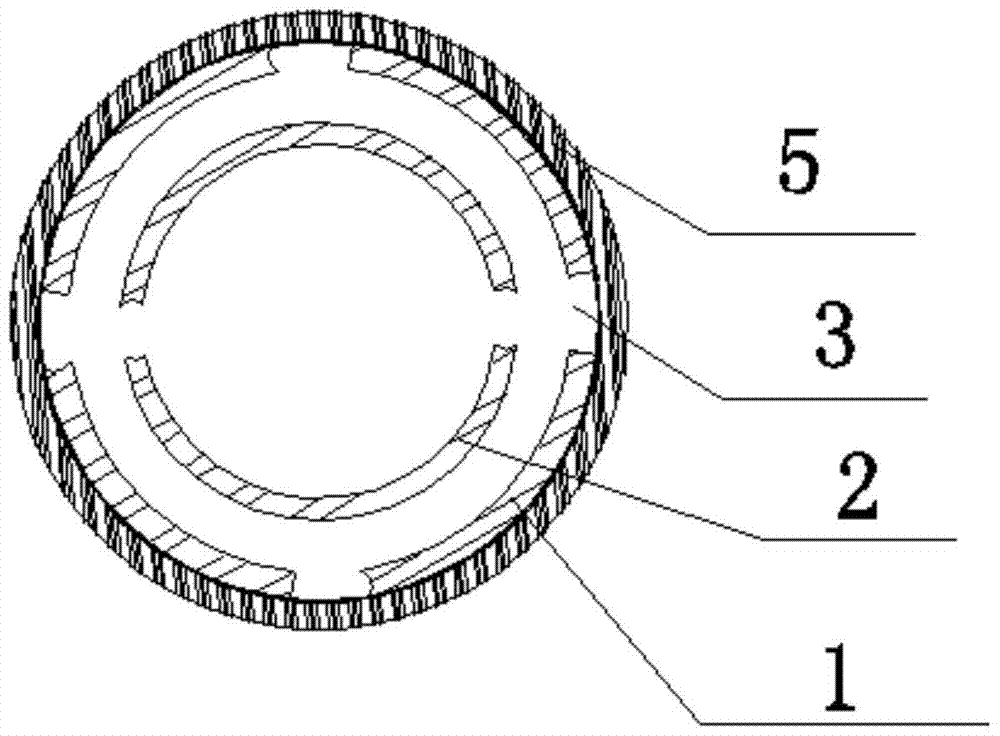

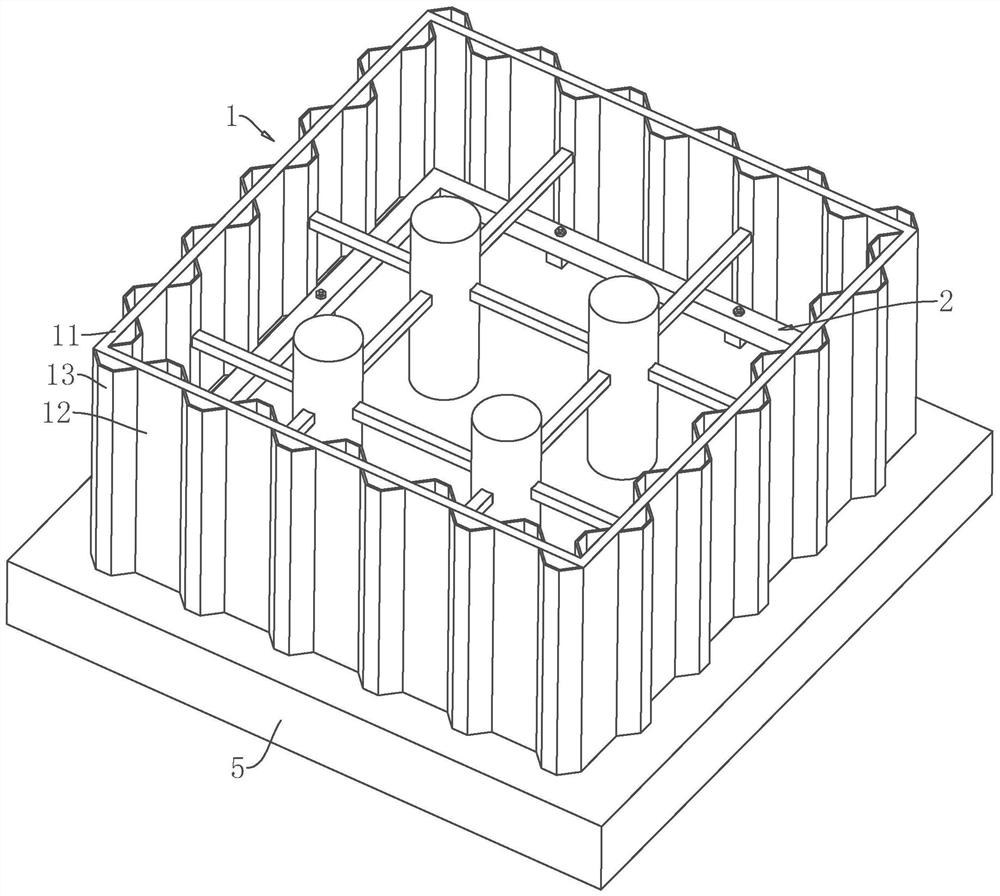

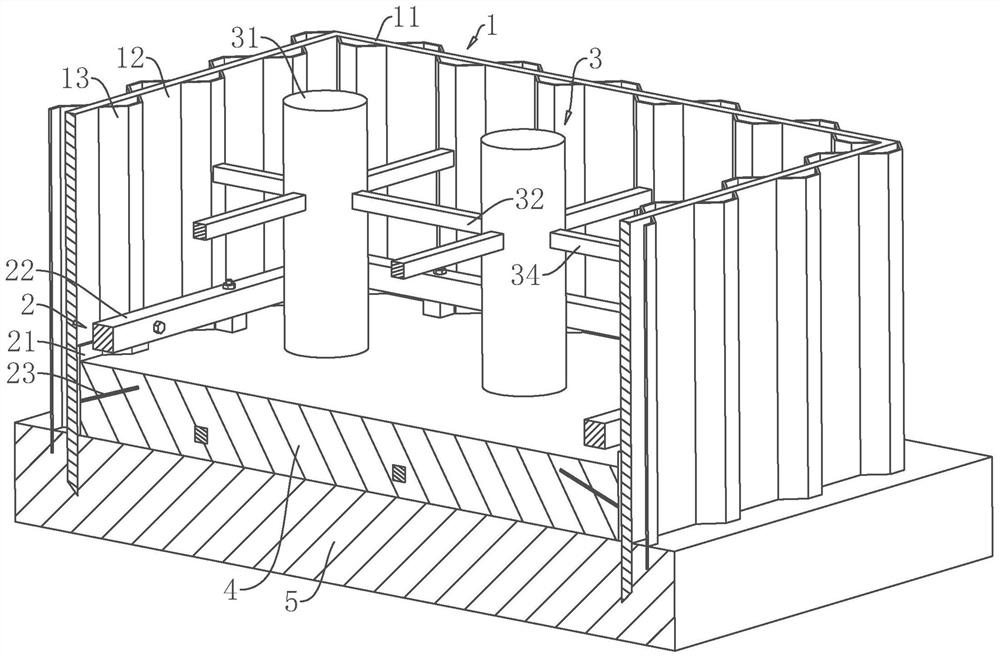

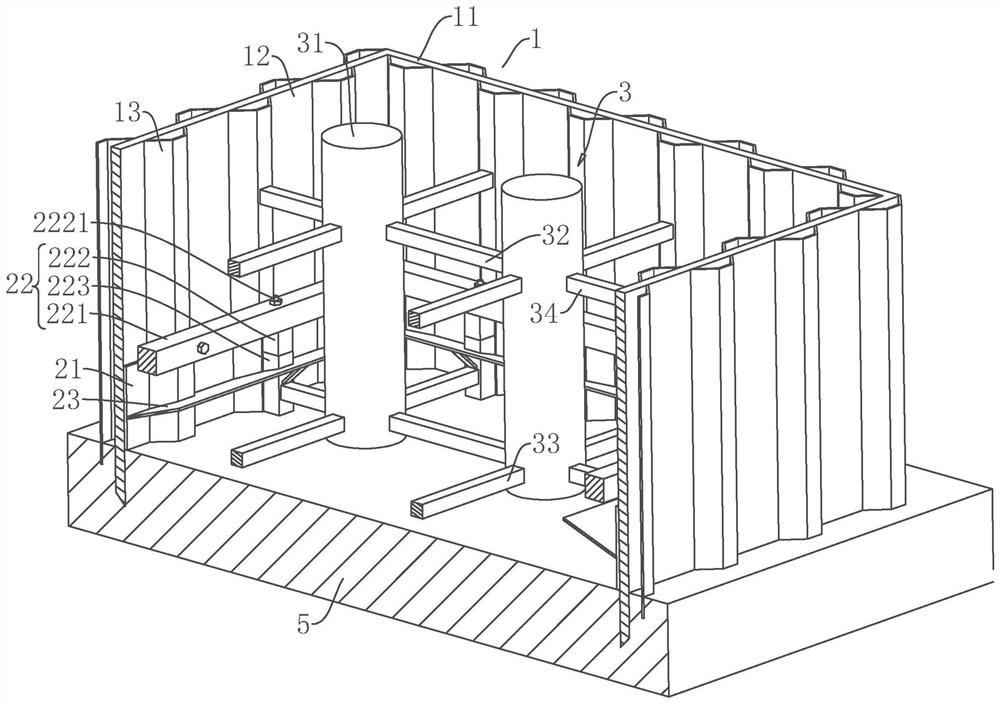

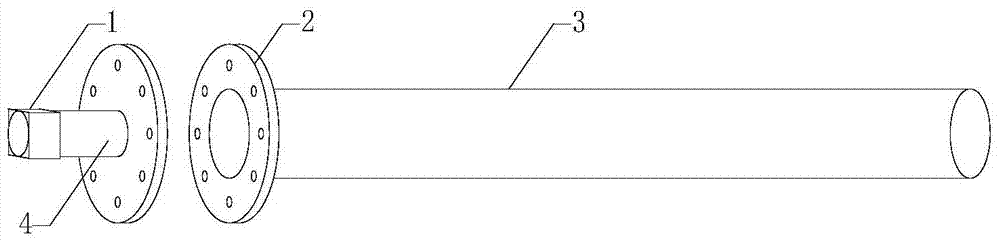

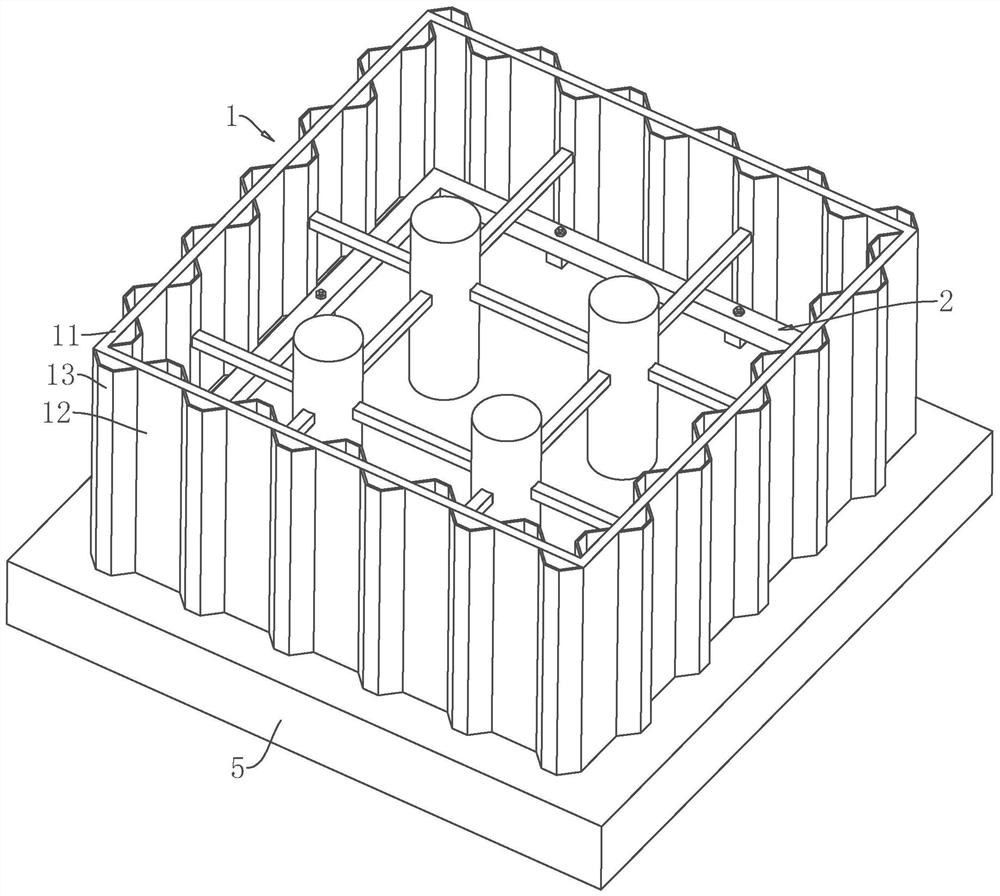

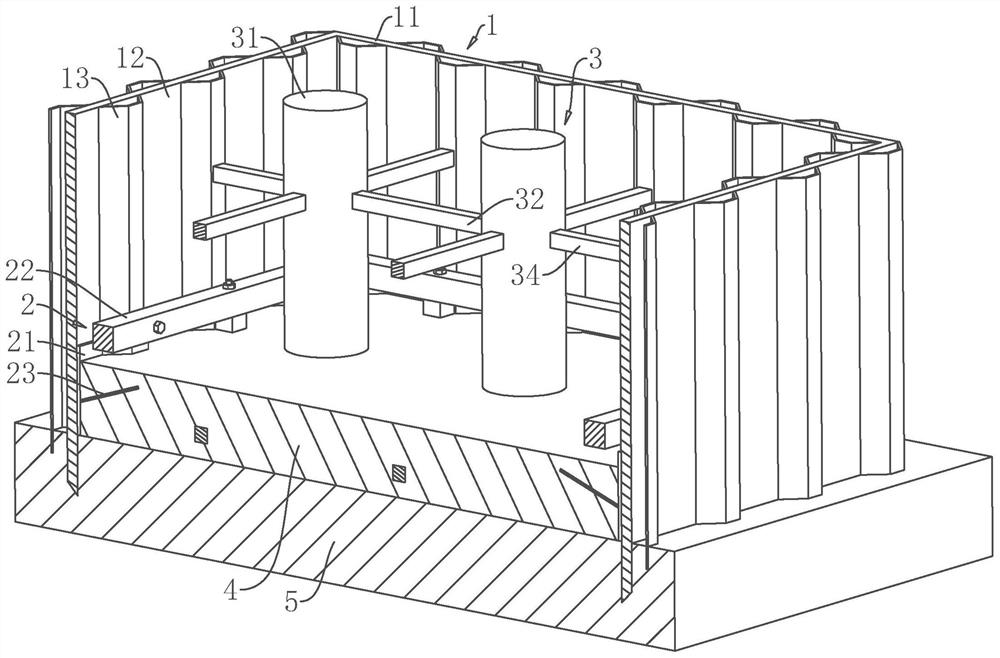

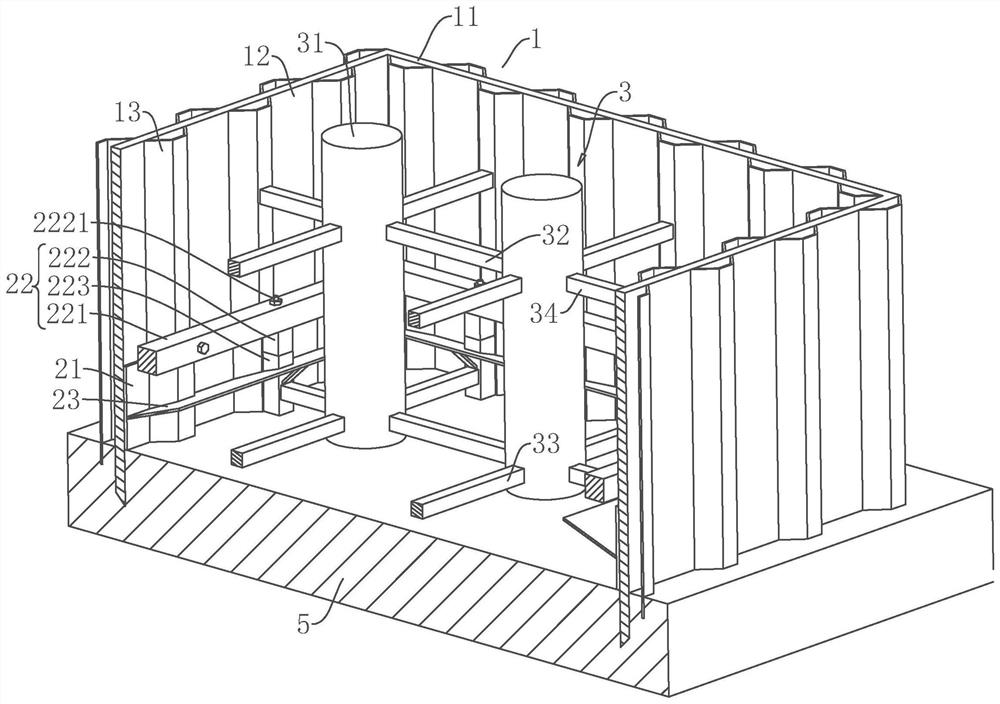

Covering type soil filled and soft soil stratum segmented reinforcing device and method

The invention discloses a covering type soil filled and soft soil stratum segmented reinforcing device and method. A covering type segmented grouting tube comprises a slurry delivery tube connected with a pressure-adjustable grouting machine; the slurry delivery tube is connected with a grouting core tube via a joint; the bottom end of the grouting core tube is closed while the top end of the grouting core tube is connected with the slurry delivery tube; a segmented grouting steel tube sleeves the outside of the grouting core tube; a plurality of internal grouting holes are uniformly formed in a bottom region of the grouting core tube; a plurality of slurry stopping rings are correspondingly arranged in the segmented grouting tube according to layer thicknesses of soil layers; a rubber slurry stopping plug and a nut are arranged on the top of the segmented grouting tube; and grouting plum blossom holes are uniformly formed in the surface of a tube body of an external grouting tube at intervals. A soil layer on the surface layer is reinforced at first to reinforce and seal a gap between the grouting tube and a hole wall so as to solve the problem that in a lower end deep and thick soft soil reinforcing process, slurry does not leak out from an orifice section and reinforcement in the depth direction is poor, and covering soil reinforcement and deep reinforcement are finished at one step by the same device.

