Patents

Literature

117results about How to "No manual work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

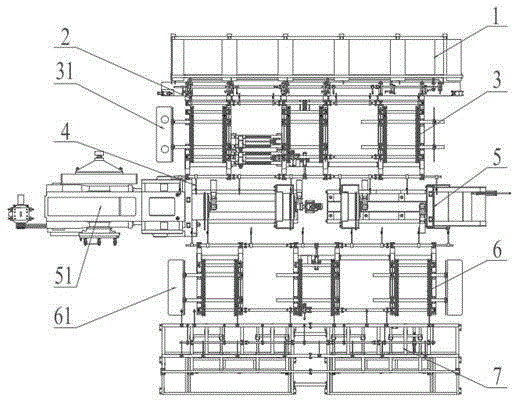

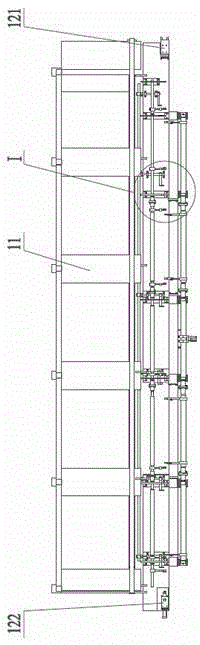

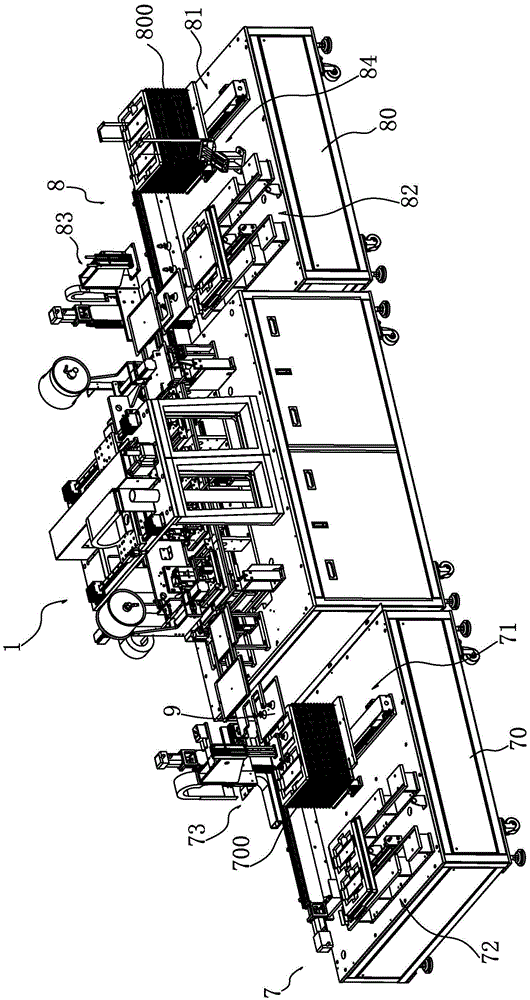

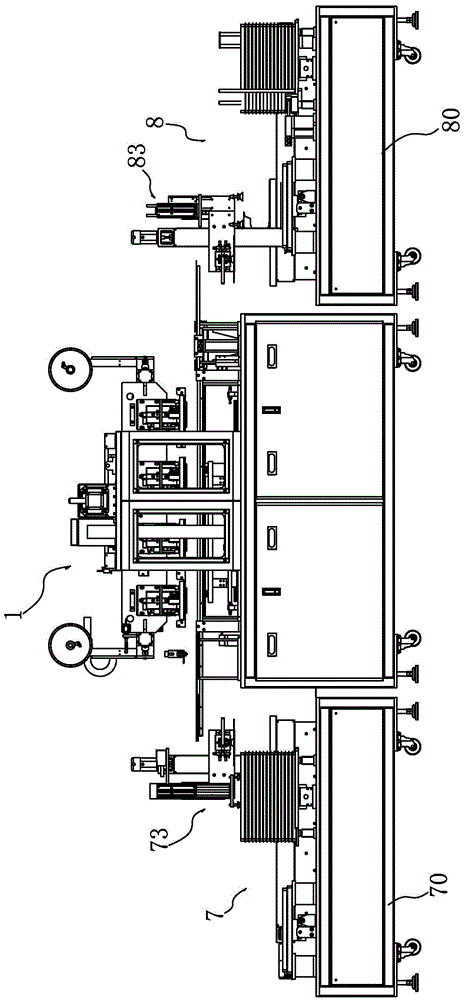

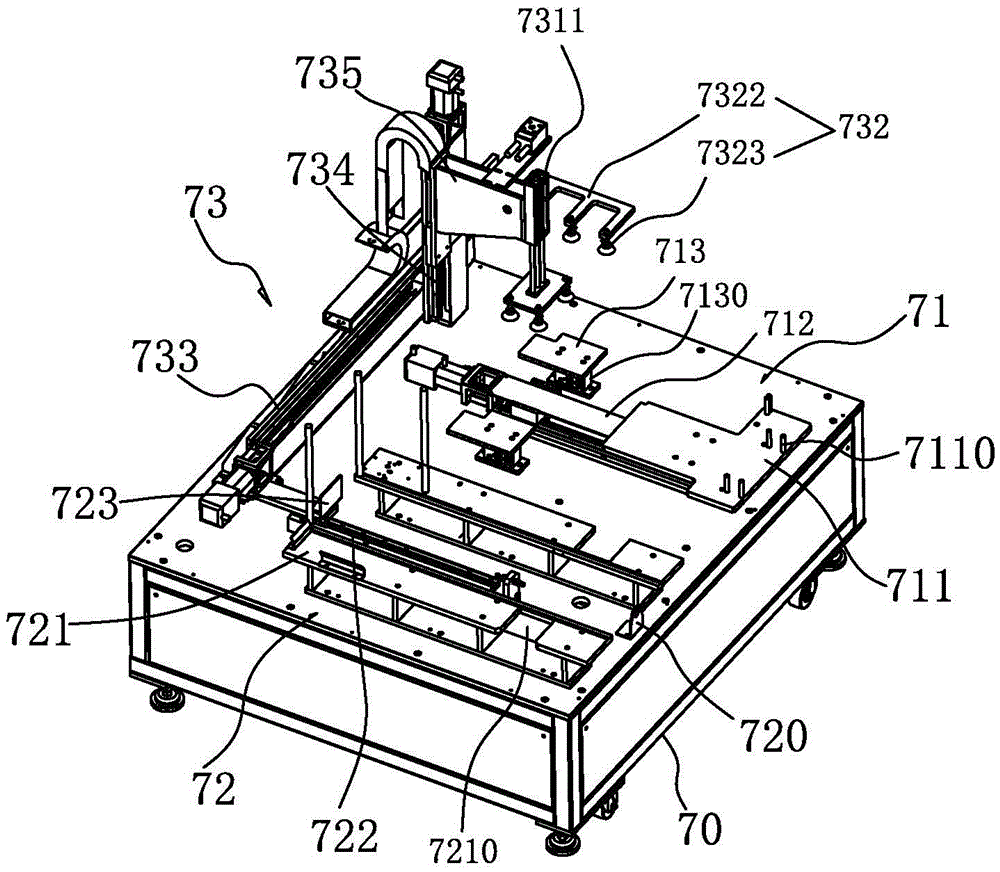

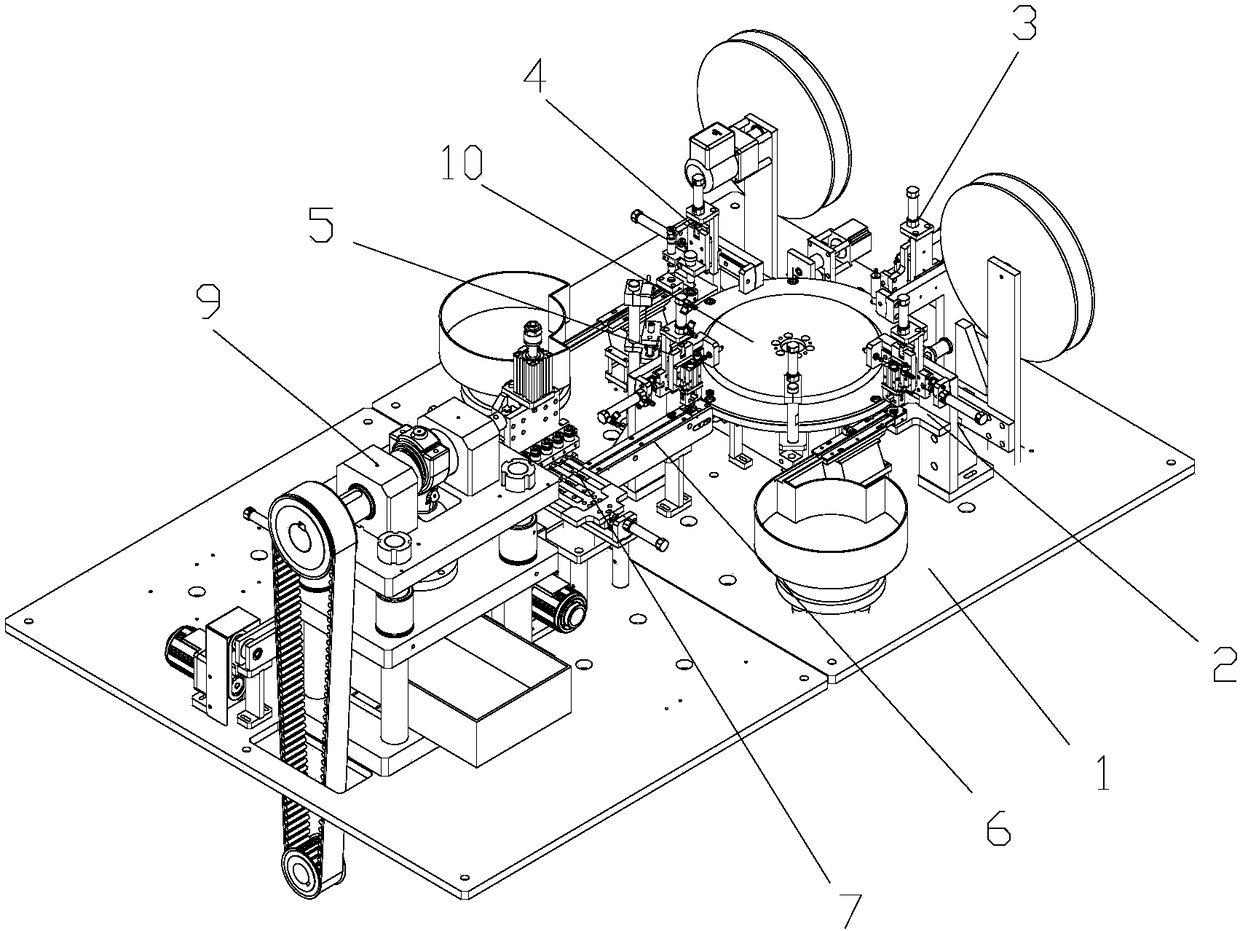

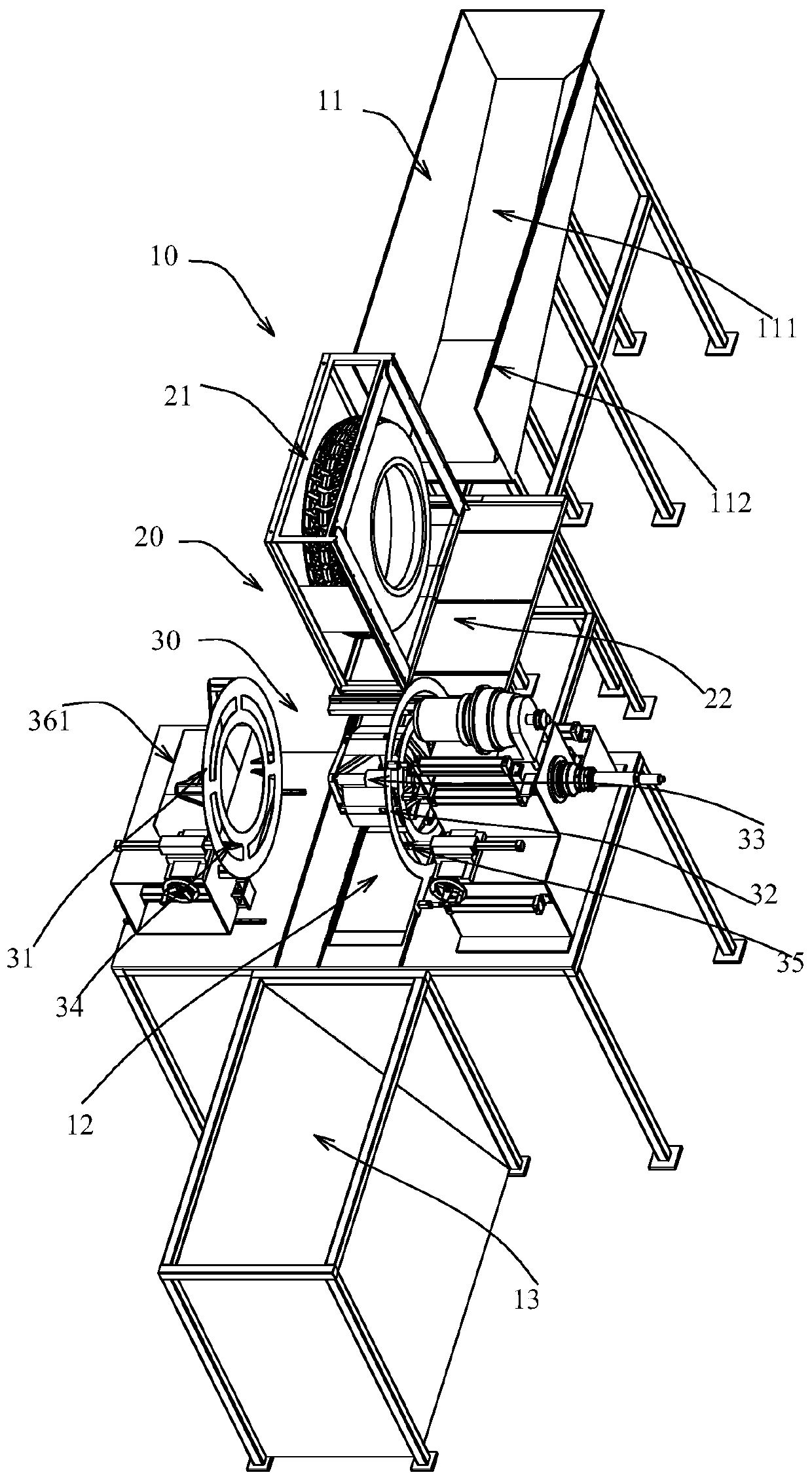

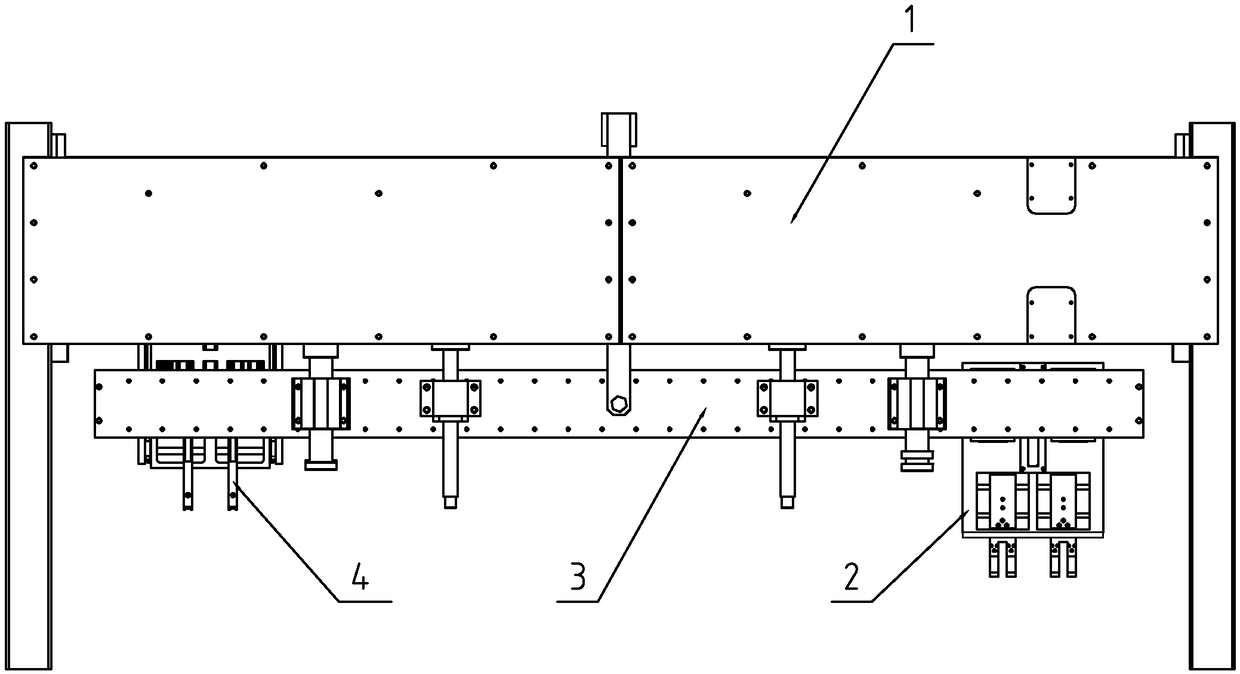

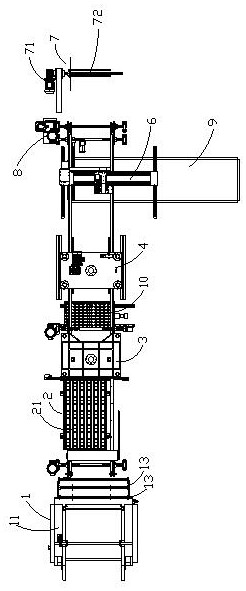

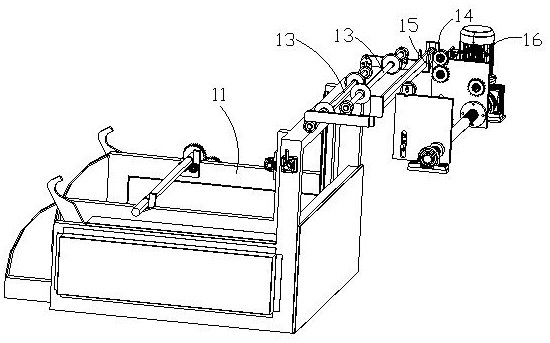

Full-automatic assembling and packaging line for disposable infusion devices

ActiveCN105083986AIncrease productivitySave human effortFilament handlingAssembly machinesInfusion setEngineering

