Tunnel horizontal rotary jet construction method

A technology of horizontal rotary grouting and construction method, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc. It can solve problems such as discontinuity and unevenness of grouting piles, and achieve the effect of improving work efficiency and controlling rock and soil deformation at low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0033] According to an exemplary embodiment of the present invention, the horizontal rotary grouting construction method of a soft rock tunnel includes the following steps.

[0034] First, in step 1, a horizontal jet drilling machine is used to drill a borehole with a specified depth, diameter and inclination on the tunnel excavation face of the soft rock construction area according to the predetermined opening position.

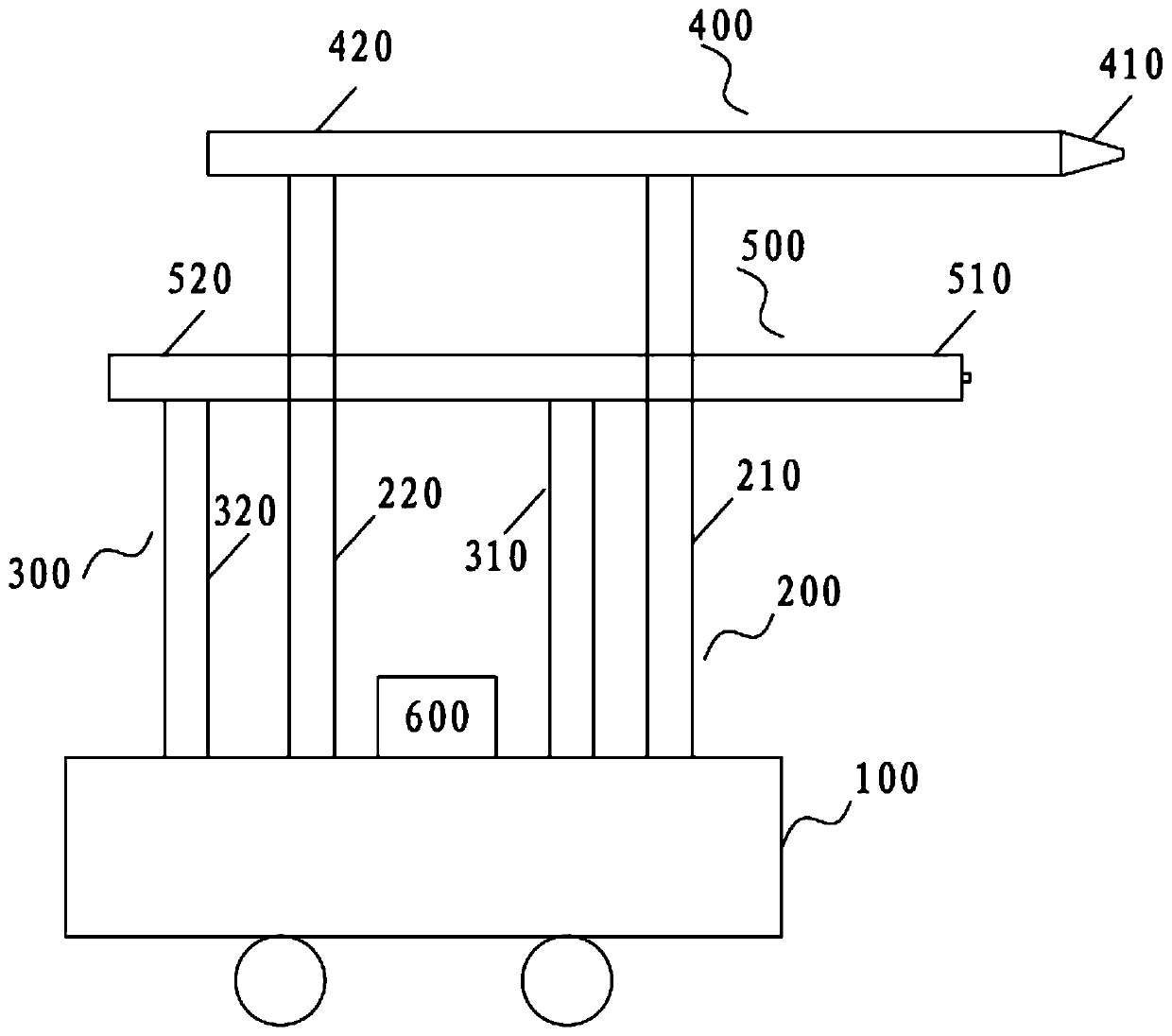

[0035] Among them, such as figure 1 As shown, the horizontal jet jet drilling machine includes a movable body 100, a drilling support frame group 200 installed on one side of the movable body, a jet jet support frame group 300 installed on the other side of the movable body, and a drilling device. 400 and spin spray device 500.

[0036] Specifically, the drilling support frame group 200 includes a first drilling support frame 210 and a second drilling support frame 220. The first drilling support frame 210 is arranged on the front end of the movable body 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com