Owner:CHINA FIRST METALLURGICAL GROUP

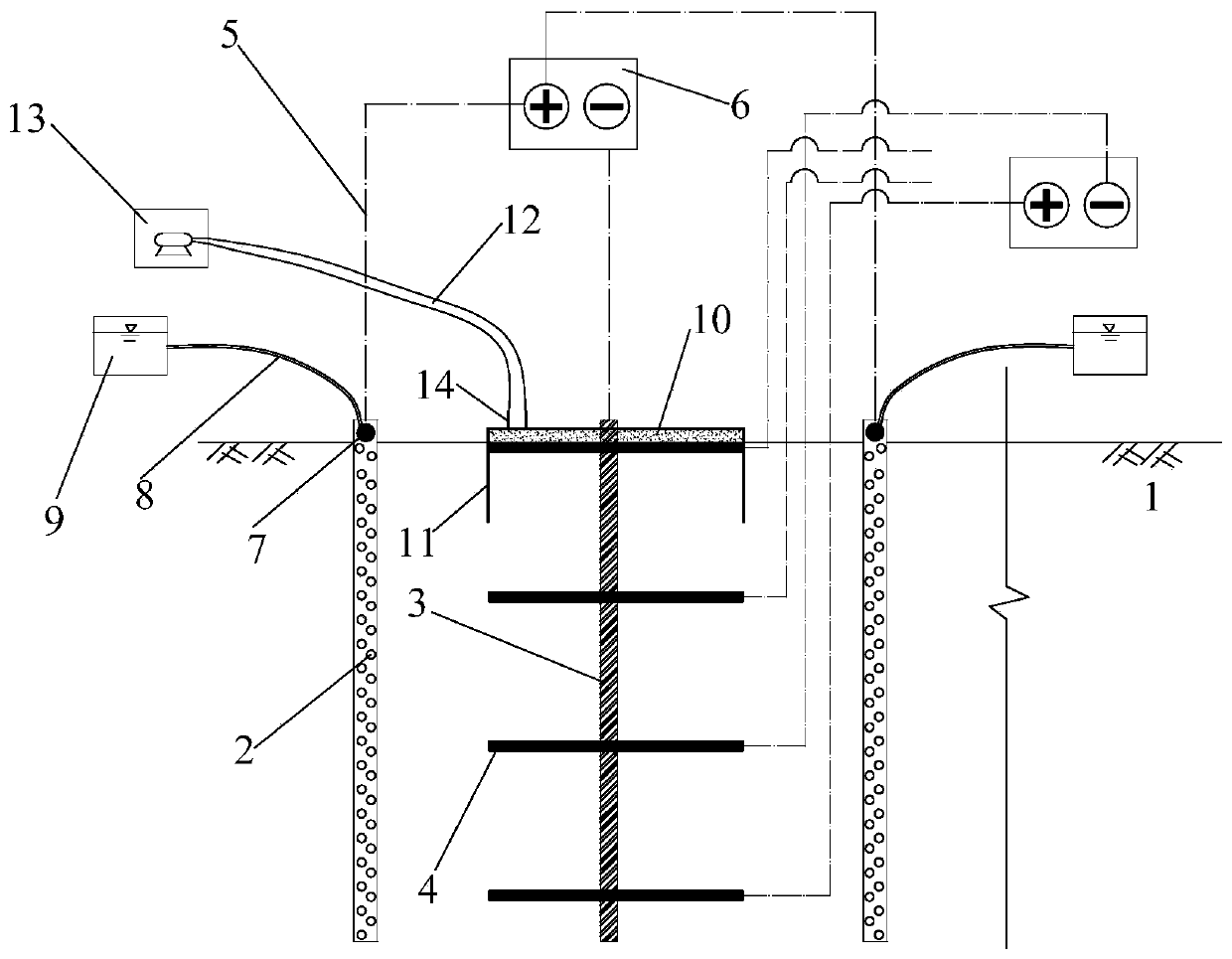

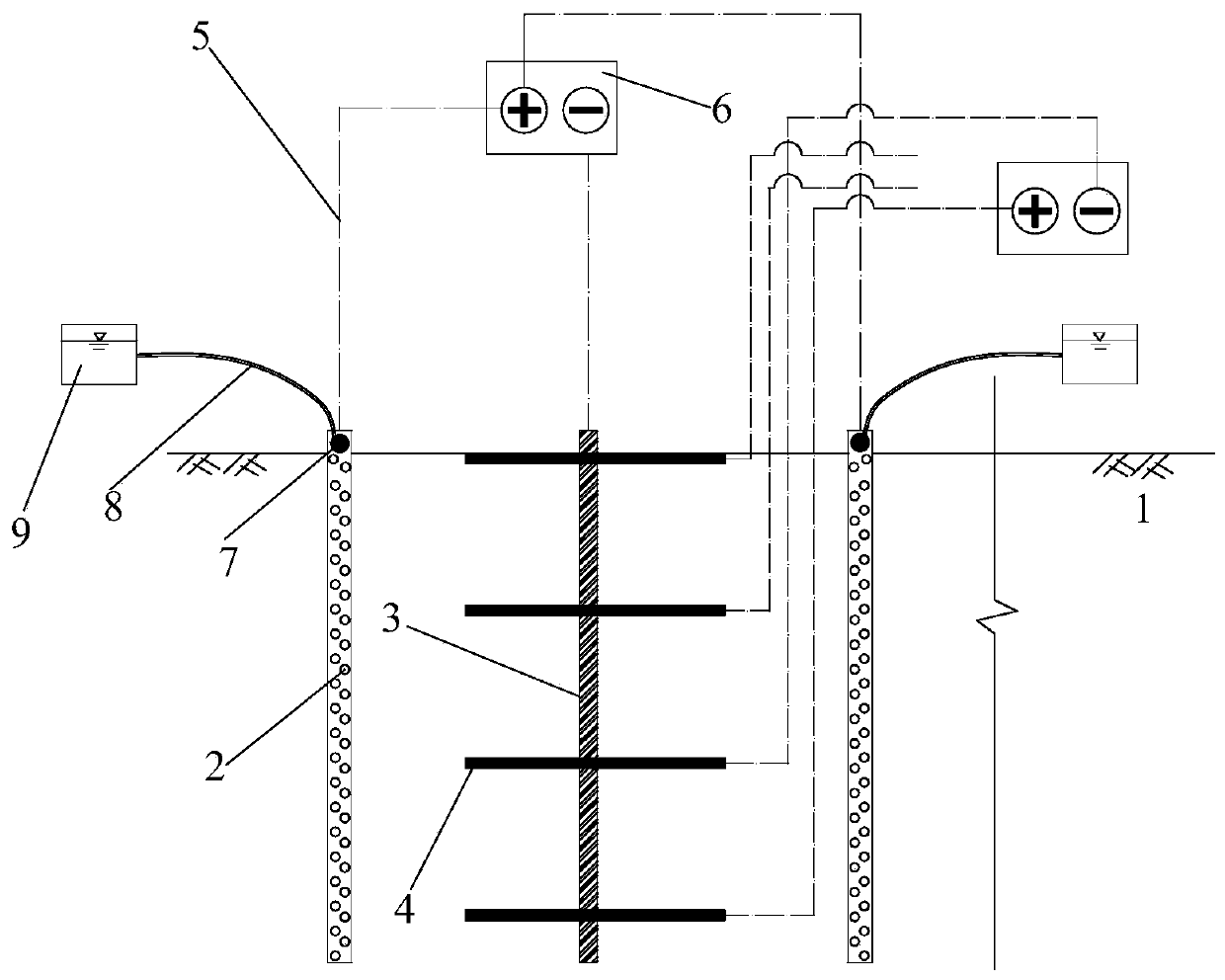

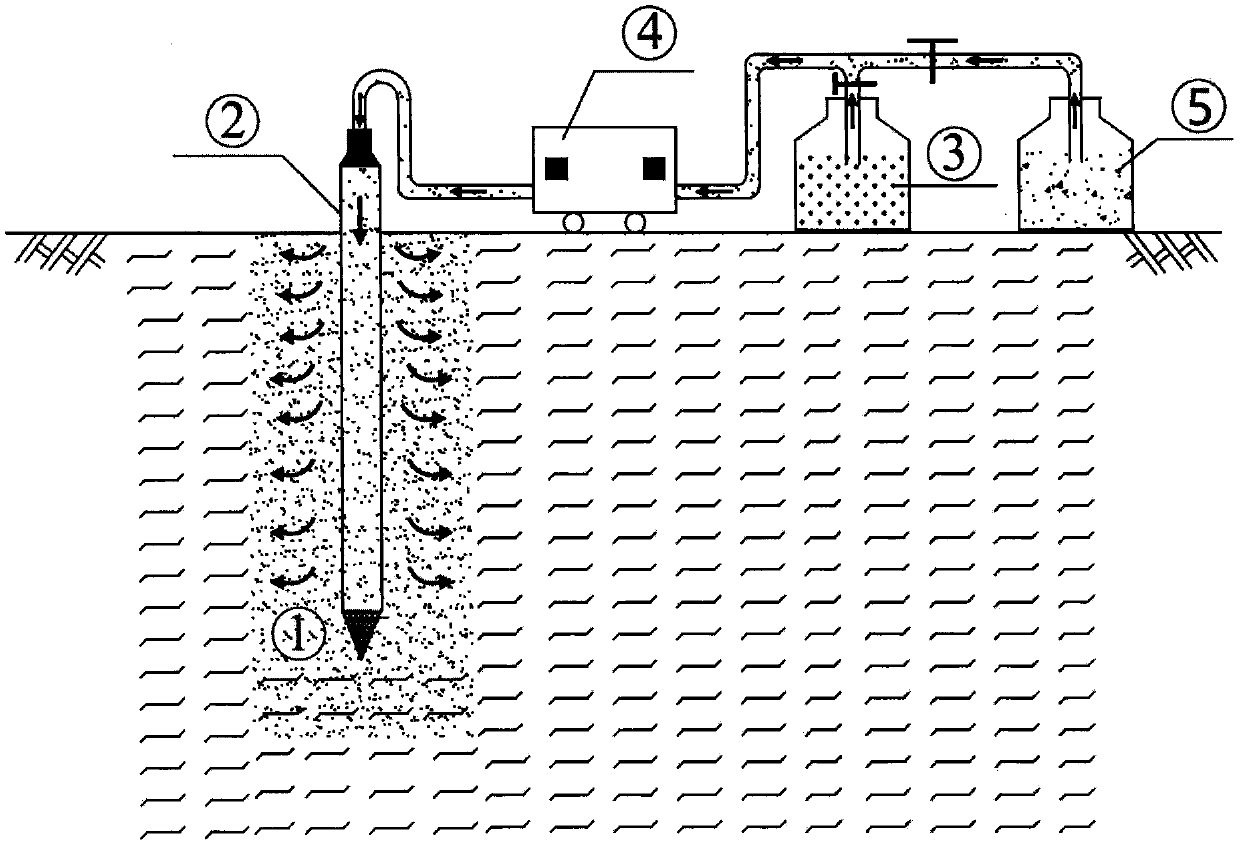

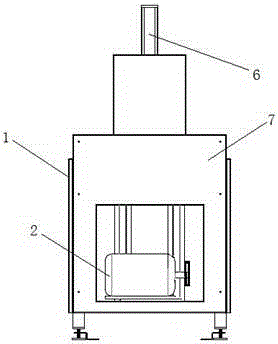

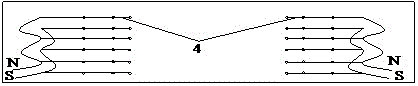

Strengthening electro-osmosis method and system used for reinforcing soft clay foundation

ActiveCN110670574AUniform reinforcementReinforcement is fast and efficientSoil preservationSoil scienceSoft clay

The invention discloses a strengthening electro-osmosis method and system used for reinforcing a soft clay foundation. The method comprises the following steps that electrodes are vertically and horizontally driven into the soft clay foundation, by forming a horizontal electric field between the vertical electrodes and a vertical electric field between the horizontal electrodes, water in a soil body is transferred into a shallow soil body in a cathode area, and discharged in a vacuum-pumping way, and in the process that the vertical anodes are electrified, spraying humidification is conducted.By means of the method, the water converged at the cathodes can be effectively discharged out of the soil body, the service life of the electrodes is prolonged, the problems are solved that in a conventional electro-osmosis method, the soil body is not uniformly reinforced, and the anodes are corroded seriously, the operation is simple, the efficiency is high, and the cost is low.

Owner:南通大学技术转移中心有限公司

Island building structure for across-riverway bridge construction

InactiveCN110700222AIncrease prestressImprove stabilityArtificial islandsUnderwater structuresPile capRiver routing

The invention discloses an island building structure for across-riverway bridge construction. The island building structure comprises a footstone, a cofferdam is fixedly connected to the edge of the top of the footstone, a base is fixedly connected to the top of the footstone, a main pier is fixedly connected to the midpoint of the top of the base, a clay wall is fixedly connected to the surface of the main pier, the surface of the clay wall is fixedly connected with a reinforcing cage protective layer, and the bottom of the clay wall and the bottom of the reinforcing cage protective layer areboth fixedly connected with the top of the base. Through cooperation of the cofferdam, the base, the main pier, the clay wall, the reinforcing cage protective layer, a pile cap, a first connecting block, a hollow column, a chute, a slider, a threaded rod, a threaded sleeve, a connecting rod, an annular groove, a limiting block and a second connecting block, the high-stability island building structure for across-riverway bridge construction is realized; and through adjustment of a connecting device, the outward prestressing force of the cofferdam can be increased, the structure is firmer during outside pressure resisting, and the adaptability is higher.

Owner:宁波西沃工程科技有限公司

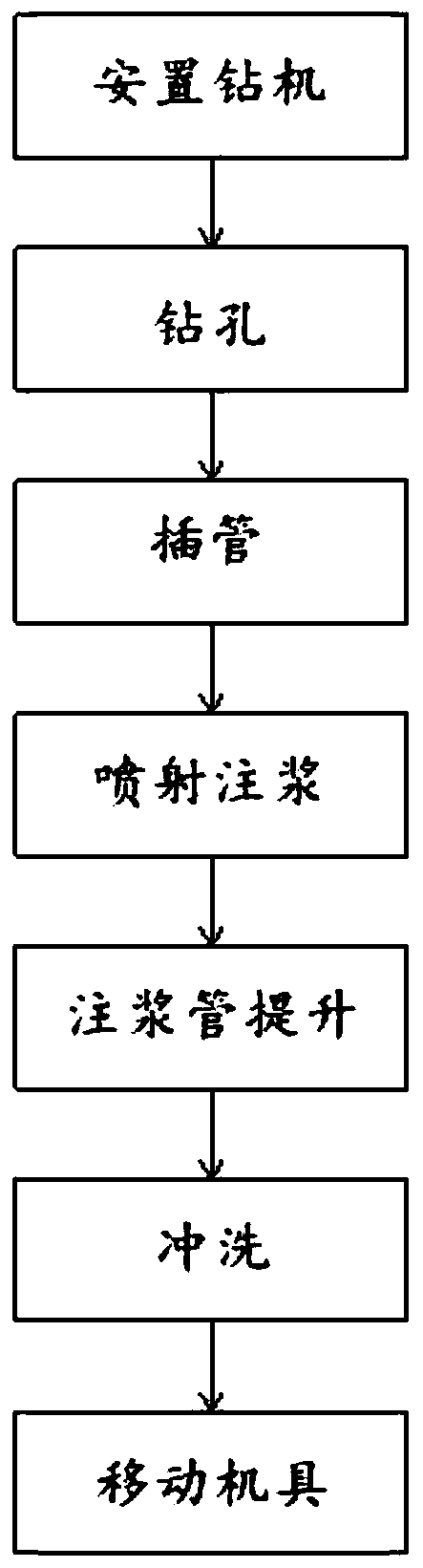

High-pressure jet grouting pile construction method

InactiveCN111455988AAdequate fitIncrease the amount of slurryBulkheads/pilesStructural engineeringCement slurry

The invention provides a high-pressure jet grouting pile construction method which achieves the technical effects of reducing construction cost and further adapting to the construction environment ofa silt geological layer by improving an existing high-pressure jet grouting pile construction technology. The method comprises the following steps that a drilling machine is installed, specifically, the drilling machine is arranged on a set hole position, inclination of a jet grouting pipe is less than or equal to 1.5%, and the distance between an injection hole and a high-pressure grouting pump is less than or equal to 50 m; drilling is carried out, specifically, the deviation between a drilling position and design is less than or equal to 50 mm, the drill bit inclination is smaller than or equal to 1.5%, and a core barrel is pulled out after drilling; pipe inserting is carried out, specifically, the jet grouting pipe is inserted into the stratum by a preset depth; spraying and grouting are carried out, specifically, spraying and grouting are carried out from bottom to top, and after rotating and spraying are carried out by 1 min at the bottom of a pile, rotation, lifting and sprayingare simultaneously carried out; the grouting pipe is lifted up, specifically, when the grouting pipe is lifted, a drilling rod is synchronously and continuously rotated without interruption, and theslurry discharge amount is between 10% and 20%; the overlapping length of subsection lifting of the grouting pipe is greater than or equal to 100 mm; washing is carried out, specifically, the groutingpipe and an operation machine are washed until no residual cement slurry exists; and equipment is moved, specifically, relevant equipment such as the drilling machine is moved to a new hole positionto carry out next pile construction.