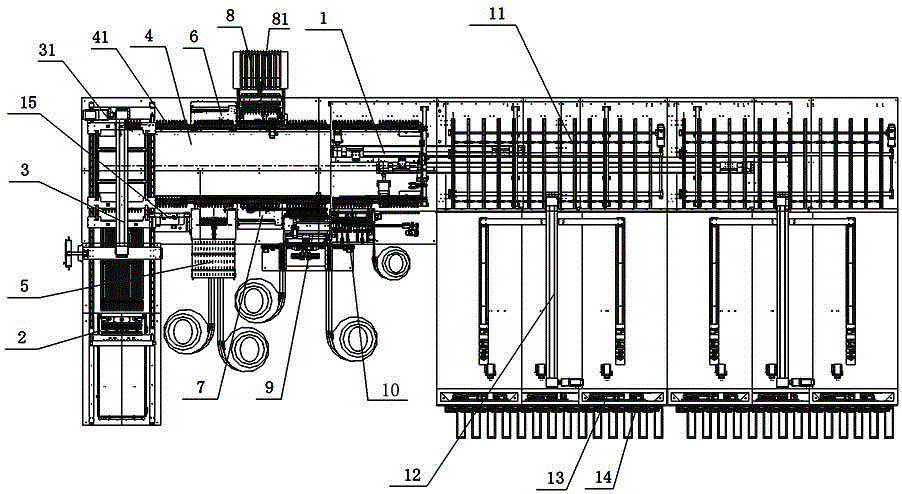

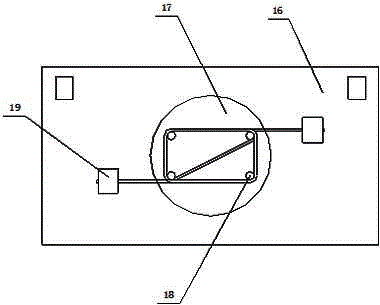

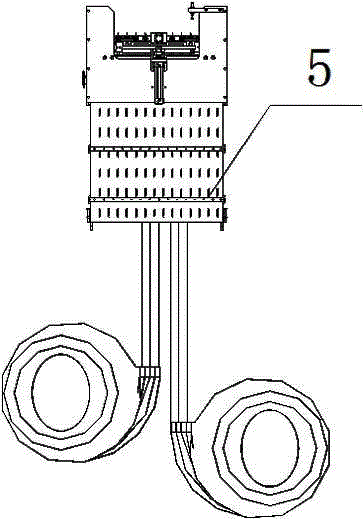

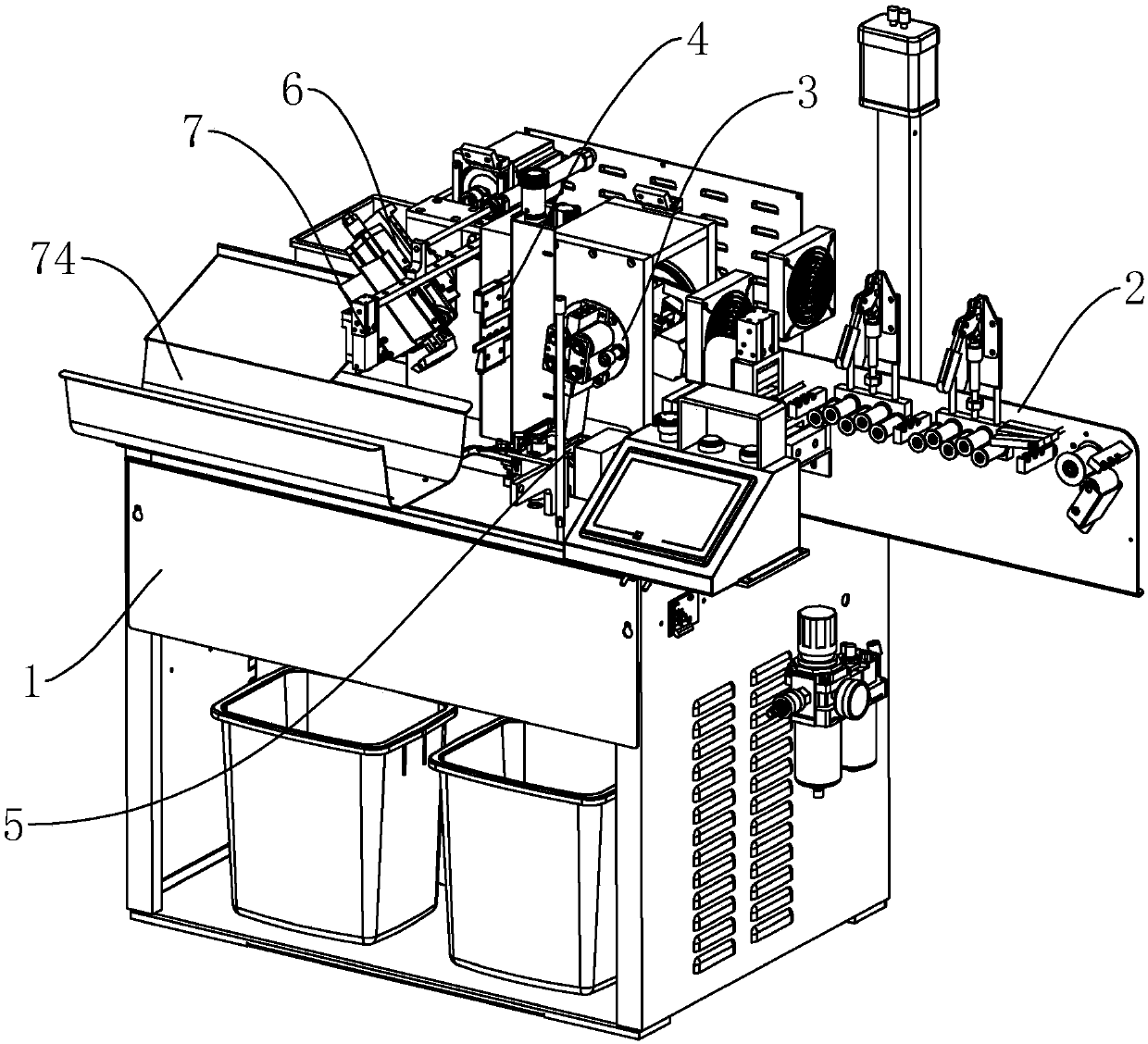

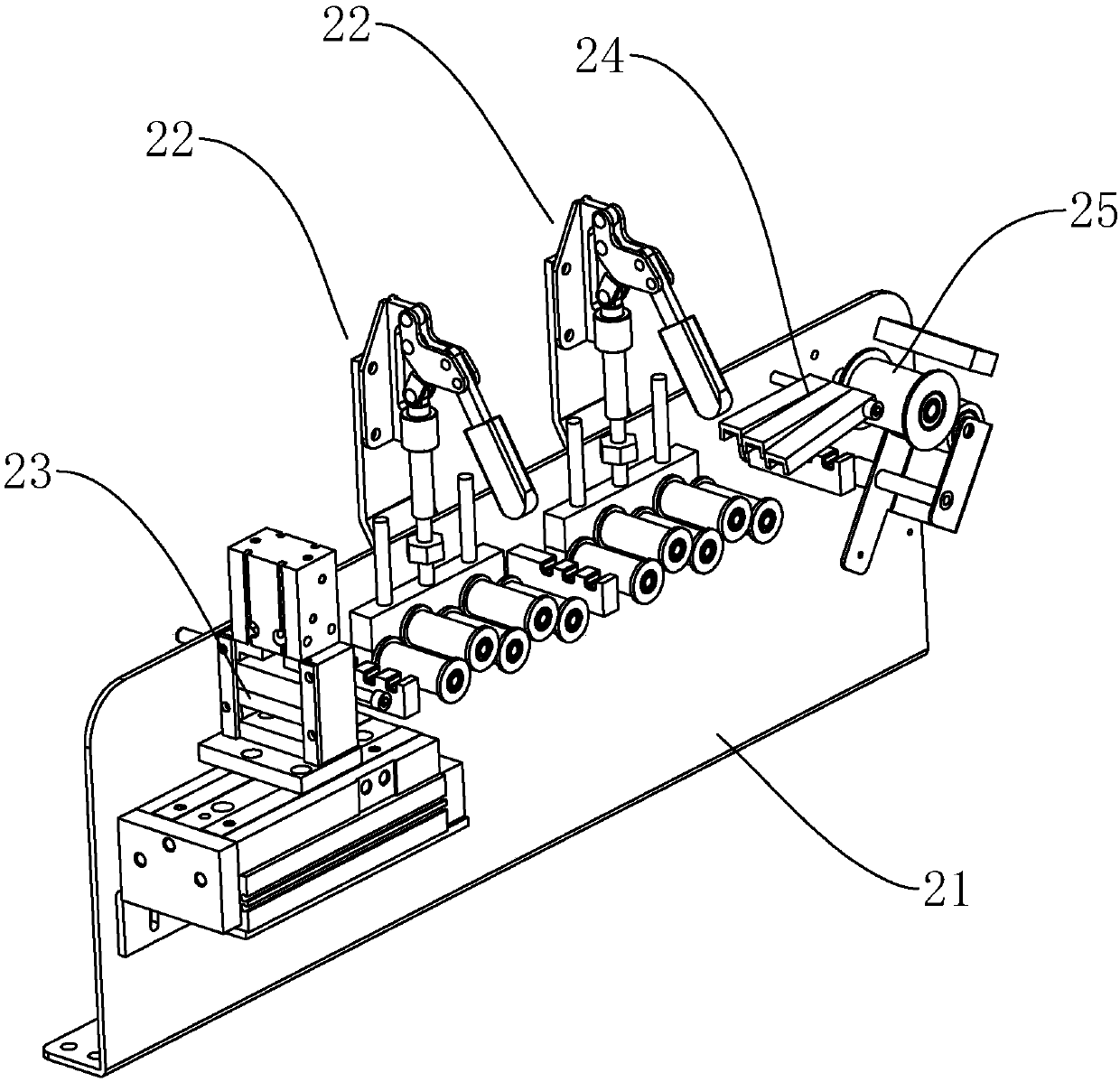

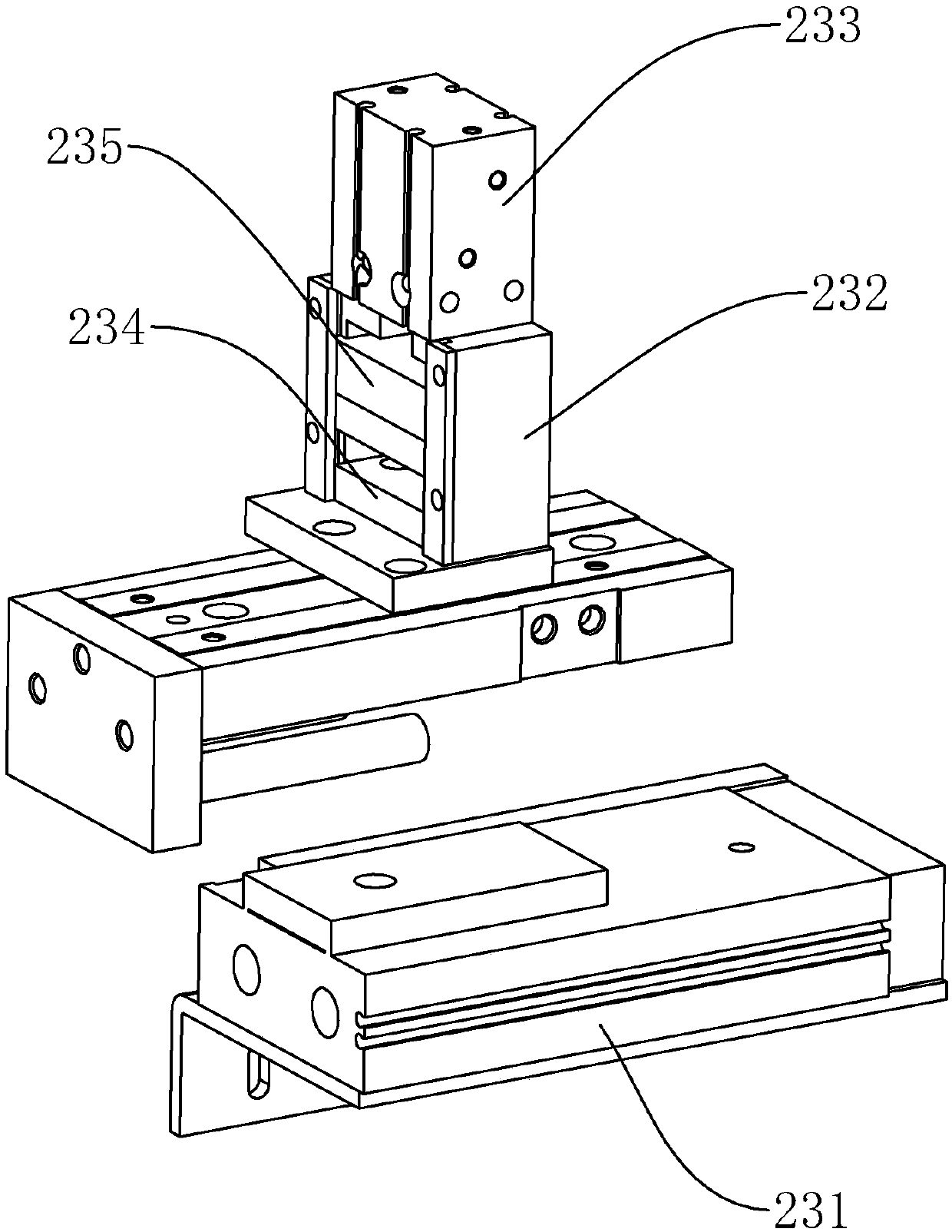

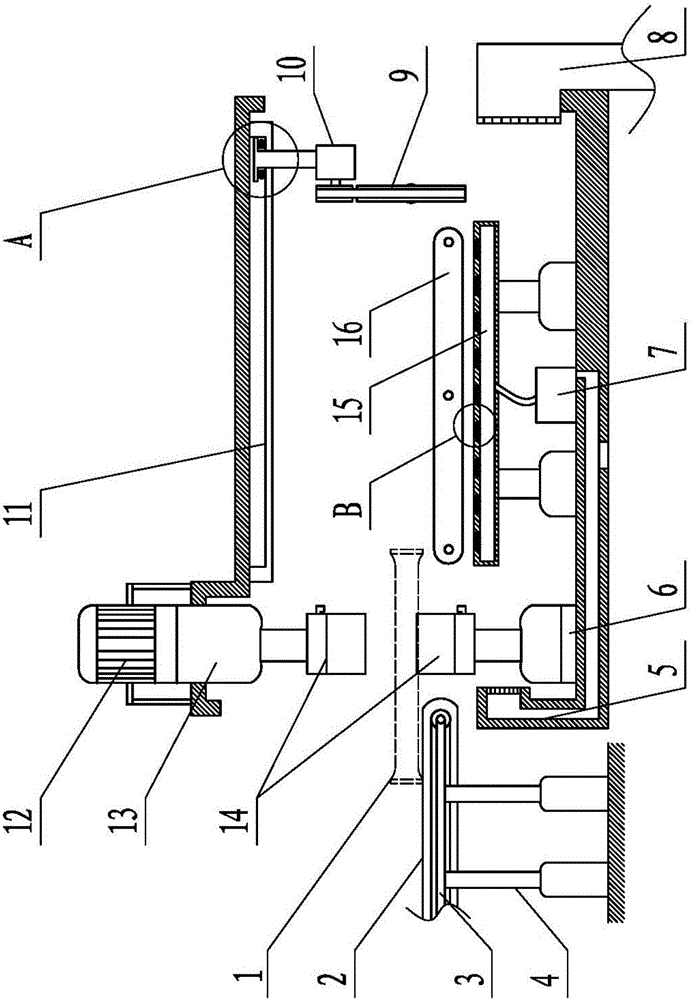

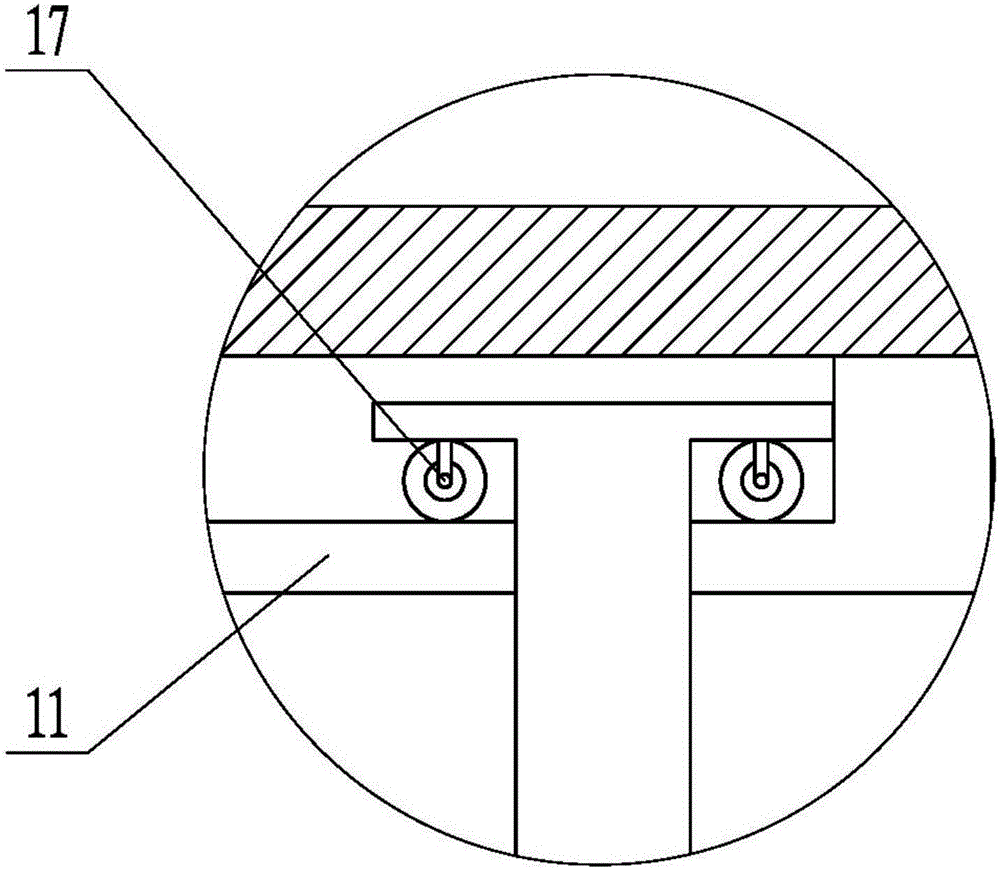

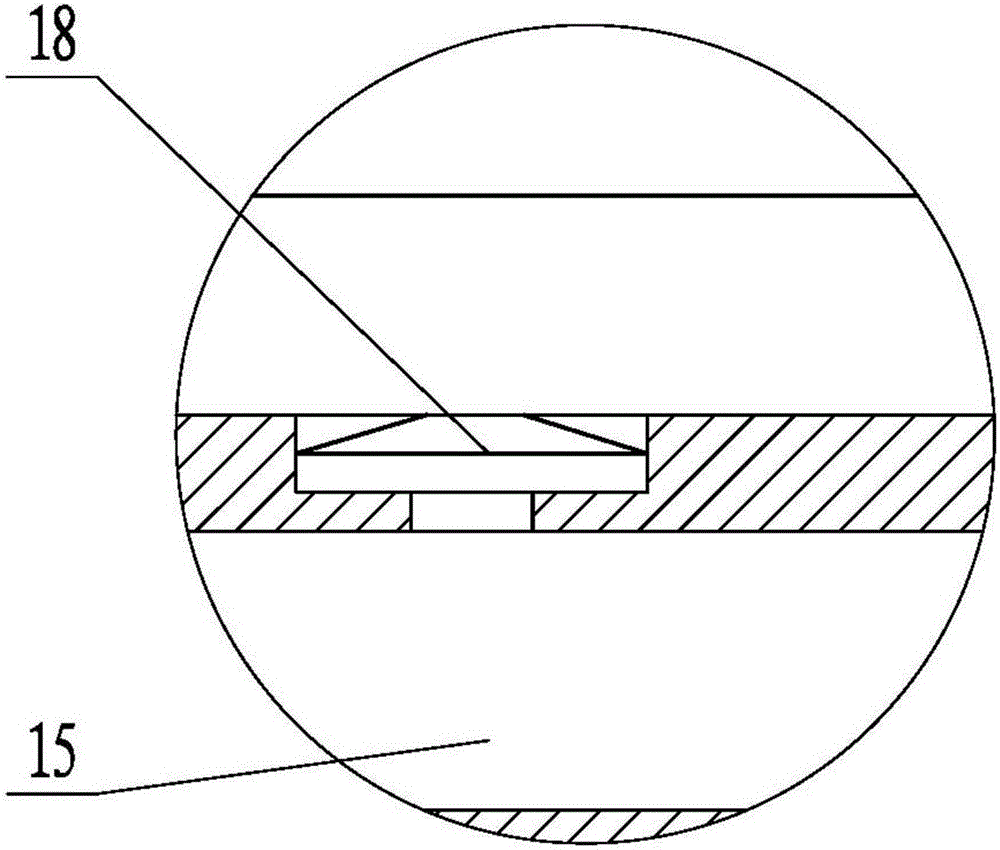

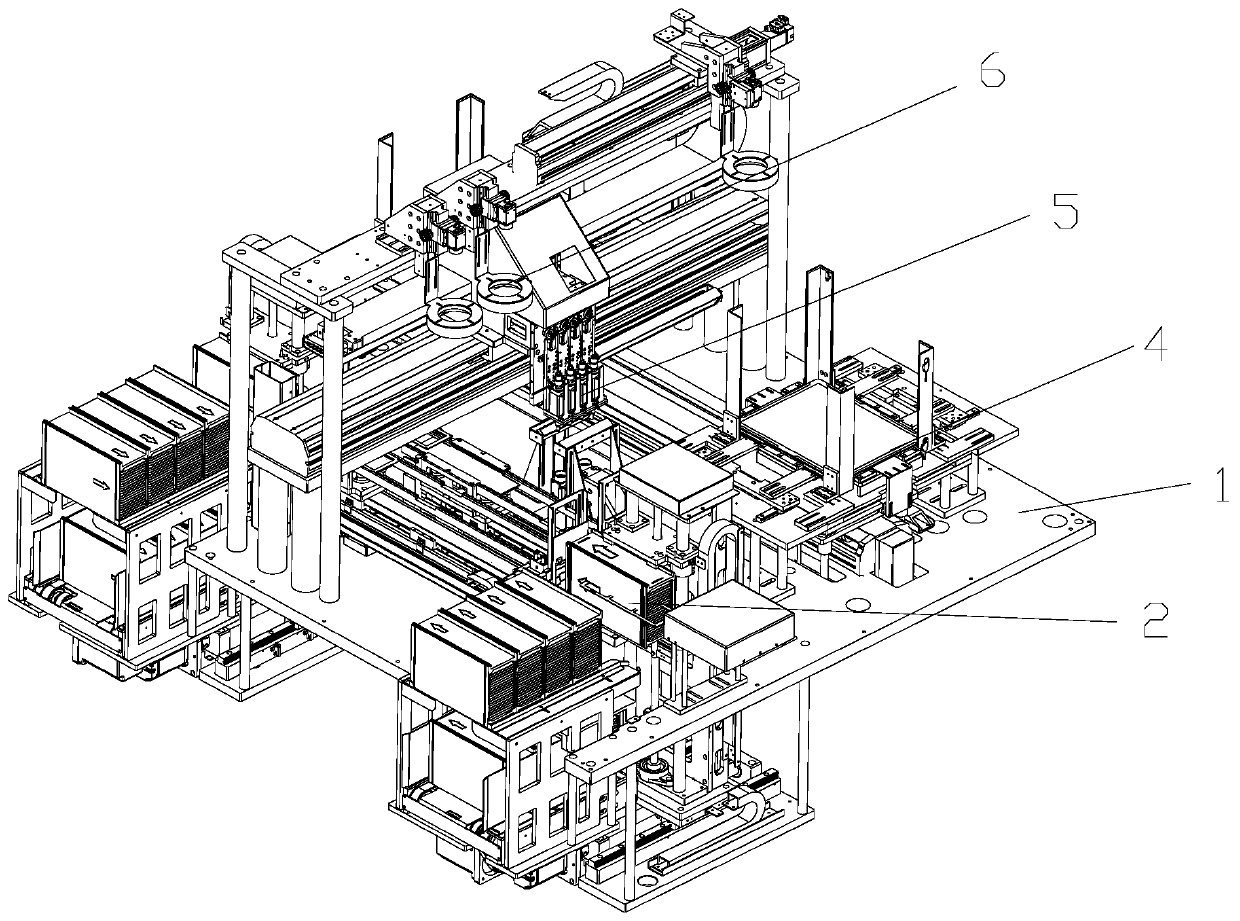

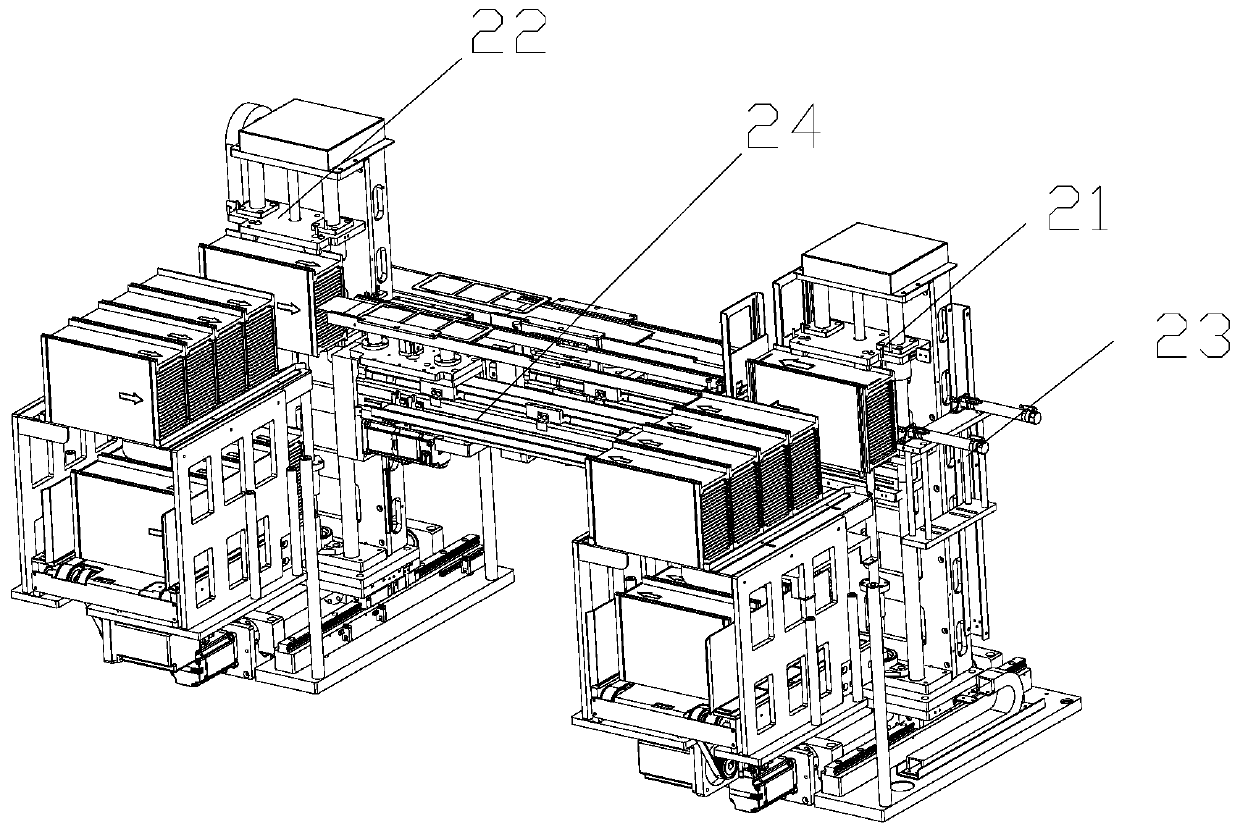

The invention discloses a full-automatic assembling and packaging line for disposable infusion devices. The full-automatic assembling and packaging line comprises an assembling line and a packaging line. A finished product transferring station (1) is arranged between the assembling line and the packaging line and is used for transferring the disposable infusion devices assembled through the assembling line to the packaging line. The assembling line is composed of a guide pipe feeding station (2), a guide pipe transferring station (3), a conveying device (4), an adjusting frame installation station (5), an infusion needle gluing station (6), a large plastic needle gluing station (7), an infusion needle installation station (8), a large plastic needle assembling station (9) and an adjusting wheel assembling station (10). The packaging line is composed of a finished product pulling station (11), a finished product transition station (12), a finished product winding station (13) and a bagging station (14). The full-automatic assembling and packaging line has the beneficial effects that the automation degree is high, the production efficiency is high, and secondary pollution is avoided.

Owner:江西科伦医疗器械制造有限公司

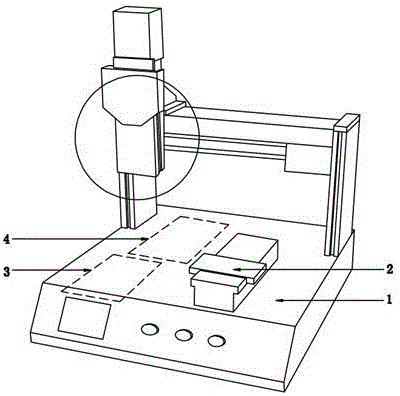

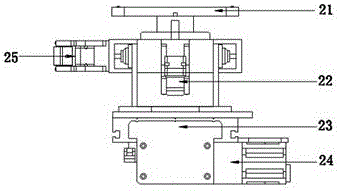

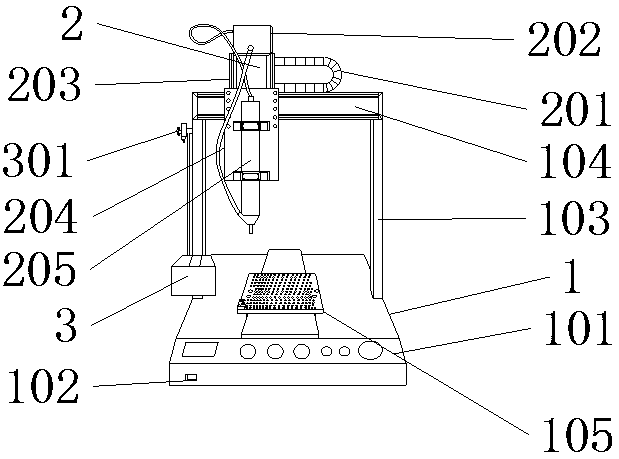

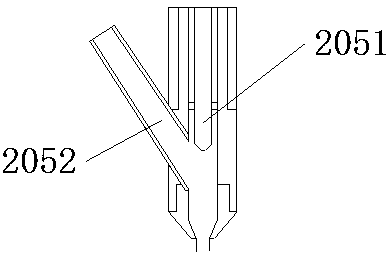

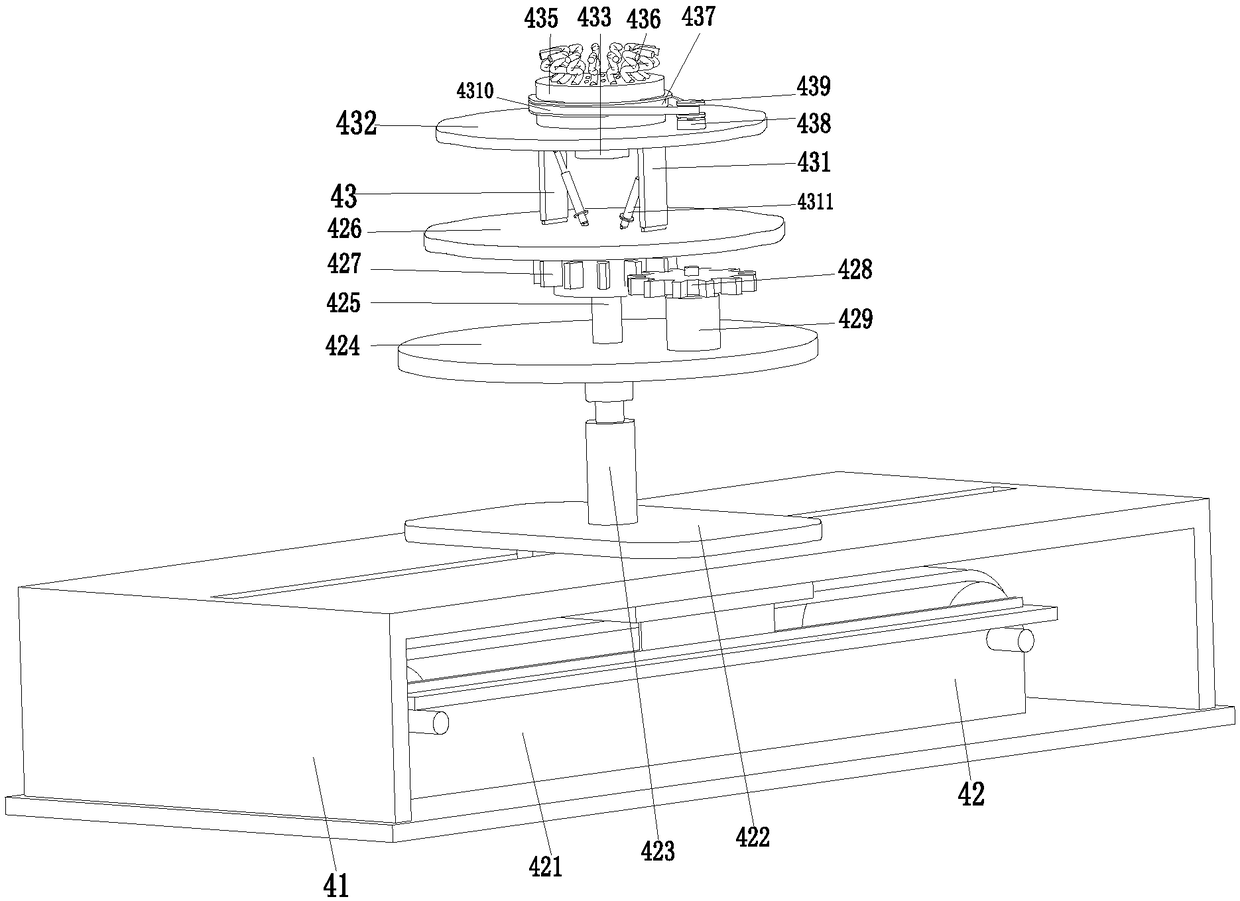

High-precision multi-axis motion three-dimensional micro-welding robot

ActiveCN106392238AImprove welding qualityHigh precisionMetal working apparatusSoldering auxillary devicesRotary stageMachine vision

The invention discloses a high-precision multi-axis motion three-dimensional micro-welding robot, and relates to the technical field of robots. The whole robot is of a standard table type robot structure, a high-precision machine vision positioning system, a high-performance graphite material superconducting welding system and a high-precision ultramicro dispensing system are arranged on a support, a three-dimensional rotating table is arranged on a work table board, and a high-precision direct drive transmission system and a central control system are connected and are arranged in the robot and are connected to an operation panel. Multiple frontier technologies of the high-performance graphite material superconducting welding system technology, the high-precision ultramicro dispensing system technology, the three-dimensional rotating table technology, the high-precision machine vision positioning system technology, the high-precision direct drive transmission system technology and the like are integrated, the robot can comprehensively replace the manual welding technology under a microscope, and the robot has the beneficial effects of being high in welding quality, welding speed, welding precision and welding efficiency.

Owner:WUXI VOCATIONAL & TECHN COLLEGE

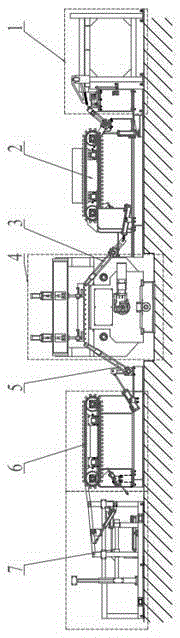

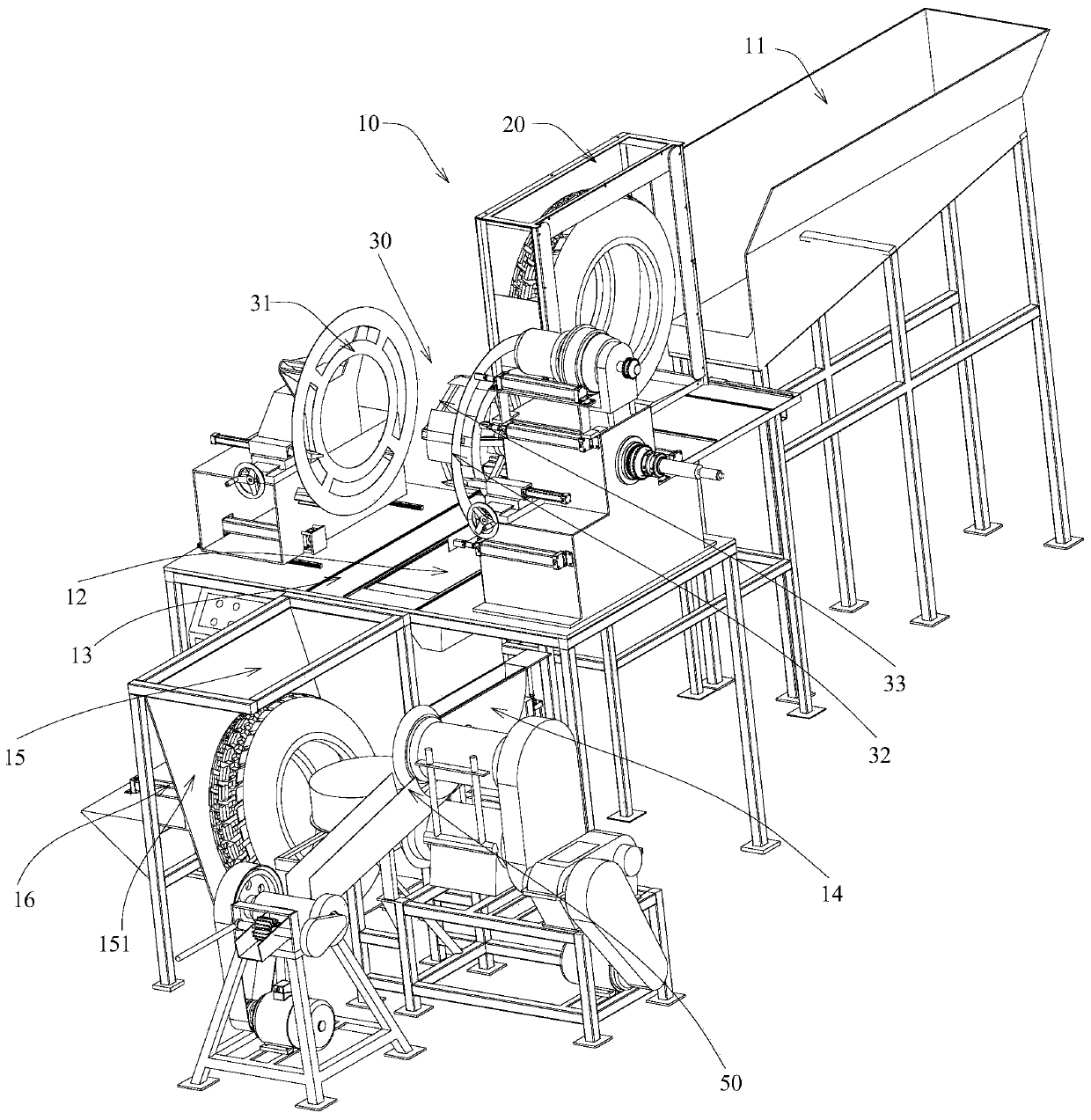

Full-automatic sucker rod forging production line

ActiveCN105397005AReduce manual operationsSave human effortForging/hammering/pressing machinesForging press drivesAutomatic controlEngineering

The invention relates to the technical field of machining equipment and automation, in particular to a full-automatic sucker rod forging production line. The full-automatic sucker rod forging production line comprises a mechanical transmission heating system, a pneumatic system, a lubricating system and a control component, wherein the control component controls the pneumatic system to provide power for the mechanical transmission heating system, and controls the lubricating system to lubricate the mechanical transmission heating system; and the whole production line is fully automatically controlled through the control component. During production, field workers only need to place bars on a beginning part of the production line, and transfer finished sucker rods at the tail end of the production line, the bars are not required to be carried manually in a production process, full-automatic operation of the production process is realized, labor and materials are saved, full-automatic production of the sucker rod forging production line is realized, the technical problem that an existing sucker rod forging production line is relatively low in degree of automation and relatively high in labor and material consumption is solved, and the full-automatic sucker rod forging production line is provided.

