Preformed hole deep-layer underwater tamping method

A deep water, pre-hole technology, applied in soil protection, construction, infrastructure engineering and other directions, can solve the problems of difficult to achieve deep underwater construction operations, difficult to achieve dynamic compaction vibration reinforcement, difficult to accurately measure the amount of compaction and other issues , to achieve the effect of saving manpower, short construction period and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

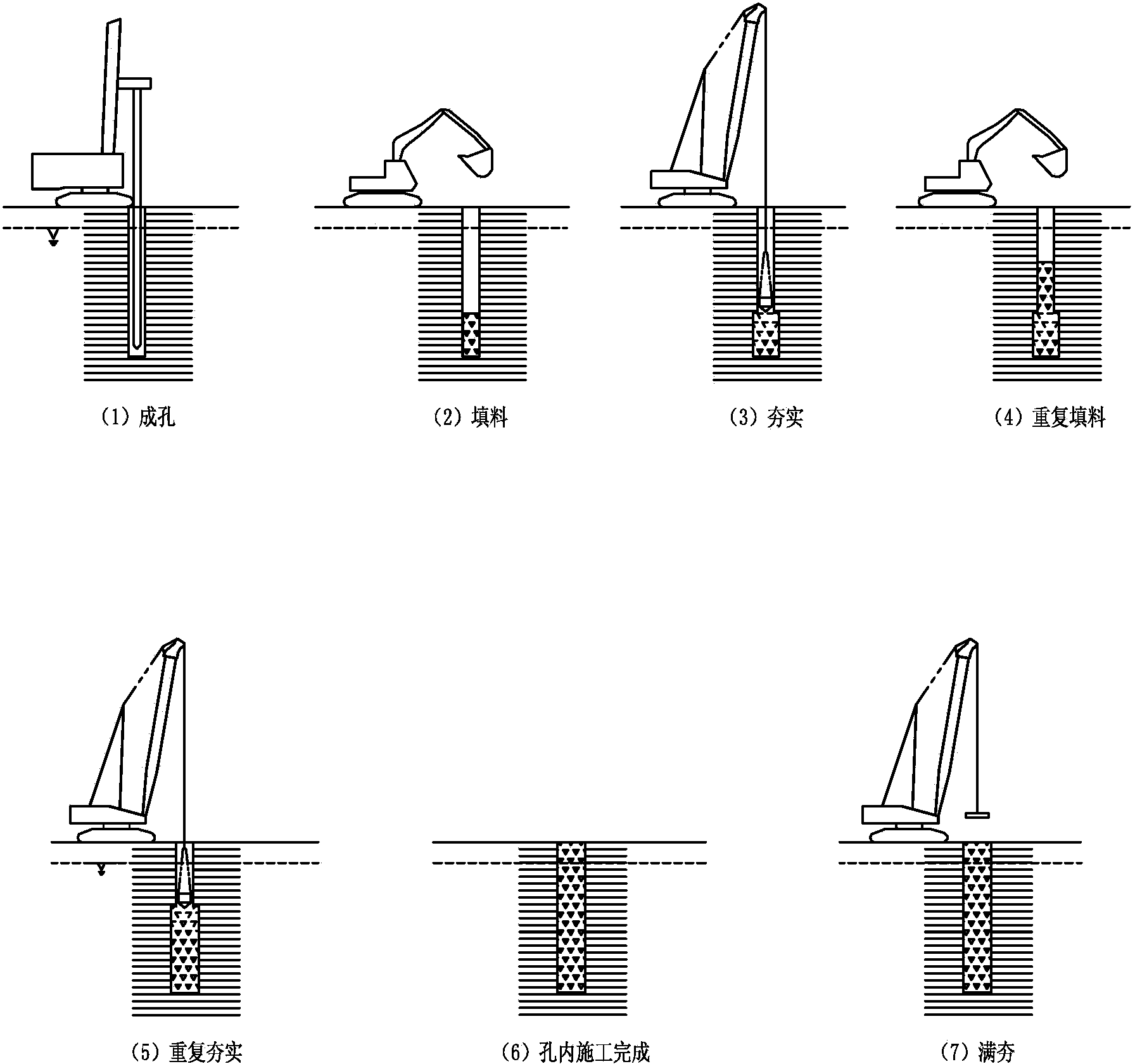

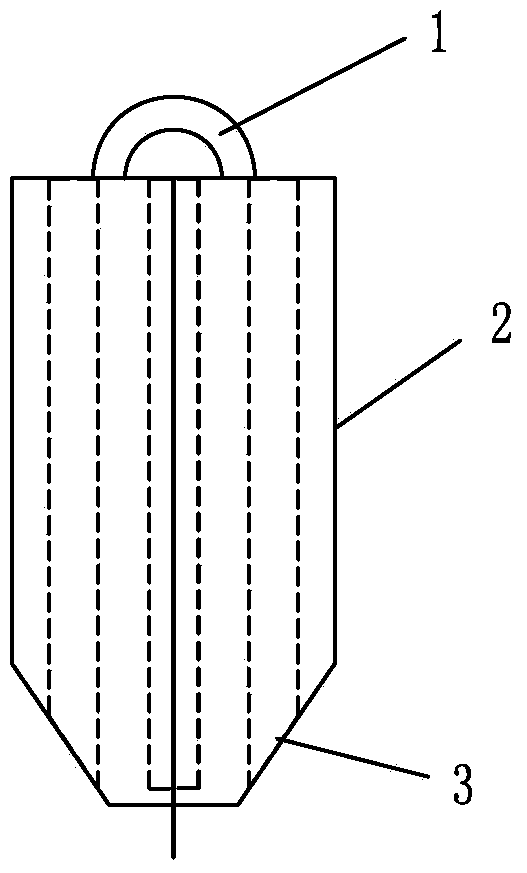

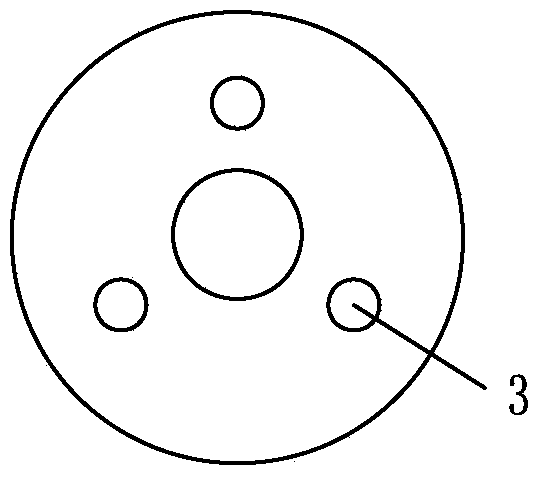

[0062] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown:

[0063] A pre-hole deep underwater compaction method, which is constructed underwater:

[0064] Reinforce the foundation soil below the groundwater level;

[0065] The rammer rises and falls in the water, and the contact point with the foundation soil is below the groundwater level;

[0066] During the construction process, the rammer will not be decoupled to realize continuous underwater operation.

[0067] It tamps in layers:

[0068] The tamping construction is carried out from bottom to top in the preformed hole;

[0069] Determine the reinforcement thickness of each layer according to the soil layer conditions, and extend the foundation to several reinforcement layers according to the reinforcement thickness;

[0070] Reinforce the foundation layer by layer from bottom to top, and the tamping energy should be adapted to the layer thickness;

[0071] The hammer closing standard is controlled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com