Owner:珠海十字门中央商务区建设控股有限公司

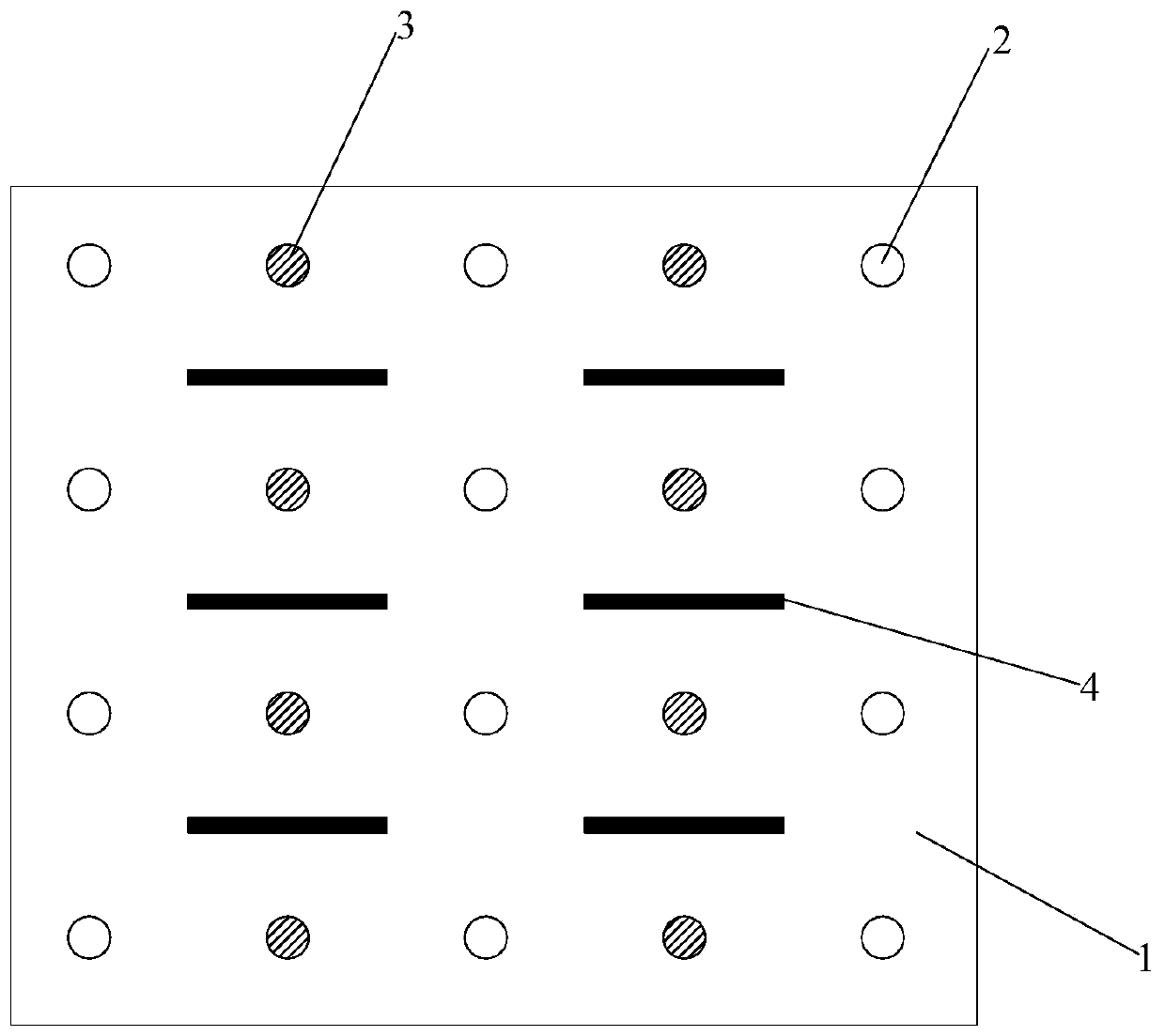

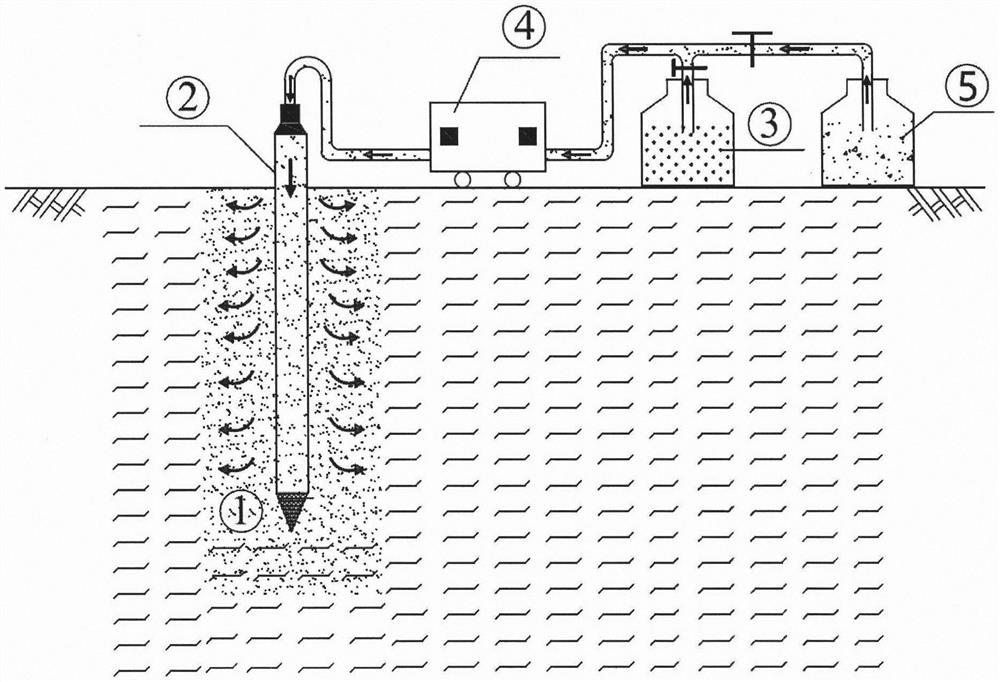

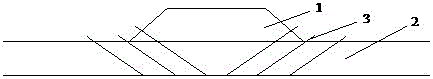

Microbiological treatment method for lead and cadmium polluted soil foundation

ActiveCN110548761AHigh strengthStrong toleranceContaminated soil reclamationMicroorganismGrowth promotion

The invention discloses a microbiological treatment method for a lead and cadmium polluted soil foundation and aims to sequentially achieve environment repairing and reinforcement on the lead and cadmium polluted soil foundation within one construction cycle. The microbiological treatment method is characterized by comprising the following steps: a, measuring leaching amounts of lead and cadmium in soil of a stratum 1 to be treated, drilling holes in the stratum 1 to be treated, and allocating grouting tubes 2; b, preparing a microorganism growth promotion liquid 3, and injecting the microorganism growth promotion liquid 3 into the stratum 1 to be treated through a grouting pump 4 every other 5 days; c, detecting urease activity of the soil in the stratum 1 to be treated, and when the urease activity is greater than 80mg / g, stopping injecting the microorganism growth promotion liquid 3 into the stratum 1 to be treated; d, preparing a cementing solution 5, and injecting the cementing solution 5 into the stratum 1 to be treated through the grouting pump 4 every other two days; and e, after preset grouting rounds are met, detecting the strength of the foundation and leaching amounts of lead and cadmium ions in the soil, pulling out all grouting tubes 2 after requirements are met, and if the requirements are not met, repeating the step d till the requirements are met.

Owner:NANJING FORESTRY UNIV

Toughness enhancer for repeated regeneration of aged SBS modified asphalt as well as preparation method and application thereof

The invention relates to the technical field of regeneration and cyclic utilization of modified asphalt, in particular to a toughness enhancer for repeated regeneration of aged SBS modified asphalt aswell as a preparation method and application thereof. The invention relates to a toughness enhancer for repeated regeneration of aged SBS modified asphalt. The toughness enhancer comprises the following components in parts by mass: 50-100 parts of polyester fibers, 20-50 parts of rubber particles, 20-50 parts of synthetic resin, 2-10 parts of an anionic surfactant and 2-10 parts of activated carbon. According to the toughness enhancer for multiple times of regeneration of the aged SBS modified asphalt as well as the preparation method and application of the toughness enhancer, the toughness enhancer can greatly improve the toughness of the regenerated SBS modified asphalt, so that the regenerated SBS modified asphalt can satisfy the use requirements after multiple times of aging.

Owner:天津恒吉生科技有限公司

Novel method of grouting under plate

The invention provides a new process for concrete pouring under plate, comprising the following steps of: pouring top plate, boring with boring machine, installing pouring pipe, and single-pore pouring. The new process has the advantages that the main novelty of the new process for concrete pouring under plate is blocking and dredging; the blocking means that the outlet passage for lost slurry is blocked and the dredging means the flowing direction of the slurry along the concrete plate; the slurry loss and waste are avoided, the construction investment is saved; the concrete pouring is carried out under the top plate, the flowing direction of the slurry is easy to be controlled, the reinforced soil is more uniform and compacter and has high quality; the concrete pouring effect is more obvious; the practices in places such as Wugang, Baogang, Debao city of Guangxi, etc. show that about 20-50% of the slurry loss can be saved relatively. The strength of soil in-situ after the concrete pouring can be directly gained by methods such as standard penetration test or light sounding test, etc. 28 days after the completion of the concrete pouring and the mechanical property is greatly improved compared with that of the soil in-situ before the concrete pouring.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