Owner:DEYANG ZHONGLIAN MACHINERY MFG CO LTD

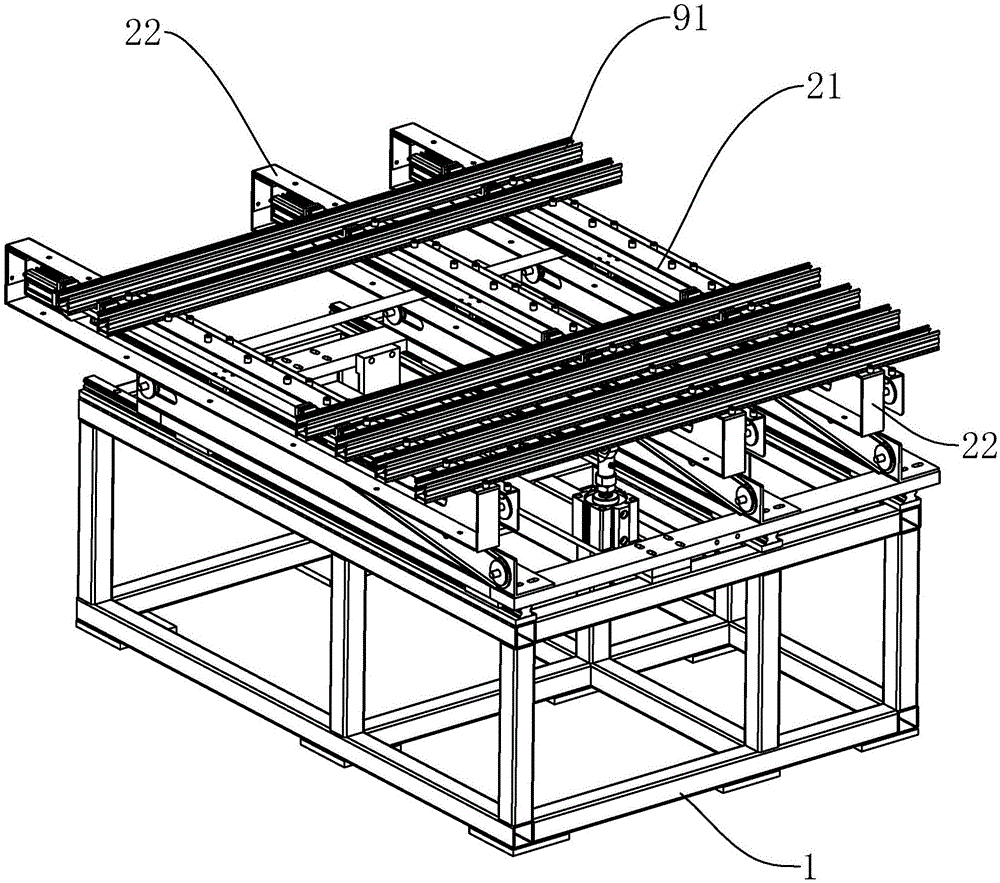

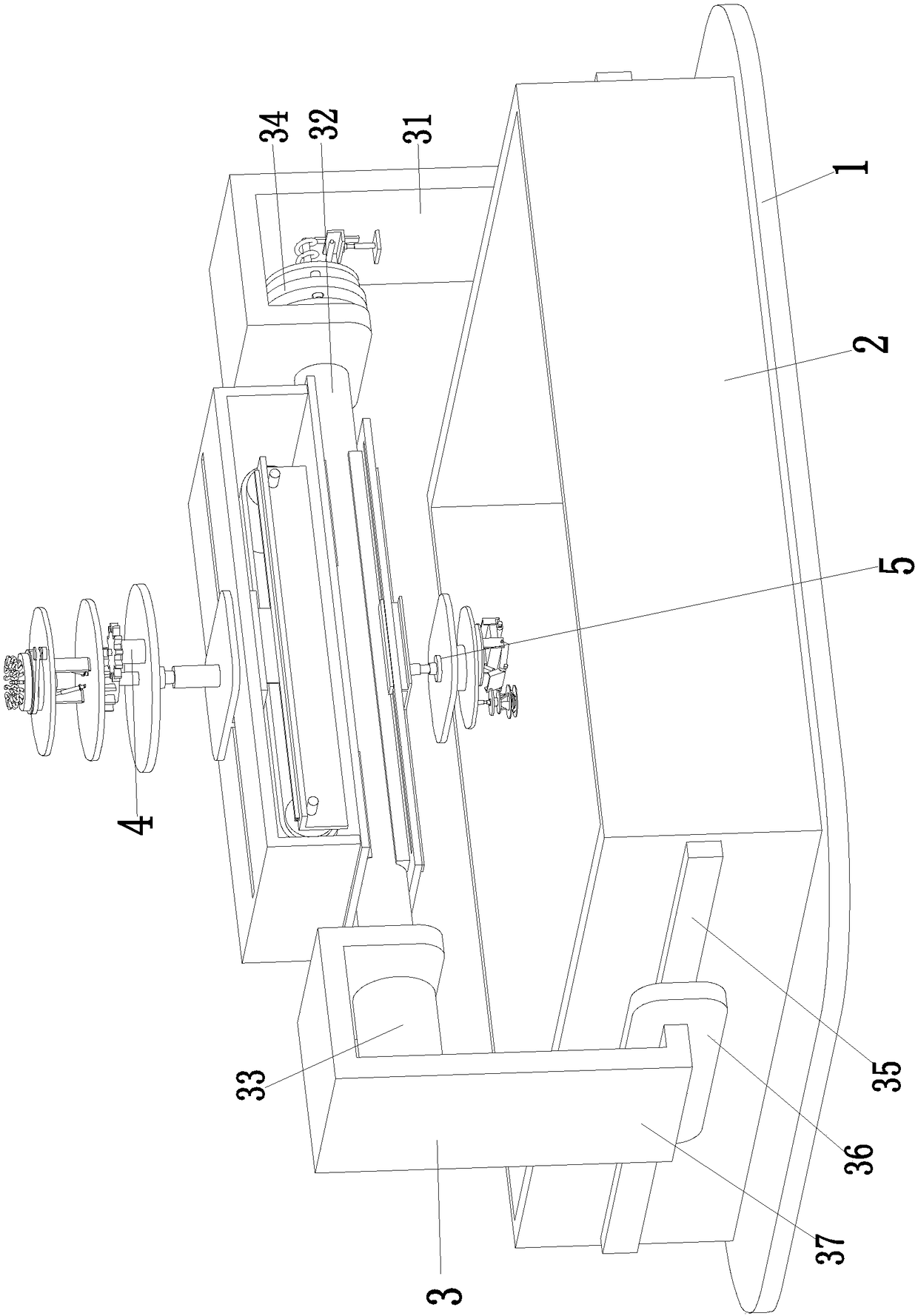

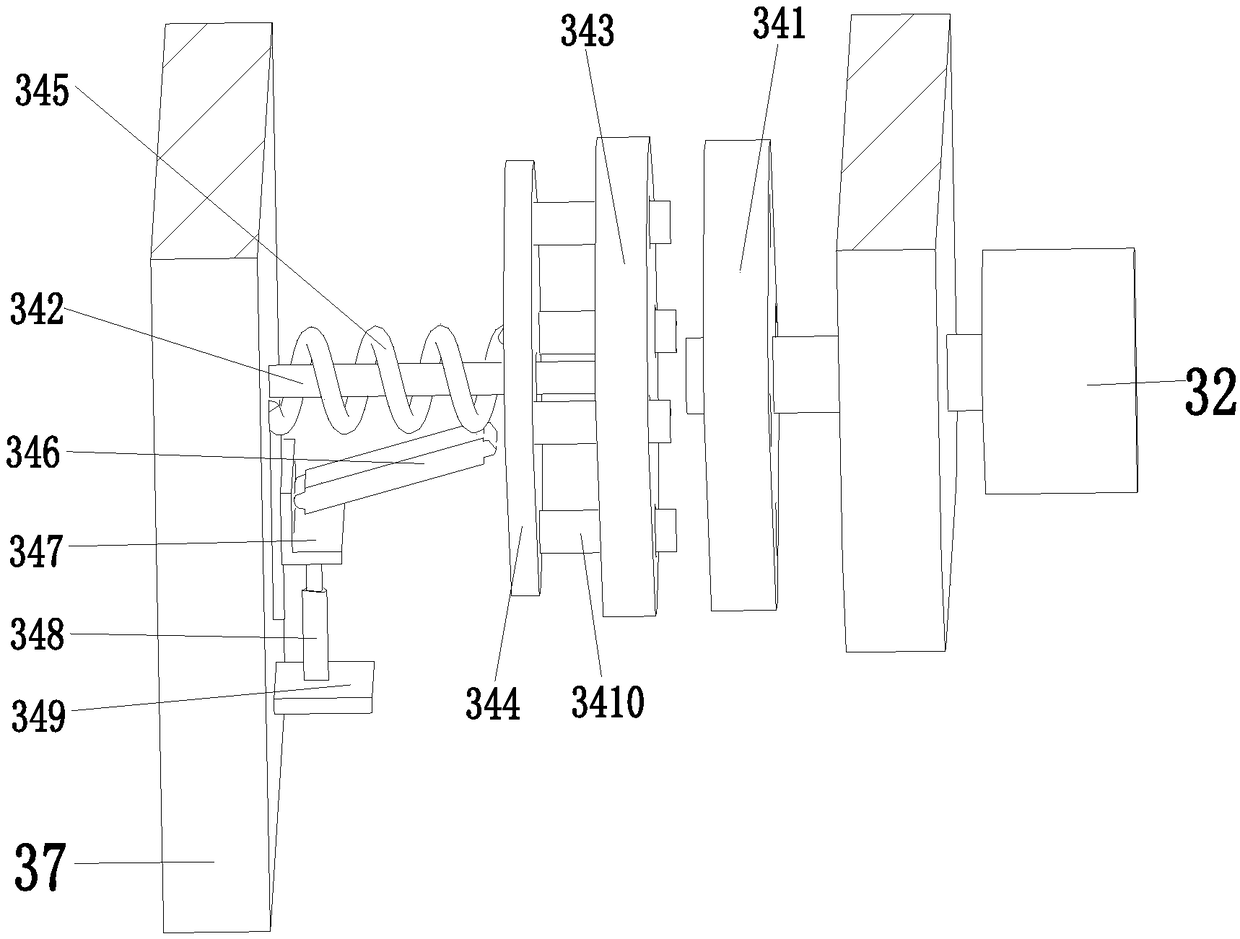

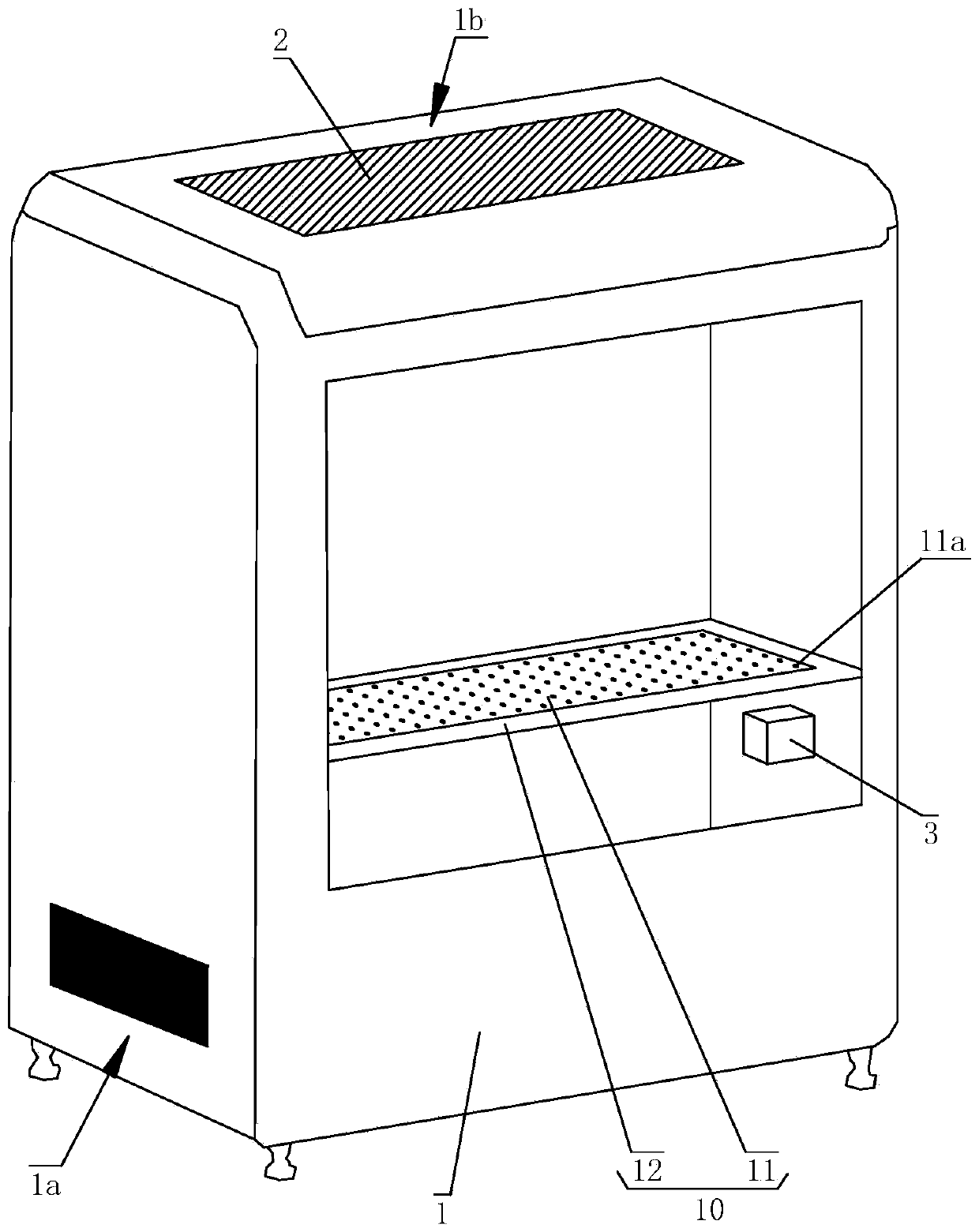

Glass coating wiping equipment

ActiveCN106824956AEnsure Wipe CleanlinessReasonable structureFlexible article cleaningManipulatorCoating

The invention discloses glass coating wiping equipment. The glass coating wiping equipment comprises a wiping device, a feeding device and a fetching device, wherein the wiping device is used for wiping a glass coating, and the feeding device and the fetching device are arranged on the left side and the right side of the wiping device. As for a workbench of the wiping device, negative pressure is generated in pores of the workbench through a vacuumizing device, and a glass piece to be wiped is sucked. From an upper feeding reel, upper wiping fabric sequentially passes through the bottom faces of all upper wiping modules and then is taken up by an upper take-up reel. The upper wiping modules, the upper feeding reel and the upper take-up reel are driven by an upper wiping driving mechanism to move synchronously in the X-axis direction or in the Y-axis direction. Negative pressure is generated in the pores through the vacuumizing device by means of a transfer rod so that the glass piece to be wiped can be sucked, and the glass piece can be driven by a transfer rod driving mechanism to move. In addition, grabbing and placing of a tray and the glass piece are achieved through corresponding mechanical arms in the feeding and fetching processes, manual operation is not needed during displacement of the tray, and full-automatic operation is achieved.

Owner:深圳聚顶科技有限公司

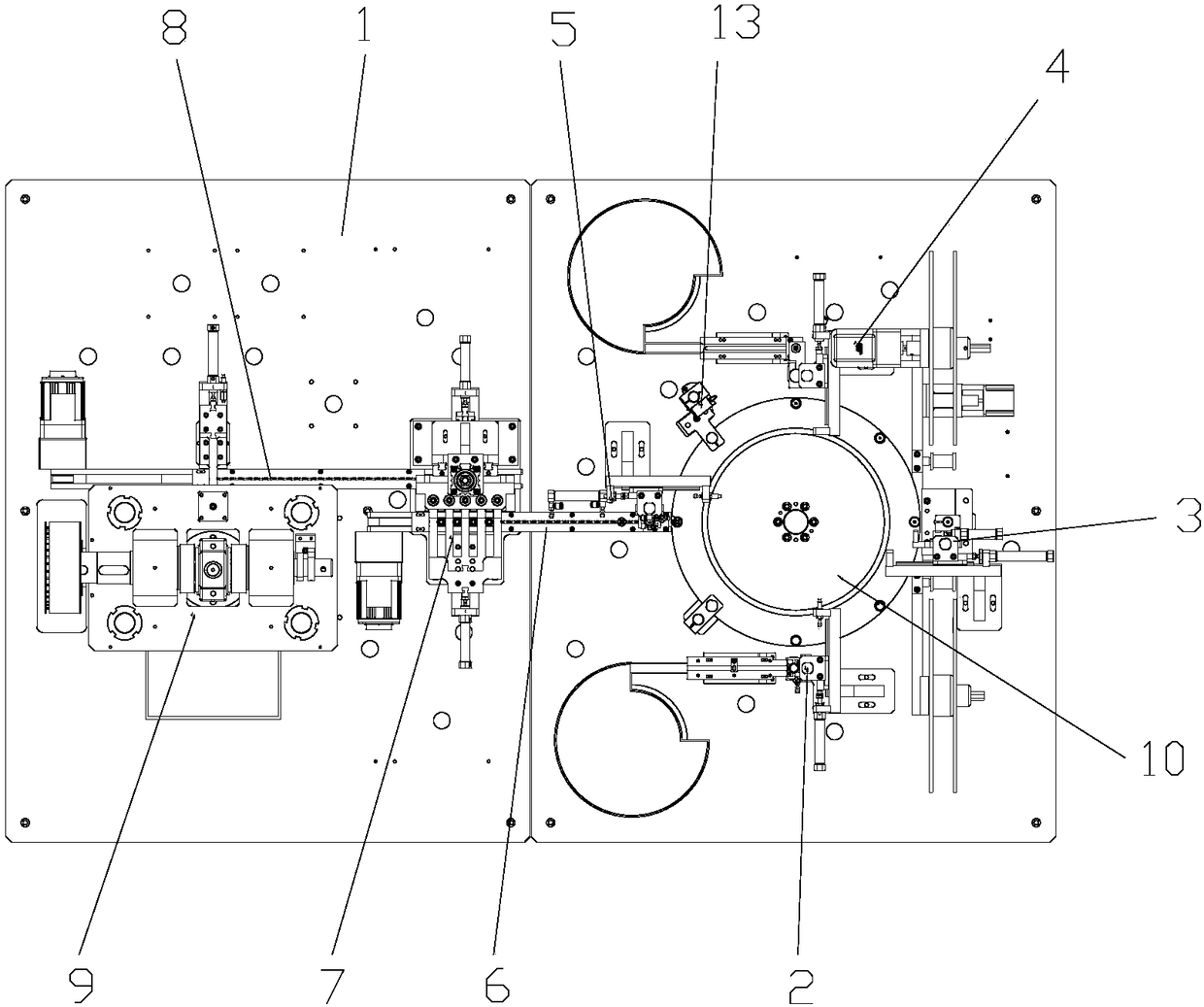

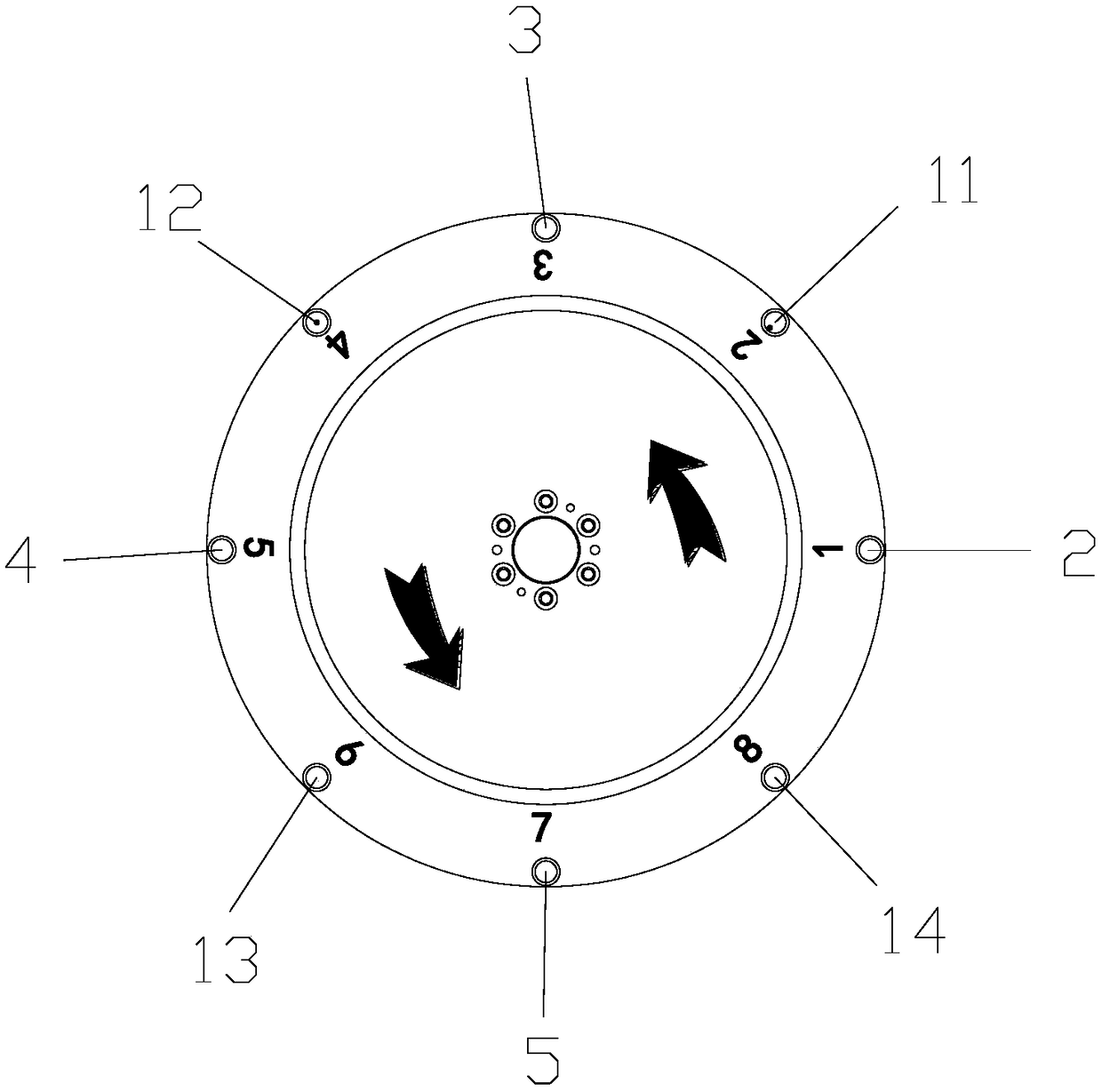

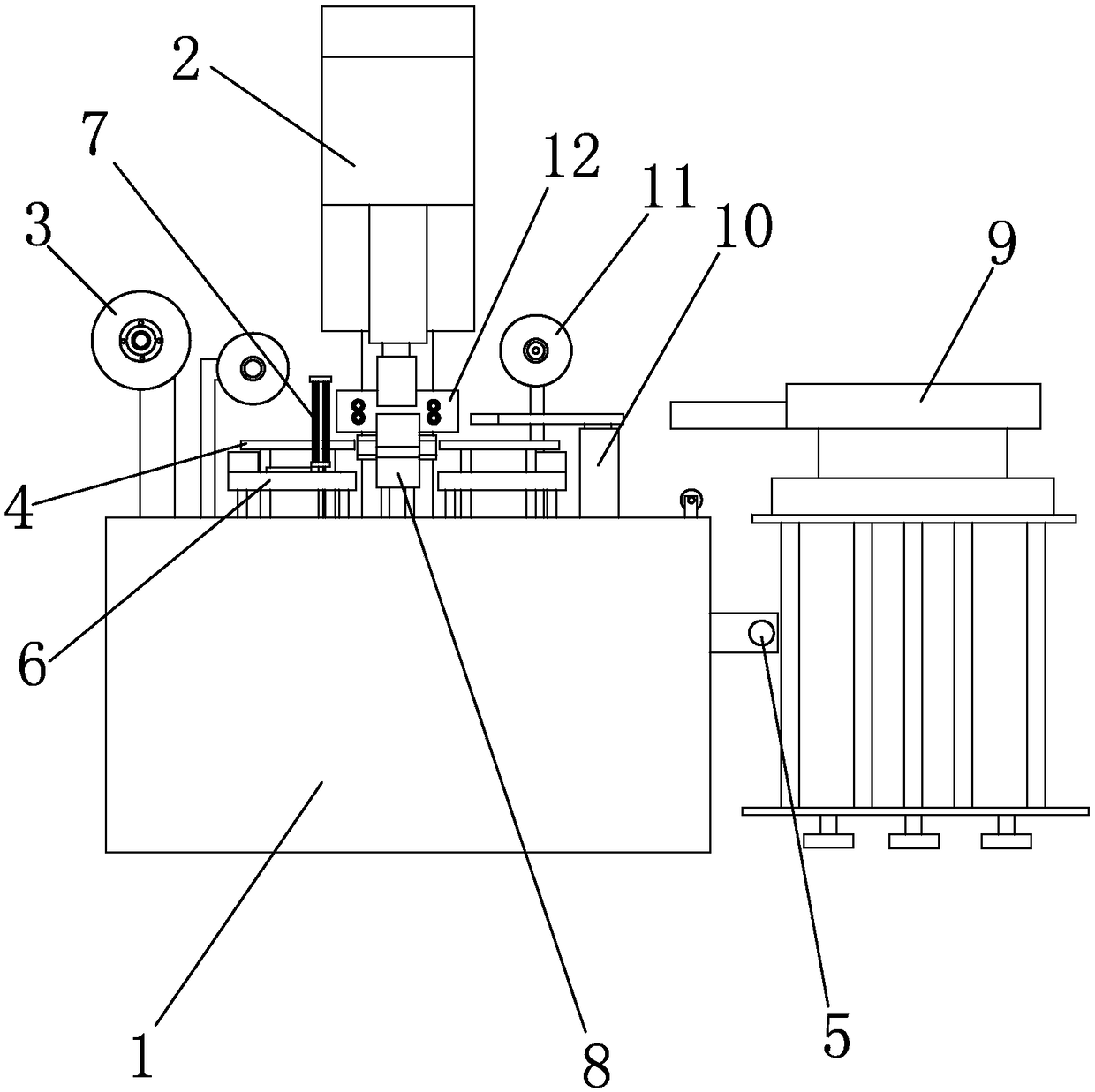

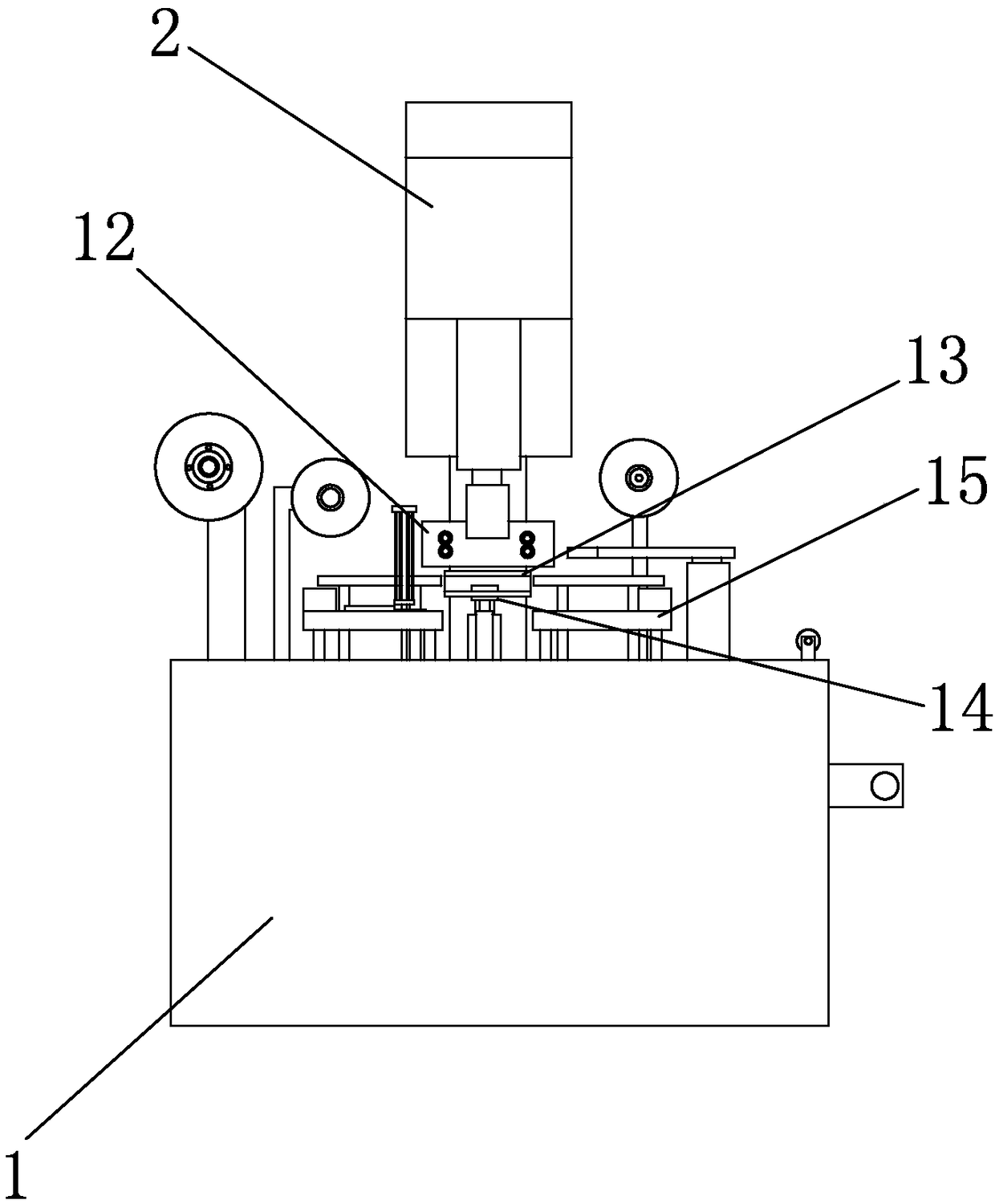

Automatic cap heat sealing machine

PendingCN108145987ANo manual workIncrease productivityPackagingMetal working apparatusButt jointMechanical equipment

The invention relates to the field of mechanical equipment, in particular to an automatic cap heat sealing machine. The machine comprises a workbench, and also comprises a bottom cover feeding mechanism, an anti-explosion membrane blanking feeding mechanism, an iron sheet feeding mechanism, a discharging mechanical arm, a feeding transferring pull wire, a material discharging pull wire, a heat sealing mechanism, a flattening mechanism, a rotary table and a main control module which are arranged on the workbench; the bottom cover feeding mechanism, the anti-explosion membrane blanking feeding mechanism, the iron sheet feeding mechanism and the feeding transferring line are correspondingly arranged on the periphery of the rotating disc in sequence; one end of the feeding transferring wire isin butt joint with the rotating disc, and the other end of the feeding transferring wire is connected with the heat sealing mechanism; the discharging mechanical arm is arranged at one end, which isin butt joint with the rotating disc, of the feeding transferring wire; the flattening mechanism is arranged on the side face of the discharging pull wire; and the main control module is used for controlling the working operation of all the mechanisms. According to the technical scheme, all the mechanisms achieve integral full-automatic operation, so that the production efficiency and the productquality are improved.

