Tire automatic treatment equipment

An automatic processing and tire technology, applied in recycling technology, plastic recycling, etc., can solve problems such as dependence on labor, low efficiency, and high work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

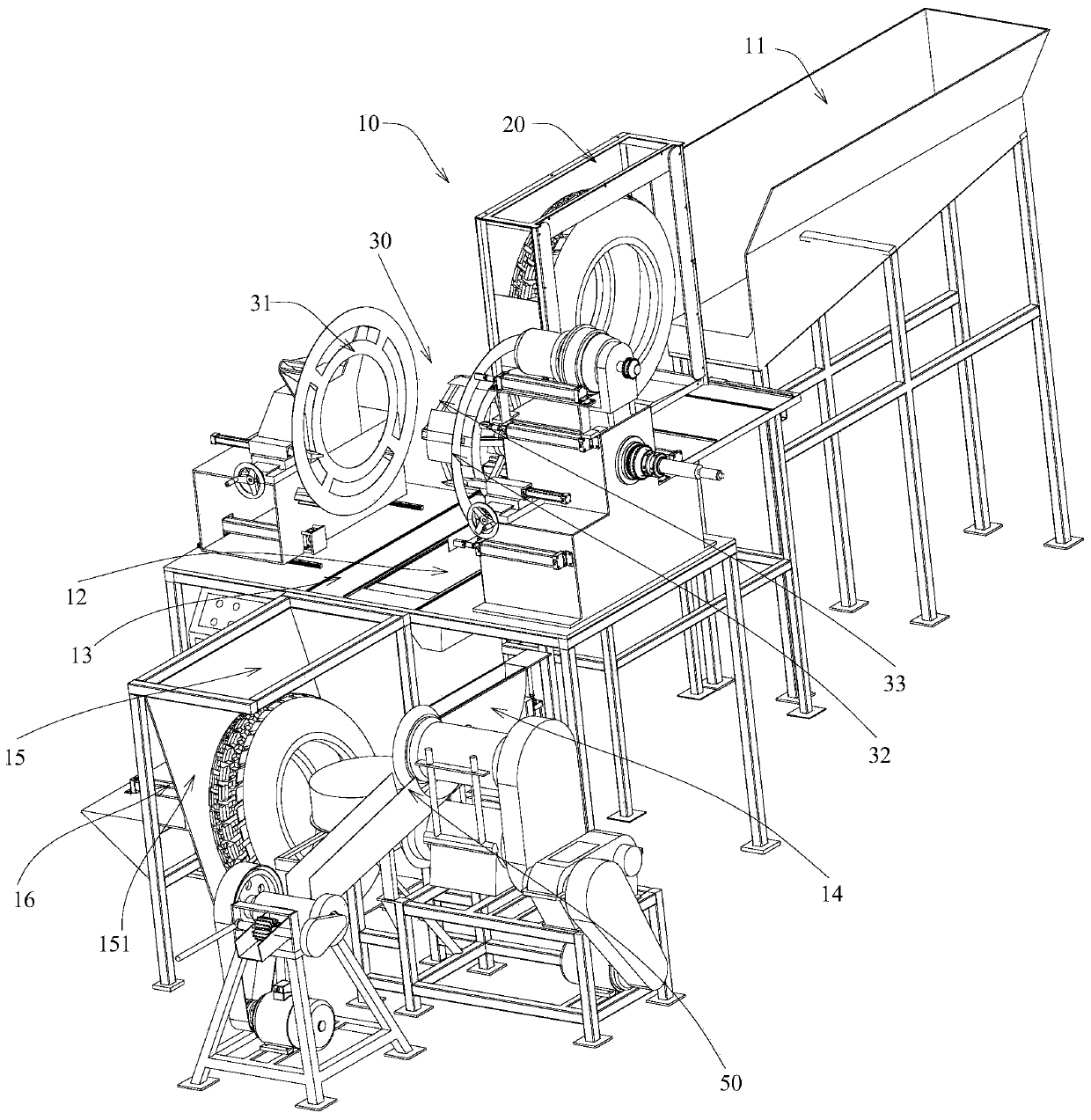

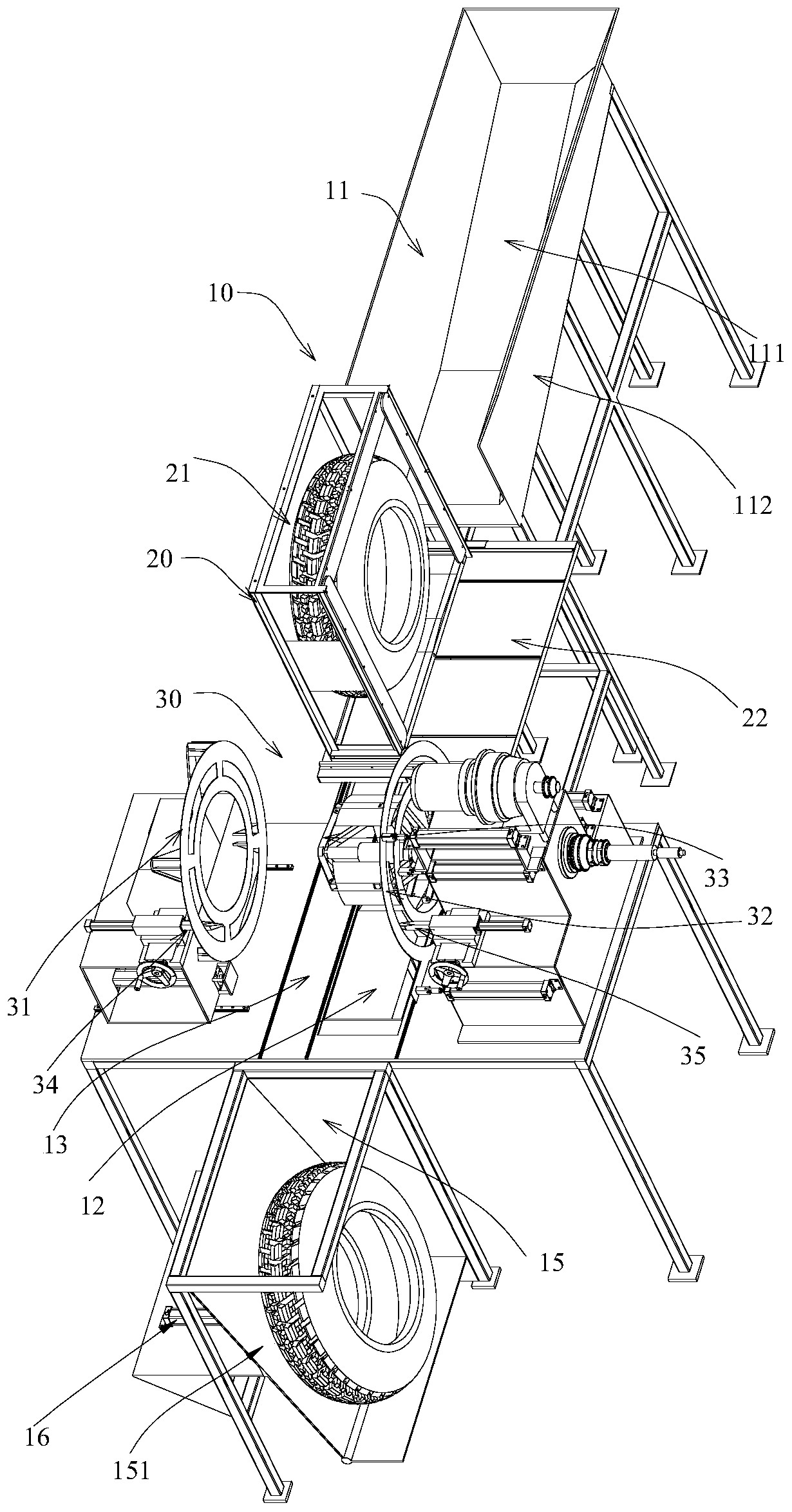