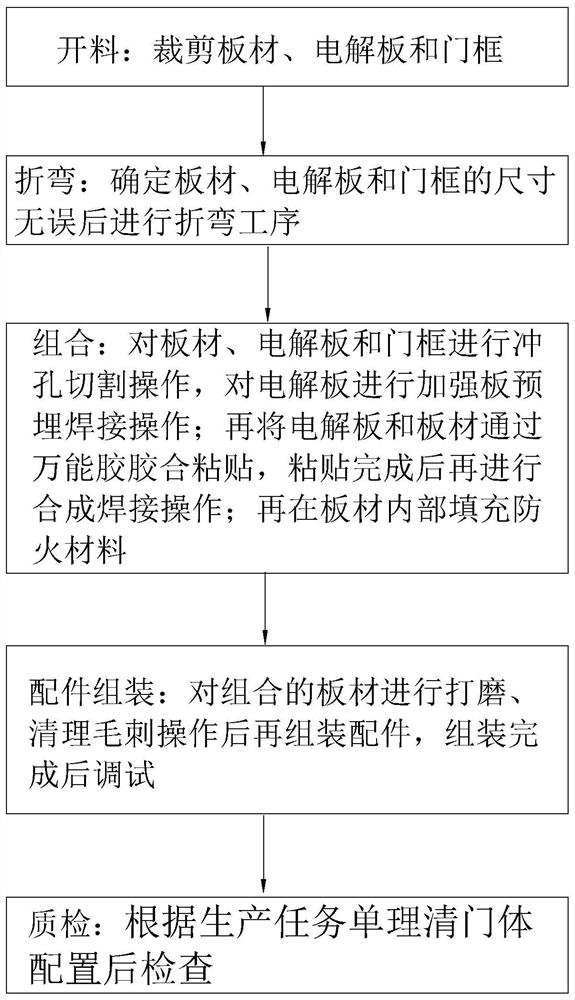

Process for manufacturing intelligent security door

InactiveCN111720014AHigh strengthLow costBurglary protectionDoor leavesElectrolysisStructural engineering

The invention relates to the technical field of security door manufacturing, and aims to provide a process for manufacturing an intelligent security door. The process includes the following steps thatcutting is conducted, and a plate, an electrolytic plate and a door frame are cut; bending is carried out, after the dimensions of the cut plate, the electrolytic plate and the door frame are confirmed to be correct, lines are drawn respectively on the plate, the electrolytic plate and the door frame, and the plate, the electrolytic plate and the door frame are bent; combination is carried out, after bending is completed, punching and cutting operations are carried out on the plate, the electrolytic plate and the door frame respectively, then a reinforcing plate is pre-buried and welded on the electrolytic plate, and after combined welding is conducted on the electrolytic plate welded with the reinforcing plate and the cut plate, the plate is filled with fire-proof materials; and accessory assembling is carried out, polishing and burr removal operation is conducted on the combined plate, accessories are assembled after the lines are drawn and holes are drilled according to the requirements, and debugging is conducted after assembling. The effect of reducing the cost of security doors with special security requirements for banks is realized.

Owner:广州淏华实业有限公司

A test device and method for demoulding microbial grouting reinforcement silt

ActiveCN109959773BEvenly distributedCan control and adjust the grouting speedPreparing sample for investigationEarth material testingMicroorganismSoil science

Owner:HEFEI UNIV OF TECH

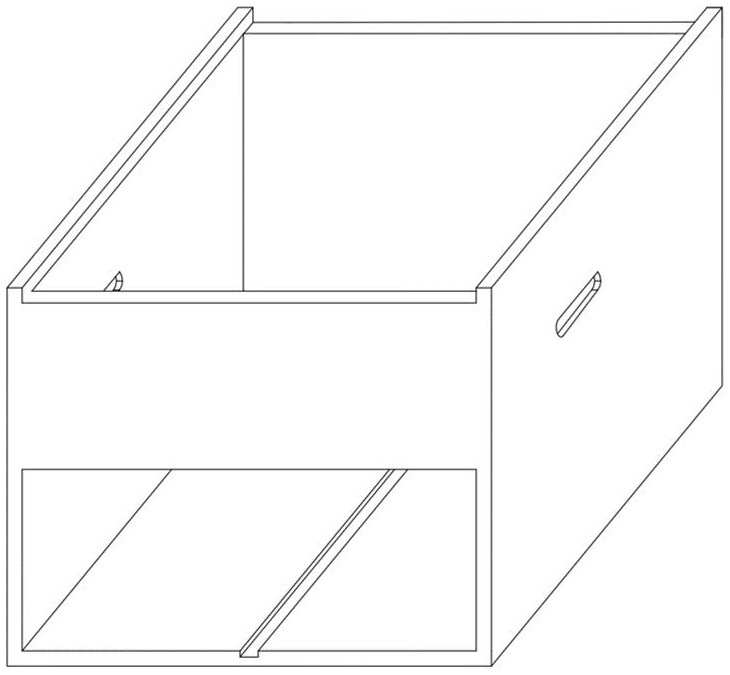

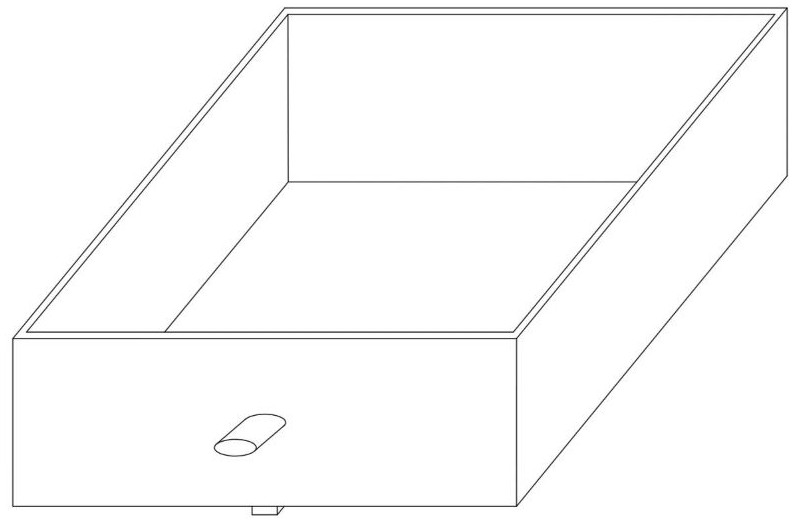

Automatic glue pressing machine for bonding elevator door plate strengthening rib

The present invention provides an automatic glue pressing machine having characteristics of high efficiency and good glue pressing quality and used for bonding an elevator door plate strengthening rib. The automatic glue pressing machine comprises a glue pressing machine frame, wherein a motor is arranged under the glue pressing machine frame and is connected to an upper pressing drum through a transmission mechanism, the upper pressing drum can be fixed on the glue pressing machine frame through a bearing in an upper-and-down movement manner, and the upper pressing drum is connected to a power mechanism for driving the upper pressing drum to move up and down. According to the present invention, the manual work is not required, the pressing and the bonding of the strengthening rib are completed on the working table, and the processing efficiency is high; the upper pressing drum is adjusted to achieve the proper height and the protection measure is not required; and the quality is ensured, and the elevator door plate strengthening rib is uniformly pressed.

Owner:苏州银海机电科技有限公司

A microbial treatment method for lead and cadmium polluted soil foundation

ActiveCN110548761BHigh strengthStrong toleranceContaminated soil reclamationMicroorganismSoil science

A microbial treatment method for lead- and cadmium-contaminated soil foundations, which can successively realize environmental restoration and reinforcement of lead- and cadmium-contaminated soil foundations within one construction period, and is characterized in that the steps of the method are as follows: a. The leaching amount of lead and cadmium ions in the soil, and then drill holes on the stratum 1 to be treated and arrange the grouting pipe 2; b. prepare the microbial growth-promoting liquid 3, and pour it into the stratum 1 to be treated through the grouting pump 4 every 5 days Inject the microbial growth-promoting liquid 3; c. detect the urease activity of the soil in the stratum 1 to be treated, and stop injecting the microbial growth-promoting liquid 3 into the stratum 1 to be treated when the urease activity is greater than 80 mg / g; d. prepare the cementing solution 5, Inject the cementing solution 5 into the stratum 1 to be treated through the grouting pump 4 every 2 days; e. After the site reaches the predetermined number of grouting times, check the strength of the foundation and the leaching amount of lead and cadmium ions in the soil, and pull out after meeting the requirements For all grouting pipes 2, if the requirements are not met, repeat step d until the requirements are met.