Owner:惠州亿恒特自动化科技有限公司

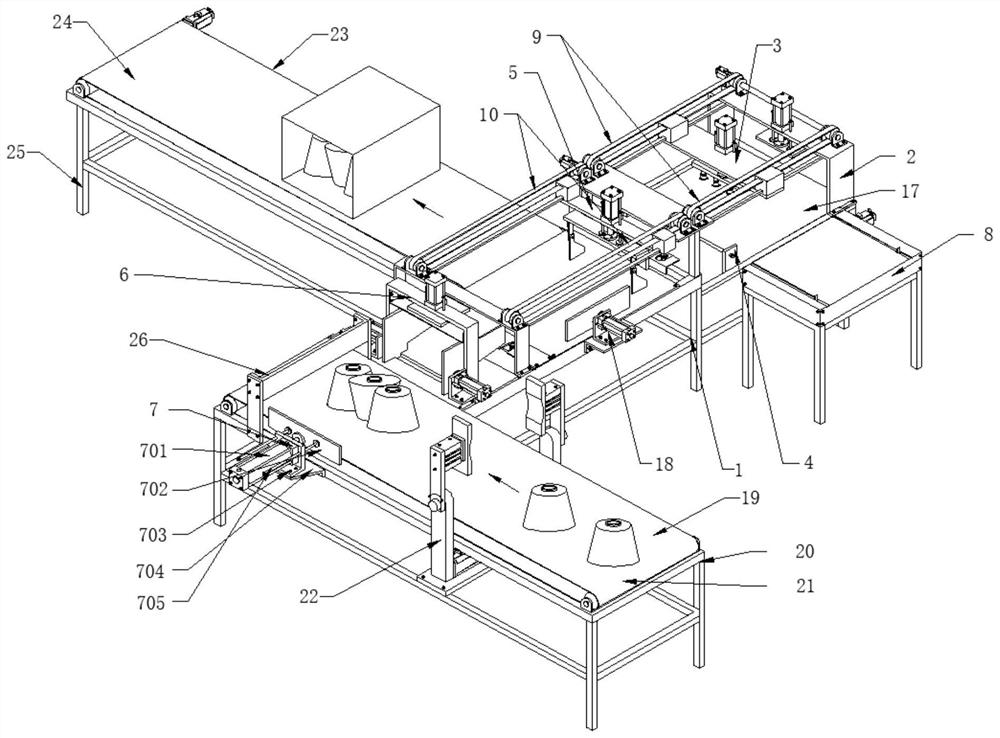

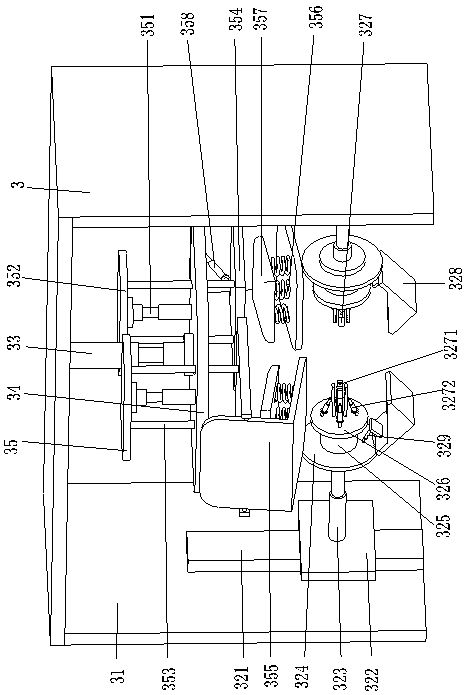

Automatic yarn bobbin bagging machine

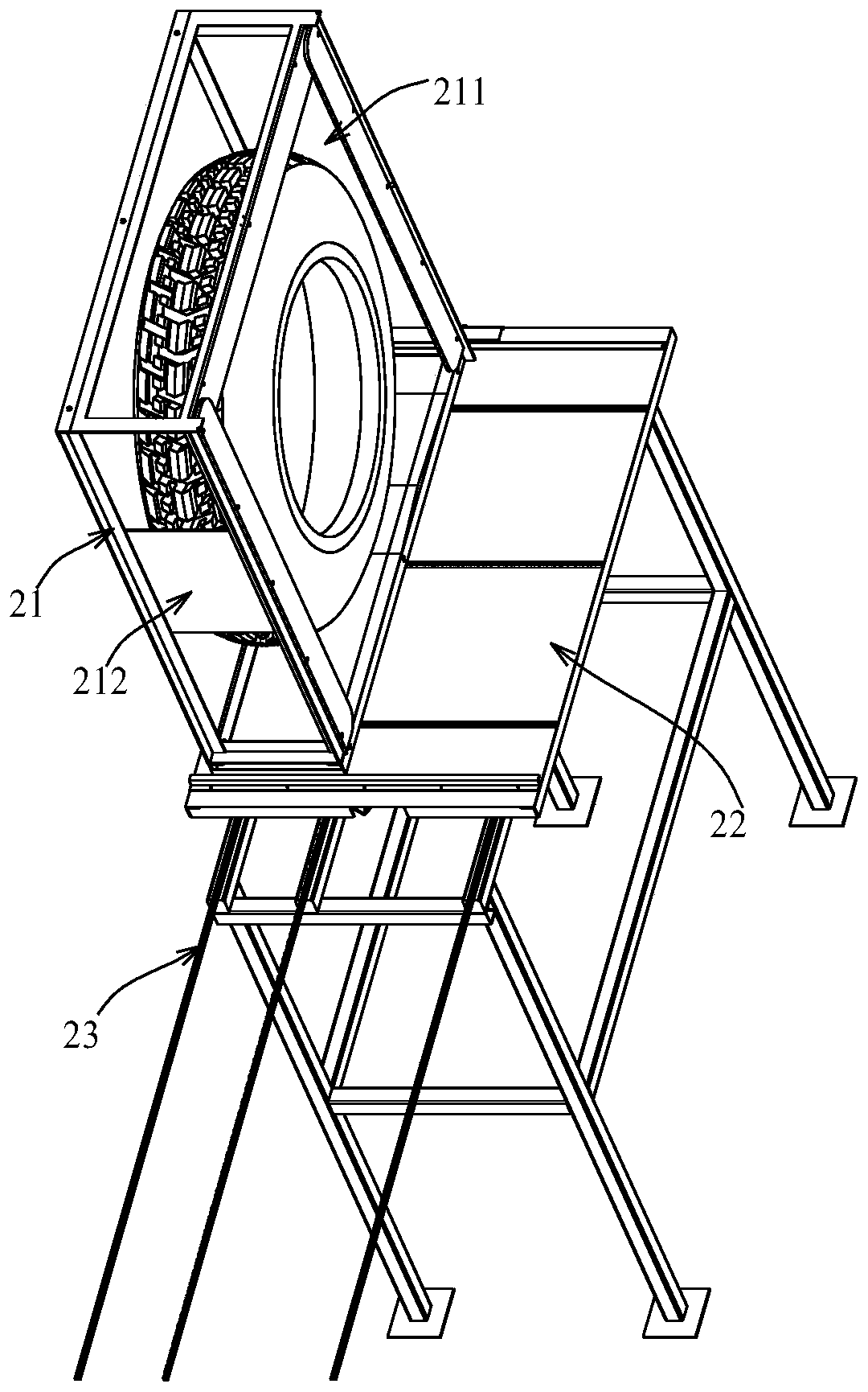

The invention discloses an automatic yarn bobbin bagging machine. The machine comprises a bag sleeving and bag taking device and a bagging device connected with the bag sleeving and bag taking device;woven bags are subjected to positioning, opening and sleeving through a bag pressing mechanism, a bag taking mechanism, a bag supporting mechanism, a bag opening mechanism and a bag sleeving mechanism in the bag sleeving and bag taking device in sequence; then adjacent bobbins are placed in a front-back staggered mode through a turning over mechanism in the bagging device, that is, every other yarn bobbin is turned over by 180 degrees through the bobbin turning over mechanism; then the arranged yarn bobbins are pushed into the bags through a bagging pushing mechanism in the bagging device; and finally the loaded bobbin bags are conveyed away through a discharging mechanism in the bagging device. According to the machine, the automation degree is high, the bagging effect is good, the manual operation is not needed, the labor cost is reduced, and the working efficiency is improved; and meanwhile, the structure is simple, the automation degree is high, bag bodies move in parallel all thetime in the bagging process, and turning-over is not needed, so that the fault of bagging failure caused by bag body deformation is avoided, and the reliability is high.

Owner:武汉道非科技有限公司

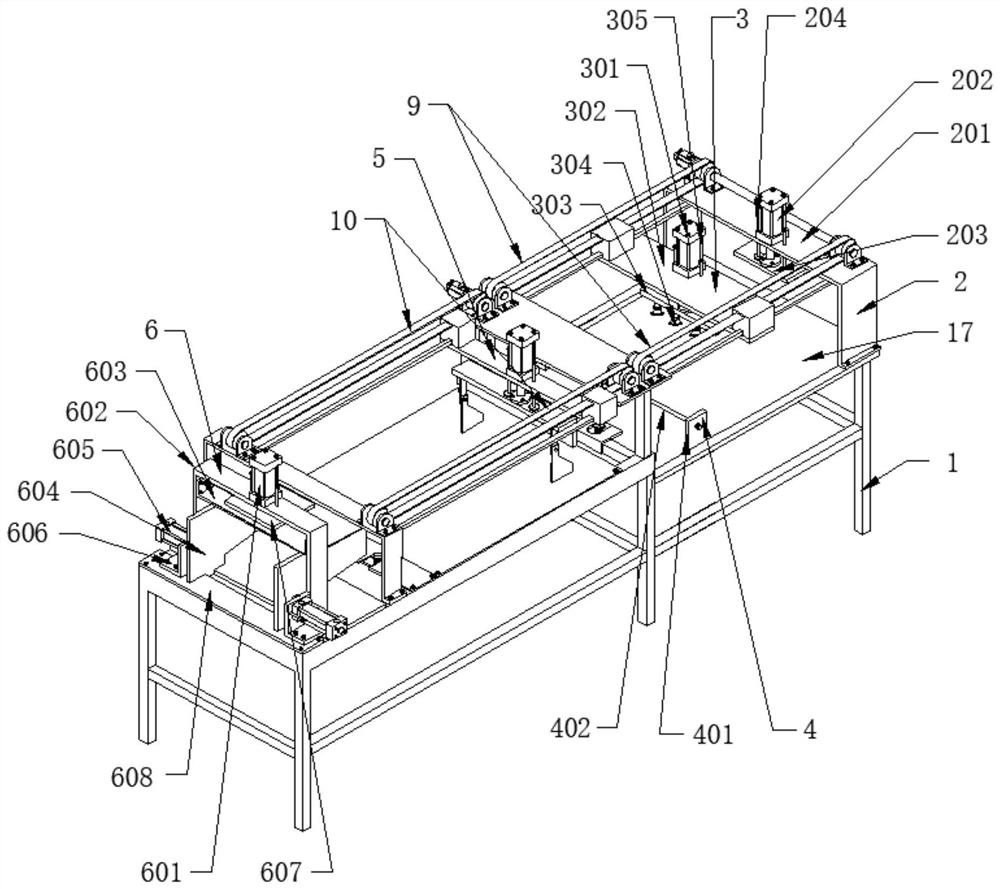

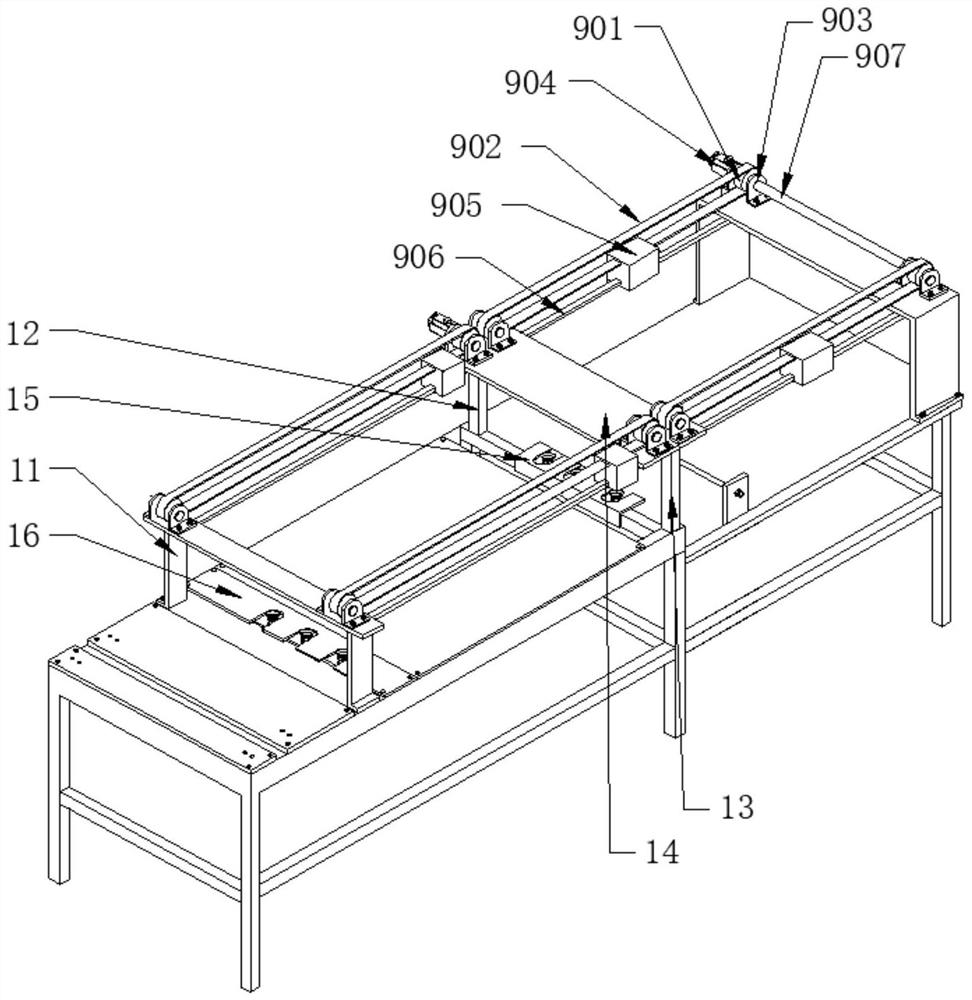

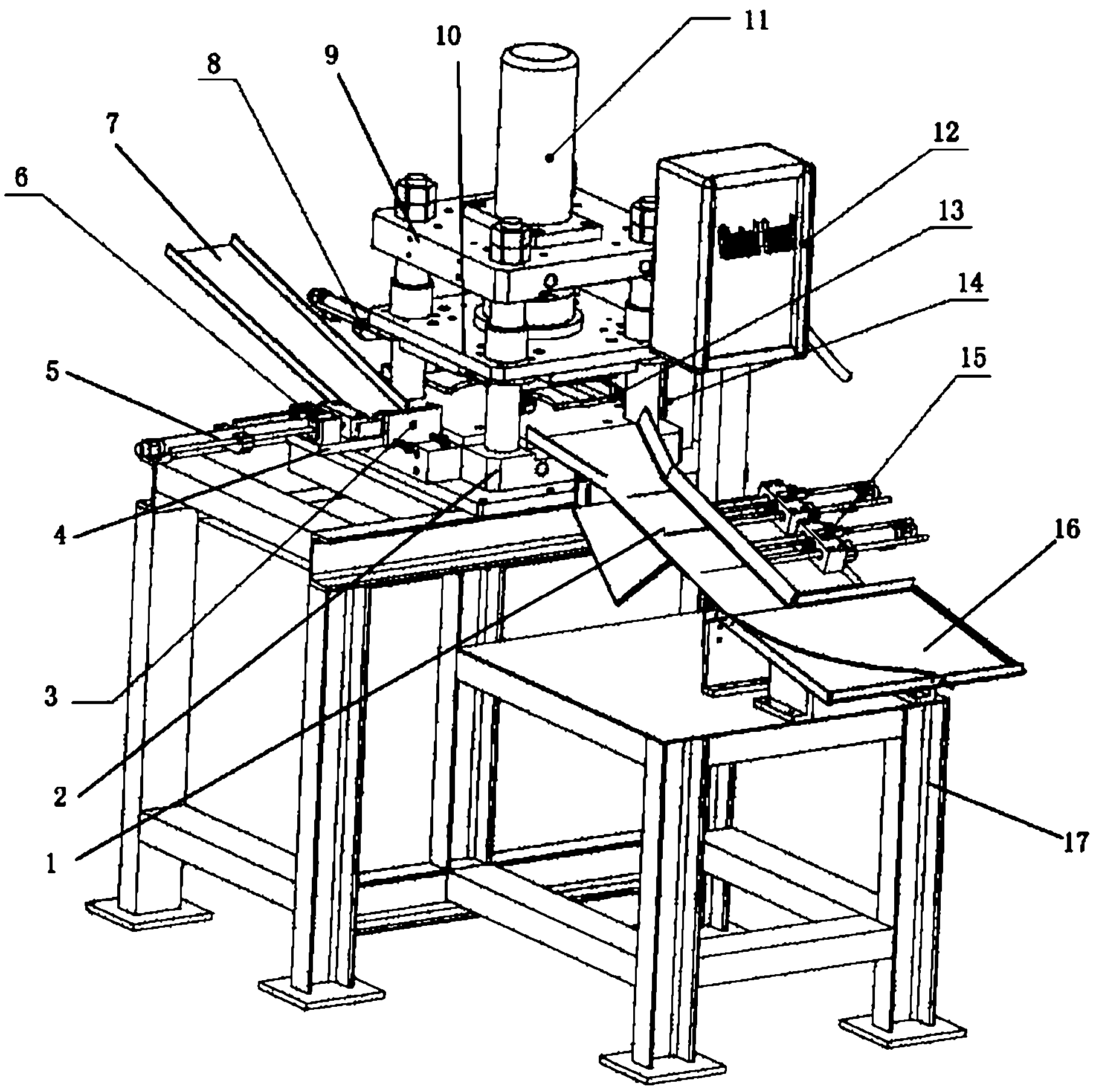

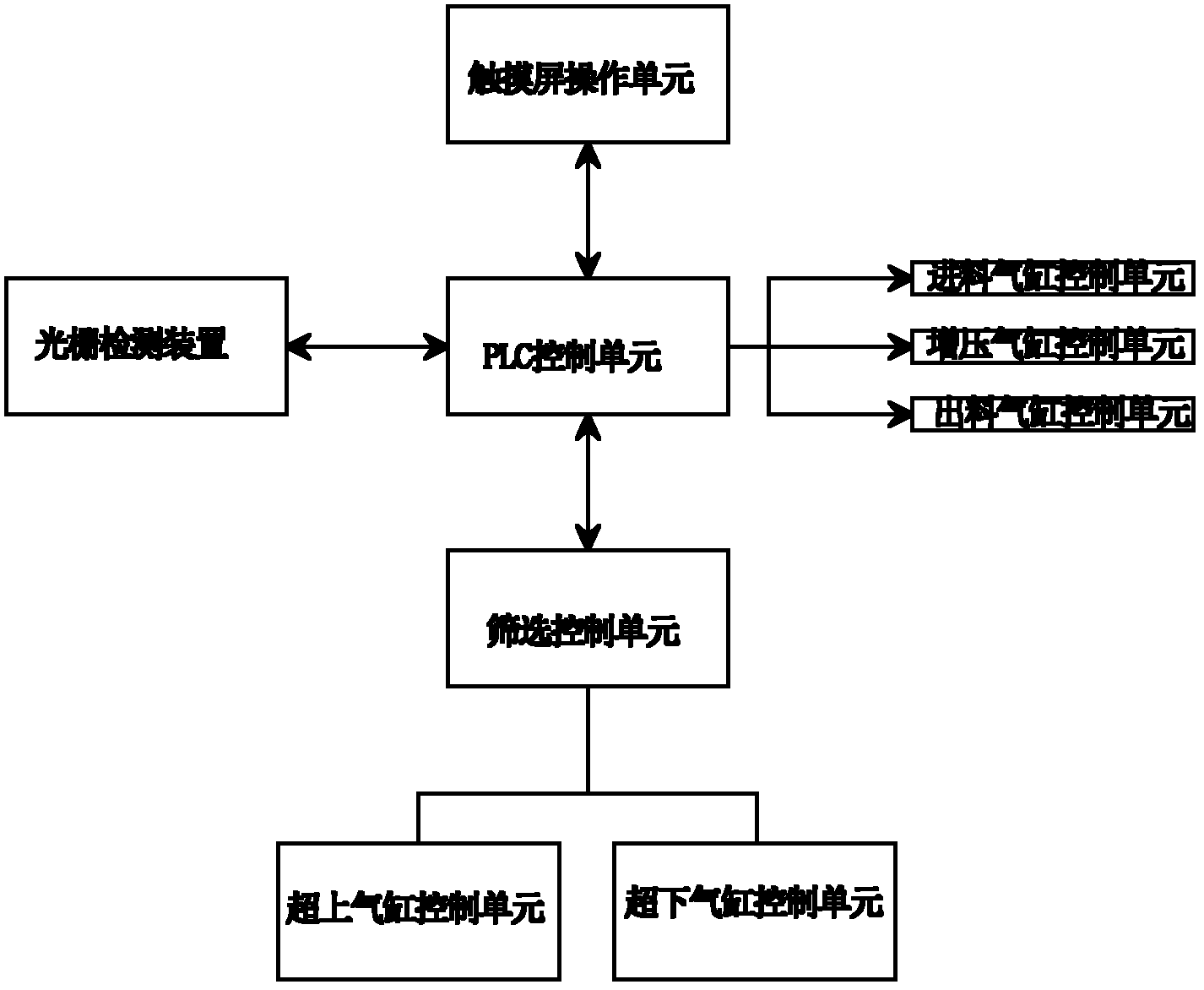

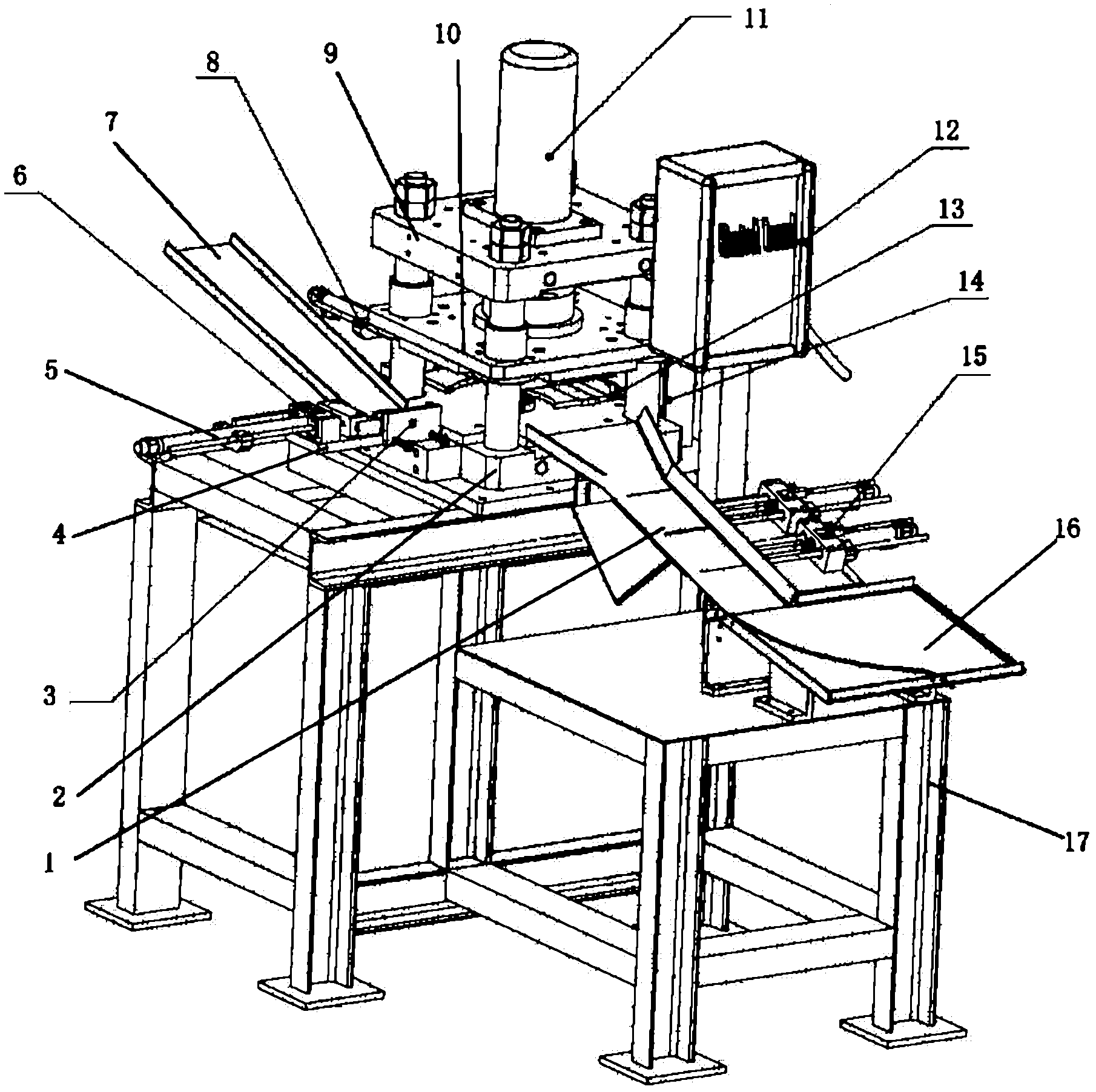

Automatic pressing and detecting machine for iron cores

ActiveCN102623165ARealize automated productionNo manual operationInductances/transformers/magnets manufactureUsing optical meansGratingEngineering

The invention belongs to the field of processing and detecting equipment for iron cores, and particularly relates to an automatic pressing and detecting machine for iron cores, which presses the iron cores and automatically sorts the pressed iron cores. The automatic pressing and detecting machine for the iron cores comprises a support consisting of a first support and a second support, and is characterized in that a pressing device for pressing the iron cores is arranged on the first support, a pushing mechanism for pushing the pressed iron cores out of the pressing device is further arranged on the pressing device, a material feeding mechanism for feeding the iron cores into the pressing device is connected to the left side edge of the pressing device, a material guiding groove connected with a material holding plate is connected to the front side edge of the pressing device, and a grating detection device for detecting the height of the pressed iron cores is arranged on the pressing device. The automatic pressing and detecting machine further comprises a control device for controlling operation of all mechanisms.

Owner:TEMPLE CHANGZHOU PRECISION METAL PROD

Gluing and assembly all-in-one machine of LED wall washing lamp

ActiveCN106425357AImprove waterproof and dustproof performanceUniform stripLiquid surface applicatorsCoatingsManipulatorLight transmission

The invention discloses a gluing and assembly all-in-one machine of an LED wall washing lamp. The machine comprises a frame, a feeding mechanism, a gluing mechanism, groove mechanisms and a grabbing mechanism; a worktable is arranged on the frame; a gluing station and a cover plate station are respectively arranged in the conveying direction of the feeding mechanism; the feeding mechanism can convey wall washing lamp frame bodies to the gluing station and the cover plate station in sequence; the gluing mechanism includes a gluing manipulator device, and a gluing head device arranged on the gluing manipulator device; the gluing manipulator device can drive the gluing head device to glue the wall washing lamp frame bodies on the gluing station in the length direction of the wall washing lamp frame bodies; at least one set of groove mechanisms is provided; the grabbing mechanism is a manipulator device; and the grabbing mechanism can grab wall washing lamp light transmission plates on the groove mechanisms and cover the wall washing lamp light transmission plates on the wall washing lamp frame bodies in the cover plate station to finish the gluing and cover plate assembly procedures of the LED wall washing lamp. The gluing and assembly all-in-one machine of the LED wall washing lamp needs no manual operation, and is high in operation precision and working efficiency.

