Chip mounting equipment based on mobile phone camera chip

A mobile phone camera and chip technology, applied in the manufacture of conveyor objects, electrical components, semiconductor/solid-state devices, etc., can solve the problems of secondary pollution of products, product pollution, and single production model.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

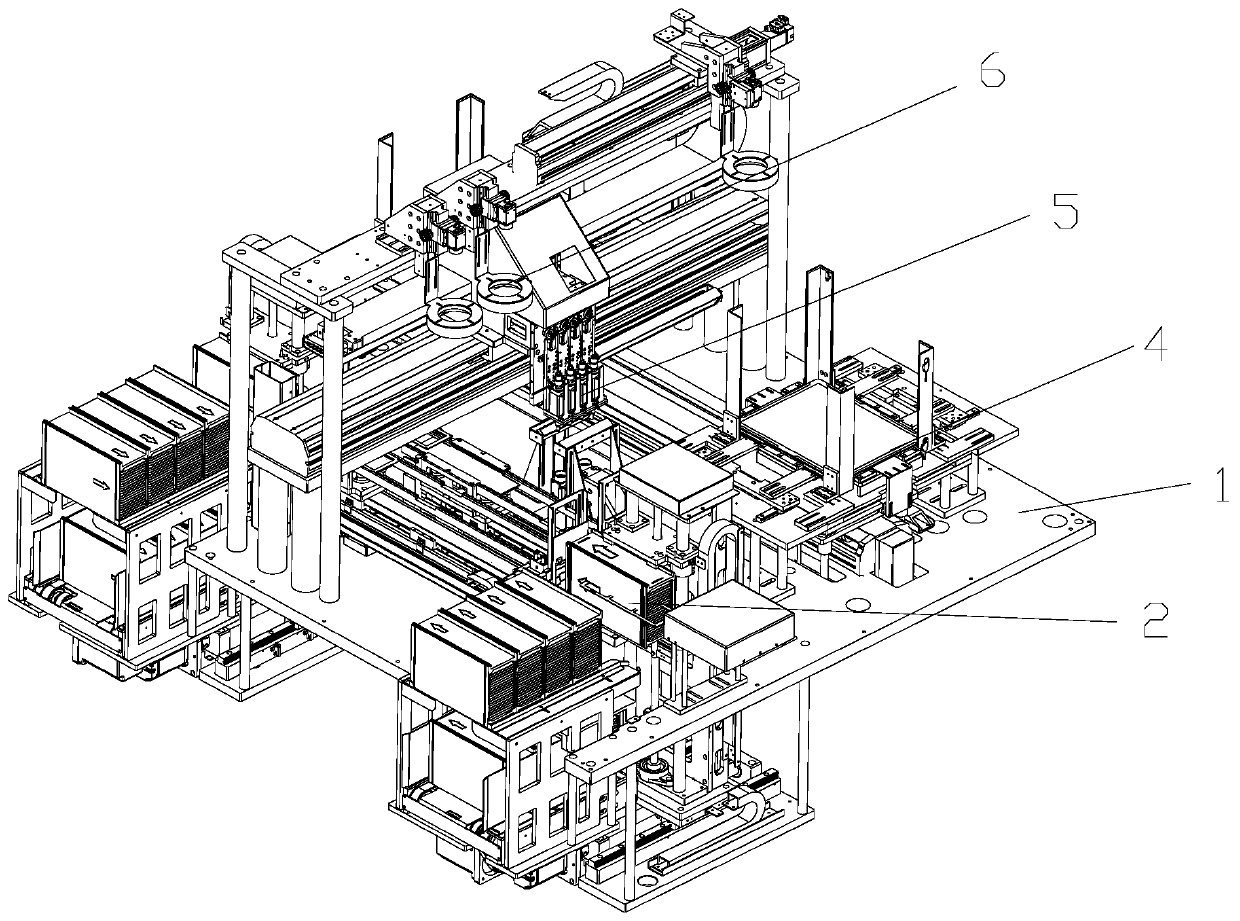

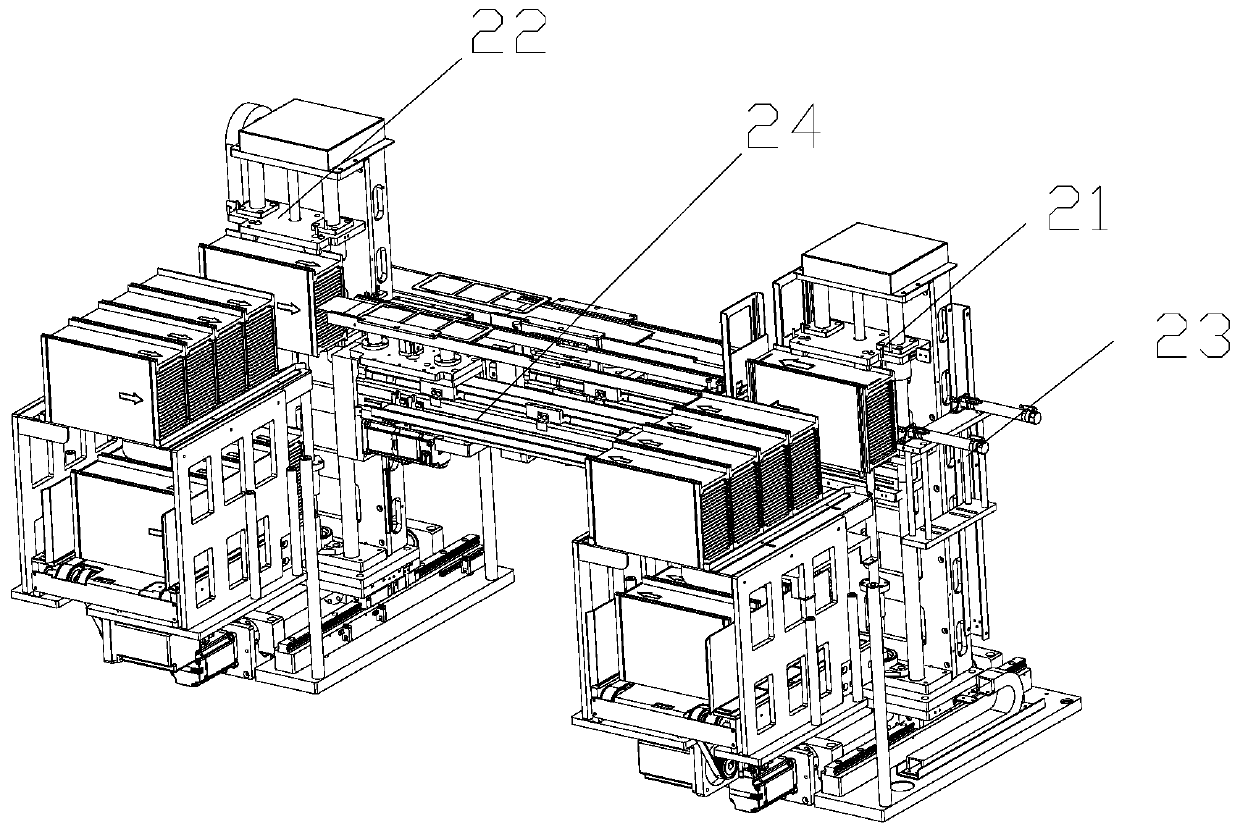

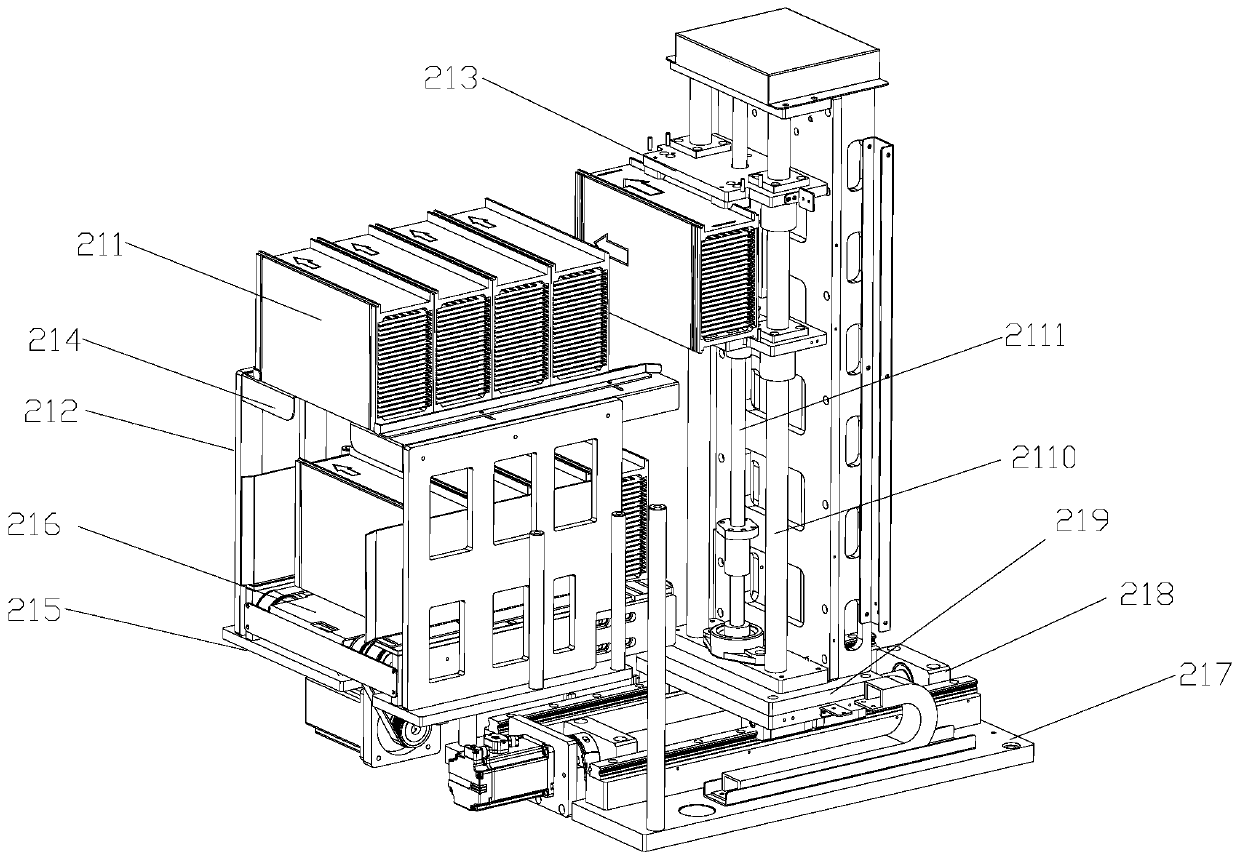

[0031] Example: such as figure 1 ~ Figure 7Shown, a kind of chip mounting equipment based on the mobile phone camera includes a work platform 1, and the work platform 1 is provided with a steel sheet carrying tape receiving and discharging cycle mechanism 2, a chip product handling mechanism 3, a chip product feeding mechanism 4 and Camera positioning