Owner:NANJING FORESTRY UNIV

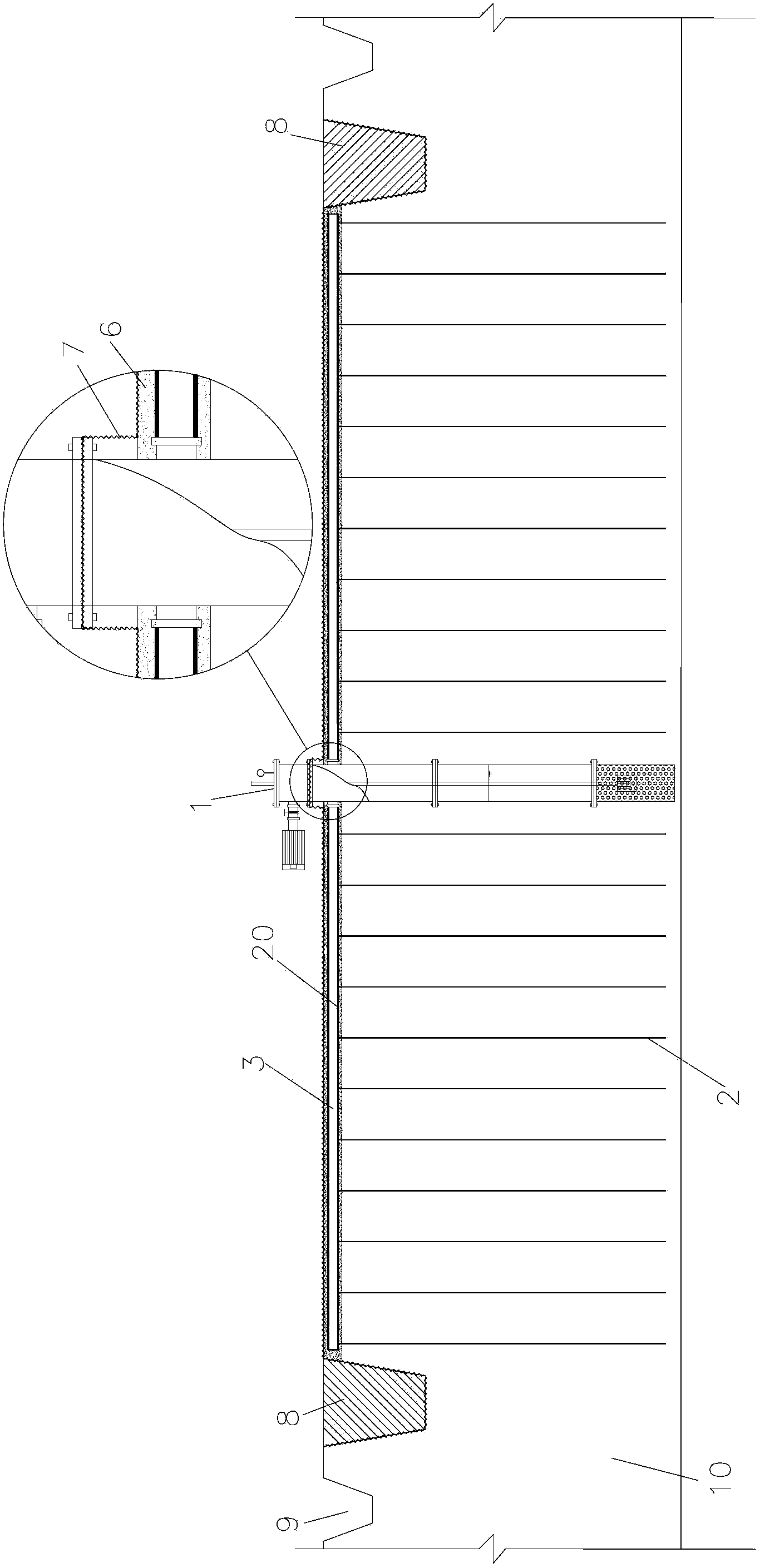

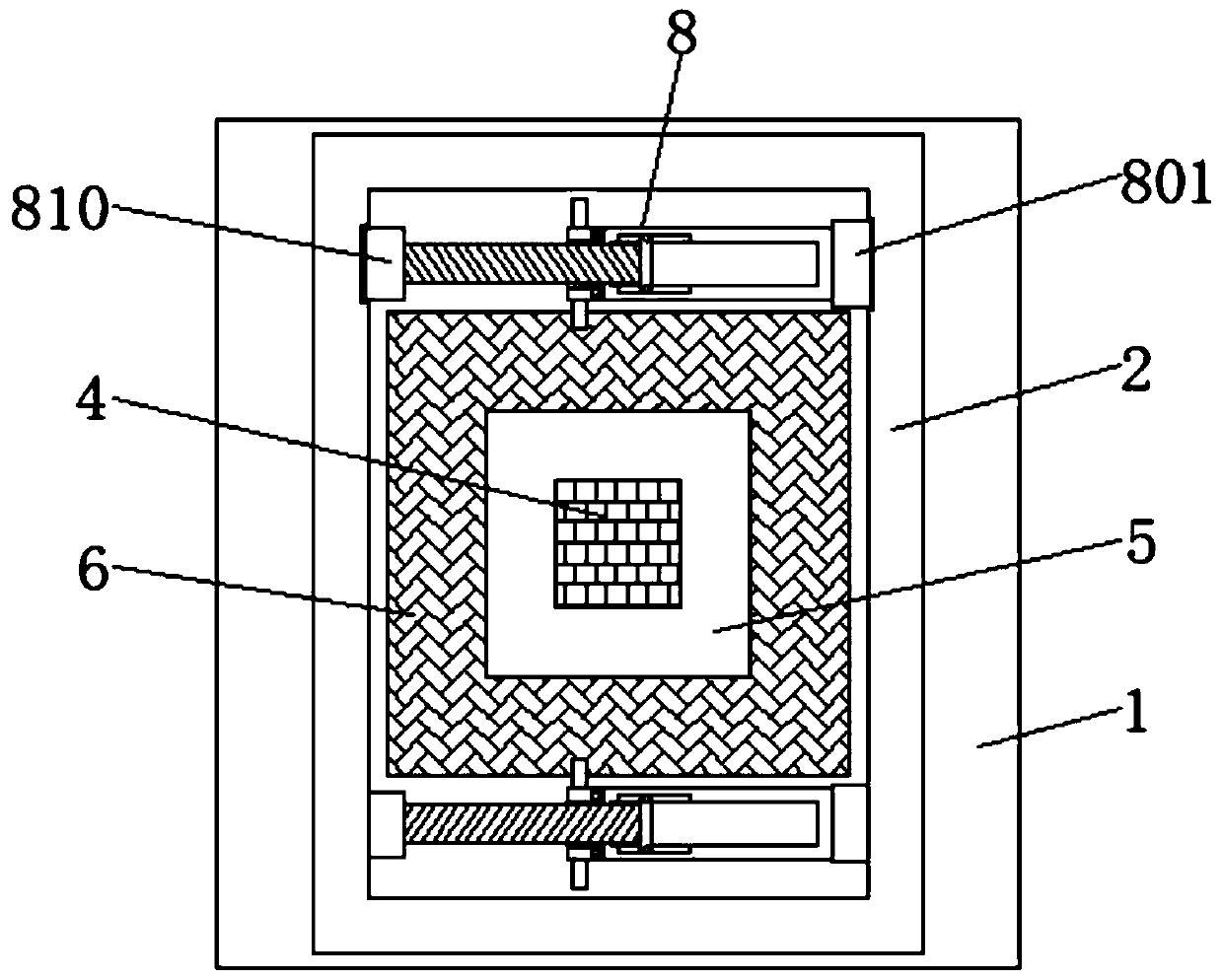

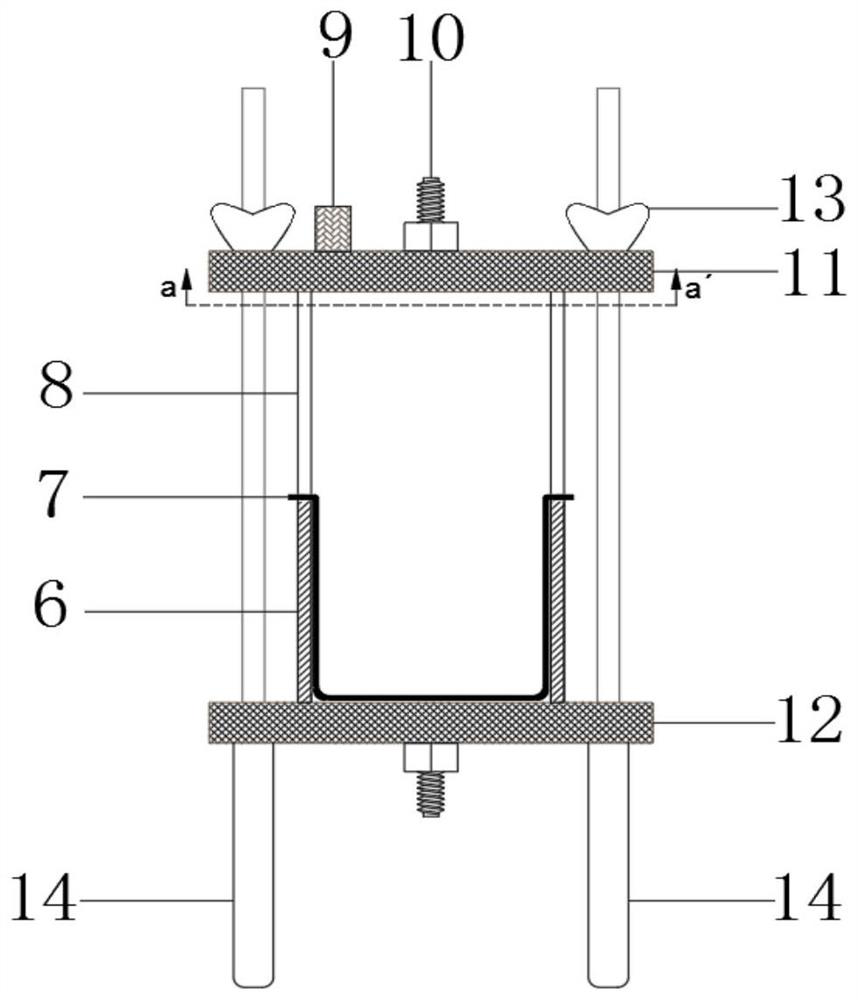

Device and method for one-dimensional microbial grouting reinforcement silt test

ActiveCN106153860BEvenly distributedUniform reinforcementEarth material testingVacuum pressureEngineering

The invention discloses a one-dimensional microbe grouting reinforcing silt test device and method. The device comprises a model groove, an air pressure device, a consolidating fluid bottle, a pressure slurry supply device, a recovery barrel, a water gas separation device and a vacuum pump, wherein the top of the model groove is connected with the consolidating fluid bottle through a hose; the consolidating fluid bottle is connected with the air pressure device through a hose; the bottom of the model groove is connected with the recovery barrel and the water gas separation device through hoses; the water gas separation device is connected with the vacuum pump; the lower end inside the model groove is provided with a separation plate with a plurality of holes; filter paper is laid on the separation plate. The upper pressing and lower suction method is used for grouting the silt; the upper part of the model groove is a pressure-resistant steel cover; a glass plate with holes is arranged at the lower part of the model groove; the filter paper is put on the glass plate with holes; the vacuum pressure applied under the glass plate with the holes can be uniformly distributed on the lower surface of the silt body. The device is used for performing grouting reinforcing test on the silt; various microbe reinforcing silt effect tests using various bacteria solutions under different conditions can be set.

Owner:HOHAI UNIV

Device and method for covering and segmentally reinforcing filling and soft ground

Owner:CHINA FIRST METALLURGICAL GROUP

A Construction Method for Electrochemical Treatment of Existing Embankment Soft Foundation

ActiveCN104452738BImprove reinforcement effectIncrease contentSoil preservationElectrochemical responseChemical solution

The invention discloses a construction method for existing dyke soft foundation electrochemical treatment and belongs to the technical field of dyke soft foundation reinforcing engineering. A chemical solution is poured into the peripheries of electrodes to increase the contents of a gel object (Fe(OH)3) and a sediment (Mg(OH)2) for an electrochemical reaction and improve the reinforcing effect of a soil body and shorten the reinforcing time. By means of the combination of the electrochemical solution and the electrochemical reaction, the distance between two rows of electrodes can be increased so as to save materials for experiments. Grooves are reserved in the peripheries of the electrodes, the chemical solution is conveniently poured into the soil body on the peripheries of the electrodes in the construction process, and the concentration of the chemical solution in the soil body on the peripheries of the electrodes is conveniently measured. The positive electrodes and the negative electrodes of a power source are converted and the chemical solution is replaced, so that the electrochemical reaction of the electrodes in the soil body is more sufficient, the reinforcing range is wide, and reinforcing effect is more uniform. The construction method for the existing dyke soft foundation electrochemical treatment is simple in implementation process, high in operability, obvious in economic benefits and remarkable in treatment effect.

Owner:YUSHUN ECOLOGICAL CONSTR +1

Bottom sealing concrete construction structure for water seepage cofferdam design and method thereof

The invention relates to a bottom sealing concrete construction structure for water seepage cofferdam design. The bottom sealing concrete construction structure comprises a cofferdam body, wherein the cofferdam body is a cubic steel sleeve box which is vertically arranged; a concrete bottom sealing layer is poured at the lower end of the inner side of the cubic steel sleeve box; an anti-seepage mechanism is arranged at the lower end of the cofferdam body; the anti-seepage mechanism comprises an anti-seepage coiled material, an anti-seepage frame and an anti-seepage water stop plate; the anti-seepage coiled material is arranged in the circumferential direction of the inner side wall of the lower end of the cubic steel sleeve box; the anti-seepage frame comprises a fixing part, a connecting part and a frame body; the fixing part is fixedly arranged on the inner side wall of the cubic steel sleeve box; the connecting part is detachably and fixedly arranged on the lower side of the fixing part; the anti-seepage frame is fixedly arranged on the lower side of the connecting part; the anti-seepage water stop plate is fixedly arranged on the frame body; and the top surface of the concrete bottom sealing layer is higher than the anti-seepage water stop plate and lower than the fixing part. The bottom sealing concrete construction structure has the effects that the fixing part and the connecting part are separated, so that the cofferdam body is separated from the connecting part, and the cofferdam body can be conveniently disassembled.

