Automatic cap heat sealing machine

A heat sealing machine and capping technology, which is applied in presses, metal processing, packaging, etc., can solve problems such as low production efficiency, unguaranteed production capacity and data, and manual cooperation, and achieve the effect of improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

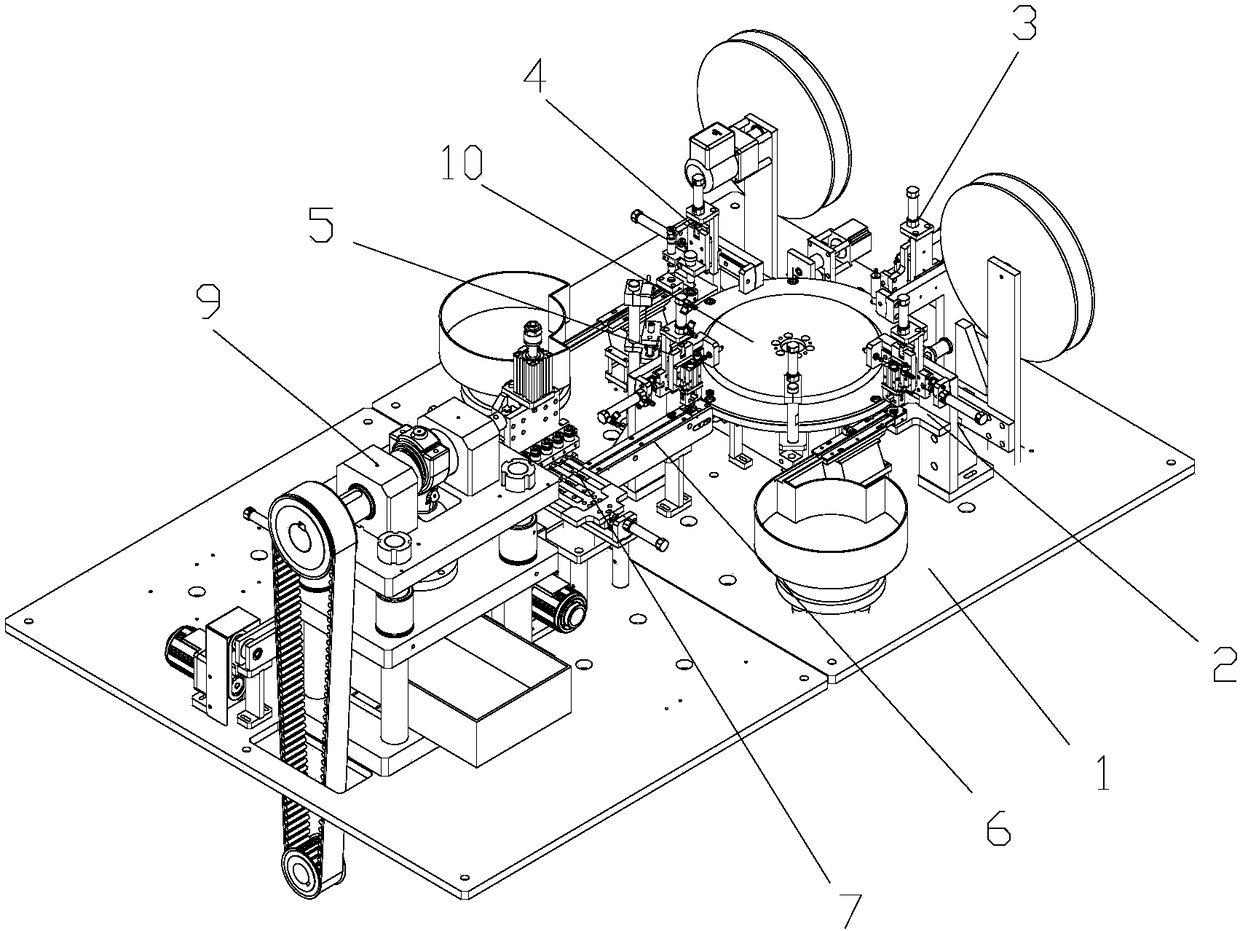