Owner:中山格帝斯自动化设备有限公司

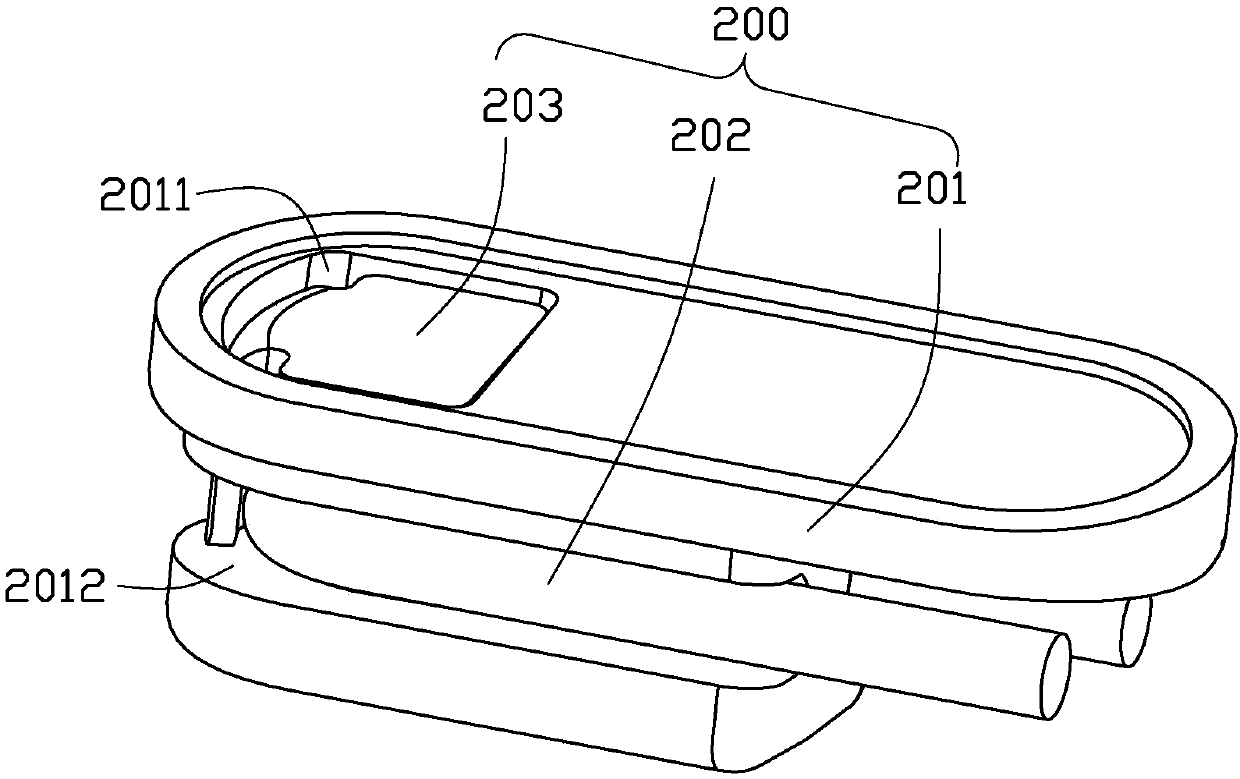

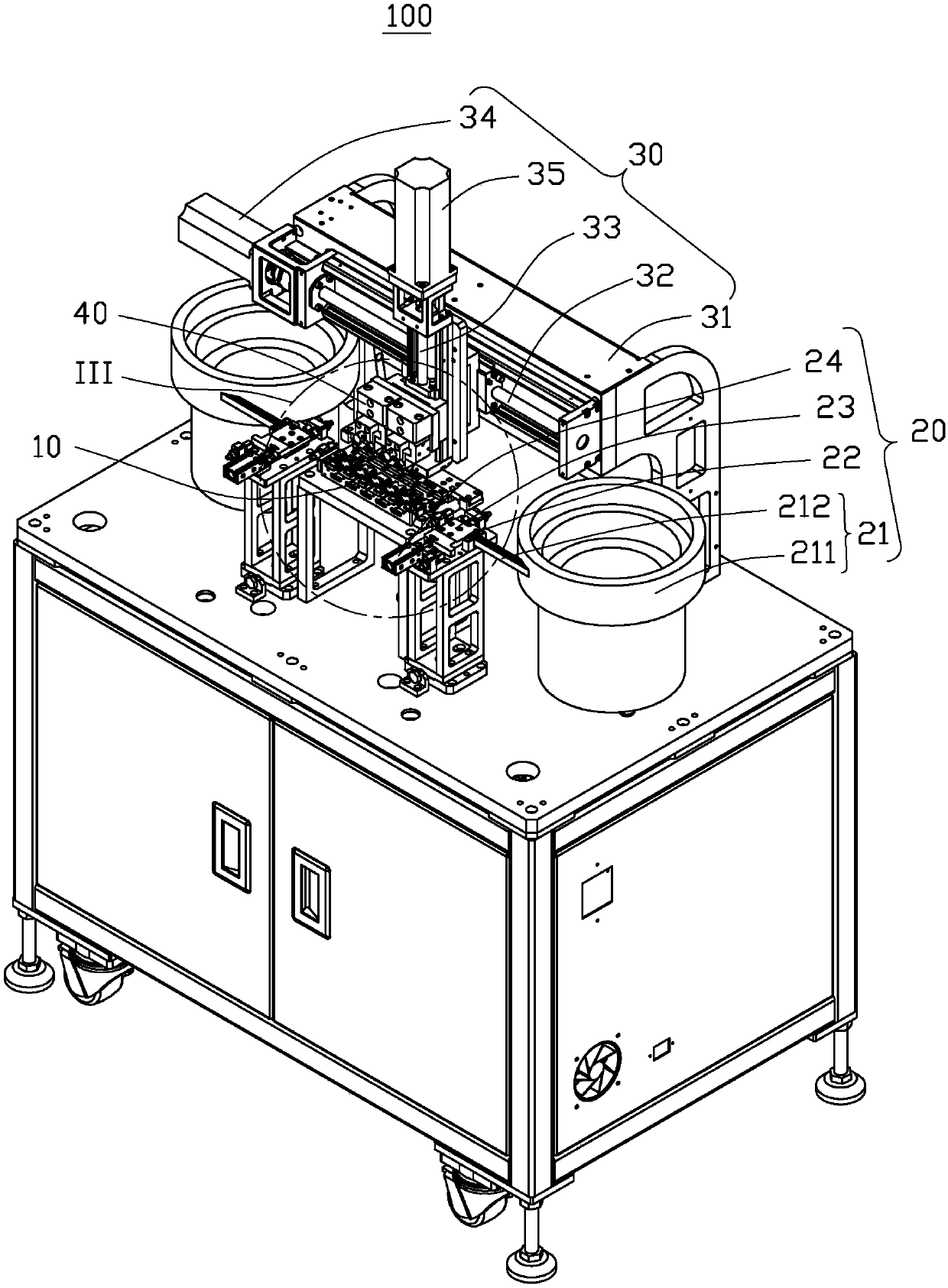

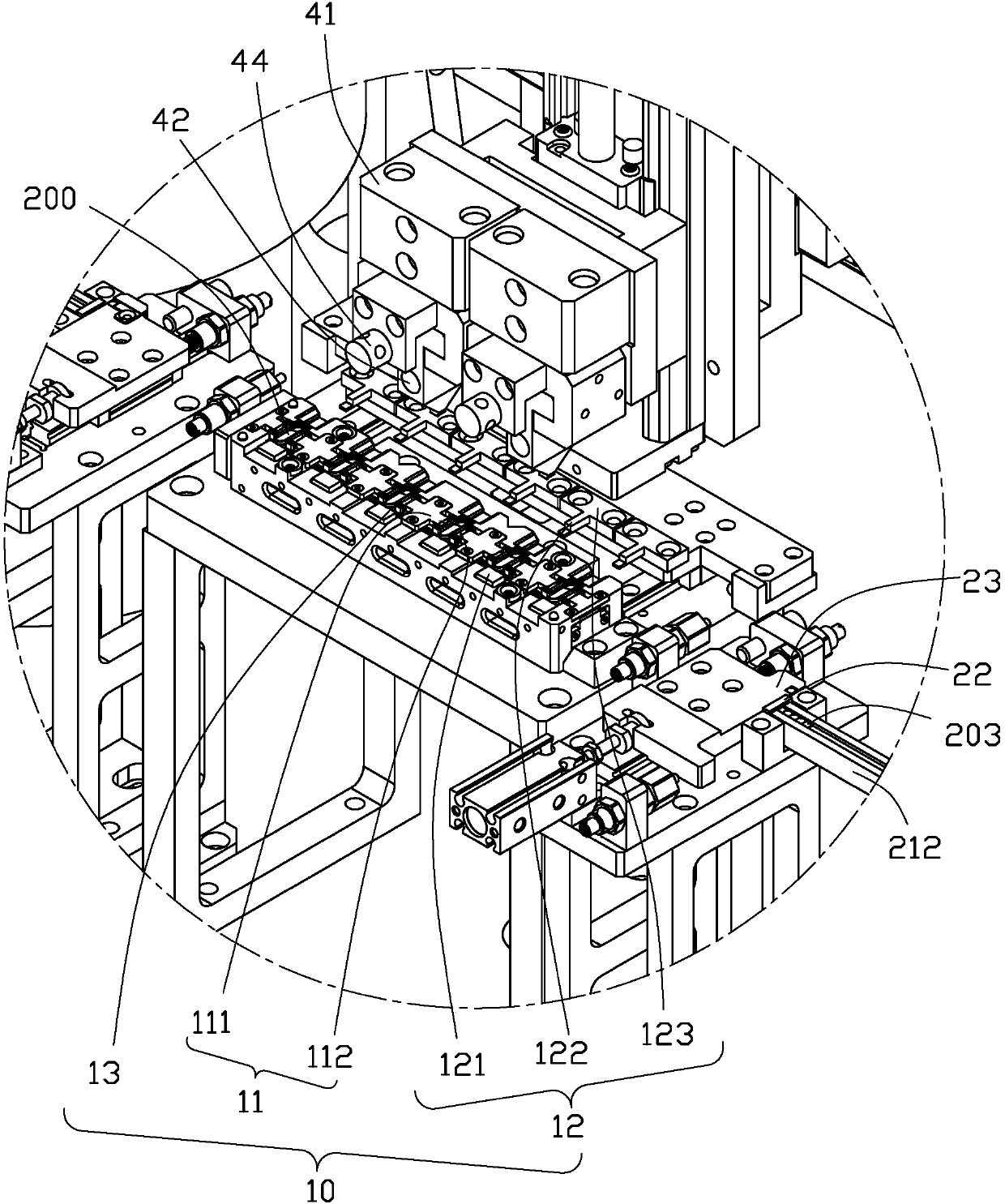

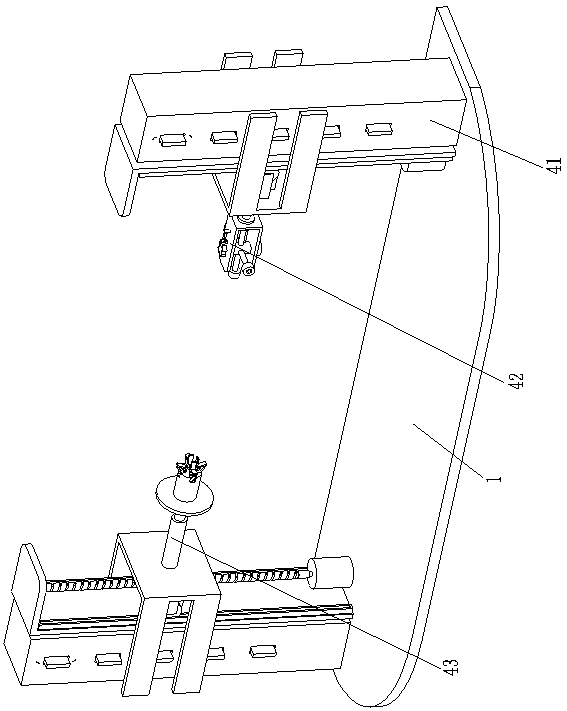

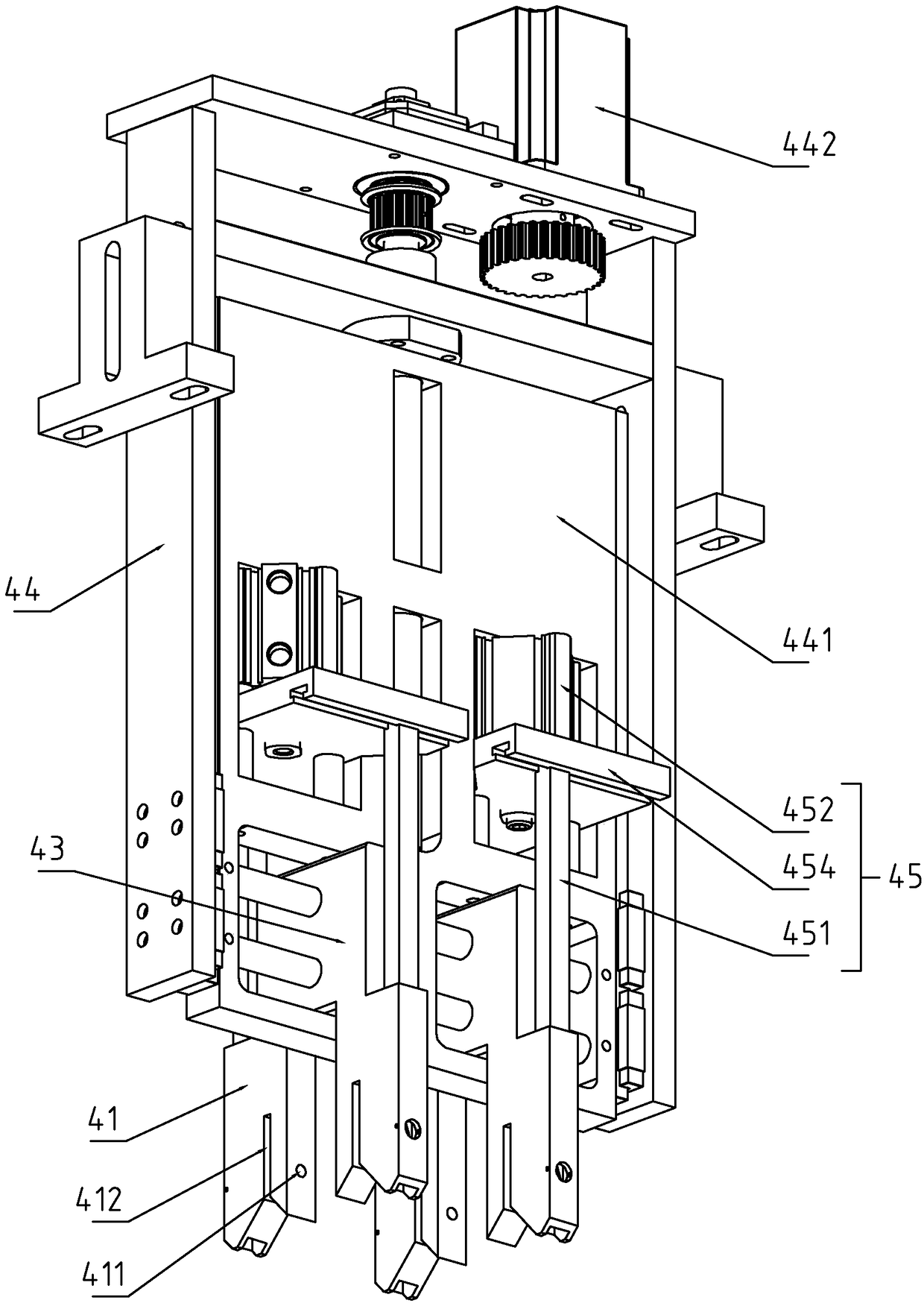

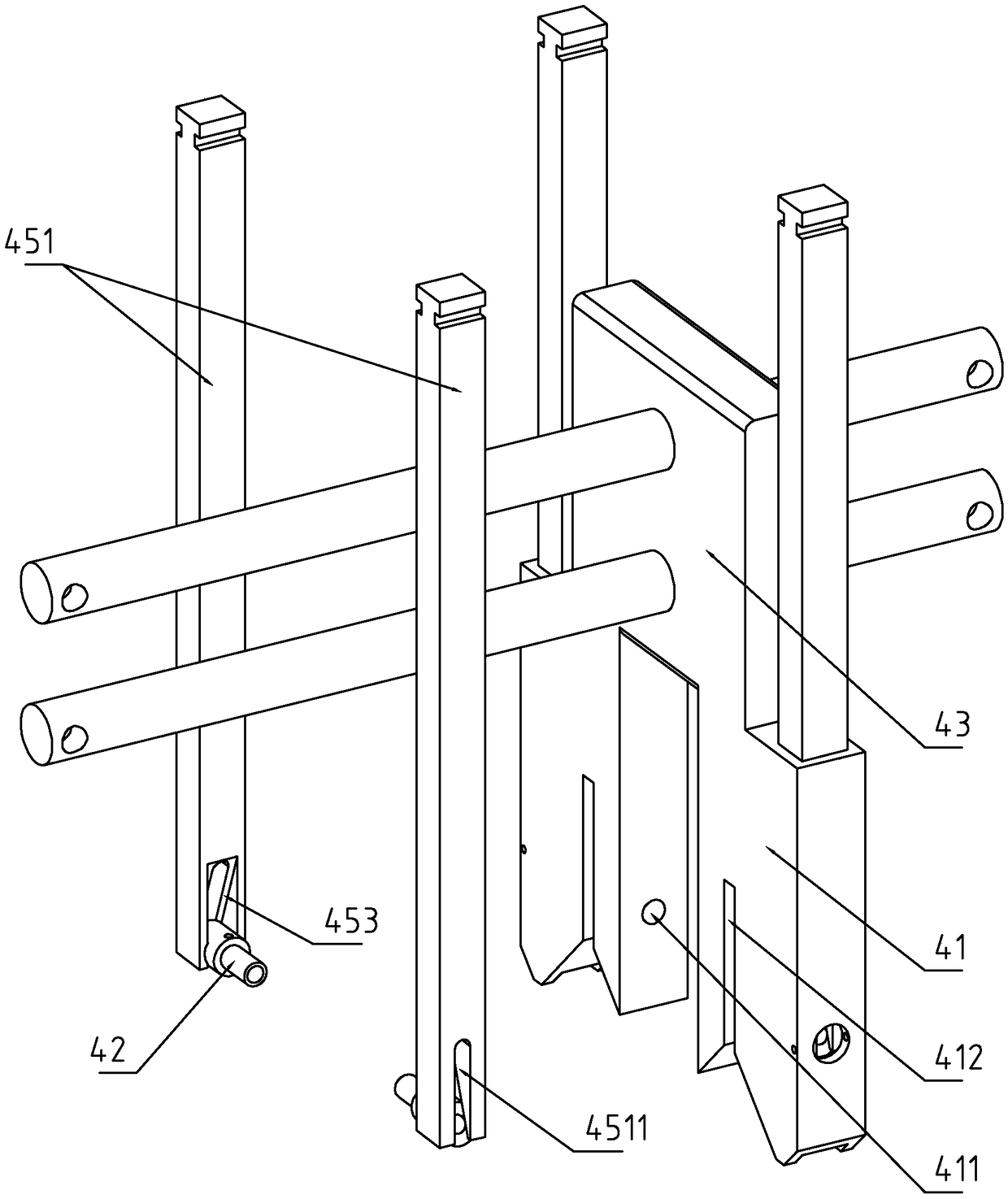

Automatic assembling device

The invention provides an automatic assembling device for assembling a workpiece which comprises a workpiece body and an inserting strip. The automatic assembling device comprises a worktable, a material conveying mechanism, a material transferring mechanism and a material suction mechanism, wherein the worktable is provided with a copying slot; the material conveying mechanism comprises a vibrating plate and a material pushing block; the vibrating plate comprises a vibrating plate body and a material channel; the material channel is connected to the vibrating plate body and used for supplyingthe inserting strip; the material pushing block is provided with a positioning groove, and the positioning groove is connected to the material channel and used for positioning the inserting strip; the material transferring mechanism comprises a support, a horizontal slide rail, a vertical slide rail, a horizontal driving part and a vertical driving part; the support is arranged at the worktable;the horizontal slide rail is arranged on the support and extends from the worktable to the vibrating plate; the vertical slide rail is arranged at the horizontal slide rail by sliding and is driven tomove through the horizontal driving part; the material suction mechanism comprises a material suction body, a suction head and a vacuum generator; the material suction body is arranged at the vertical slide rail by sliding and is driven to lift through the vertical driving part; the suction head is connected to the vacuum generator and extends out of the material suction body in order to suck theinserting strip, and then the suction head can move to the worktable to insert the inserting strip into the material suction body.

Owner:FU DING ELECTRONICSAL TECH JIASHAN

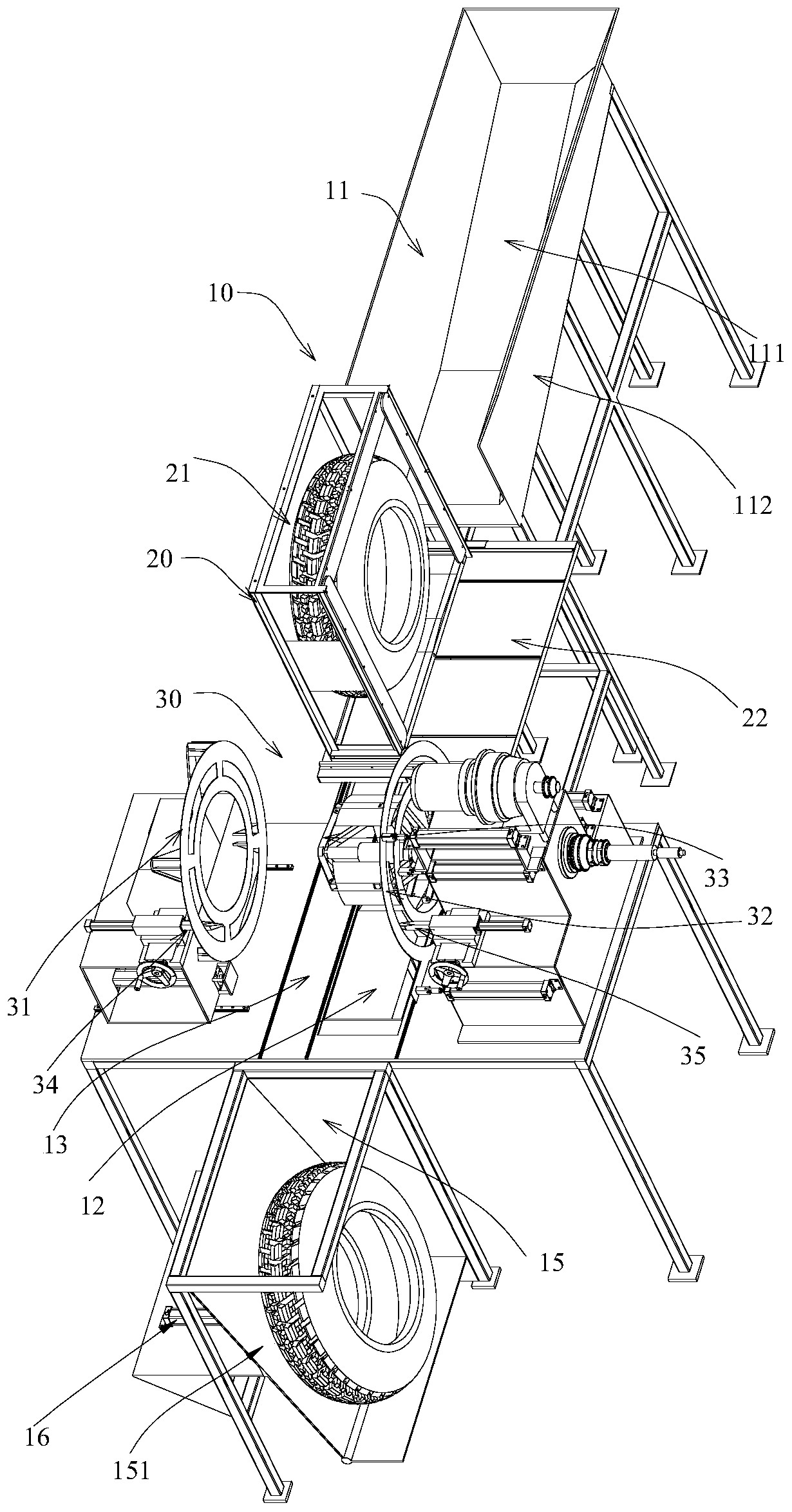

Tire automatic treatment equipment

The invention discloses tire automatic treatment equipment. The tire automatic treatment equipment comprises a machine body, a positioning mechanism for positioning tires and driving the tires to moveto a ring cutting station, a ring cutting mechanism mounted in the ring cutting station and comprising a first fixing piece, a second fixing piece, a first cutter, a second cutter and an inner ring fixing module, and an outer ring cutting mechanism, wherein the first fixing piece and the second fixing piece are oppositely arranged at intervals; the first fixing piece can axially move near or faraway from the second fixing piece; and the inner ring fixing module is inserted in the second fixing piece, and is pivoted to the machine body. The tire automatic treatment equipment can separate inner rings of the tires from outer rings, and can cut the outer rings.

Owner:GENOX RECYCLING TECH

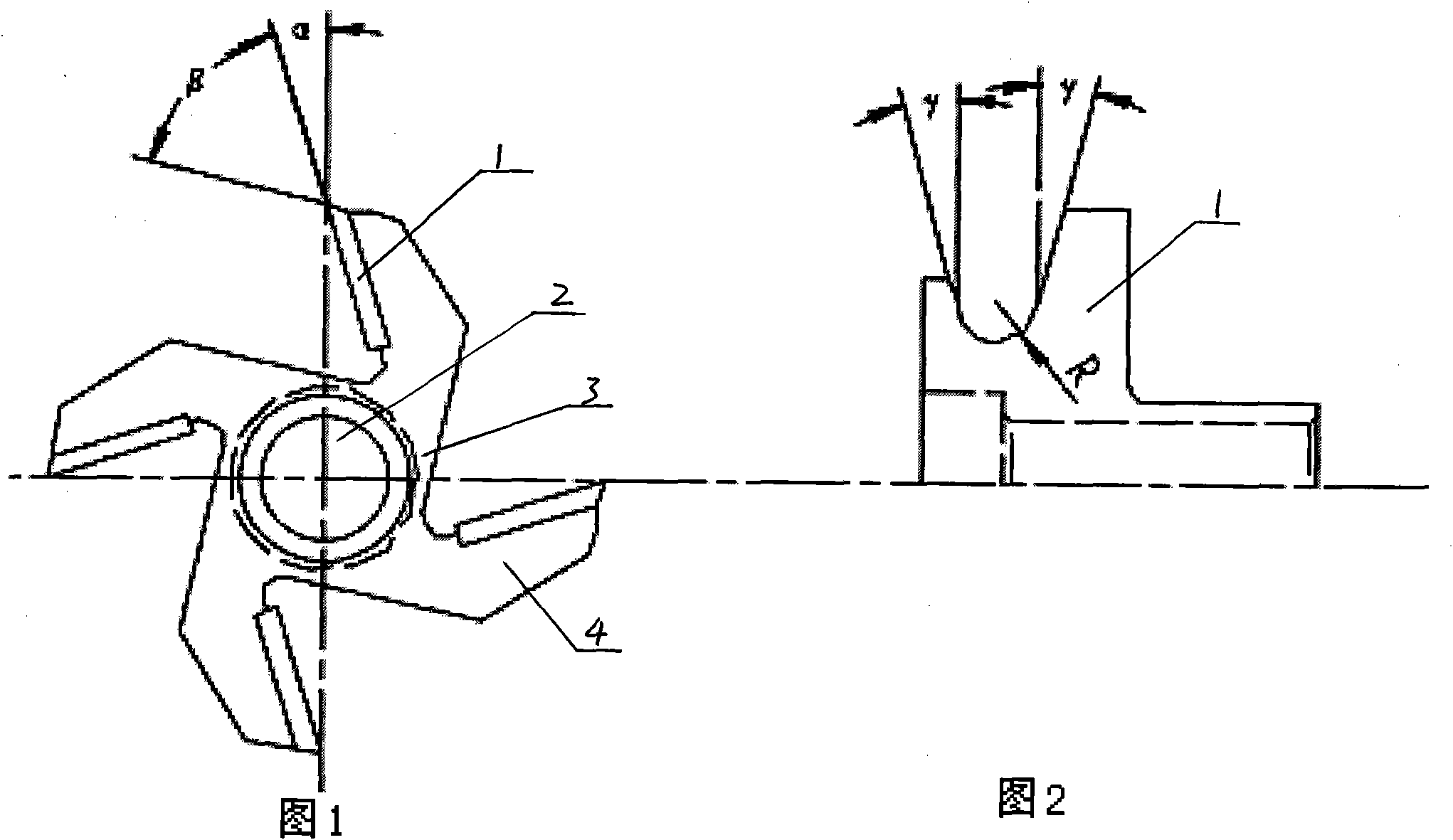

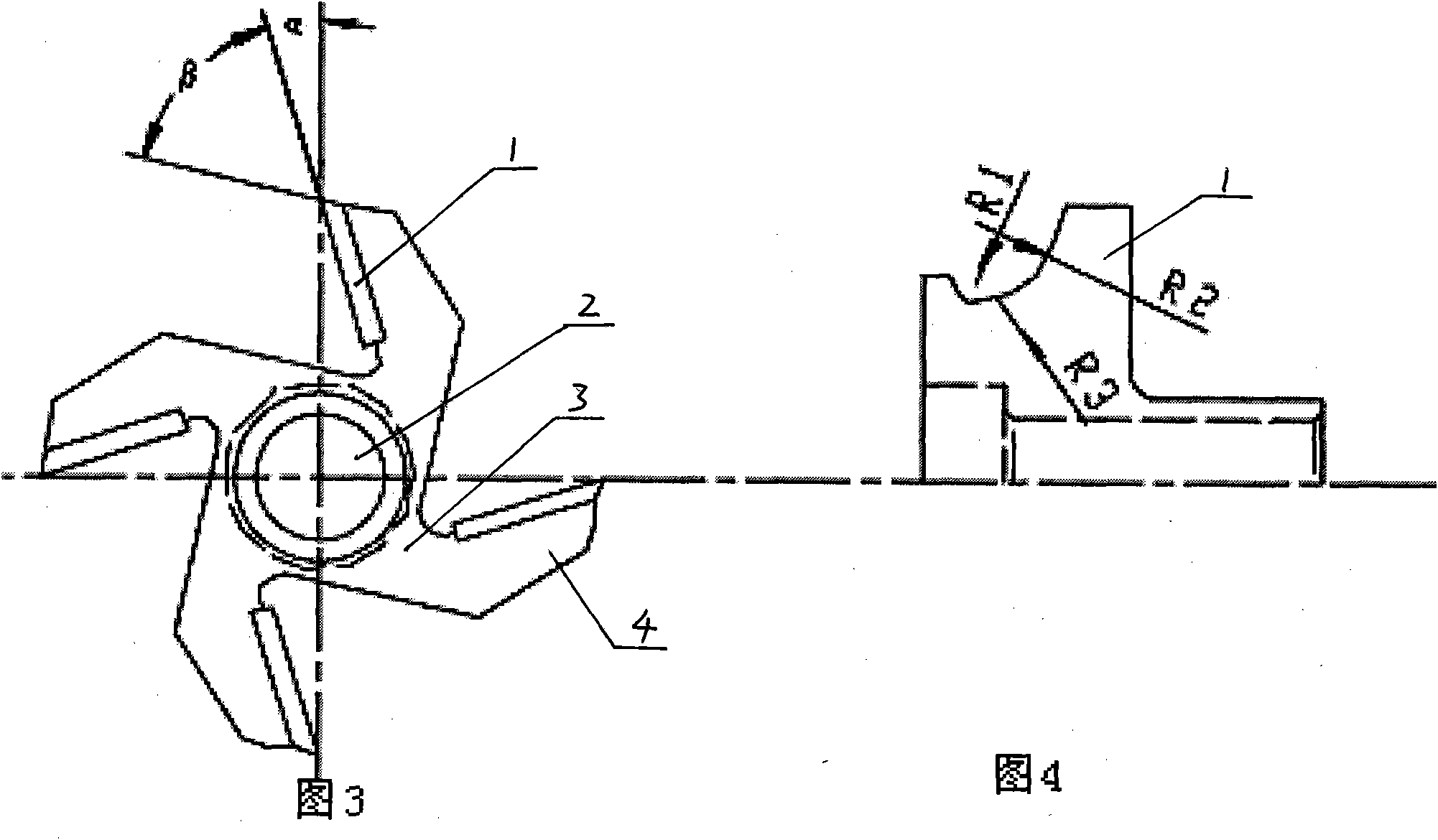

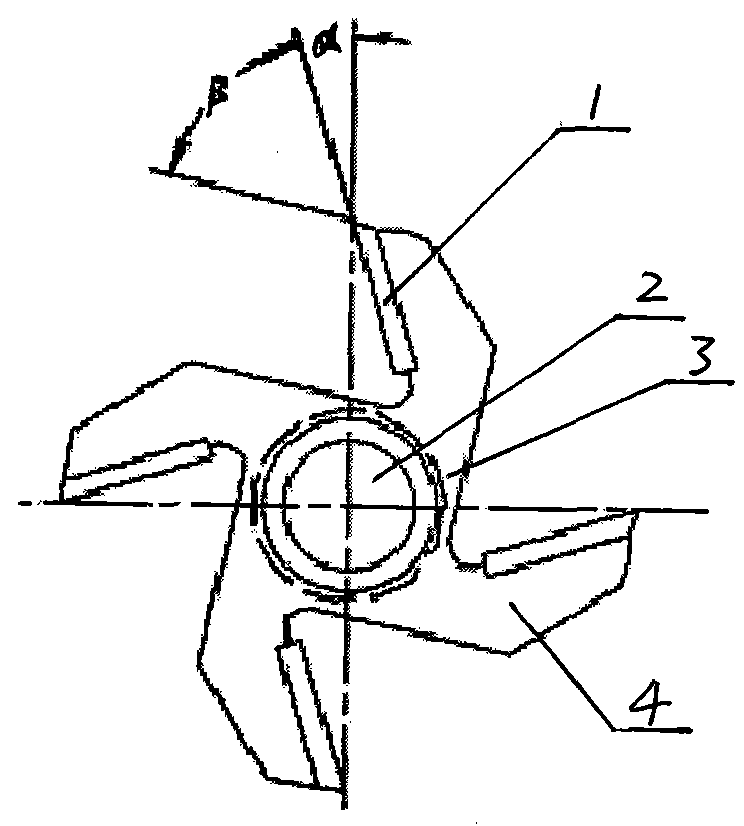

Moulding milling cutter

ActiveCN102029421AReduce processing timeGuaranteed machining accuracyMilling cuttersSurface finishMilling cutter

The invention discloses a moulding milling cutter. A cutter body is in a circular truncated cone shape; four inclined planes are evenly distributed at the outer edge of the end surface of one end part of the cutter body; a cutting tool is respectively fixed on concave platforms of the four inclined planes; the cutting edge of the cutting tool is in an arc shape matched with a cut arc shape of a cut workpiece; both ends of the cutting edge of the cutting tool respectively form an angle gamma (gamma is not greater than 15 degrees) with the tangent lines of two end circular arcs; the front end surface of the cutting edge of the cutting tool and a radial shaft of the end surface of the cutter body form an angle alpha (alpha is equal to 5-8 degrees); the middle part of the cutter body is provided with a penetrated counter bore; and a cutter shaft assorted with a machine tool is arranged in the counter bore. The invention ensures the processing precision and the surface finishment; the cutter body is in a counter bore structure of which the middle part is penetrated, can be clamped with a milling machine through the cutter shaft and is convenient to clamp; the arc processing of the workpiece can be completely finished by the milling machine of the milling cutter without manual operation, thereby shortening the processing time of the workpiece and improving the production efficiency.

