Mold overturning and locking mechanism

A locking mechanism and mold technology, which is applied in the field of the lower mold installation mechanism of a molding machine, can solve the problems of time-consuming, complicated manual operations, and labor costs, and achieve the effect of convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

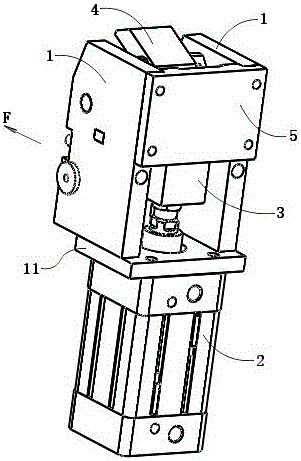

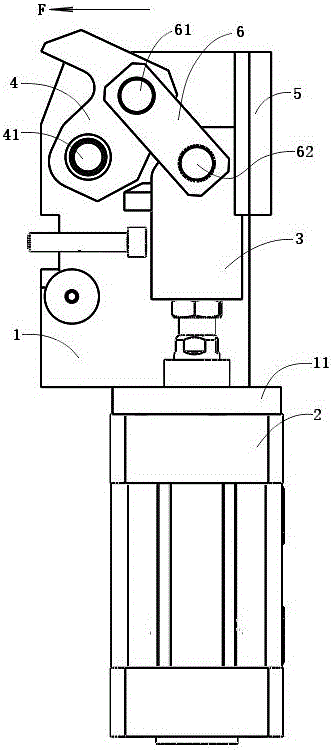

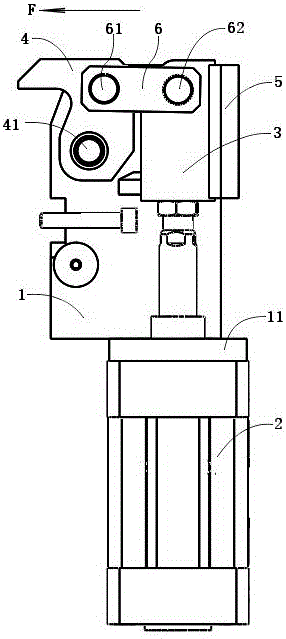

[0016] The mold turning and locking mechanism in this embodiment is a mechanism installed on the side of the lower mold table of the forming machine. Such as Figure 6 As shown, 9 is the lower die platform of the forming machine, and 91 is the mold turning locking mechanism of the present embodiment. Figure 6 Contains four mold turnover locking mechanisms 91 in. Four mold turnover locking mechanisms 91 are arranged on the edge of the lower mold platform 9 opposite in pairs, and are used to fasten the mold placed on the lower mold platform 9 . The specific structure of the mold turnover locking mechanism 91 is as follows: figure 1 , figure 2 , image 3 , Figure 4 As shown, it includes a side mounting plate 1, a cylinder 2, a traction block 3, a locking block 4, a back support plate 5 and a connecting rod 6.

[0017] There are two side mounting plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com