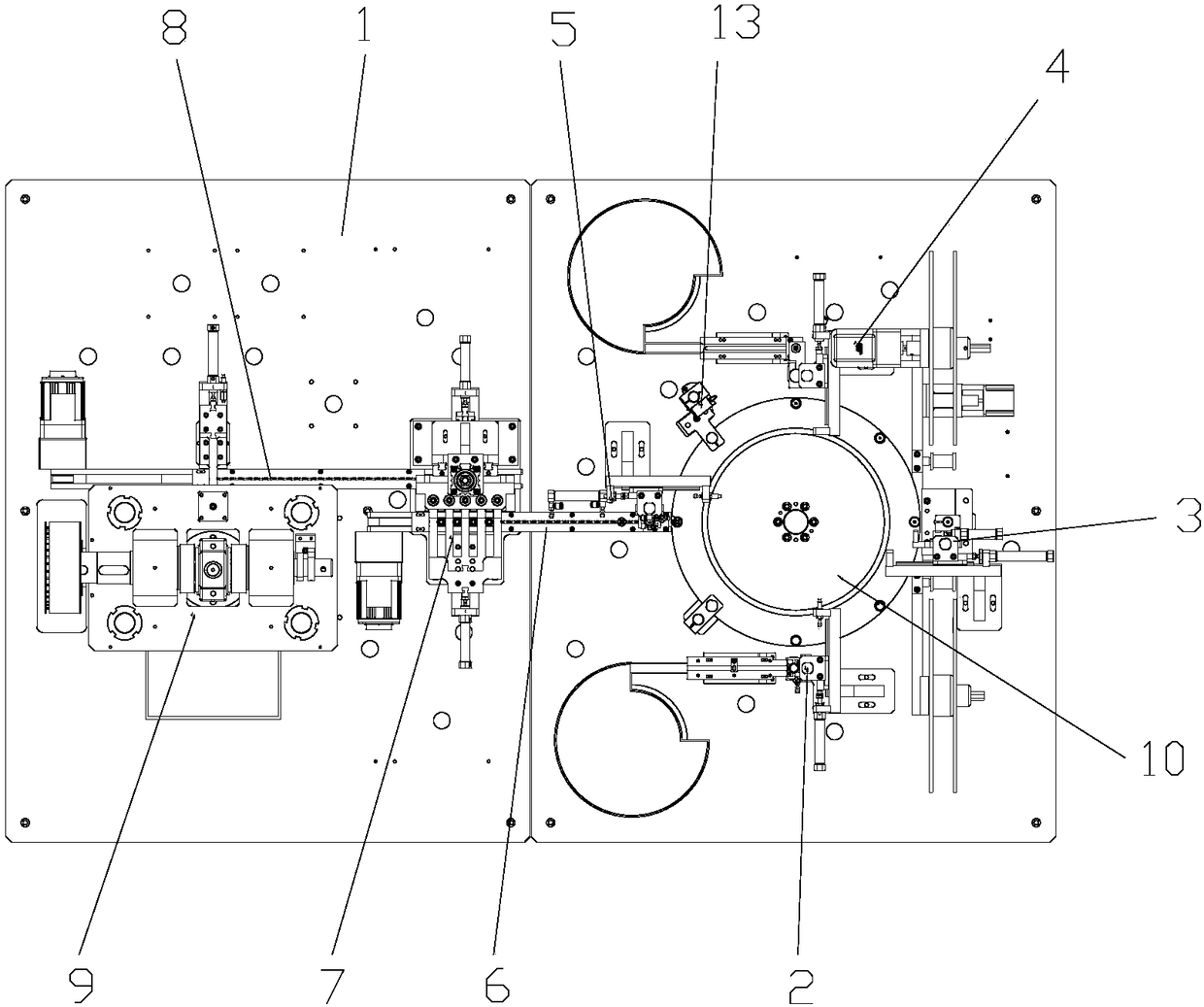

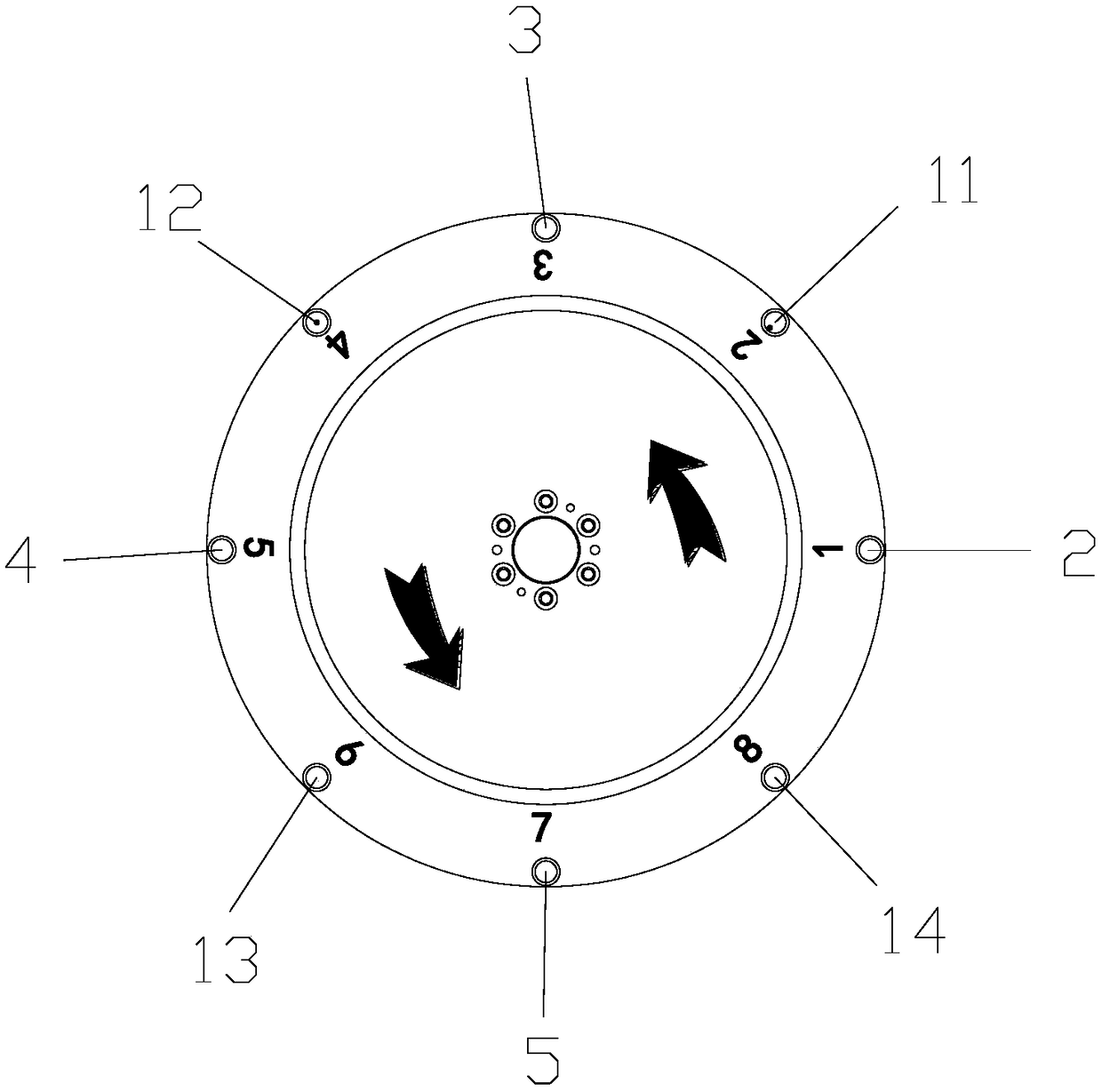

[0028] Such as figure 1 , figure 2 , image 3 As shown, this embodiment discloses an automatic cap heat-sealing machine, comprising a workbench 1 and a bottom cover feeding mechanism 2 arranged on the workbench 1, an explosion-proof film punching and feeding mechanism 3, an iron sheet feeding mechanism 4, an outlet Material manipulator 5, material feeding transfer cable 6, heat sealing mechanism 7, material discharging cable 8, flattening mechanism 9, turntable 10 and main control module (not shown in the figure); bottom cover feeding mechanism 2, explosion-proof membrane punching and feeding The mechanism 3, the iron sheet feeding mechanism 4 and the feeding transfer line 6 are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com