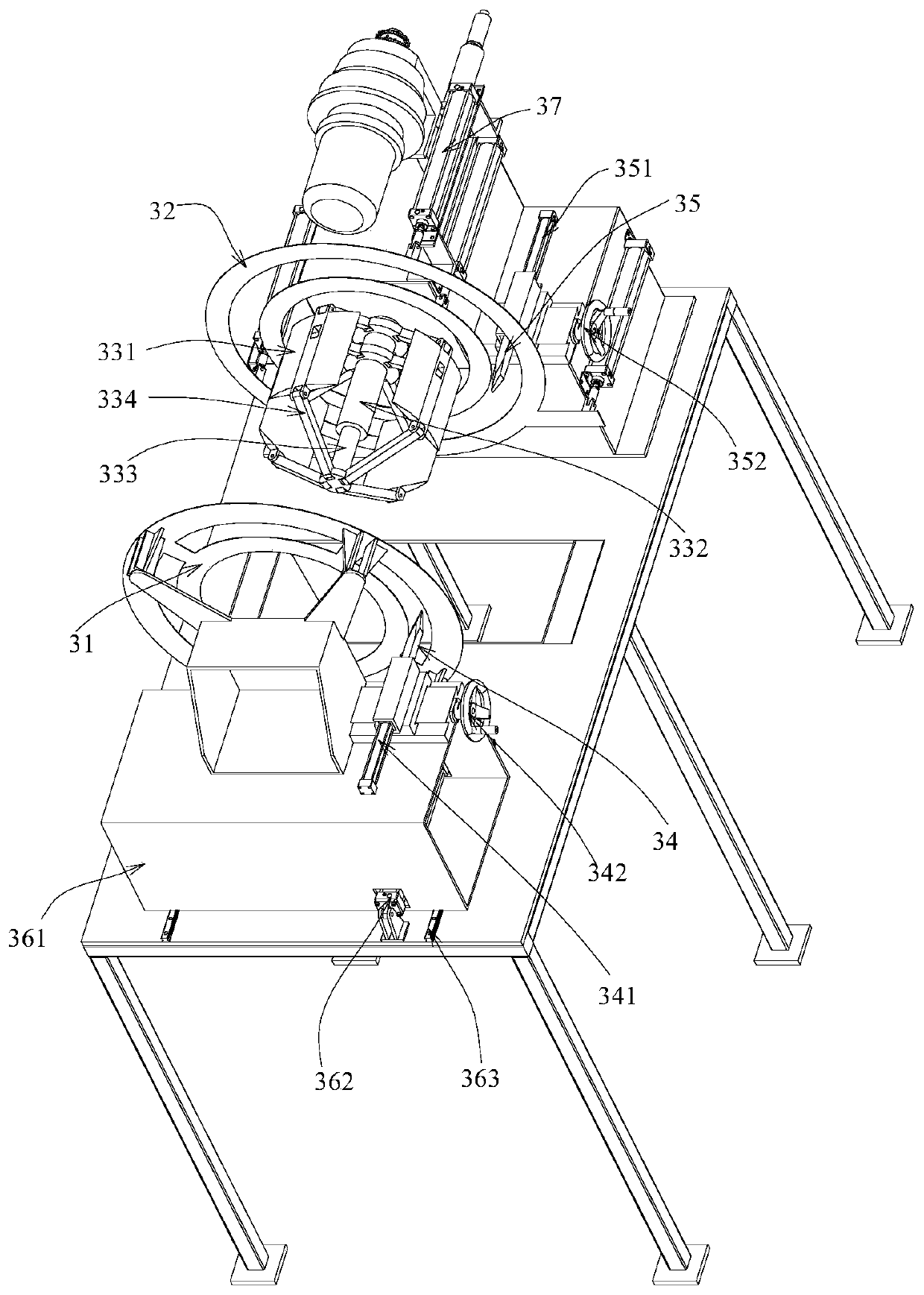

[0032] Such as Figure 1-5 The shown automatic tire processing equipment includes a body 10, a positioning mechanism 20, a ring cutting mechanism 30 and an outer ring cutting mechanism 50, and a positioning station and a ring cutting station are arranged on the body 10. The above positioning mechanism 20 is installed on At the positioning station, it can move from the positioning station to the ring cutting station. And this positioning mechanism 20 is used for tire is positioned, when it moves to ring cutting station by positioning station, can drive the tire in positioning mechanism 20 to move to ring cutting station by positioning station.

[0033...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com