Owner:BAODING TIANWEI BAOBIAN ELECTRICAL

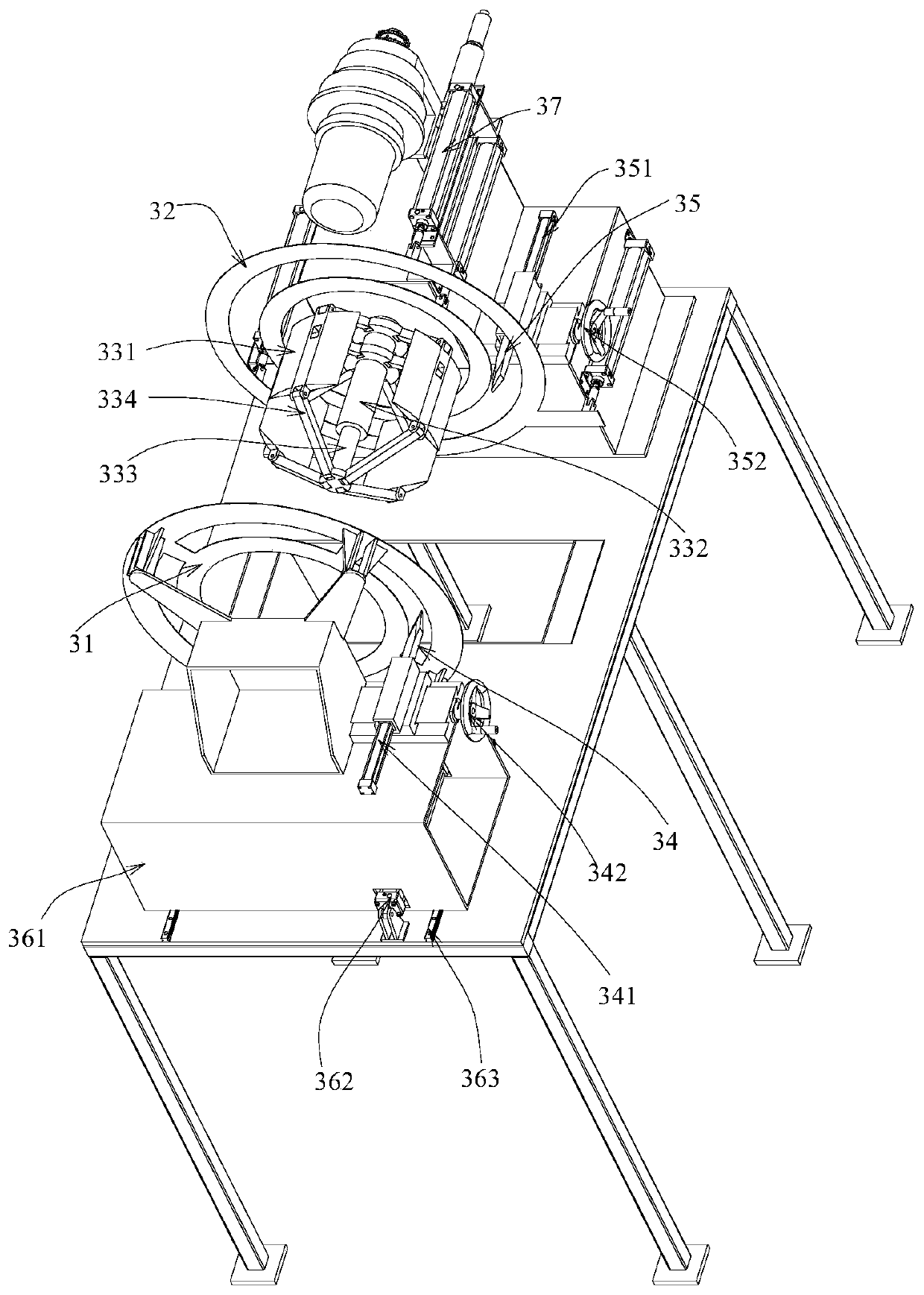

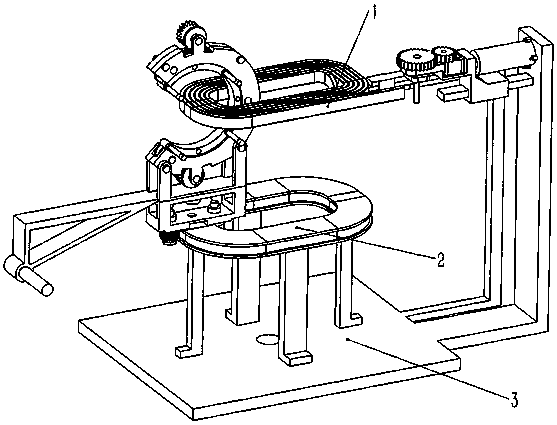

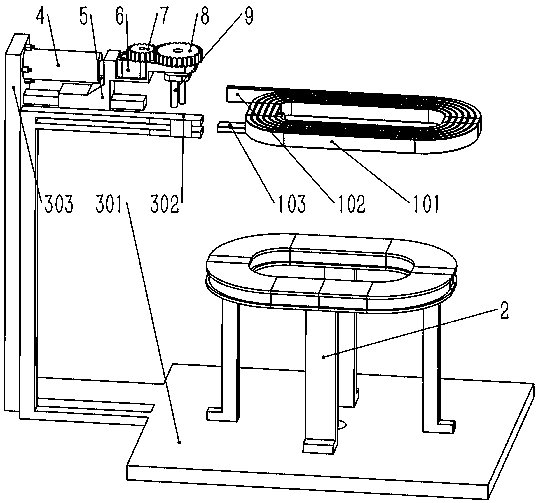

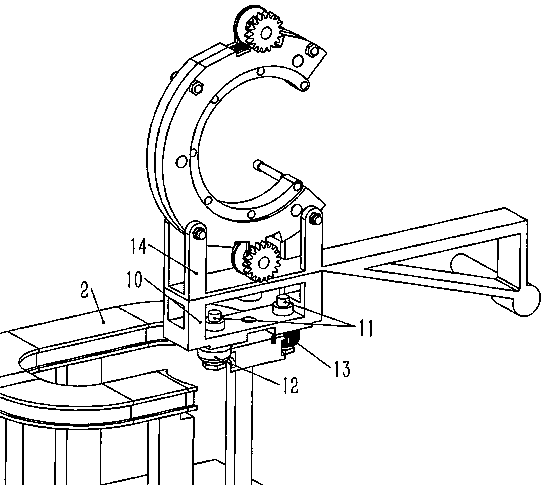

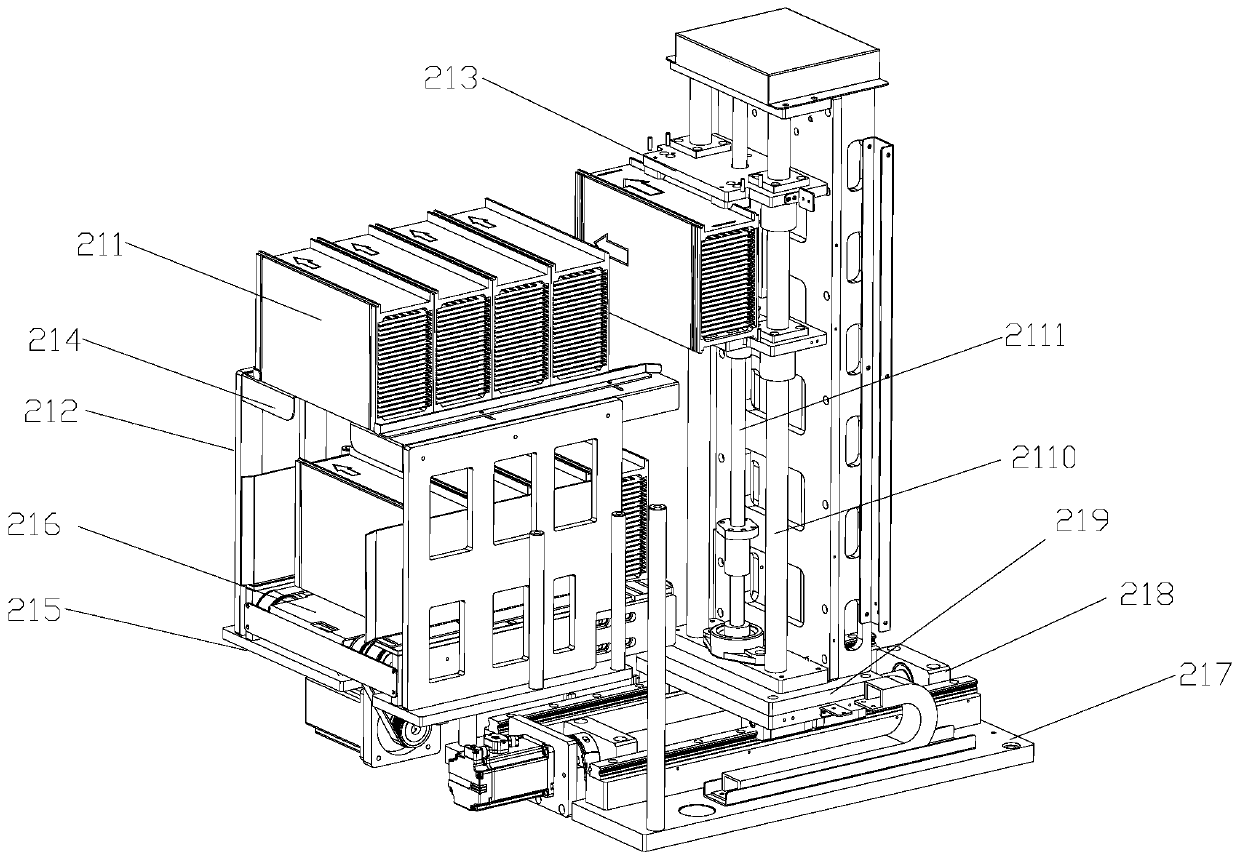

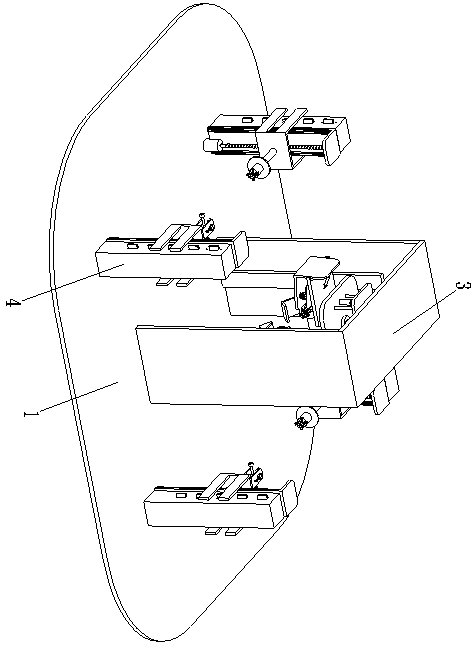

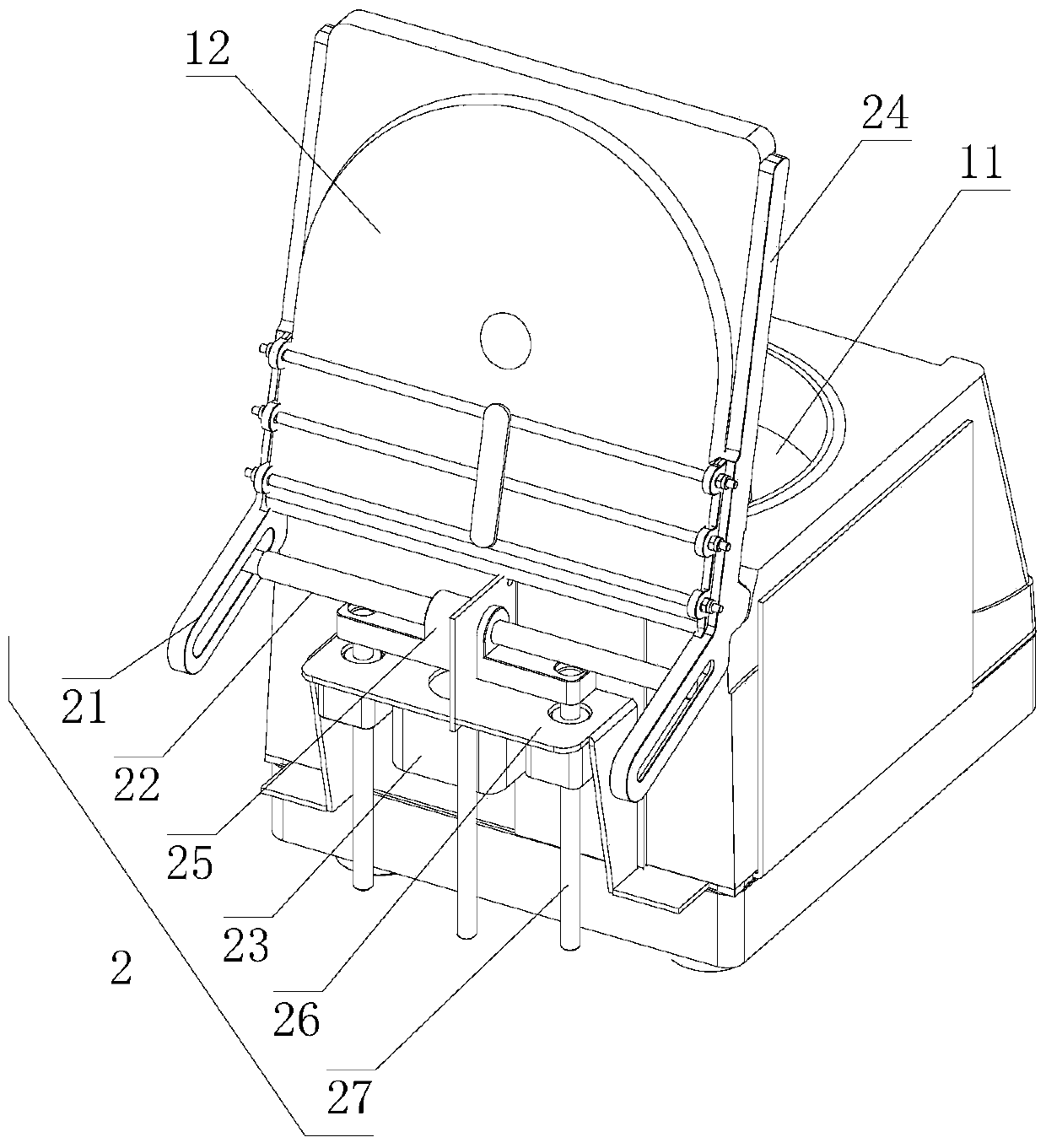

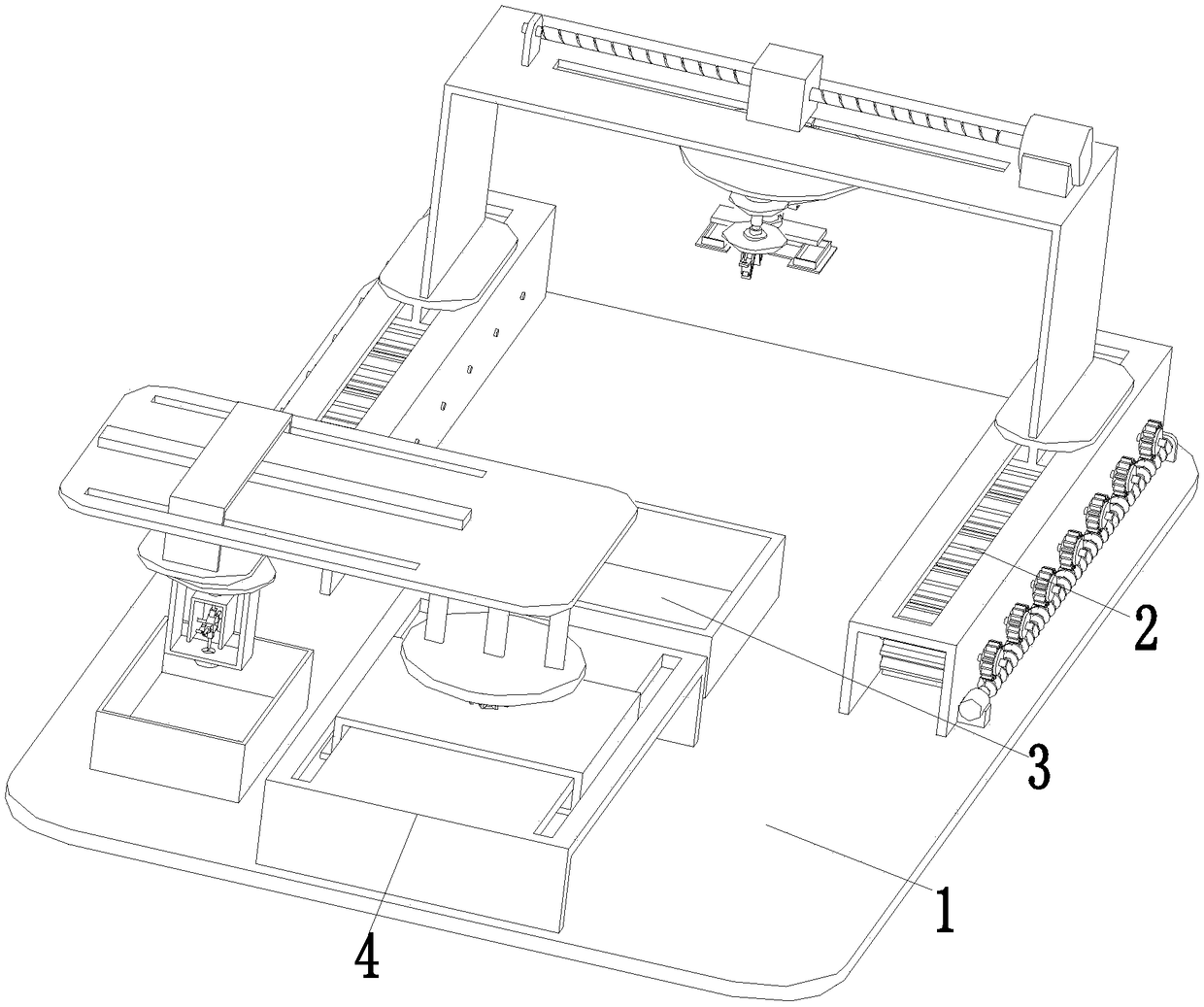

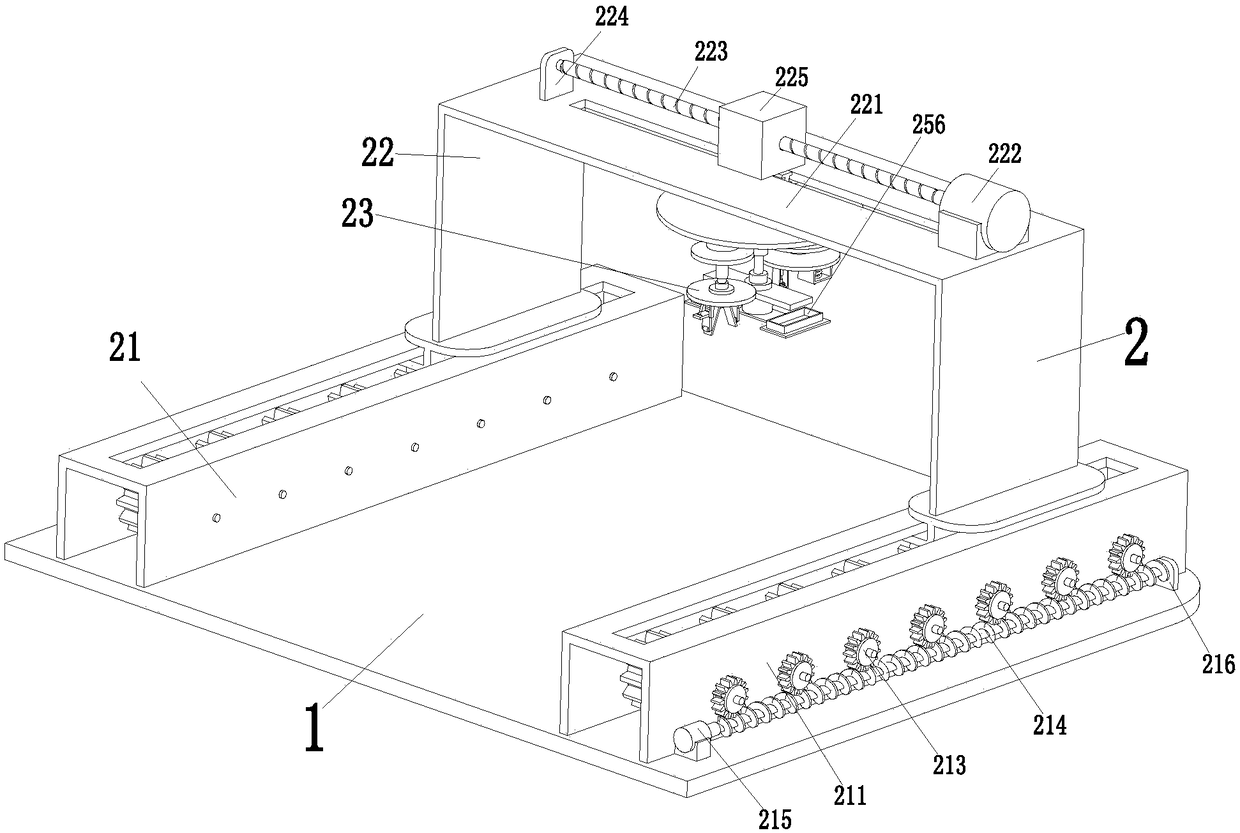

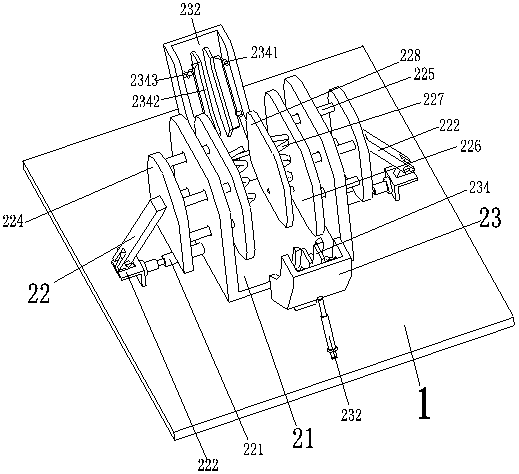

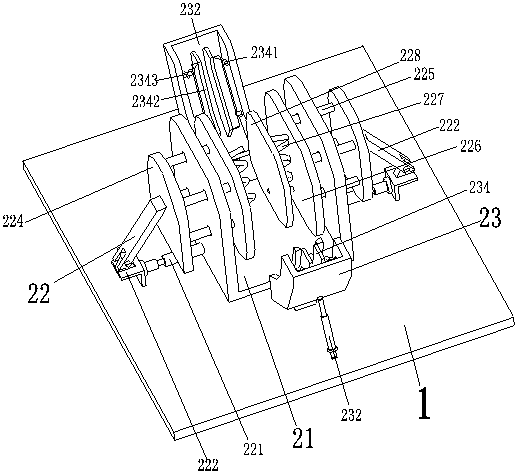

Automatic insulating cloth winding robot for rectangular coil of motor

InactiveCN108428548ARealization of winding operationAvoid pinch roll interference problemsCoils manufactureComputer moduleConductor Coil

The invention provides an automatic insulating cloth winding robot for a rectangular coil of a motor. The automatic insulating cloth winding robot includes a continuous winding module, a track profiling module and a clamping module. The automatic insulating cloth winding robot has the advantages that continuously automatically winding an insulating cloth around the rectangular coil, particularly for two particular electrodes extending out of the rectangular coil, the insulating cloth can be continuously automatically wound and efficient operation is achieved. The automatic insulating cloth winding robot is simple in structure; according to the features of the rectangular coil, single-point clamping is adopted, so that too much interference formed in the insulating cloth winding process isavoided. The designed profiling track is a rectangular track, and the insulating cloth winding process is directly suitable for a rectangular frame; and external feeding is adopted, to achieve continuous feeding of the insulating cloth. The automatic insulating cloth winding robot is simple in structure and reliable, the shape of the profiling track can be adjusted to adapt to various coil shapes,the winding efficiency is high, and the automatic insulating cloth winding robot can save cost and improve efficiency.

Owner:张美蓉

Tin dipping machine for processing wires

The invention discloses a tin dipping machine used for processing wires. The tin dipping machine comprises a rack, a wire straightener, a wire conveying mechanism, a cutter rest mechanism, a wire pulling mechanism, a tin furnace mechanism and an output mechanism; during work, a wire is fed in the wire straightener for being straightened; the wire is conveyed to the cutter rest to be cut off through the wire conveying mechanism, and wire stripping and twisting are realized through cooperation of the wire conveying mechanism; a wire stripping end is driven by a rotation mechanism to rotate to the tin furnace mechanism for tin dipping; then the wire is conveyed to a wire pulling clamping claw component; the tail end of the wire is cut off by the cutter rest mechanism; then wire stripping andtwisting are performed through cooperation of the pulling component; then the tail end of the wire is driven by a wire pulling and rotating mechanism to rotate to the tin furnace mechanism for tin dipping; and finally, the the wire subjected to tin dipping through the wire pulling mechanism is clamped and output to a finished product collection mechanism by the output mechanism, so that tin dipping operation is finished. No manual work is needed; the automation degree is high; the mechanism integrity is high; the structure is compact; the size is small; and double-head multi-wire tin dipping can be finished simultaneously, so that production efficiency is high.