detection mechanism 5; the steel sheet carrier tape receiving and discharging cycle mechanism 2 includes a steel sheet carrier tape discharging device 21, a steel sheet carrier tape receiving device 22, a steel sheet carrier tape pushing device 23 and a steel sheet carrier tape feeding device 23. Belt conveying device 24; the steel sheet carrying tape discharging device 21 is identical in structure to the steel sheet carrying tape receiving device 22 and is arranged correspondingly front and back, both including several magazine magazines 211, storage brackets 212 and movable jaws 213; the magazine magazine 211 is provided wit...

Embodiment approach

[0035] The biaxial transmission device includes a bottom plate 217, on which a second ball screw motor module 218 is arranged, and the screw nut on the second ball screw motor module 218 is fixedly connected to the moving support plate 219 and Carry the moving support plate 219 to do left and right linear reciprocating motions; the moving support plate 219 is provided with two left and right corresponding and vertically placed optical axes 2110 and a third ball screw motor module 2111, the movable The clamping jaw 213 is arranged on the optical axis 2110, and at the same time, the lead screw nut of the third ball screw motor module 2111 is fixedly connected to the movable clamping jaw 213 and carries the movable clamping jaw 213 to reciprocate in a straight line up and down. Movement; the working principle of the steel sheet loading and unloading cycle mechanism 2 is: the movable jaw 213 is connected to the biaxial transmission device, and the movable jaw 213 can be freely move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com