Owner:蒙城安路蓝海交通投资有限公司

A kind of forward type localized double-liquid grouting device and construction method

ActiveCN105200978BSimple structureSuitable for live productionSoil preservationArchitectural engineering

Owner:SHANDONG UNIV +1

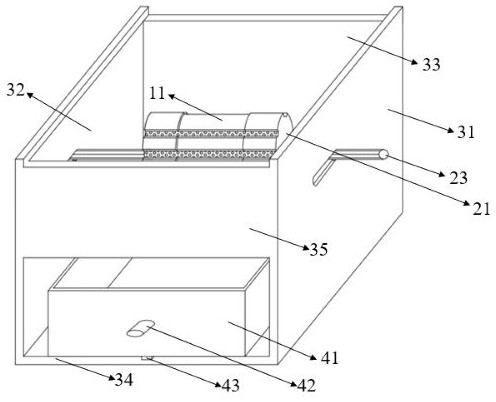

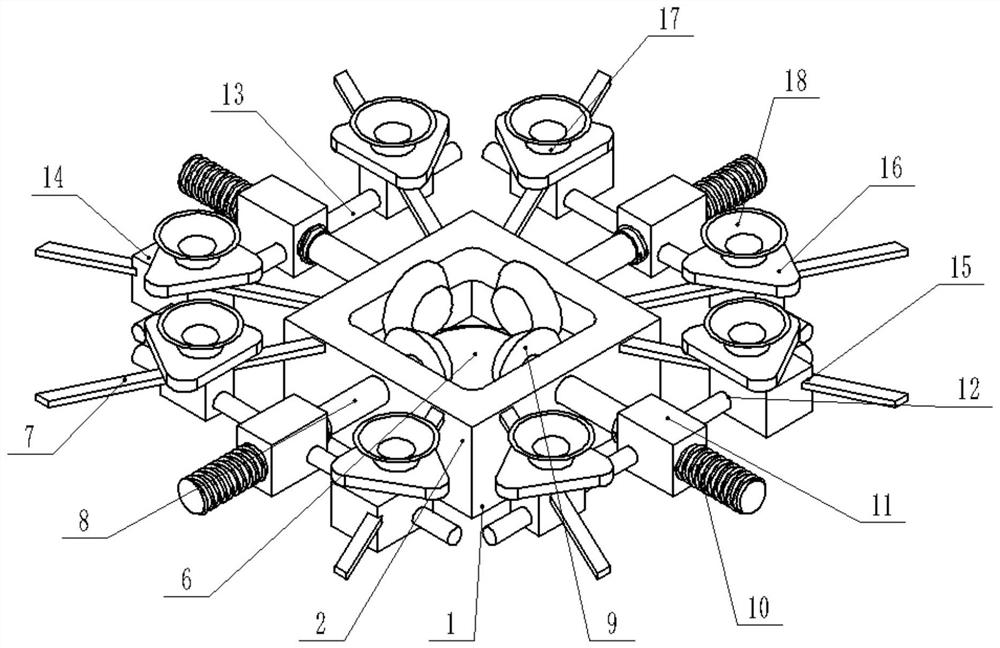

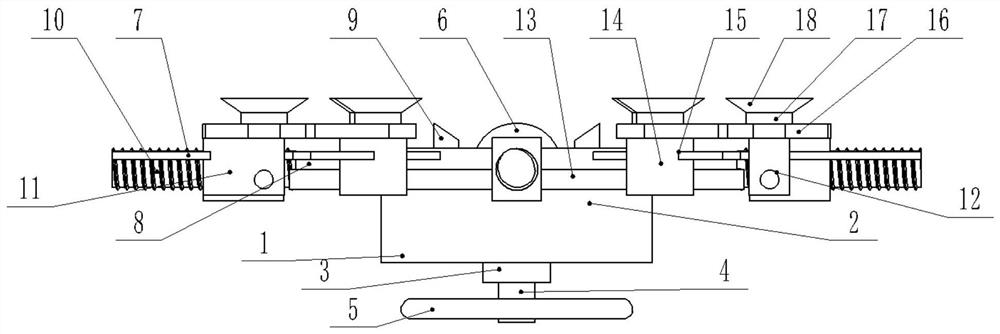

Test device for reinforcing soil body based on MICP technology and use method

PendingCN114705530AUniform reinforcementReinforcement saves time and effortPreparing sample for investigationEarth material testingPeristaltic pumpMicroorganism

The invention discloses a test device for reinforcing a soil body based on an MICP technology and a use method. The device is composed of a sample preparation mold and a liquid injection auxiliary system. The sample preparation mold comprises a semicircular three-dimensional thin-wall groove cylinder, a thin-wall round cover with slotted edges, an octagonal prism supporting rod and a solid anti-seepage strip; the liquid injection auxiliary system comprises a device base, a three-dimensional hollow side plate, a side plate connecting and fixing plate, a movable hollow upper sealing cover and a drawer type waste liquid collecting bin. When a microorganism solidification aeolian sand sample is prepared, aeolian sand is filled into a sample preparation mold, thin-wall round covers with slotted edges are buckled at the two ends, a solid anti-seepage strip is embedded into the slotted position of the mold, the sample preparation mold is fixed in a liquid injection auxiliary system through an octagonal prism supporting rod, and after liquid is circulated through a peristaltic pump, the sample preparation mold is filled with the solid anti-seepage strip. And the liquid is conveyed to the opening in the groove through the liquid injection hose for injection. The method has the characteristics that the material consumption is reduced, the phenomenon of non-uniform pouring caused by solidification of part of soil is avoided, and the pouring efficiency and the reinforcing effect can be obviously improved.

Owner:LIAONING TECHNICAL UNIVERSITY

Steel structure plane reinforcing structure

InactiveCN112065094AImprove reinforcement effectUniform reinforcementBuilding repairsEngineeringBevel gear

The invention discloses a steel structure plane reinforcing structure, and relates to a reinforcing device. The steel structure plane reinforcing structure comprises a chassis, a box body is fixedly connected above the chassis, a shaft sleeve is fixedly connected below the middle part of the chassis, the shaft sleeve is rotatably connected with a rotating shaft, and the bottom end of the rotatingshaft is fixedly connected with a control turntable; the steel structure plane reinforcing structure is characterized in that the top end of the rotating shaft is fixedly connected with a driving bevel gear; limiting plates are fixedly connected to the upper portion of the middle of the side wall of the box body in a front-back symmetry manner; plate grooves are connected with the limiting platesin a sliding manner; and a triangular supporting plate is fixedly connected to the upper portion of a sliding block, an air extractor is fixedly connected to the middle of the upper portion of the triangular supporting plate, and a suction cup is arranged at the air extraction end of the air extractor. Compared with a traditional reinforcing structure, the reinforcing structure has the advantagesthat the reinforcing range of the reinforcing structure can be adjusted, the reinforcing effect of the reinforcing structure is better, reinforcing is more uniform, and the reinforcing structure is simple in structure, convenient to operate and good in use experience.