Owner:赵维

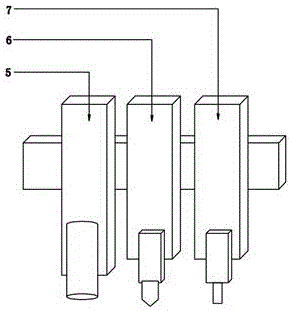

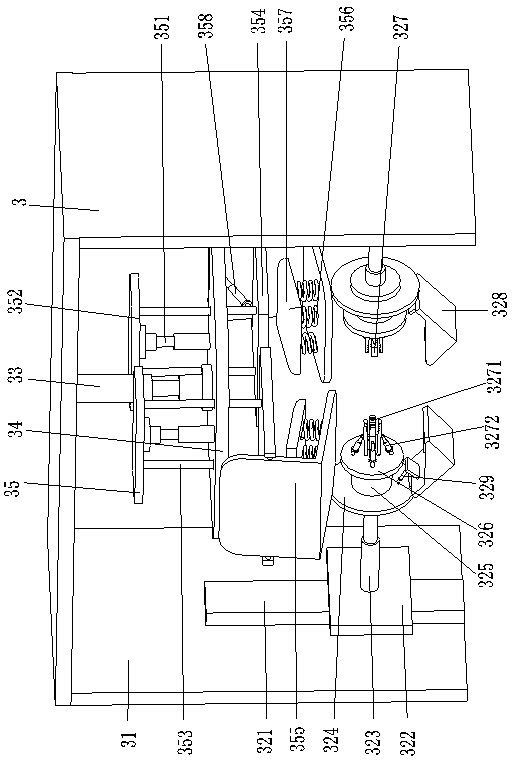

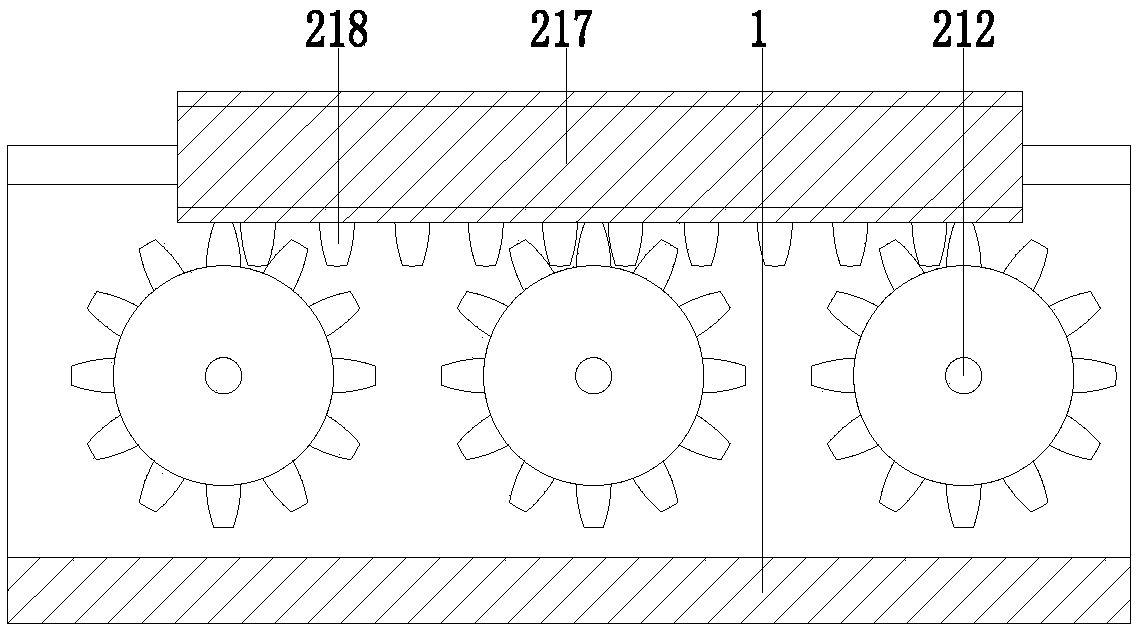

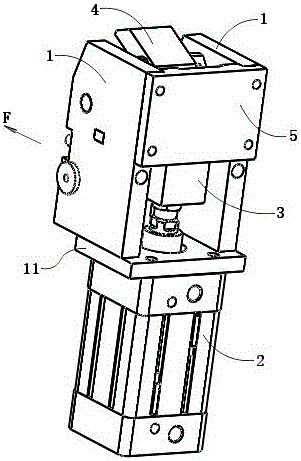

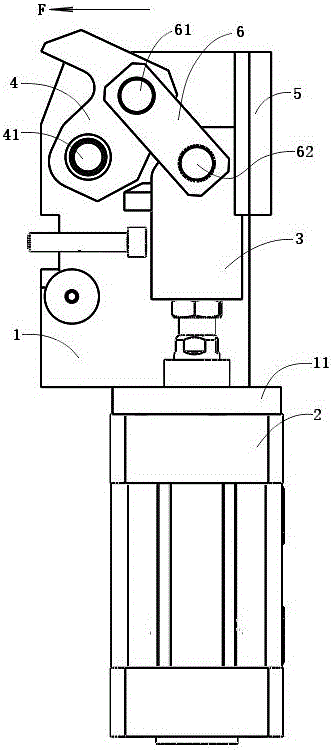

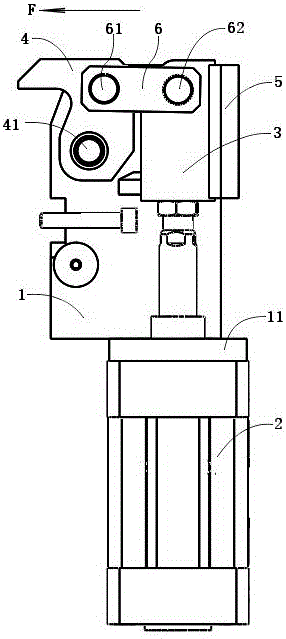

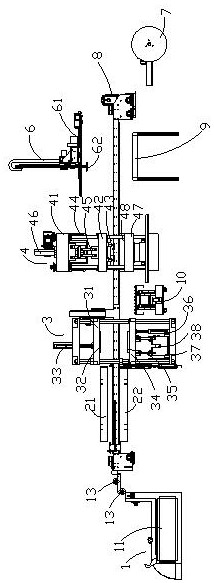

Branch knot removing and length measuring equipment for bamboo bone of folding fan

ActiveCN105150312ASimple processAdaptableMeasurement devicesCane mechanical workingEngineeringGroup operation

The invention discloses branch knot removing and length measuring equipment for a bamboo bone of a folding fan, and belongs to the field of mechanical automation equipment. The branch knot removing and length measuring equipment comprises branch knot removing equipment and bamboo material length primary selection equipment. By the adoption of the equipment, the branch knot removing operation at the ends of a bamboo material and the length grouping operation can be treated precisely. Through the equipment, the middle of the bamboo material can be clamped, and then branch knots at the two ends of the bamboo material are treated through bamboo material rotating operation of a reversing motor. The technology is simple, and processing reliability and precision are both excellent. According to the bamboo material length primary selection equipment, a plurality of length inductive probes are arranged on a rack, the inductive probes are arranged front and back into two parts, the front probes and the back probes are combined differently for use so that detection of different length distances can be conducted, and primary length selection can further be conducted on the bamboo material. A stepped selecting and material conveying device is used for conveying the bamboo material, and meanwhile the screening, removing and discharging processes of the bamboo material are completed through free rotating conveying belts and an ejector rod, so that the production process is simplified, and the automatic and efficient production needs can be better met.

Owner:泉州市光升信息科技有限公司

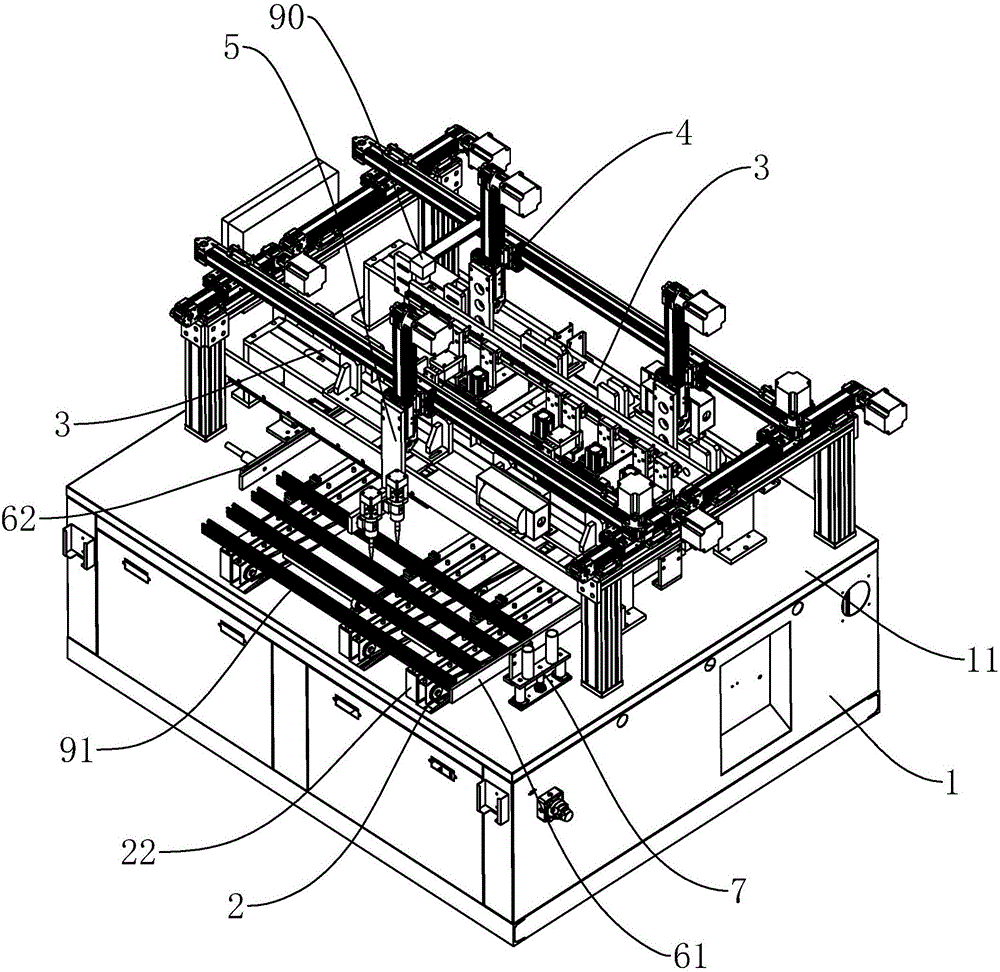

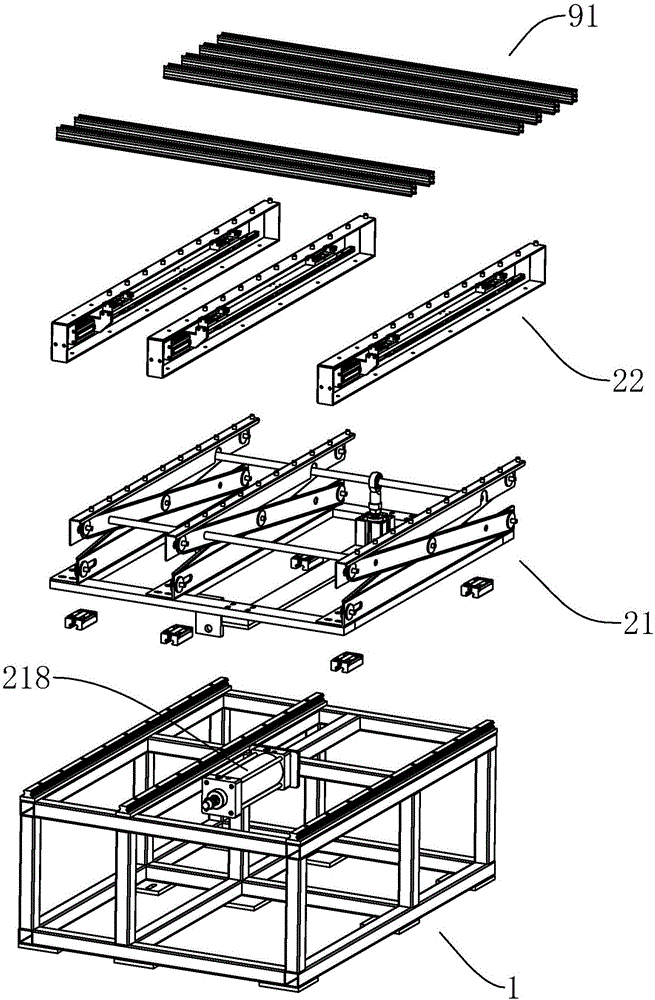

Chip mounting equipment based on mobile phone camera chip

PendingCN111223802ANo manual workImprove packaging efficiencySemiconductor/solid-state device manufacturingConveyor partsEmbedded systemElectrical and Electronics engineering

The invention discloses chip mounting equipment based on a mobile phone camera chip, which comprises a steel sheet carrier tape receiving and discharging circulating mechanism, a chip product carryingmechanism, a chip product feeding mechanism and a camera positioning detection mechanism, wherein the steel sheet carrier tape receiving and discharging circulating mechanism comprises a steel sheetcarrier tape discharging device, a steel sheet carrier tape receiving device, a steel sheet carrier tape pushing device and a steel sheet carrier tape conveying device; the chip product carrying mechanism comprises a suction device and a moving device; and the chip product feeding mechanism comprises a Tray, two Tray stacking devices which are correspondingly arranged front and back, and a Tray transfer device. The equipment is used for carrying out steel sheet carrier tape packaging on the mobile phone camera chip, a mobile phone camera chip product is placed on an insulating carrier tape ofa steel sheet and is protected through the insulating carrier tape, the whole equipment runs in a full-automatic mode, the packaging precision is high, and the working efficiency can be greatly improved.

Owner:苏州美仪自动化设备有限公司

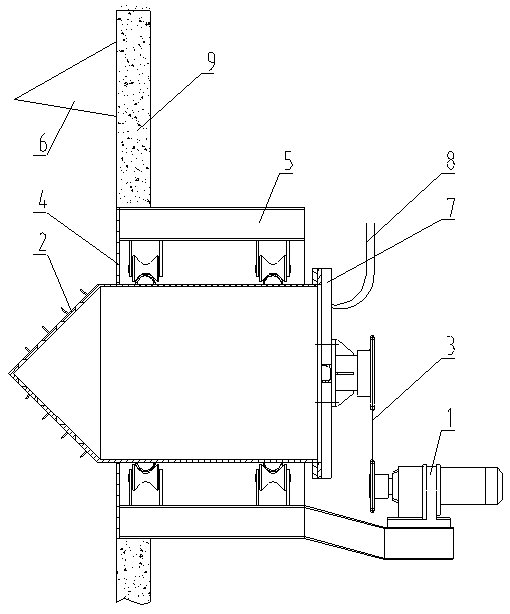

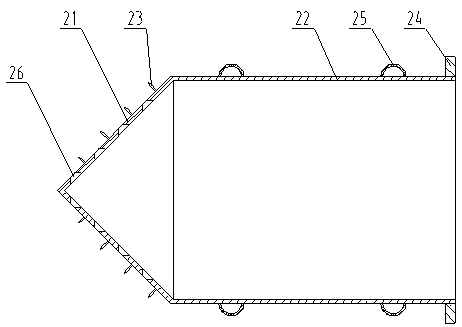

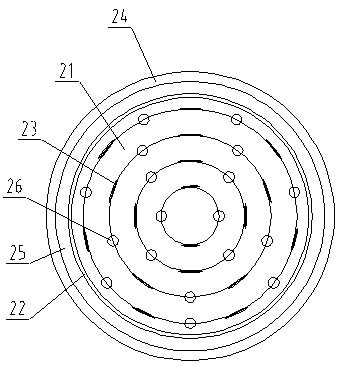

Rotary cylindrical garbage storage bin leachate guide device

PendingCN110732176AEnsure smooth flowReduce labor costsGrain treatmentsMoving filtering element filtersPhysicsStructural engineering

The invention discloses a rotary type cylindrical garbage storage bin leachate guide device which comprises a rotary transmission assembly, a rotary type guide cylinder assembly (2), a sealing baffle(4) and a base (5); the inner end of the base is installed on a bin wall (9) through a preformed hole and extends into a maintenance channel outside the bin; the rotary type guide cylinder assembly (2) comprises a garbage inrush disc (21), a rotary guide cylinder (22), blades (23) and a leachate hole (26); the garbage inrush disc is of a conical structure, is connected with the rotary guide cylinder in parallel and is located in the bin; a cutterhead and the leachate hole are formed in the garbage inrush disc, and the rotary guide cylinder rotates in the base through the rotary transmission assembly; and the sealing baffle seals and blocks a gap between the rotary guide cylinder and the base. The blades arranged on the conical garbage inrush disc can be driven by the rotation of the rotaryguide cylinder to poke up morphological garbage in the storage bin, movement of garbage in a local area is triggered, the arch breaking effect is achieved, and it is guaranteed that leachate flows smoothly.

Owner:上海市机电设计研究院有限公司

High-efficient detaching recycling equipment used for waste shared bicycle body parts

ActiveCN108544199AReduce labor intensityNo manual operationMetal working apparatusSingle vehicleEquipment use

Owner:泰州市海通资产管理有限公司

Tire ring splitting machine

PendingCN110126128ASeparation maneuver implementationNo manual workPlastic recyclingEngineeringMechanical engineering

The invention discloses a tire ring splitting machine. The tire ring splitting machine comprises a machine bod, a positioning mechanism and a ring splitting mechanism, wherein the ring splitting mechanism comprises a first fixing part, a second fixing part, a first cutting knife, a second cutting knife and an inner ring fixing assembly, the first fixing part and the second fixing part are arrangedat an interval, the first fixing part can move towards the position close to or away from the second fixing part in the axial direction of the first fixing part, the inner ring fixing assembly is connected in the second fixing part in a penetrating mode and is pivoted to the machine body, the inner ring fixing assembly is used for being inserted into the inner periphery of an inner ring of a tireand abutting against the inner periphery of the inner ring of the tire when the positioning mechanism moves to a ring splitting station, the first fixing part is used for fixing the tire on the innerring fixing assembly to move towards the position close to the second fixing part so as to enable the tire to be clamped between the first fixing part and the second fixing part, the first cutting knife is arranged on the machine body, and the second cutting knife is arranged on the machine body. According to the tire ring splitting machine, the inner ring and the outer ring of the tire can be separated.

Owner:GENOX RECYCLING TECH

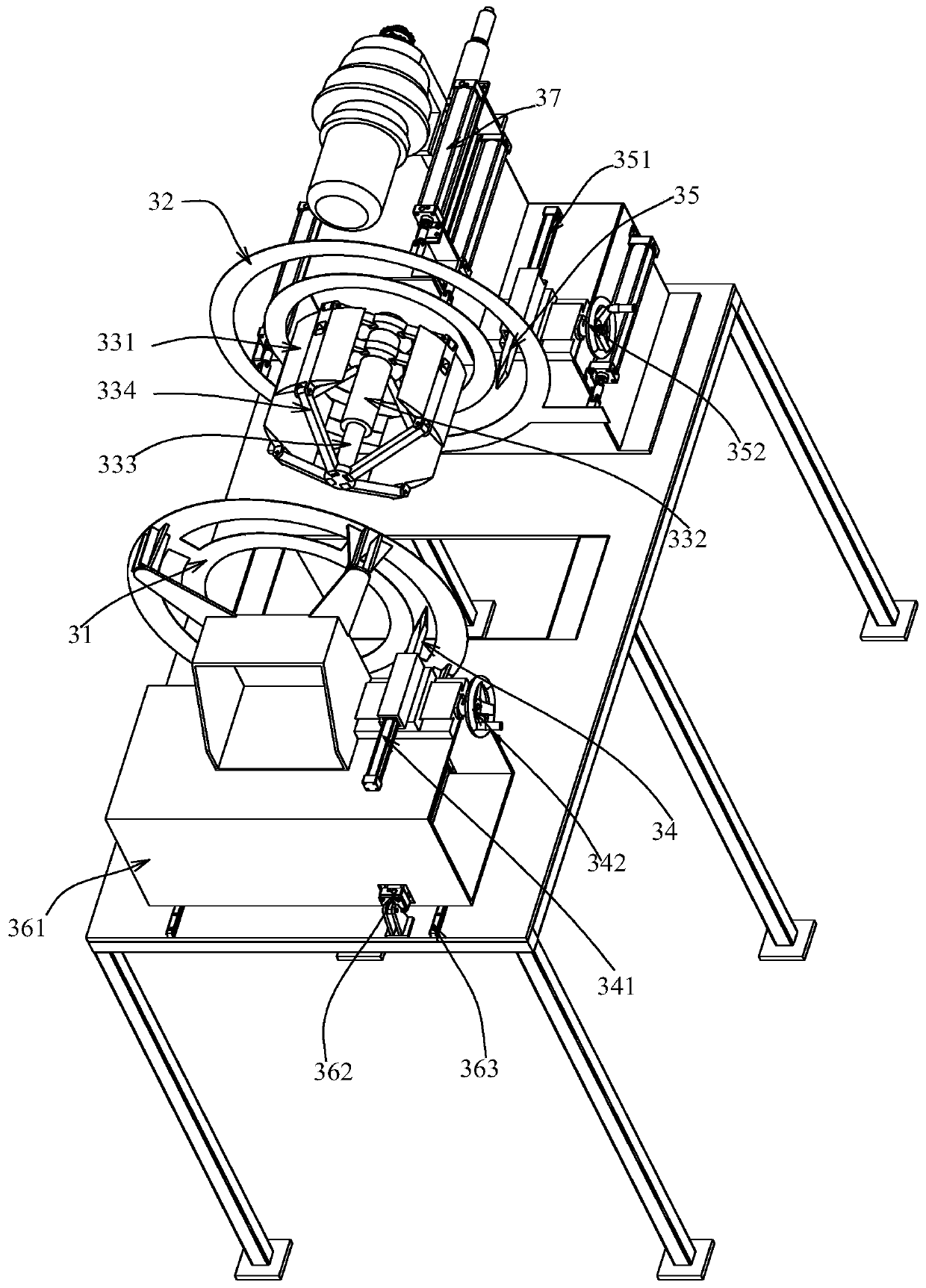

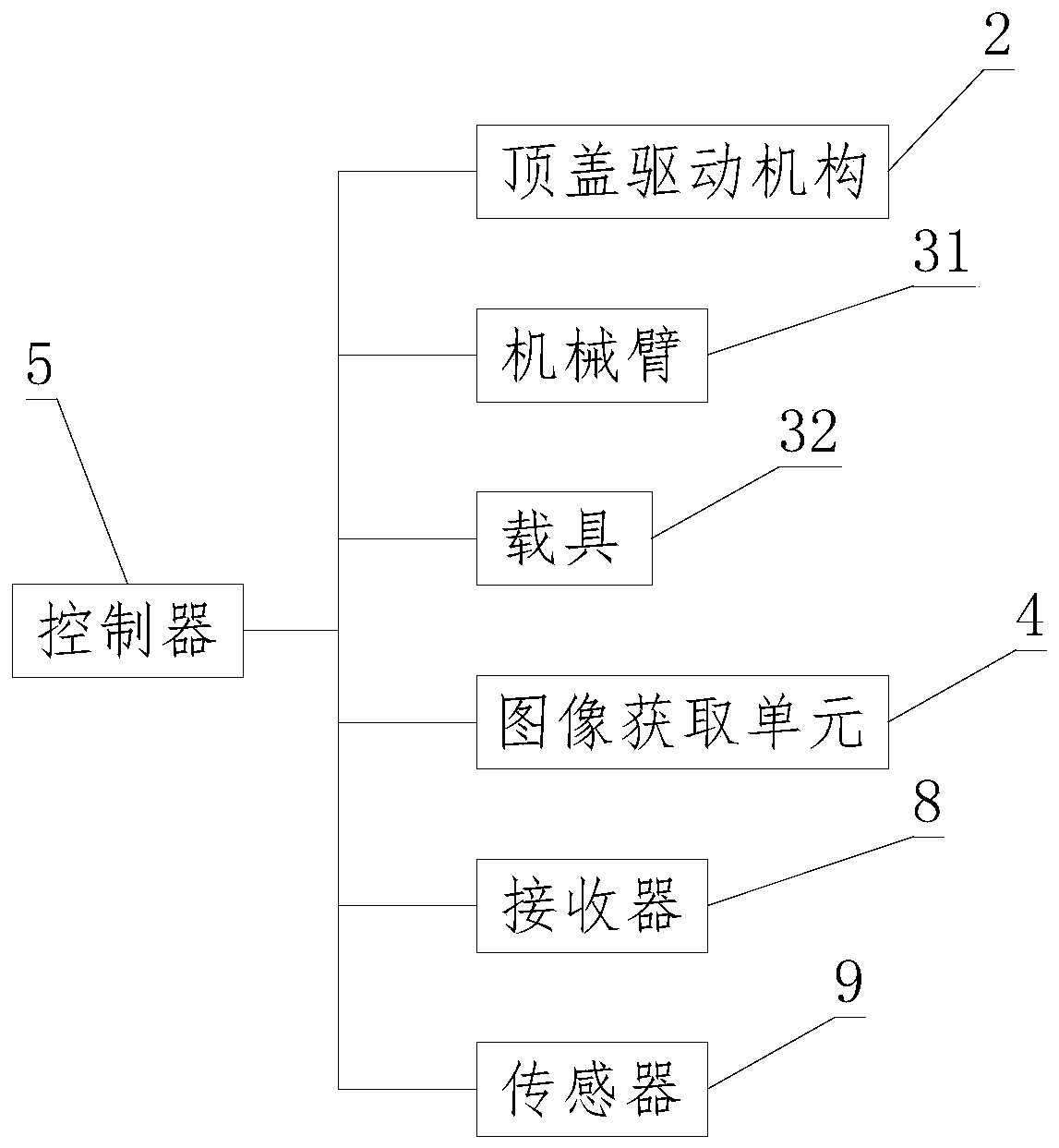

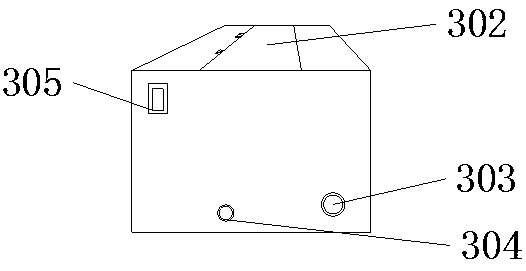

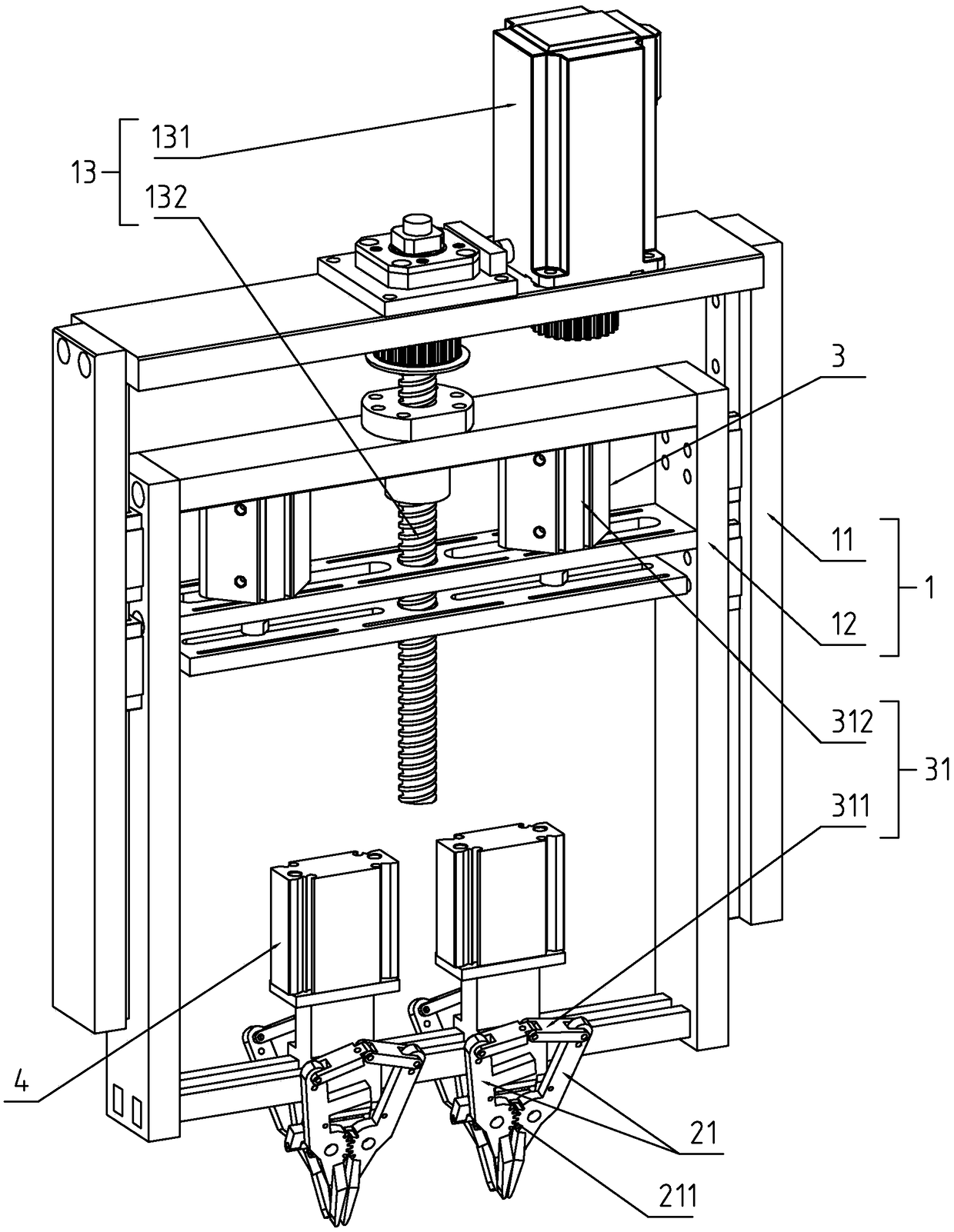

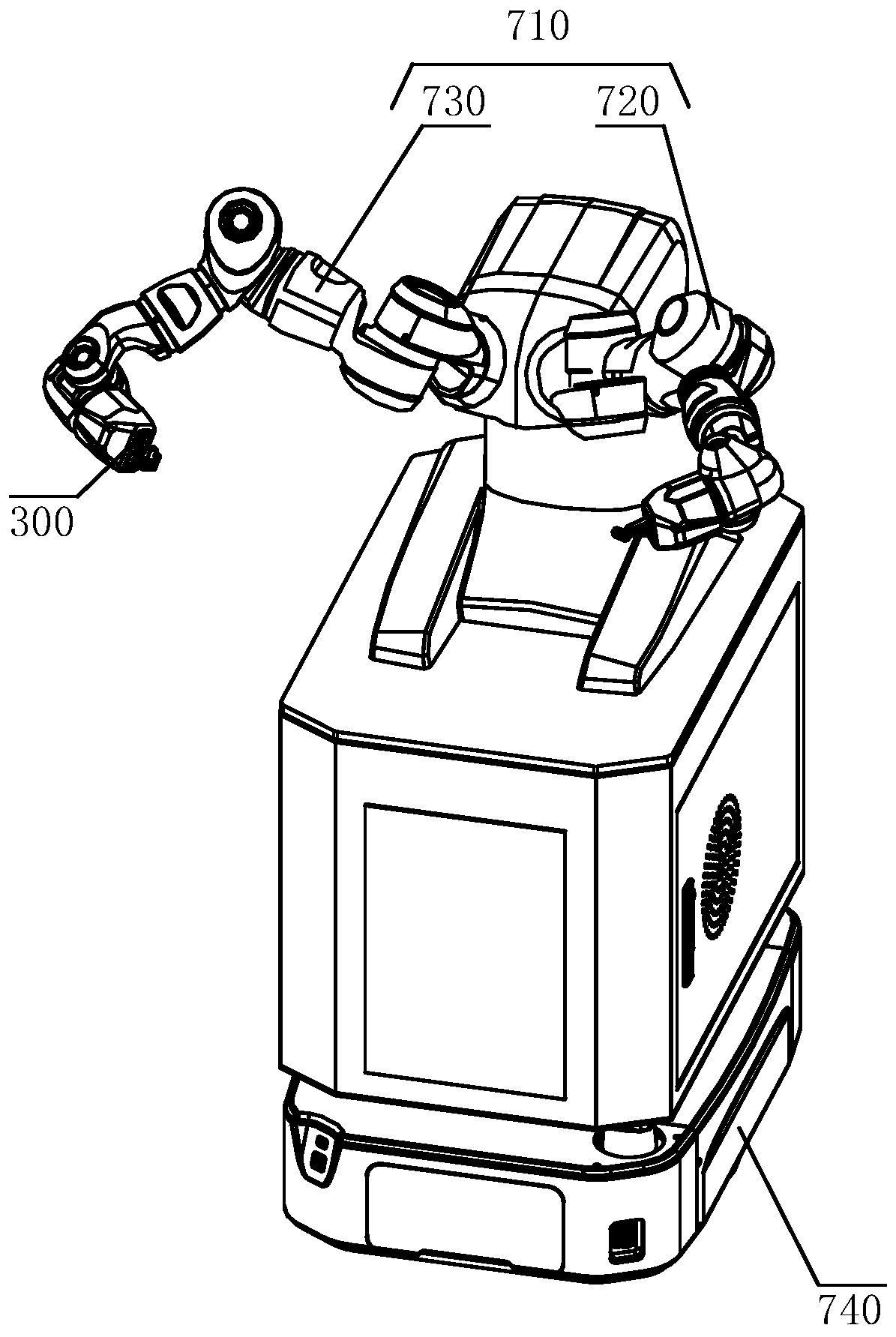

Reagent centrifugal system

InactiveCN110694804AImprove centrifugation efficiencyImprove system efficiencyCentrifugesControl engineeringControl cell

The invention relates to the technical field of centrifuges and discloses a reagent centrifugal system which comprises a centrifuge, a turnover unit, an image acquisition device and a control unit; the centrifuge is provided with a top cover capable of being opened and closed and a centrifugal portion provided with a plurality of placing grooves for centrifugal tubes; the turnover unit is used incooperation with the centrifuge and is provided with a mechanical arm capable of taking and placing the centrifugal tubes; the image acquisition device can obtain an image of the centrifugal portion in the centrifuge in a state that the top cover is opened; and the control unit is in communication connection with both the image acquisition device and the mechanical arm and can control the taking and placing action of the mechanical arm by analyzing a stop position of the centrifugal portion according to the image obtained by the image acquisition device. For the reagent centrifugal system, byarranging the image acquisition device and the turnover unit and using the control unit to control the actions of the two of the image acquisition device and the turnover unit, taking, placing and position transferring of a reagent in the reagent centrifugal system can be automatically and mechanizedly achieved without manual operation, the taking, placing and position transferring efficiency of the reagent are greatly improved, and thus the centrifugal efficiency of the reagent centrifugal system is correspondingly improved.

