Row batter pile driving construction method and variable amplitude static pile press for implementing method

A technology of static pile driver and construction method, which is applied in the field of hydraulic pile drivers, can solve the problems of large footprint of pile drivers, slow construction speed, affecting construction efficiency and cost, etc., and achieves increased safety margin design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

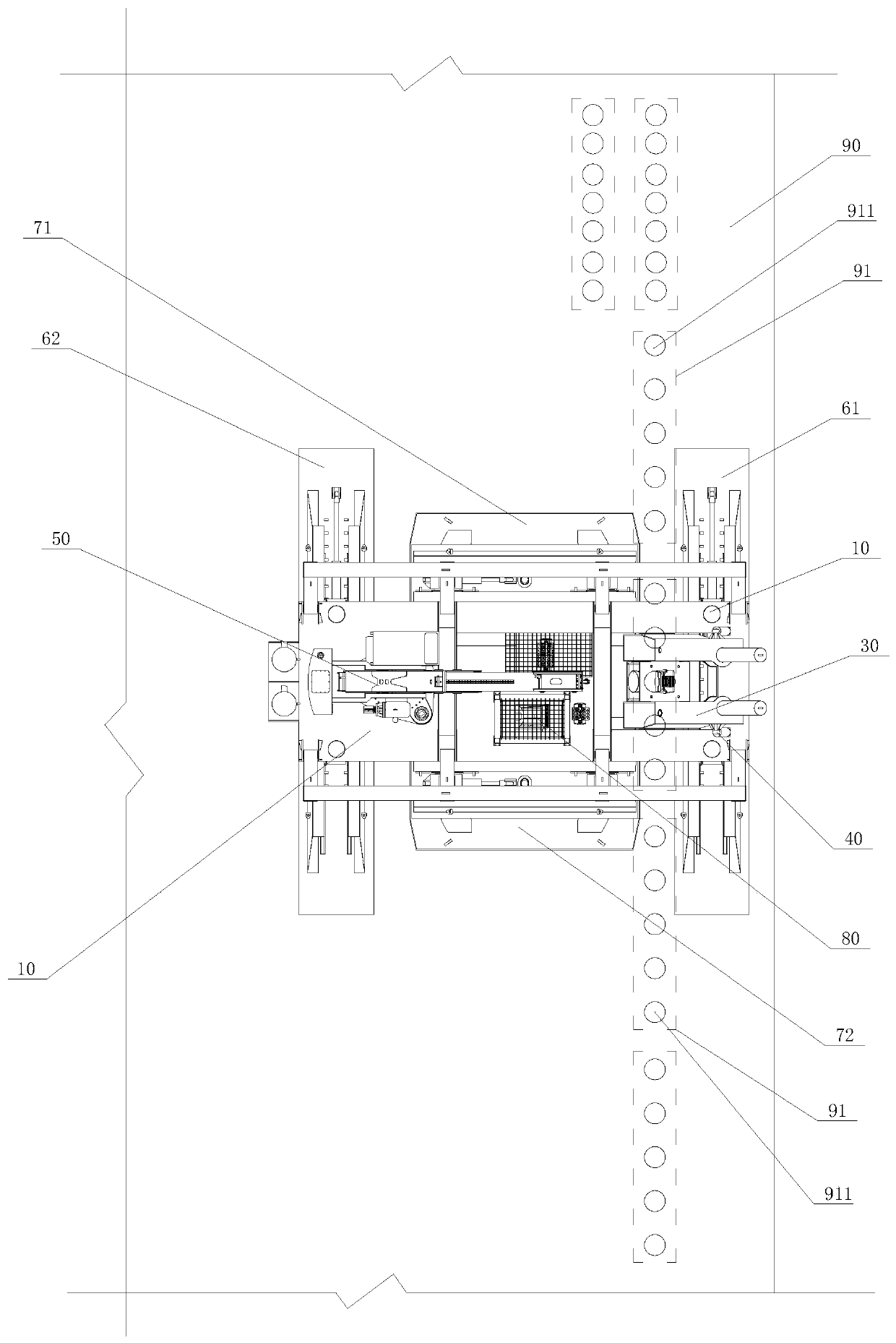

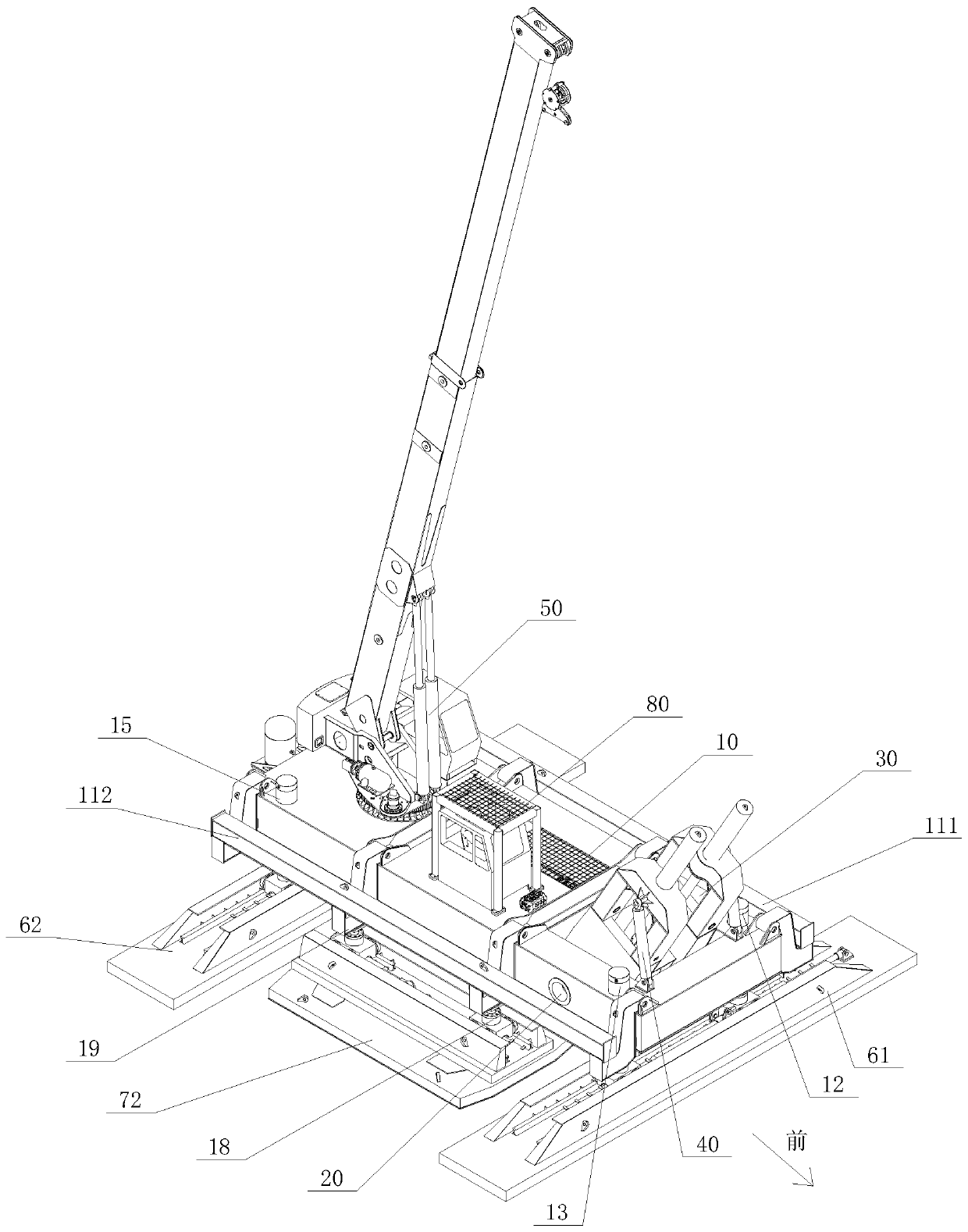