Owner:安徽春博环保科技有限公司

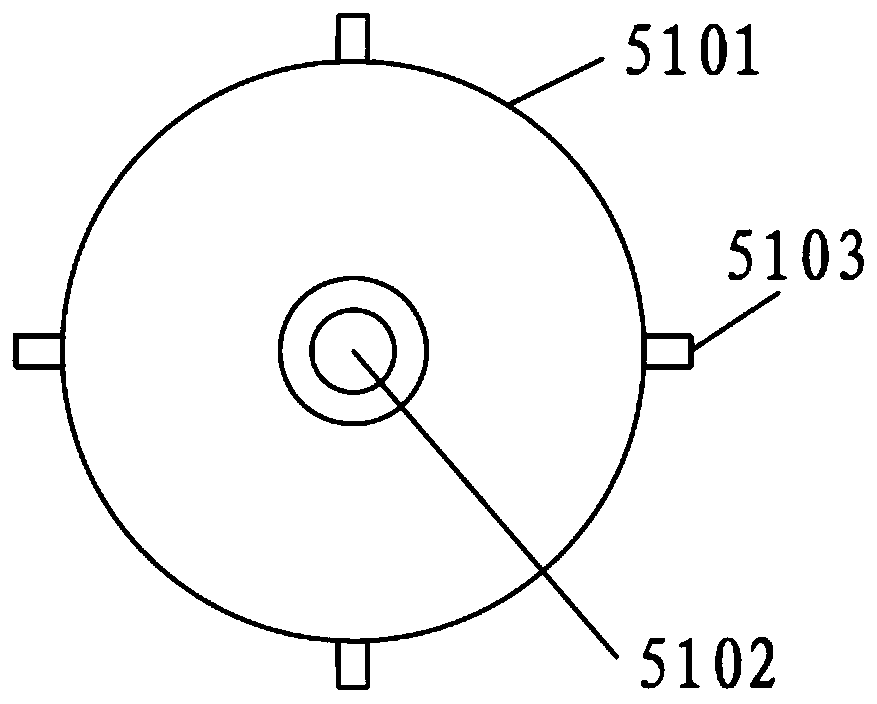

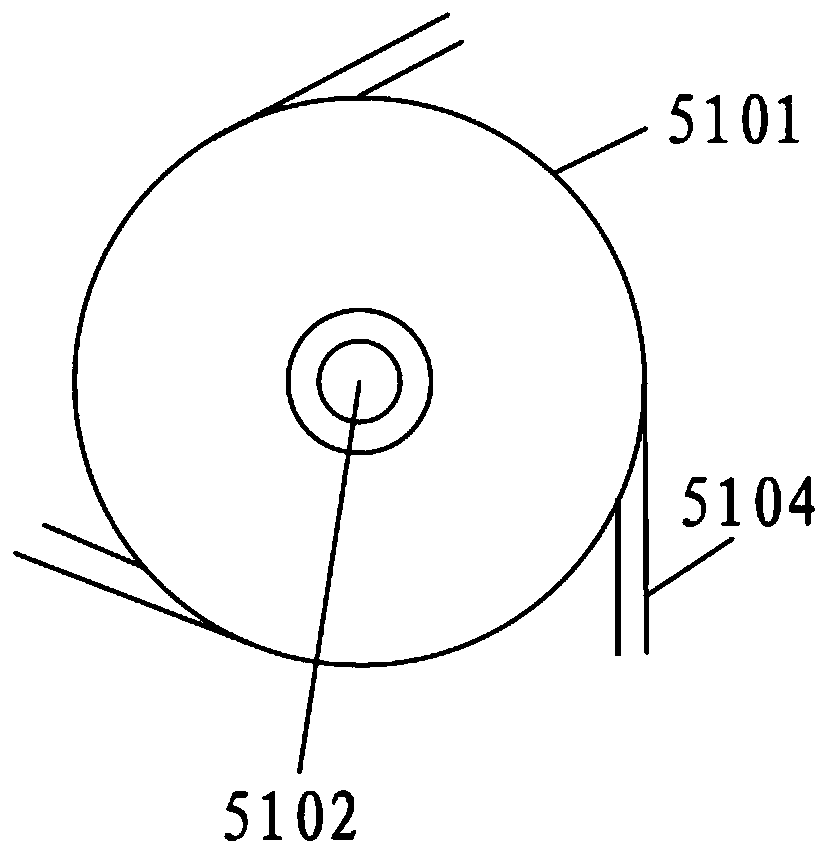

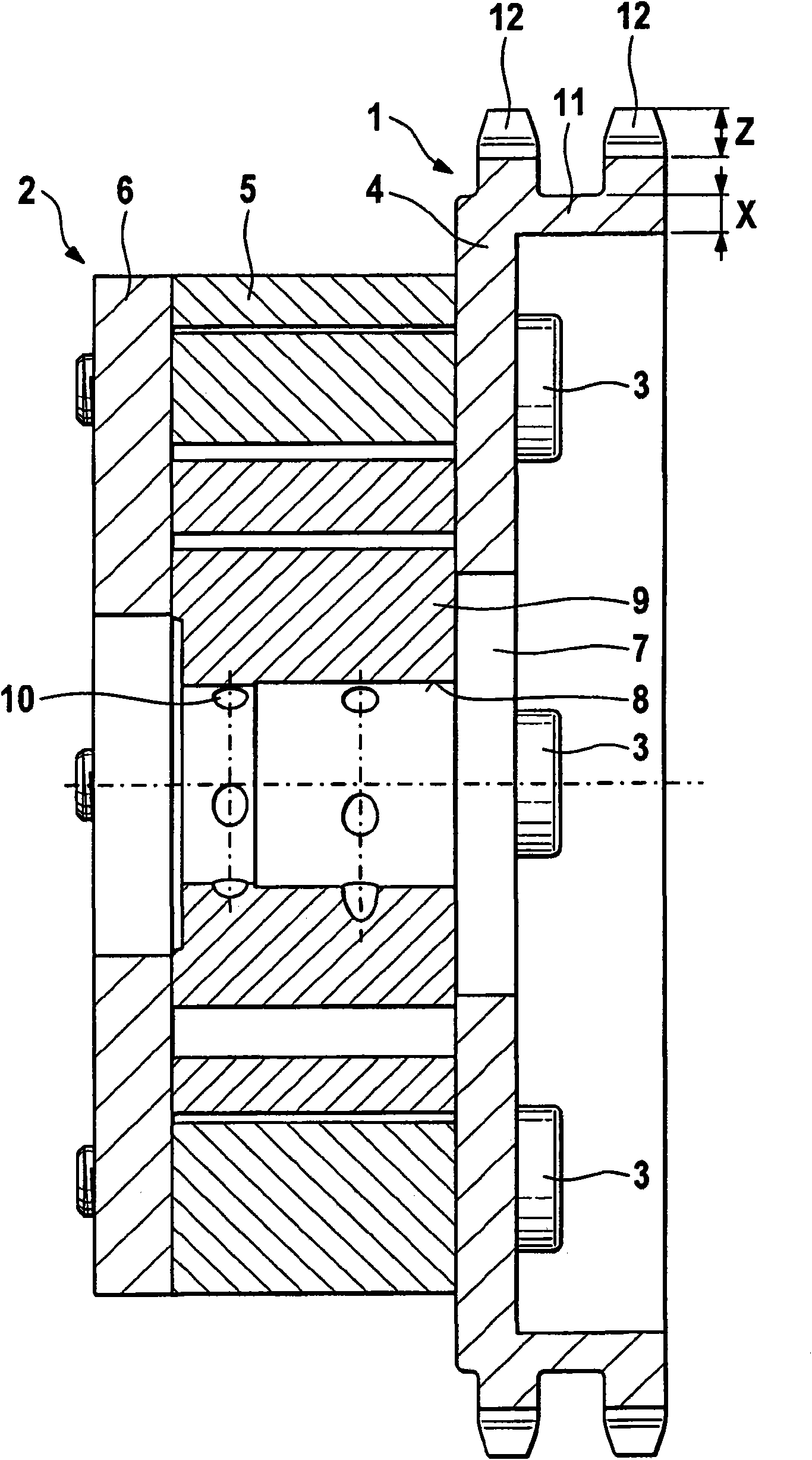

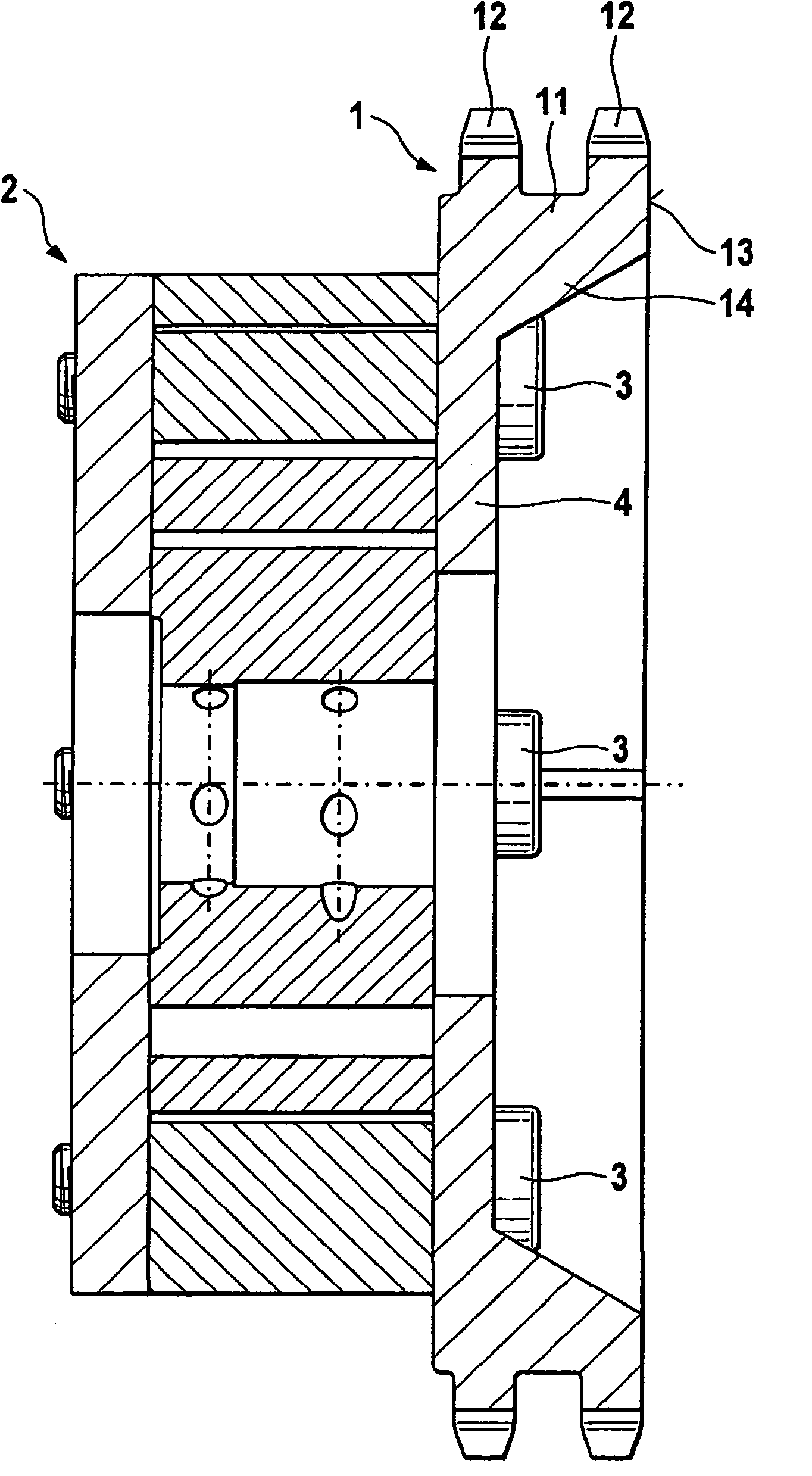

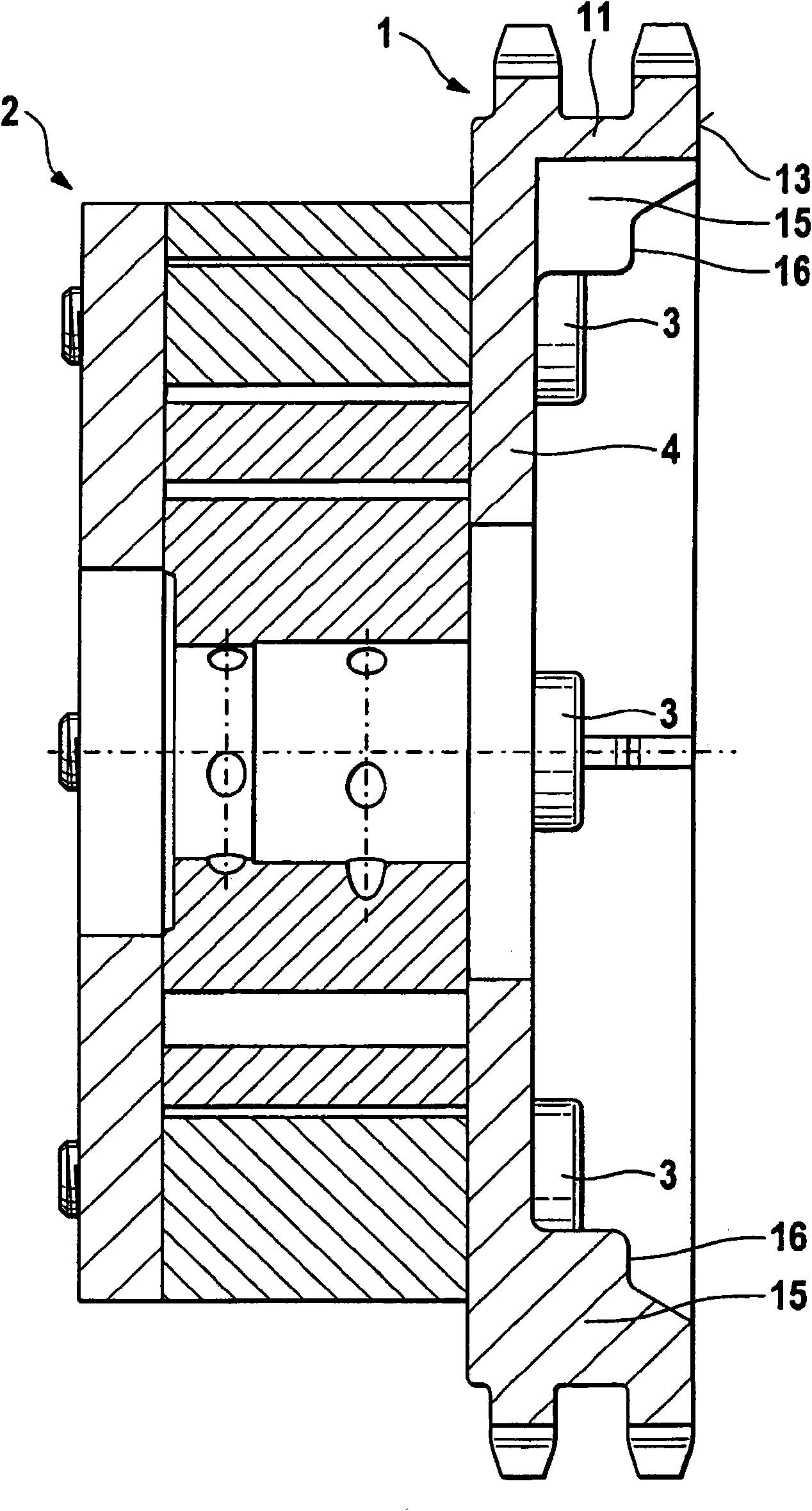

Modular construction camshaft adjuster with a chain or belt wheel

InactiveCN101970810AReduce distortionUniform reinforcementValve arrangementsPortable liftingEngineeringSprocket

The invention relates to a modular construction camshaft adjuster (2) for the camshaft drive of an internal combustion engine with a chain or belt wheel (1), comprising at least one wheel rim (12) facing radially outwards with tooth engagement recesses Z, an annular wheel plate (4) around a central circular opening (7) and an essentially cylindrical wheel wall (11) with a wall thickness X, projecting in an axial direction from the annular wheel plate (4), such that the wheel wall(11) and the wheel plate (4) together form a cup shape. The minimum wall thickness X of the essentially cylindricalwheel wall (11) beneath the at least one wheel (12) is equal to half the tooth engagement recess Z and the cup-shaped chain or belt wheel (1) is made from a lightweight material.

Owner:SCHAEFFLER TECH AG & CO KG

A kind of seepage cofferdam design back-sealing concrete construction structure and its method

This application relates to a concrete construction structure for seepage cofferdam design, including a cofferdam body. The cofferdam body is a vertically arranged cubic steel casing, and a concrete bottom sealing layer is poured at the lower end of the inner side of the cubic steel casing. The lower end of the cofferdam body is provided with an anti-seepage mechanism. The anti-seepage mechanism includes an anti-seepage coil, an anti-seepage frame, and an anti-seepage water-proof board. The seepage frame includes a fixed part, a connecting part and a frame body. The fixed part is fixedly installed on the inner wall of the cubic steel box, the connecting part is detachably fixed and installed on the lower side of the fixed part, and the anti-seepage frame is fixedly installed under the connecting part. On the side, the anti-seepage water-proof board is fixedly installed on the frame body, and the top surface of the concrete sealing layer is higher than the anti-seepage water-proof board and lower than the fixed part. The application has the effect of separating the fixing part from the connecting part, thereby separating the cofferdam body from the connecting part, and facilitating the detachment of the cofferdam body.

Owner:蒙城安路蓝海交通投资有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com