Owner:上海宏滩生物科技有限公司

Efficient full-automatic screw locking machine

InactiveCN107775329ANo manual workGuaranteed cleanlinessMetal working apparatusEngineeringMulti axis

The invention discloses a high-efficiency full-automatic screw locking machine, comprising a high-efficiency full-automatic screw locking machine, including a machine base, the upper surface of the machine base is provided with a fixed table for placing articles, and the fixed table for placing articles and the upper surface of the machine base The connection is fixed by screws, the left and right sides of the machine base are provided with support columns, and the support columns are fixedly installed on the left and right sides of the machine base. This kind of automatic locking screw machine adopts a multi-axis automatic locking screw machine. Through the connection port of the computer host computer, different working procedures can be set by connecting to the computer according to the different products, and the electric screwdriver can be controlled to automatically complete the locking of the screw. The manual work is completely done by the machine, and without manual work, it can avoid personnel contacting the product to ensure the cleanliness of the product. This kind of automatic screw locking machine can automatically feed the material through the screw arrangement machine, and it only needs to set the program through the computer. Can.

Owner:陈钦楠

Non-woven fabric powder cover composite machining equipment

The invention discloses non-woven fabric powder cover composite machining equipment. A machine table, an ultrasonic compound machine, a C-shaped material moving plate, a moving positioning base, a non-woven fabric transferring device, an inner ring feeding device and a plastic support feeding device are included. The ultrasonic compound machine is arranged on the machine table. A fusion welding head of the ultrasonic compound machine is vertically downwards arranged. The C-shaped material moving plate is arranged below the fusion welding head and provided with a circular hole. The corresponding position of the circular hole is provided with the moving positioning base. The machine table is provided with a second air cylinder. The second air cylinder is connected with the moving positioningbase. The non-woven fabric transferring device makes non-woven fabrics horizontally pass through the middle of the C-shaped material moving plate. The inner ring feeding device places an inner ring to the moving positioning base. The plastic support feeding device places a plastic support to the moving positioning base. By means of the non-woven fabric powder cover composite machining equipment,automatic powder cover producing and assembling can be achieved, the production cost is low, efficiency is high, the product quality stability is good, the yield is high, meanwhile, glue does not needto be used, and environment friendliness is good.

Owner:比优特(苏州)塑胶科技有限公司

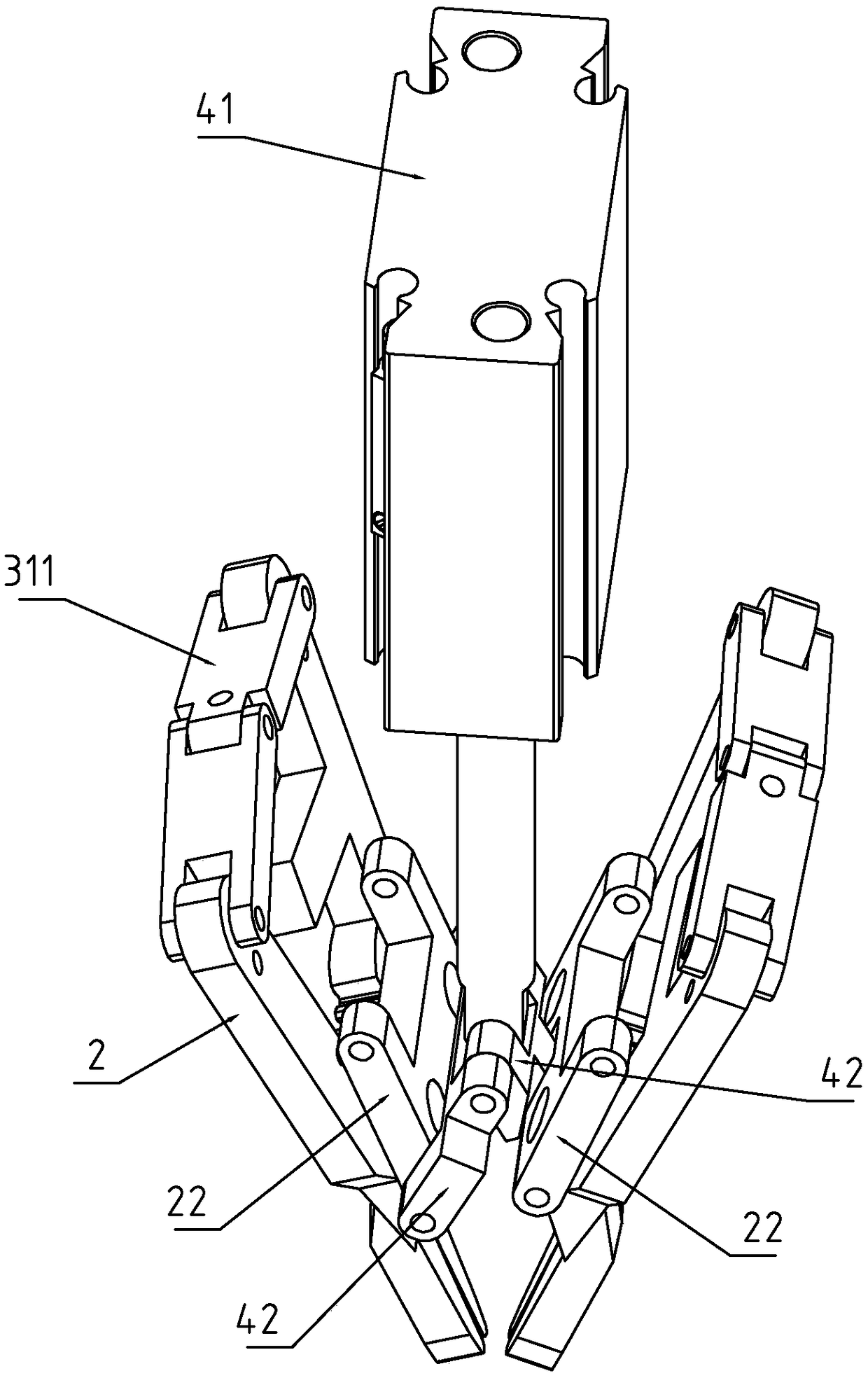

Lead acid storage battery electrolyte injection device capable of realizing automatic dismounting of gas discharge plug

InactiveCN108110206AReduce labor intensityEasy to operateFinal product manufactureCell component detailsGas-discharge lampHuman use

The invention relates to a lead acid storage battery electrolyte injection device capable of realizing automatic dismounting of a gas discharge plug. The lead acid storage battery electrolyte injection device comprises a bottom plate; the front end of the bottom plate is provided with a dismounting device; a battery placing frame is arranged at the middle part of the bottom plate; the rear end ofthe bottom plate is provided with an injection device; the dismounting device comprises two dismounting moving mechanisms arranged on the bottom plate; the dismounting moving mechanism are symmetrically arranged on the two sides of the bottom plate; the upper end of each dismounting moving mechanism is provided with a dismounting adjusting mechanism; the lower end of each dismounting adjusting mechanism is provided with a dismounting performing mechanism. The lead acid storage battery electrolyte injection device is capable of solving problems in the prior art that in artificial injection ofbattery electrolyte process, the battery gas discharge plug should be unscrewed by manual operation, an air-vent should be penetrated, a seal washer should be removed, electrolyte injection should becompleted by human using tools, artificial unscrewing of the gas discharge plug is low in efficiency, electrolyte left in batteries can be easily splashed in manual operation process, and artificial injection of electrolyte is not accurate.

Owner:刘秀娟

Traditional Chinese medicine seed sprouting cultivation equipment special for treating hospital neurological diseases

InactiveCN108174650ARealize the function of automatic cultivation managementReduce labor intensitySelf-acting watering devicesGerminating apparatusDiseaseGourd

The invention relates to traditional Chinese medicine seed sprouting cultivation equipment special for treating hospital neurological diseases. The traditional Chinese medicine seed sprouting cultivation equipment special for treating hospital neurological diseases comprises a bottom plate; a cultivation frame is placed on the bottom plate; the cultivation frame can cultivate seeds; a moving transformation device is arranged on the cultivation frame; a water whisking device is arranged at the upper end of the moving transformation device; a clamping and storage device is arranged at the lowerend of the moving transformation device; the moving transformation device comprises two moving mechanisms arranged on the cultivation frame; and a transformation rotating roller is arranged between the two moving mechanism through a bearing. The problems that in the process of cultivating traditional Chinese medicine calabash seeds through the existing manual management, the cultivated calabash seeds needs to be subjected to waster whisking operation manually, the germinated calabash seeds need to be selected manually, the water whisking quantity cannot be controlled accurately by manual waterwhisking operation, seeds cannot grow normally caused by water whisking quantity unbalance, the germinated seeds are manually selected inaccurately, the seeds are liable to omit, and the germinated seeds are manually clamped not in time are solved.

Owner:洪娇娇

Auxiliary device for cooperating rope threading of carrier bag rope threading machine

PendingCN109263146AMake sure to go throughInhibit sheddingBag making operationsPaper-makingEngineeringManipulator

The invention discloses an auxiliary device for cooperating rope threading of a carrier bag rope threading machine. The auxiliary device is characterized by comprising a rope pulling manipulator located on the side, away from rope threading equipment, a rope pulling driving assembly used for adjusting the clamping or opening states of the rope pulling manipulator and a rope pulling pulling assembly used for driving the rope pulling manipulator which holds a rope body to move, the rope pulling manipulator comprises two rope pulling clamping claws of which the middles are hinged, the rope pulling pulling assembly comprises a rope pulling fixing frame, a rope pulling sliding frame which is slidably connected with the rope pulling fixing frame and a rope pulling frame driving assembly which isused for driving the rope pulling sliding frame to slide on the rope pulling fixing frame, the sliding direction of the rope pulling sliding frame on the rope pulling fixing frame is the direction close to or away from a bag body, and the rope pulling manipulator is arranged on the rope pulling sliding frame. By means of the auxiliary device, the defects of the need of manual inspection and the failure of performing in-position rope head threading can be overcome.

Owner:温州临界科技有限公司

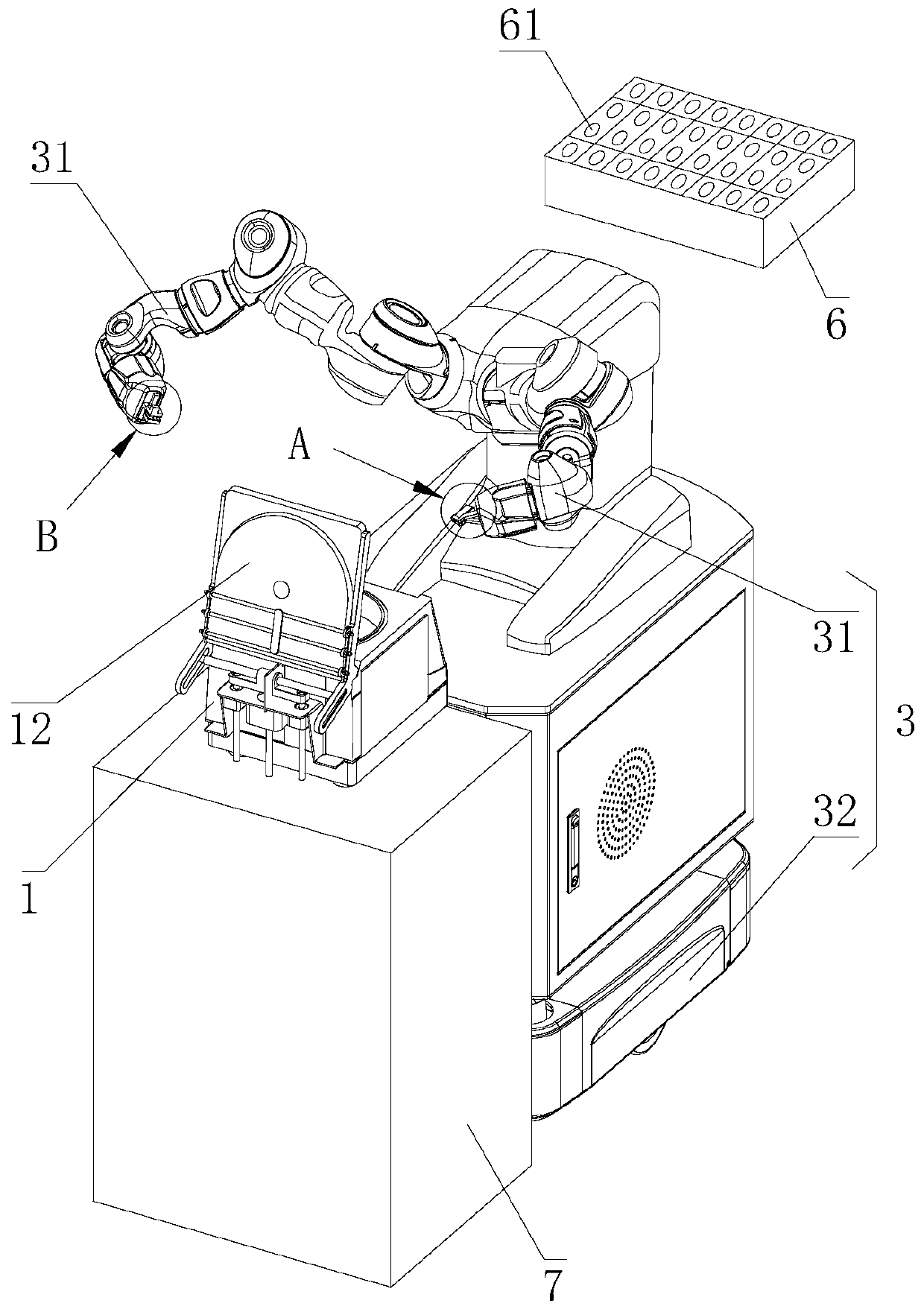

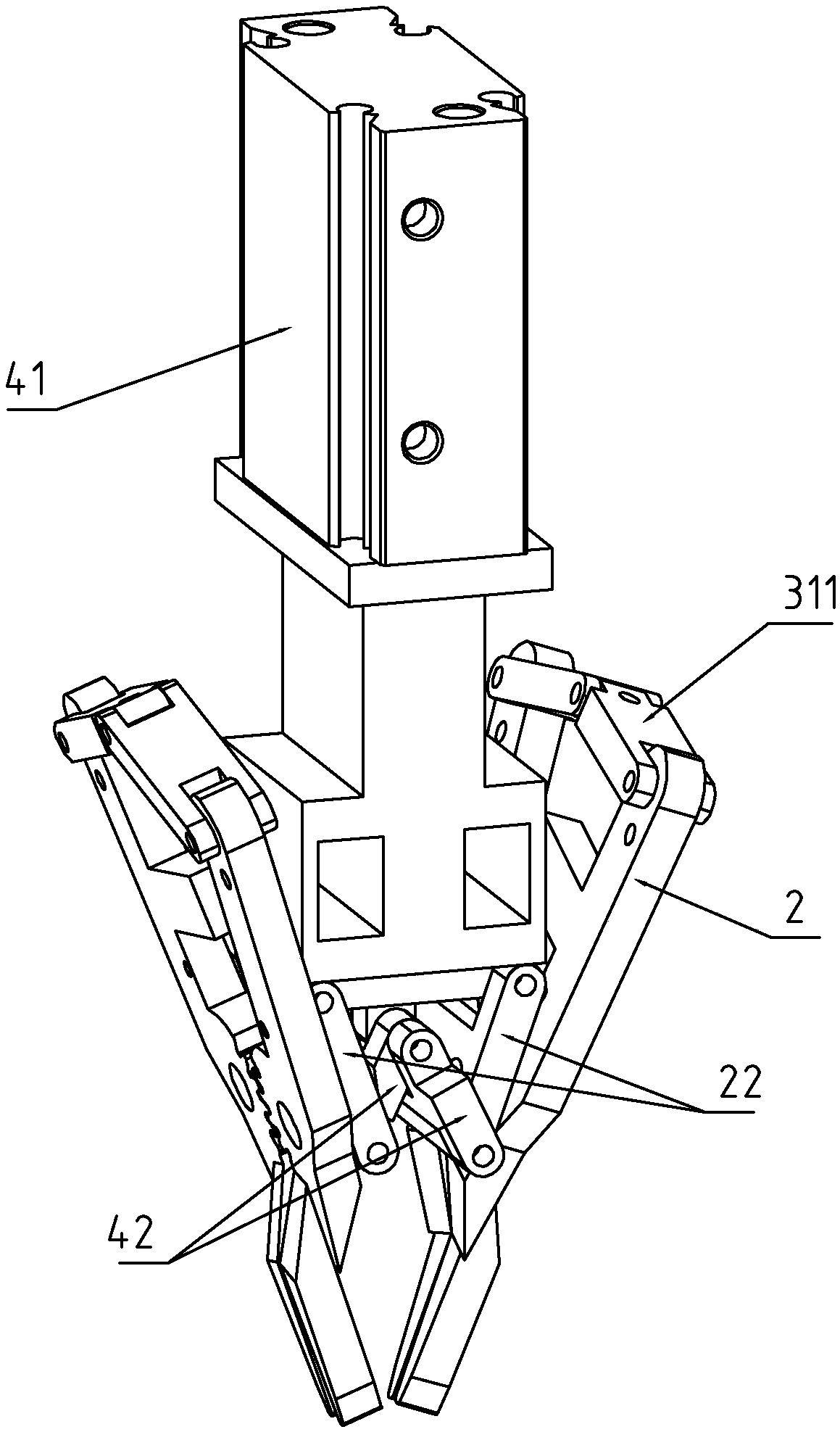

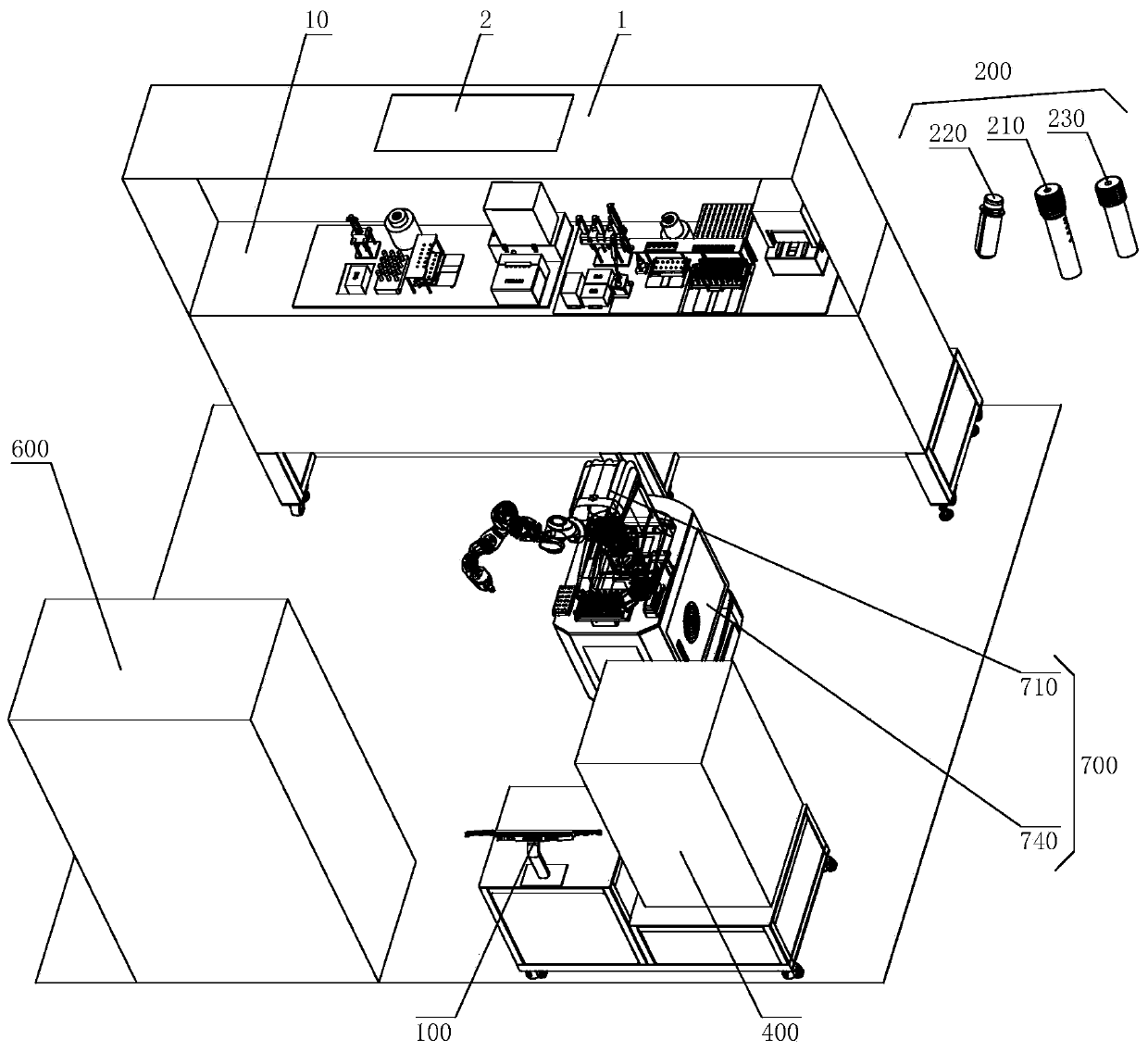

Gene detection system

PendingCN111575172ASave human resourcesReduce testing costsBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyHazardous substance

The invention relates to the technical field of gene detection, and discloses a gene detection system. The gene detection system comprises a control unit, a reagent consumable unit, a label identification unit, a constant-temperature storage unit, a cabinet body, an efficient filtering unit, a gene detection device and a turnover unit; the cabinet body is provided with an air inlet and an air outlet, wherein an operating table for placing operating instruments is arranged in the cabinet body; and the air outlet of the cabinet body is filled with the efficient filtering unit. According to the gene detection system, a pipetting assembly and other devices are integrated on the operation table in the cabinet body, the steps of liquid moving and taking and the like are carried out on the operation table, and harmful substances generated in the experiment process are filtered out through the efficient filtering unit, so that reagents can be prevented from being polluted by pollutants in theenvironment, and pollution of reagents related to biological hazards to the environment can also be avoided.

Owner:上海宏滩生物科技有限公司

Cleaning method on basis of high-rise glass cleaning devices

ActiveCN106073616ASimple structureEasy to useCarpet cleanersFloor cleanersPressure sensorArchitectural engineering

The invention discloses a cleaning method on the basis of high-rise glass cleaning devices. The high-rise glass cleaning devices comprise cleaning fluid spraying modules, first transverse telescopic rods, second transverse telescopic rods, first longitudinal telescopic rods, second longitudinal telescopic rods, brushes, first pressure sensors, second pressure sensors and control modules. The first longitudinal telescopic rods and the second longitudinal telescopic rods are parallel to glass, one end of each of the first longitudinal telescopic rods and the second longitudinal telescopic rods is fixed onto a wall, and the other ends of the first longitudinal telescopic rods and the second longitudinal telescopic rods are fixedly connected with one ends of the first transverse telescopic rods and the second transverse telescopic rods; the other ends of the first transverse telescopic rods and the second transverse telescopic rods are respectively fixedly connected with the brushes by the first pressure sensors and the second pressure sensors; brush surfaces of the brushes face the glass. Cleaning fluid is sprayed to the glass by the cleaning fluid spraying modules when the high-rise glass cleaning devices work, the brushes can cling to the glass by the aid of the first transverse telescopic rods and the second transverse telescopic rods, and the first longitudinal telescopic rods and the second longitudinal telescopic rods are responsible for brushing the glass. The cleaning method has the advantages that the high-rise glass cleaning devices are simple in structure and convenient to use; manual operation can be omitted, the glass can be automatically cleaned, and accordingly the safety of staffs can be guaranteed.

Owner:HAIMEN DADE INTPROP SERVICE CO LTD

Tool for intelligently pulling out saddle of waste shared bicycle

ActiveCN108527238AImprove stabilitySmooth recyclingMetal-working hand toolsVehicle frameSingle vehicle

The invention relates to a tool for intelligently pulling out a saddle of a waste shared bicycle. The tool comprises a bottom plate; two wheel locking devices are installed on the bottom plate and aresymmetrically arranged on the front side and the back side of the bottom plate respectively; a saddle dismantling device is installed at the middle part of the bottom plate; the bottom plate is provided with a bicycle frame positioning device; the bicycle frame positioning device is arranged below the saddle dismantling device; and the saddle dismantling device comprises a dismantling fixing frame installed on the bottom plate. The tool provided by the invention can solves the problems that in the existing bicycle body part recovery process of the waste shared bicycle, a bicycle body needs tobe manually fixed, nuts of fixed wheels and the saddle need to be manually dismantled, fixing of the bicycle body with help of the tool by a person is infirm, and the labor intensity of manually dismantling the fixing nuts is large; and the saddle needs to be manually pulled out from the bicycle body, so that the labor intensity of pulling out the saddle manually is larger, a force of pulling outthe saddle manually is uneven in control, a body is easily strained, safety hidden dangers exist and the like.

Owner:平邑现代中药产业园有限公司

Perforating device for handbag stringing machine

PendingCN109353075AEffective movementReduce manufacturing costBag making operationsPaper-makingEngineeringManipulator

The invention discloses a perforating device for a handbag stringing machine. According to the technical scheme, the perforating device is characterized in that the perforating device comprises a rack, a bag moving mechanical arm, movement equipment and perforating equipment; the bag moving mechanical arm comprises a bag moving mounting rack, a bag moving fixed clamp claw, a bag moving movable clamp jaw and a bag moving clamping assembly; the perforating equipment comprises perforating through holes, perforating knives, perforating drive equipment and perforating seats; a bag containing gap isarranged on each perforating seat; the perforating knives are connected to one sides of the width of the bag containing gaps in a sliding manner; the perforating through holes are located in the other sides of the width of the bag containing gaps on the perforating seats; the perforating drive equipment comprises perforating drive rods and a perforating driver; the sliding direction, on the perforating seats, of the perforating drive rods and the sliding direction, on the perforating seats, of the perforating knives are arranged in a cross manner; and perforating drive bevels are arranged onthe end faces, facing the perforating knives, of the perforating drive rods and / or the end faces, facing the perforating drive rods, of the perforating knives. The perforating device is small in sizeand can cooperate with the mechanical arm to perforating work.

Owner:温州临界科技有限公司

Mold overturning and locking mechanism

The invention discloses a mold overturning and locking mechanism which comprises two side edge installing plates, an air cylinder, a traction block, a locking block, a back supporting plate and a connecting rod. The two side edge installing plates are vertically installed on a bottom plate in parallel. The back supporting plate is installed on the two side edge installing plates and located on the back portion. The locking block is composed of a transverse part and a vertical part and shaped like the Arabic numeral 7. The transverse part of the locking block is located at the top end of the vertical part of the locking block and faces the front portion of the whole mechanism. The bottom of the vertical part of the locking block is erected between the two side edge installing plates through a swing shaft. A first movable shaft is arranged at the junction of the transverse part of the locking block and the vertical part of the locking block. The traction block is located between the locking block and the back supporting plate and attached to the back supporting plate. The air cylinder is installed below the bottom plate. A piston rod of the air cylinder penetrates through the bottom plate and then is connected with the bottom of the traction block. A second movable shaft is arranged on the traction block. The two ends of the connecting rod are connected with the locking block and the traction block through the first movable shaft and the second movable shaft correspondingly.

Owner:ANHUI KINGPOWER EQUIP & MOLD MFR

Food box forming all-in-one machine

PendingCN112721298ASave manpower, material resources and timeIncrease productivityBox making operationsPaper-makingProcess engineeringMaterial resources

The invention discloses a food box forming all-in-one machine which comprises a feeding mechanism used for feeding sheets to a next station; a heating mechanism used for heating the sheets conveyed by the feeding mechanism; a forming mechanism used for forming the shapes of products through a plastic uptake forming method; a cutting mechanism used for cutting off the formed products from the sheets; a discharging mechanism used for carrying the cut products to a conveyor; a waste rolling mechanism used for automatically collecting sheet waste; and a material pulling mechanism used for enabling the sheets to sequentially pass through all the stations from the feeding station to the waste material rolling station. The food box forming all-in-one machine provided by the invention comprises a plurality of integrated mechanisms, so that continuous operation can be achieved, final products can be produced, manpower, material resources and time are saved, the production efficiency is improved, and the production cost is reduced; and in addition, manual operation is not needed, and safety and sanitation are achieved.

Owner:昆山中德利机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com