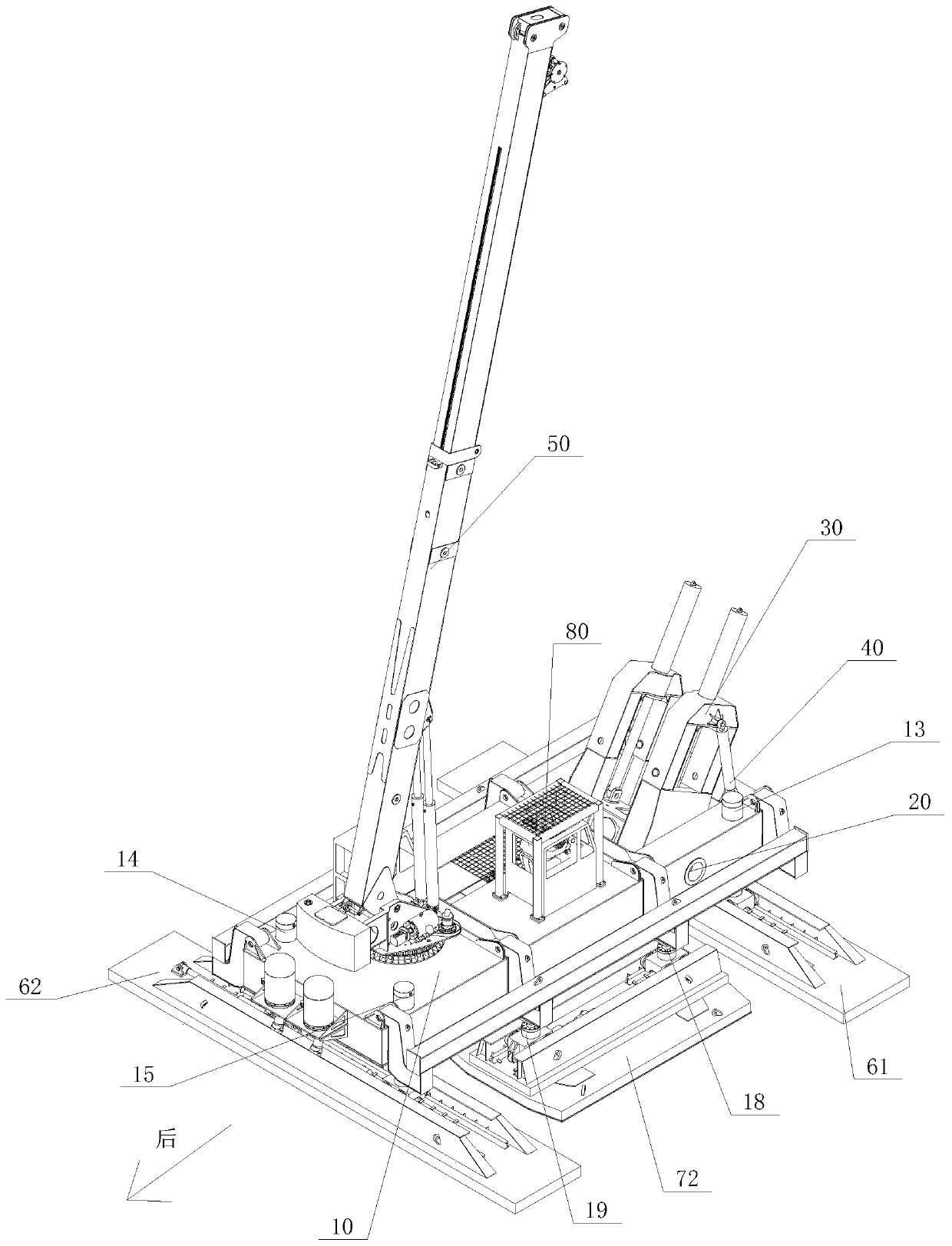

[0072] see Figure 1-12 , the embodiments of the present invention will be described in detail below.

[0073] like figure 1 As shown, the piling construction method of row inclined piles provided by the embodiment of the present invention comprises the following steps:

[0074] (11), the pile driver is in place, and the luffing type static pile driver is moved to the construction area 90 where the site has been leveled. The luffing type static pile driver includes a host platform 10, a rotating shaft 20, a hydraulic pile driver Mechanism 30, luffing cylinder 40, hoisting mechanism 50, lateral movement mechanism, and longitudinal movement mechanism. The transverse movement mechanism includes the first long boat 61, the second long boat 62, the first long boat telescopic cylinder 631, and the second long boat telescopic cylinder. 632, the longitudinal movement mechanism includes the first short boat 71, the second short boat 72, the first short boat telescopic oil cylinder 73...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com