Automatic insulating cloth winding robot for rectangular coil of motor

A technology of rectangular coils and insulating cloth, applied in coil manufacturing, inductor/transformer/magnet manufacturing, circuits, etc., can solve the problem of narrow space when rectangular coils are wound, and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

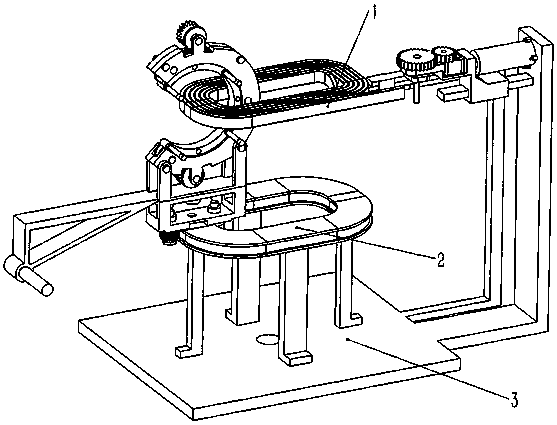

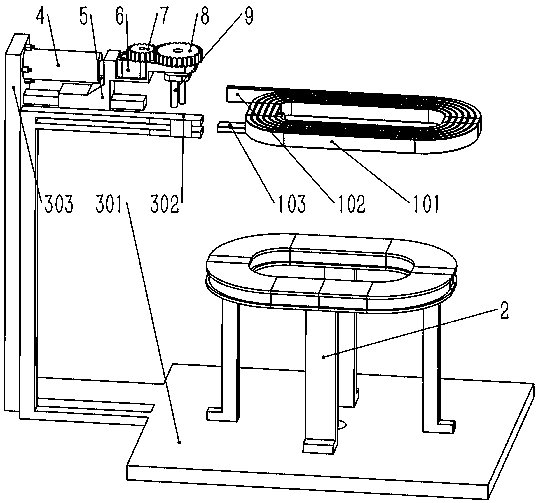

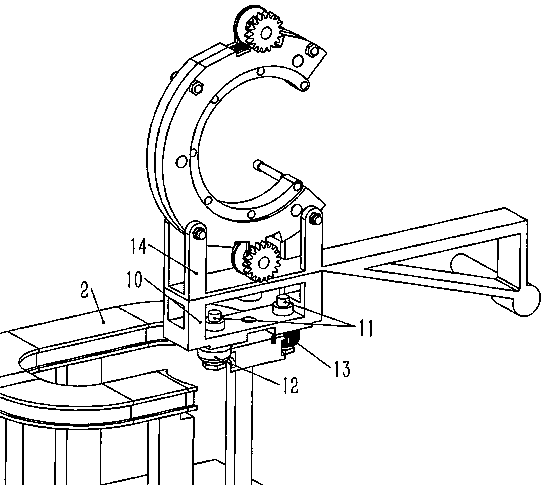

[0018] Such as Figure 1-4 As shown, a motor rectangular coil automatically wraps the insulation cloth robot, and its working principle is: the rectangular coil 1 is clamped on the electrode head clamping block 302 of the mounting frame 3 by bending the electrode head 102, and the guide frame 10 is adjusted so that C The gap of the mold frame 16 is fitted on the rectangular coil frame 101 of the rectangular coil 1, and then the insulating cloth roll is hung on the material shaft 15, and the insulating cloth is wound around the winding roller 21, and then wound on the rectangular coil frame 101, through The driving pinion 23 drives the driving friction wheel 22 to rotate, and then drives the C-shaped winding ring 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com